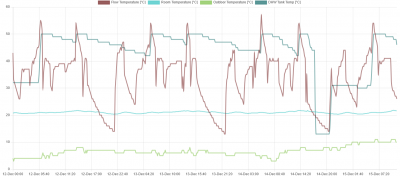

More data for the last week. Starting with Homely Connect and a simple view of my temps for flow, water, home & outdoor:

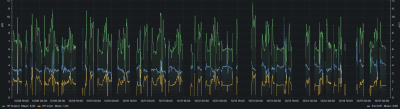

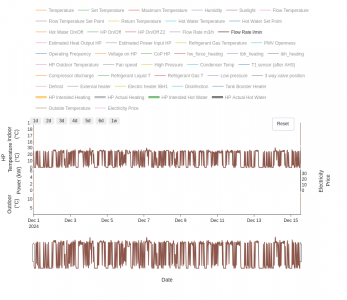

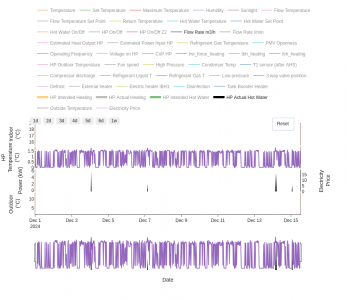

Now a couple of graphs that might be slightly more comparable from Home Assistant, so driven by Modbus data:

Midea 16kW ASHP, 15 rads and 4 underfloor circuits. Solar, batteries and Smart#1 EV with Hypervolt Home 3 Pro.

Homely smart control system, with additional modbus monitoring & installer app/web access. Techie and data nerd.

Host 424 on visitaheatpump.com: https://app.visitaheatpump.com/hosts/424

Posted by: @el_presidenteThe Modbus data is where much of the value is

I agree, and not only does it allow you to read a lot of data, you can also use the same connection to write to Midea heat pumps. I do most of my stuff using python scripts, but I have a residual Home Assistant installation still in place and it for example not only displays the DHW tank temperature, it also has a switch for turning the DHW heating on and off. Outside HA, I have a script that auto-adapts the weather compensation curve when the actual indoor air temp (IAT) deviates significantly from my desired IAT. It does so by writing to the registers holding the LWT at the right and left hand end of 'curve 9', Midea's custom weather compensation curve. It's a sort of small scale DIY Homely control. The bottom line is there is a lot you can do once you have a modbus connection.

I calculate energy out using the LWT and RWT (and so delta t) and flow rate collected over modbus (plus of course specific heat). The Midea modbus values are in close enough agreement with independent measurements of the delta t (thermometers) and flow rate (analogue inline flow meter) meaning I think my energy out figures aren't too far of the mark.

One major oddity I have found, and it would be very interesting to see what what your Midea heat pump does, is that the flow rate seems clamped most of the time to 1.43m^3/h or thereabouts. The Midea Engineering Data manual says it is capable to ranging from 0.7 to 2.75m^3/h - clearly this isn't happening in my case, and importantly it appears to restrict output in cold weather.

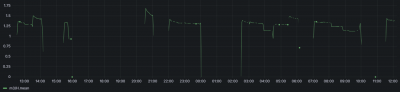

I see the current flow rate on you dashboard above is 0.00m^3/h - the pump is off (as other indicators also show). Can you chart the flow rate over say 12 or 24 hours and post it here? Here's mine for the last 24 hours, mid blue line towards the centre of the upper chart. Note the charted value is the actual value x 10 to make it easier to read. As you can see, it spends most of the time pegged to 1.43m^3/h:

Midea 14kW (for now...) ASHP heating both building and DHW

We cross posted! This chart of yours

appears to show (in the blue flow line which I take it is LWT) cycling as mine does with what look like setbacks. I think the slow frequency cycling is probably normal for Midea heat pumps, and is part of their way of modulating output.

Midea 14kW (for now...) ASHP heating both building and DHW

If it helps, this is my flow rates, with peaks of around 1.6 to 1.7 but mostly in the 1.3 to 1.5 range, as collected from Modbus for the last 24 hours:

It's probably worth pointing out that my system is not open loop. The primary flow rates shown here are from the outdoor pump unit to a secondary heat exchanger attached my cylinder and that water contains glycol. So my system has separation and a second pump to feed the existing central heating and the DHW coil with plain (no anti-freeze) hot water.

This design was easier for the installer and protects the heat pump, but I'm sure it sacrifices some efficiency.

Midea 16kW ASHP, 15 rads and 4 underfloor circuits. Solar, batteries and Smart#1 EV with Hypervolt Home 3 Pro.

Homely smart control system, with additional modbus monitoring & installer app/web access. Techie and data nerd.

Host 424 on visitaheatpump.com: https://app.visitaheatpump.com/hosts/424

@el_presidente , give http://dashboard.homelyenergy.com/ a try- it provides a lot of the info that connect masks off as a pro feature. I hope they keep the dashboard available but suspect given connect they will paywall the pro stuff and kill dashboard to move people over to this. If you have a connect account the credentials should be the same for the dashboard.

It's interesting that the flow temps @cathoderay reports back are accurate- this means it might be worth comparing your modbus derived data on scop/cop to what the dashboard tells you. My system is the same as yours, plate heat exchanger mounted to the cylinder and glycol on the HP side of the exchanger. Homely's calculation of the COP relies on the manufacturer look-up-table and assumes water rather than glycol as the transfer medium since they don't have a heat meter. If your calculations line-up with what homely is saying this would be good news as it likely means the midea tables are not wildly overestimating performance. Homely reports my COP over the past two weeks is 3.95 for heating and 3.97 for hot water which seems pretty high given an outside temp of six degrees on average. I'd love to know how accurate that is though. It has been very reasurring watching homely do its thing over the apocalyptic pricing on agile the last few days. It really only sips power in the peak times and makes the most of the dips.

@el_presidente - hmm, interesting! Thanks. Mostly in the 1.3 to 1.5 range is not that far from where mine runs (mostly 1.43m^3/h). My chart is based on minute data (data collected every minute, no smoothing applied, raw data charted as is. Your chart has m3/H.mean - is that perhaps a moving average (which can smooth out variations) or is it raw data as mine is?

I don't think our system designs are that different. I too have a plate heat exchanger between in my case the primary circuit and the secondary radiator circuit and the primary circuit has glycol in it. None of this is surprising if you heat pump came from Freedom, they give installers a kit of parts and strict instructions on how to do the installation. As you say, the idea is to make things easier for the installer, all the bits needed are available from one place, and the manual is designed to be idiot proof.

PHEs don't directly lower efficiency, what they do is require the heat pump to run a bit hotter to get an adequate 'LWT' on the secondary circuit - if it would run at 40 without a PHE, it may need to run at 43 to get 40 on the other side of the PHE for example - and it's the running a bit hotter that has the impact on efficiency. On the other hand, I do like the idea of hydraulic separation. No rad crud in the primary circuit and no pushing glycol round the radiator circuit.

Midea 14kW (for now...) ASHP heating both building and DHW

Thanks for that! A different view that I hadn't seen. Will soak it in and see if it helps me compare the Midea/Homely values for input/output to those from other sources. If I get some conclusions I'll report back.

Midea 16kW ASHP, 15 rads and 4 underfloor circuits. Solar, batteries and Smart#1 EV with Hypervolt Home 3 Pro.

Homely smart control system, with additional modbus monitoring & installer app/web access. Techie and data nerd.

Host 424 on visitaheatpump.com: https://app.visitaheatpump.com/hosts/424

@starkers - also very interesting, sounds like another Freedom based installation (PHE etc, only my PHE is next to the cylinder at floor level, not on the cylinder). It looks like that (Homely?) plot of yours has flow rate on it, but it is lost in all the other data. Can you tease it out in some way?

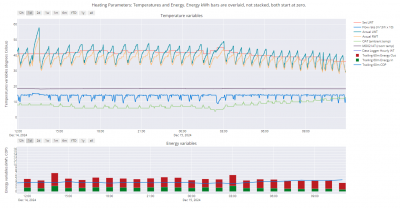

Note that all my data is collected once a minute over modbus, and then I or rather my pythons scripts calculate the energy in and out (and so COP) from the raw parameters, summed over an hour, to get the lower bar chart with COP in my plots.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay See attached for flow rate in l/min. It's not using a sensible scale and doesn't seem to provide a way to adjust it, but for reference the highest peaks are at 30l/min, the modal value when moving glycol (ie with those peaks removed but looking at the average maximum) is about 26l/min. These correspond to about 1.8m^3/hr and 1.5m^3/hr. The system should be relatively unrestricted as the filter cages were washed out about 3 weeks ago.

I wonder if we're seeing less than the design maximum due to the PHE being a restriction?

Aha. My guess may indeed be the case. I just realised if it's due to the PHE being a restriction the DHW bypasses this. Guess where the 1.8m^3/hr spikes occur. In the attached I've added when demand for DHW was (it's the black spikes in the lower portion of the plot). Looks to me like the HP can produce higher flow rates but the PHE isn't letting it happen, or, the HP firmware doesn't think supplying the max flow rate is needed when supplying heating, and only ramps it when supplying DHW.

@starkers - thanks, very interesting. it looks like you have the same step pattern, though it is somewhat obscured by the long interval on the x axis. If you click the top left 1 day button (looks like Homely use a modified python plotly plot) you will open out the plot somewhat and see the steps more clearly. I wouldn't be at all surprised if your heat pump is slow cycling (see my earlier plot for what that looks like), which Midea heat pumps appear to do most if not all of the time.

Posted by: @starkersI wonder if we're seeing less than the design maximum

I think we are, or at least I am.

A bit of background. Most of the time my heat pump can match my heat loss, but in cold weather, 5 degrees OAT (outside air temp) and less, it can't, and my IAT (indoor air temp) falls, enough to matter (I start feeling cold). It also makes the system an MCS 'fail'. I have been looking into why this is the case, and what can be done about it.

Some background numbers. My Freedom heat loss calculator based loss, which was used to size my heat pump, is 12.3Kw, to be matched by a 14kW heat pump. It then turned out that Midea heat pump badge outputs are wildly misleading, when it matters (say zero OAT and higher flow temps) the output falls to around 11.3kW - not enough. It then turned out that my actual heat loss (determined empirically) is considerably less than the Freedom estimate, at about 10kW or maybe a bit less. The heat pump should be OK - but it isn't.

The usual suspect is of course the PHE, but his doesn't actually cause loss (any heat lost from a PHE is 'lost' into the house), it causes inefficiencies. As mentioned earlier, the heat pump flow temp has to be set a bit higher to get the actual flow temp we want in the secondary circuit, and it is this having to run at a higher flow temp that causes inefficiency, because heat pump efficiency falls with rising flow temp. The effect isn't huge, maybe as low as 5% in a well set up system (eg COP of 4 => COP of 3.8). I decided to stick with the PHE for the reasons given earlier (no rad crud in primary circuit, no shoving glycol round the secondary circuit. The heat pump might be a bit less efficient overall, but it should nonetheless be able to heat the house adequately, albeit using a slightly higher flow temp. It appears the PHE isn't directly to blame, but see below.

I then started to look for other explanations, and it became apparent the the heat transfer limiting factor is the flow rate. Recall that the heat transferred is

kW = flow rate x LWT (leaving water temp) - RWT (returning water temp) delta t x specific heat capacity of the fluid

which means given the specific heat is fixed for any one circumstance, the only way you can transfer more hear is by increasing either the flow rate of the delta t (or both).

Plugging in some numbers into the equation, at a delta t of 3.5 degrees (a not unusual average in my system, average because it is cycling) and a specific heat of 3.9 kJ/kg.K (20% glycol) and a flow rate of 1.43m^3/h, my system can transfer 5.42kW - OK in mild - moderate weather, but not when it is cold.

The highest peak delta t my system ever gets to is about 8 degrees, with the average (defrost cycles included) at around 4.5 degrees. Re-arranging the above equation to solve it for flow rate, to get the 10kW of transfer I need in cold weather, I need a flow rate of 2.05m^3/h, which it never gets anywhere near. In fact it appears none of our three Midea heat pumps ever push the flow rate above around 1.8m^3/h, though it is probably fair to say mine is the worst performer. Whatever is rate limiting the flow rate is rate limiting the heat transfer, and that is why my house gets cold in cold weather.

All three of our flow rate charts show the same thing - the flow rate spends most of its time at a fixed rate, with dips below but never or only bery rarely peaks above. Allowing for axis anomalies and converting your L/min to m^3/h, I think your 'standing' flow rate is probably very close to mine, around 1.43m^3/h. Yet the Midea Engineering Data manual clearly shows the primary circulating pump as being a PWM capable pump (with wires to do it) with, in the case of a 14kW heat pump, a range of 0.7 - 2.75m^3/h.

I am still working on what causes the circulating pump to not use all its range. One possibility is it (or its PWM controls) are faulty, the other possibility is the system primary circuit resistance is too high, and it in effect chokes the flow rate. Or it might even be both. My installer is trying to get more operating data from Freedom so we can get to the bottom of this problem and fix it.

PS Just seen your latest post:

Posted by: @starkersI just realised if it's due to the PHE being a restriction the DHW bypasses this.

I had exactly the same thought a few days ago - the DHW heating takes the PHE out of the loop. In my case there is minimal change in flow rate, maybe up to 1.5m^3/h, ergo the PHE is not a major obstruction - unless the coil in the DHW tank is a similar obstruction (unlikely). Try and zoom in on your plot (as mentioned earlier) to see more detail and the actual pattern.

Posted by: @starkersLooks to me like the HP can produce higher flow rates but the PHE isn't letting it happen, or, the HP firmware doesn't think supplying the max flow rate is needed when supplying heating

Pretty much a succinct summary of what I have said in windy form above.

Midea 14kW (for now...) ASHP heating both building and DHW

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 303 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 57 seconds ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 10 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 32 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 8 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 24 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago