Ecodan - optimal external installation?

I think this notion of an 'optimal' install is something of a chimera. Every installation is different, and the majority of forum users have experience of just the one installation. From what you have said (though images are worth a thousand words) your installation seems to be fine, the installers haven't done anything stupid.

If you are having vibration issues at the heat pump then it might be an equipment issue rather than a pipework issue. I have noise inside introduced by the circulation pumps, but only small amounts of occasional mechanical noise and the sound of the air being moved from the outside unit. The units weigh around 100kg so you wouldn't want any slight vibration to be converted into sound or transmitted to the rigid, fixed pipework, but they aren't going to move around like washing machines.

You ask a few questions:

28mm pipework should run as far as you can take it into the house - you need volume of water in the system to cover defrosts.

You protect the outside pipework and the pump either by having glycol so the water can just sit at very cold temperatures, or you circulate the warm water in the pipes to keep the outside parts from freezing – the anti-freeze valves are a fail-safe should you be unable to power the water circulation. You would not want to be dumping glycol.

Full bore valves are isolating valves...

Mitsubishi EcoDan 8.5 kW ASHP - radiators on a single loop

210l Mitsubishi solar tank

Solar thermal

3.94kW of PV

I’d consider my system to be installed quite optimally… I have one anti freeze valve, no flexis, and over 20m of buried primary pipework.

I also don’t have any hydraulic separation, and I have 400mm clear to the rear of the evaporator.

Off grid on the isle of purbeck

2.4kW solar, 15kWh Seplos Mason, Outback power systems 3kW inverter/charger, solid fuel heating with air/air for shoulder months, 10 acres of heathland/woods.

My wife’s house: 1946 3 bed end of terrace in Somerset, ASHP with rads + UFH, triple glazed, retrofit IWI in troublesome rooms, small rear extension.

Posted by: @harriup28mm pipework should run as far as you can take it into the house - you need volume of water in the system to cover defrosts.

Yes. Where would the optimal position and method of stepping down? I assume nearest the unit, so at the unit's inlet/outlet - but not sure how.

You protect the outside pipework and the pump either by having glycol so the water can just sit at very cold temperatures, or you circulate the warm water in the pipes to keep the outside parts from freezing – the anti-freeze valves are a fail-safe should you be unable to power the water circulation. You would not want to be dumping glycol.

Thank you.

Full bore valves are isolating valves...

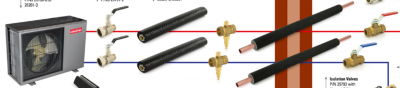

From the BES component diagram in the OP (relevant section below), it shows 'isolator valves' and 'full bore valves' - though, having just looked at it again, I've just noticed the isolator valves are inside the property:

The isolator valves I mentioned describing my install are Inta lever ball valves - I assume these should be full bore to maximise flow rate and be positioned as the primary pipework exits the brickwork outside? Is there any value in having a second set at the unit's inlet/outlet too?

Posted by: @rhh2348What's the optimal / minimum length and shape of flexihoses (and why, if not for best performance and least vibration)?

I'd appreciate anyone's thoughts on this, having read in one or two posts (I now can't find...) that longer hoses can reduce/eliminate vibrations travelling through the primary pipework elsewhere.

-

Struggling to get CoP above 3 with 6 kw Ecodan ASHP

5 days ago

-

Rate the quality of your heat pump design and installation

7 days ago

-

Ecodan Zone 2 Mitshibishi thermostat Auto Adapt

1 month ago

-

Ecodan Pump Issues… Circulation pump turns off when heat pump compressor turns off

2 months ago

-

New Mitsubishi Ecodan 11.2kW installation - L9 errors and maybe more

2 months ago

- 27 Forums

- 2,520 Topics

- 58.6 K Posts

- 580 Online

- 6,800 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

Yes, here's mine. From the service manual parts numbers...

By bobflux , 4 minutes ago

-

Had to learn the hard way 🤣 now I'm sharing T...

By bobflux , 19 minutes ago

-

RE: Issue with a Grant Air Source Heat Pump & Tado Smart Thermostat

Im assuming from your original post that hysterisis ref...

By JamesPa , 1 hour ago

-

RE: Heat Pump vs New Gas Boiler for Inherited House - Worth the Extra Cost?

Hi @fretless6 Mike, I have experience with Taggas (Re...

By Old_Scientist , 3 hours ago

-

RE: Daikin Altherma 3 LT compressor longevity question

@bobflux With my limited HA skills I can't ad...

By Ubert767 , 5 hours ago

-

RE: Underfloor Heating Installation Issues with Heat Pump

I'm going to install Thermacome ACOSI+ radiant ceiling....

By bobflux , 7 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Now seems a good time to summarise the costs and effici...

By benson , 8 hours ago

-

RE: Tell us about your Solar (PV) setup

@mk4 Charge to 100%, discharge down to 10%.

By bobflux , 9 hours ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

The simplest wired option is usually the Growatt Ethern...

By Jonatan , 15 hours ago

-

RE: Electricity price predictions

@jamespa And it seems some of the nasty public cloud...

By Batpred , 22 hours ago

-

RE: Jokes and fun posts about heat pumps and renewables

Technology is rapidly advancing. BBC News reported th...

By Transparent , 1 day ago

-

RE: Do Fridges and Freezers have COP ratings?

@editor Thank you all for your replies and submitted in...

By Toodles , 1 day ago

-

I know and yes. The secondary deltaT wont necessaril...

By JamesPa , 1 day ago

-

RE: Designing heating system with air to water heat pump in France, near Lyon

Just love the way you put it! 🤣

By Batpred , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thank you for sharing. So it seems that your Schneid...

By Batpred , 2 days ago

-

RE: Forum updates, announcements & issues

@upnorthandpersonal thanks for the thoughtful, consider...

By Mars , 2 days ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

@mk4 All 21 panels have their own Enphase IQ7a microinv...

By Toodles , 2 days ago

-

RE: Setback savings - fact or fiction?

Great, so you have proven that MELCloud is consistently...

By RobS , 3 days ago

-

RE: Mitsu PUHZ120Y 'Outdoor Temp 'error?

Thanks David & James It almos...

By DavidAlgarve , 3 days ago

-

RE: Surge protection devices SPDs

@trebor12345 - your original Topic about the right type...

By Transparent , 3 days ago

-

RE: Help needed with Samsung AE120RXYDEG

@tomf I’ve been sent this from a service engineer at Sa...

By Mars , 3 days ago

-

RE: Buying large amp bidirectional RCD and RCBO

Yes... I went through this particular headache and ende...

By bobflux , 4 days ago

-

O-oh! Let's take this as an opportunity to 'pass the ...

By Transparent , 4 days ago