Ecodan Minimum Run Time, Flow & COP

We have an 11.2KW Ecodan with an FTC6, installed 2022 with a 300l HW tank and 10 circuits of Wundasmart underfloor heating in around 120 sqm, installer (who was generally great) left every circuit thermostatically controlled.

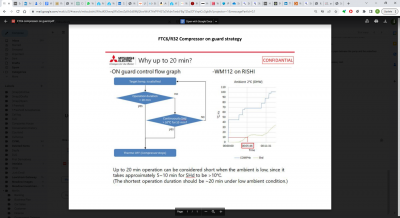

We spent a lot of time learning about the system over the last year, and one quirk of the Ecodan is a minimum run time which it imposes on itself and the impact on flow temperatures. After conversations with Mitsubishi, this is called the Compressor On Guard Strategy, which enforces a 20 minute minimum runtime, unless the Superheat has been >10C for 10 minutes. It took us a long time to find out from Mitsubishi that this existed.

It doesn't matter a lot what the above means, but the effect - a minimum run time - is interesting. Normally if the pump's minimum heat delivery is higher than the demand, then during low flow conditions (e.g. only a few thermostats calling for heat) the flow temp rises and the pump will turn itself off when flow exceeds 5C above the compensation curve set temperature. In our case, with flow around 27C that might be when flow hits 32C, cunsuming around 1KW of energy.

However the Ecodan will prioritise the importance of keeping on running over halting when exceeding the flow temperature, and will keep trying to heat the water while it keeps running. The compressor runs harder and harder as the temp spirals and we were recording 55C flows at which point it turned off. This incurred very high energy consumption (3KW or more).

This had a huge impact on the COP, dropped below 3 during mild weather. During cold weather it's never a problem, there's always enough flow because so many circuits are calling for heat and minimum runtimes are over 20mins anyway.

We contemplated adding a buffer (cost around £1K installed) but instead trialled removing all thermostatic control in all rooms except the coldest one and using full system volume all the time with the compensation curve driving the system. The result in mild weather is dramatic: we can keep flow temps at 23C above 13C outside, the pump cycles twice an hour with max flow never exceeding 5C above set flow temp, Melcloud-reported COP is regularly over 5 and often over 6, it appears to be phenomenally efficient, borne out by much lower daily energy usage in mild weather.

We do have some small challenges with some warmer rooms getting a couple of degrees C above what we'd prefer but it is cheaper to just live with the extra heat, cost goes up if we re-introduce any thermostatically control rooms, because the volume reduced and pump works harder as above. Our Wundasmart manifolds use automatic balancing valves which set the circuit flow dependant on flow/return temps and can't be manually adjusted down, which is an unfortunate side-effect of an automated system.

The lesson learned is that Ecodans and lots of thermostats really don't work well in mild weather and it's much cheaper (and generally nicer) to go to the effort of working out the right compensation curve and running low flow temps against your full system volume.

Might be useful to anyone with an Ecodan, lots of thermostats and seeing big spikes in flow temps and energy consumption several times an hour during mild weather.

Rod

Posted by: @rodMight be useful to anyone with an Ecodan, lots of thermostats and seeing big spikes in flow temps and energy consumption several times an hour during mild weather.

Rod

Welcome to the forum and thank you for the detailed report. I must admit that I was not aware of the Compressor On Guard Strategy, which I don't believe is mentioned in the manual.

Your findings about thermostats is not only relevant to Ecodan owners, but probably all heat pump owners.

Very interesting. My (14kW) ASHP can definitely run the compressor in bursts of less than 20 minutes when in heating mode. It doesn't do it very often and only when in WC mode and mild conditions. It never heats to more than one or two degrees above WC set point though, although I have only two zones, which means the ASHP is heating at least half my house at any one time. Interestingly, although the compressor stops after less than 20 minutes, I don't think it is ever in heating mode for less than 20 minutes. That is, it spends some time in heating mode while delivering no energy.

This is heating you're talking about btw - the label on the graph on your attachment mentions DHW?

I've never heard of Compressor on guard or Superheat; it's not mentioned on the manuals afaik.

@derek-m if you skim through this Samsung doc, you will see details how a double compressor "heat pump"/AC works, some of this data is pointless to anyone but the engineers that need to look(improve/make a new model) at the machine beyond checking the refrigerant charge.

@kev-m Yes, it's in heating mode. For reasons I still don't understand the HP can spin up to do a DHW cycle when the tank temp is very close to setpoint and cut out immediately the set point is reached without entering the On Guard strategy, even if it's only a couple of mins long. Mitsubishi could not explain why the strategy is used for heating but not for water.

This stuff definitely isn't in the manual and isn't generally known to the support teams, it was only when I pressed them that this appeared.

Thanks fazel, much appreciated.

I suspect that the training manual is for industrial type units, since the smallest compressor of a twin compressor unit is rated at roughly 19kW, and each compressor in the main unit is rated at 25kW. I don't think that it would get planning permission. 😋

Nevertheless the manual appears to give a good description of the inner workings of a heat pump, which is very similar, if not exactly the same, as a domestic sized unit.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 398 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Without knowing it, @andrewj, you've laid down the gaun...

By Majordennisbloodnok , 45 seconds ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 5 minutes ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 38 minutes ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 1 hour ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 2 hours ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 4 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 4 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 4 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 5 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 20 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 22 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago