It's a lot better than HIVE, which was cycling 5+ times per hour with me! Just leave it set to a high temperature and use climate/weather compensation to regulate heat. No need to disconnect it. The ASHP protects itself from excessive stop/start cycling, but will always control better and more efficiently if it's not doing that.

please forgive me for simple

questions.

if I have the thermostat set high so it is calling for heat all the time but have the trvs all low (as we are out all day) that will use less electricity but keep the house ticking over hopefully..?

Posted by: @sirpatchuk1980please forgive me for simple

questions.

if I have the thermostat set high so it is calling for heat all the time but have the trvs all low (as we are out all day) that will use less electricity but keep the house ticking over hopefully..?

I would suggest that the only TRV's that should be used are ones in bedrooms or unused rooms, all others should be fully open all the time.

For best overall efficiency, the heat pump controller should regulate the LWT based upon the WC curve, since using TRV's will throttle the water flow rate and possible cause short cycling. Most heat pump controllers allow an offset to be applied to the WC curve to lower the indoor temperature during a desired time period.

We have two log burners in the house and had the second one installed to use to supplement the heating.

With the heating been on all the time will there be no requirement for the log burners or will or effect the ashp running?

Posted by: @sirpatchuk1980We have two log burners in the house and had the second one installed to use to supplement the heating.

With the heating been on all the time will there be no requirement for the log burners or will or effect the ashp running?

The heat energy output of an ASHP is very much dictated by the size of the compressor, and the minimum pressure and temperature of the refrigerant gas it is compressing, which is dependent upon the minimum speed at which the compressor can be operated. So a unit rated at 12kW, may have a minimum continuous output of say 3kW.

As the outside air temperature increases, the heat loss and hence heat demand reduces, and will eventually get to the point, where the heat pump is producing more heat energy than is required to meet demand. To prevent the indoor temperature from increasing, it is therefore necessary for the heat pump to stop supplying heat energy for a period of time, just as a gas or oil boiler would do.

If the stopping and starting of the heat pump becomes too frequent, this is described as short cycling.

One possible way to help prevent short cycling, would be to use a standard type room thermostat, with a hysteresis of 1C, and set the thermostat at the desired room temperature. As the outside air temperature increases it is likely that the indoor temperature will also increase to the point where the heat pump is stopped by the thermostat reaching its upper limit. The heat pump will therefore remain stopped until the indoor temperature falls by 1C and the thermostat resets, at which point the heat pump will restart.

Whilst the above method will not prevent the heat pump from cycling, it should extend the period between cycles to a more acceptable level.

Operating log burners will of course impact how your heat pump operates, so it is for the user to decide how best they can both be used.

Quick update - I had an heating engineer take a visit to our place and has suggested the following :

- Change the 28mm primary heat pump piping to 35mm. Apparently this would be the minimum for a 17kw heat pump to ensure the high flow rates are achieved and maintained.

- Changing the volumiser to a buffer tank creating the separation between the heat pump and heating circuit. This should reduce the amount of cycling that is likely to occur. Having read Brendon's (@heacol) recommendations against installing a buffer tank I was trying to understand under what conditions it would make sense to install the buffer tank. The engineer mentioned generally any heat pump over 10kw should have a buffer and definitely a 17kw HP given the flow requirements for it to work efficiently. The buffer should stop the cycling but may reduce efficiency because the buffer is always being heated.

- using the manufacturer's controller for everything

- At the moment we have 2 zone values and these would be replaced with diverter with hot water priority. I don't think this makes any difference to efficiency but just a better setup as at the moment it's controlled by a timer

- 16mm UFH piping at 100mm spacing which makes sense if the intention is to lower the flow temperature as much as possible.

@soniks change 28 mm primaries--- wrong, I have 30Kw heat pumps on 28 mm primaries very successfully

Buffer tank--- Wrong in any circumstance unless you want to double your heating bill.

Replace Honeywell type zone valves with a 3 port diverter valve---- correct if it is a full bore ball valve version, Not a Honeywell type valve.

Your under floor at 100 mm spacing is perfect, as many circuits as possible should not have any thermostats or actuators, preferably more than 70%.

Open all under floor circuits, radiators etc full and the flow rate should be around 32 L/min with the pump on full

Close all circuits with control and the flow rate should not be below 13 L/min.

If the system falls between these values, set your weather compensation to 40@-2 and 25@15, and then leave the heat pump alone to do its job. You may have to fine tune it if the house gets too warm or cold. Using this method, you will get the lowest running costs and best comfort levels.

@soniks FYI we have all brand new pipework and its 28mm, we have the volumiser with the heat element in it and we are getting flow rate of 32 with rad and UFH circuits on. When Simon from Grant and Stone came to our house I asked him about buffer tank and he said it would not give more benefit that the volumiser and would cost more ... which echos what Brenon Uys said.

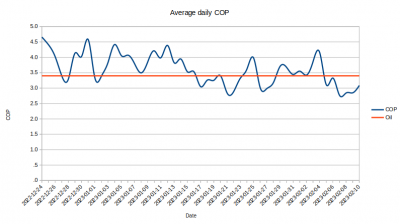

So far for me biggest differences are (a) coming of economy 7 and heating the DHW for hour from 2:30 to 3:30pm instead of during night, (b) enabling the volumiser immersion during defrost cycly and configuring for supportive heating at 5degrees, (c) changing from WC flow temp from 45 at -2 to 40 at 0 with 30 at 20 ..... will try 40@-2 and 25@15 in future ...... trying few tweaks out to see effect .... trial and error is useful.

Biggest factor is weather, I now record daily the hi/low at 00/06/12/18 and my smart meter reading

https://www.timeanddate.com/weather/@2634553/historic

For feb highest was 82, lowest 28 kwh .... I reckon ave 15 of that is house appliances and my thirsty PC.

Posted by: @soniks- Change the 28mm primary heat pump piping to 35mm. Apparently this would be the minimum for a 17kw heat pump to ensure the high flow rates are achieved and maintained.

Afaik, you need to target a flow velocity of 0.8 to 1.2 m/s to avoid too much noise, wear and tear on the pipes etc. That is probably what the heating engineer is on about.

28mm copper pipe is internal diameter 26.2, so a flow rate of 39 lpm gives a flow velocity of 1.2 m/s

Now you need to pick a dT that keeps you under 39 lpm.

my calculations [kW = l/s ⋅ 4.18 ⋅ ΔT] suggest a dT of 6.3 degC to meet 17kW @ 39 lpm.

I have a similar issue, in that when I installed my heat pump (16kW), I put in 28mm, and probably could/should have put in 35mm - at least to the first UFH manifold. I have decided to live with the 28mm given that the house will not need 16kW for many days of the year and I can remain within the 0.8<->1.2 m/s by adjusting the dT up a bit.

In summary, I am aligned with the other comments, 28mm is likely ok, 35 would be in the "perfection" category, but is not strictly necessary.

If heating engineer understood the "maths" of efficiency, he would not recommend a buffer tank. It seems that most heat pump training pushes the message to the installer "if you don't want a flow rate related call out, install a buffer tank". As @heacol mentioned, if you want to double your running costs, install a buffer tank.

I have a single circuit, single pump, no glycol, no buffer, no volumiser heat pump system in a 170 sqm pretty old house with a mixture of radiators and UFH on 28mm pipes, 100mm UFH spacing, 15mm to radiators, with pretty good CoP.

So the recommendations were coming from a heat geek installer who I would have expected to know about system design and his suggestion to use 35mm was because of the maths behind pipe size flow rates but we didn't go through the workings.

The property has 258sqm of heating space and I don't know if that makes a difference to the design suggestions proposed. When the system was installed there was only the circulating pump in ASHP which I'm told is very strong already 12m head but we struggled to find sufficient heat distributed to the radiators. An additional pump was installed after where the old one used to be and this helped heat the radiators better. The engineer said because they are installed in sequence there will be distortion and this was the other reason for installing a buffer to keep the separation between the heat pump circuit and the heating circuit. He did say his preference would be to avoid installing a buffer as it reduces cop but in our case he said it will help reduce cycling which we have seen with our setup.

@william1066 with your setup are you finding your system cycling? What is the heat loss for your property out of interest.

I have to admit as a consumer it's very difficult to know which is the right approach hearing the conflicting advice.

@soniks As I said, 28 mm will be fine, a 28 mm pipe has an internal diameter of 26.2 mm, the Grant 17 Kw will produce about 14 Kw at -2 at 50 odd degree. To achieve this, at a Delta T of 8, you need a flow rate of 25 l/min and the velocity will be approximately 0.77 m/sec. If it is a poor system and the pumps do not modulate, to transmit 17 Kw, you will need 30 l/sec which will have a velocity of 0.94 m/sec.

Someone is trying to make money where it is not warranted, or the Heat Geek course is not all it is made out to be. I know what I think.

Pumps, in series, do not cause distortion as long a there is about 10 times the diameter of the pipe between them. It adds the pressure of the two pumps together, and you will receive about 90% of the sum, therefore 2 X 6 m head pumps will supply about 10,8 m head in real terms. Pumping is not taught in this country, it is one of the first topics we will be discussing and demonstrating in our training. Heating is about moving water, if the water does not move, there is no heating. The description of the 12 m head pump actually means nothing, every pump has its own performance characteristics, a 12 m head pump may have less usable flow and pressure than a 7 m head pump in reality.

You are correct regarding conflicting advice, that is usually the case when an installer base is very badly trained and short on facts.

@heacol thanks for all your responses. The problem I have is when the Grant engineer came he disconnected the HP from the system and connected his flow monitoring rig he was able to see flow rates up 30lpm. Once he connected it back to the system it dropped to 17lpm at 50c for heating and 15.5 lpm at 55c for DHW. He suggested there is an issue in the system and not the heat pump itself.

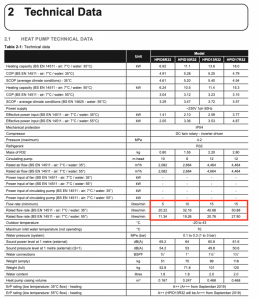

Looking at the Grant install manual I can see this. At 7c/35c water 50.88 lpm is required by the pump. If that is correct how could we achieve this given we are hovering around the 17lpm mark.

From what I can understand this could be because :

- Pipe sizing issues - the house was extended by the previous owners and we don't know how the piping has been done in the areas that were extended

- Incorrect piping somewhere in the property. Part of the reason we are looking to UFH as then we know there can't be any piping issues.

- Blockage in the system - the system was flushed before the heat pump was installed but maybe this is required again

- Currently the piping goes up from the garage into the loft across a long run to the middle of the house where the old cylinder was and connects back to the original piping - I think this is was the distribution point previously. The piping is 22mm copper as it comes into the loft and then 22mm plastic for the loft run then back to copper. I'm not sure whether going into the loft affects the pump performance given it's effectively 2 stories

- Stronger pump required maybe?

- I noticed there were no air vents installed in the garage and I can hear what sounds like trickling water in the volumiser when the HP is in operation (the volumiser is installed on the return). Is all of this normal? Perhaps there is air trapped and has no where to escape out from the volumiser - could this cause issues. There are air vents installed in the loft however.

- Could there be any other reason for a degradation in flow rate?

So our pumps are in sequence with the second pump installed in the middle of the property maybe 10m away. Based on your previous response you don't think this would cause an issue with distortion? Is your suggestion to keep both pumps in that case?

Many thanks again

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 327 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Having consulted with the plant wrangler in chief, it w...

By AndrewJ , 8 minutes ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 18 minutes ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 41 minutes ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 1 hour ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 3 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 3 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 4 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 5 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 7 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 19 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 21 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago