15mm piping and the need for flow separation

Posted by: @heacolit is not always possible to achieve a perfect scenario, but the best you can get with your current installation, will still be cheaper to run than a gas or oil boiler,

Exactly. I don't have the experience to know the "practical tricks of the trade" as it were, just a background that makes the maths relatively easy to understand.

I just can't see how the current pipe work can get to the max output of the unit, which is 12kW [A7/W35]. It may not need to, most of the time.

Posted by: @mike-hI would love to get rid of my buffer tank, but my problem is the size of my existing pipework

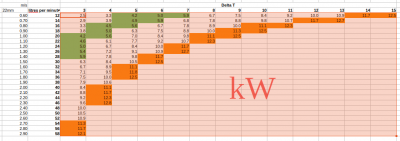

I think that Brendons plan is a good practical one driven by experience. From a theory point of view, and assuming your radiators can dissipate it. the below is what you would need to achieve for max load (orange) and at about 40% (green). Just spot check my formula.

@william1066 Thank you, The heat pump and system will work, with reduced performance at a Delta T of up to 14 Deg C, above that, it will probably become unstable.

We do not live in a perfect world, and often we follow behind a bunch of idiots, our job is to make the best of the situation that is presented to us.

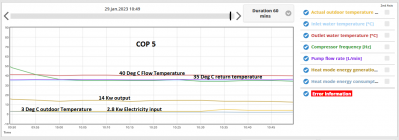

For interests sake, I have just posted this picture on LinkedIn, the screenshot was taken about 2 hours ago, the house is about 260m2, uninsulated, solid stone property in the Lake District, the primary pipework is 22mm at one end of the house (about 30 meters long) and about 50% of the radiators are on 8mm microbore. The data is taken directly from the 12 Kw Panasonic's online system. An installation, considered by the industry as impossible.

@heacol I suppose on a new system with new rads and new pipework, some inhibitor and simple Strainer will suffice?

Off grid on the isle of purbeck

2.4kW solar, 15kWh Seplos Mason, Outback power systems 3kW inverter/charger, solid fuel heating with air/air for shoulder months, 10 acres of heathland/woods.

My wife’s house: 1946 3 bed end of terrace in Somerset, ASHP with rads + UFH, triple glazed, retrofit IWI in troublesome rooms, small rear extension.

@heacol Thank you so much for your advice. That is really helpful. My understanding of heating systems has been gradually increasing since joining this forum, especially from following your posts. I have not come across auto bypass valves before, so will need to do more research on their usage. I am presuming that they maintain proper flow through the HP, while allowing lower flow through the 15mm pipework. The 22mm pipework would still need the same flow rate as the HP though. Interestingly, even on the lowest setting of the secondary pump, the delta T between the water going to and returning from the radiators is only 7 deg C. The drop across the buffer is 4 deg C!

Posted by: @william1066

- Samsung documentation says min/max for heating dT is 5-15 (though mine accepted a setting of 3 and delivers 3 - I think recommended is 5)

@william1066 are saying you able to adjust the HP's target DT directly on the samsung?

If as per the OP, you knew your system wasn't able to cope with the higher flow rate of a lower DT due to smaller pipework, can you set its operating parameters so that it runs at a wider DT and thus lower flow rate can deliver the necessary heat transfer?

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @william1066@mike-h With your Internal Diameter of 20.6 and flow of 22 you have a speed of 1.1 m/s. That will give you 6.27 kW of heat at dT 5. I will, at some point, find or build a google spreadsheet with the calculations mentioned in my post, then you can take a look. I think that taking your time is the right thing to do. If you did the maths on the efficiency delta between having and not having a buffer thank, it is probably not great in the short term. Over 20 years, it likely adds up, but I think taking your time to make the right changes is important.

@william1066 Thanks for this. I have been looking at all the formulae. Assuming a velocity of 1.0 m/s is acceptable (0.9 m/s being the recommended value), then 20 L/min at a Delta T of 7 would have a velocity of 1.0 m/s and provide 9.8 kW of heat which is my design heat loss at -3.7 deg C. That assumes I ditch the glycol and install anti freeze valves. As my current flow rate has often hovered around 20 L/min and still warmed the house, I am hopeful that this might be sufficient. I am not sure whether it is more efficient to have a higher flow rate and a lower delta T, but in one of Brendon's posts he says that a delta T of 8 deg C is the most efficient. I have altered the target delta T on my Samsung to 8, but it still seems to operate around 4-5 deg C, presumably as the heat requirement is lower now it is milder and it can't adjust the flow rate. Either that or the value I altered doesn't mean what I think it means.

Assuming the flows to my 11 radiators are all equal, which of course they won't be, the flow in my 15mm piping should be around 4/11 of the total flow, which for 22 L/min total flow would equal 8 L/min. This produces a velocity of 0.92 m/s which is ideal.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 431 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Without knowing it, @andrewj, you've laid down the gaun...

By Majordennisbloodnok , 19 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 23 minutes ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 56 minutes ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 1 hour ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 2 hours ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 4 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 4 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 4 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 6 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 20 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 22 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago