Posted by: @cathoderayI also note you appear to be using extremely low amounts of energy compared to me.

I am taking only the COP during my economy 7 cheap rate - so only first[ish] 7 hours of the day, and switched off the hot water. My hot water COP is down to about 1.5 right now so affects my overall cop quite a bit, I think I have an issue with my heat exchanger . So trying to exclude those numbers. So yes, this is not a whole day of consumption. My 15% delta is half of Glyns, likely because this is just the glycol difference. I am using the temperature data from the Samsung heat pump. If I put in more accurate temp sensors, my COP may go up a bit more. My target is the 5.9 achieved by "the heat geeks"

You may want to review this post from Glyn.

FWIW, I have calculated the weekly and overall discrepancies between my Class 1/Class B external heat pump only kWh meter (I think I am right in saying Class 1 and Class B mean the same thing, 1% accuracy) and Midea's reported kWh use, and in fairness the Midea figure's aren't that bad. Over 21 weeks, the Midea app (not modbus, I don't yet have enough data, but I think it will be the same) under-reported by 2.45%. The bad news is the discrepancy varies considerably week by week, from a 6.21% under-read to a 2.45% over-read. This variation means I can't simply apply a single correction factor to weekly reading. Grrr...

The external meter has an electrical pulse as well as LED pulse output and I am investigating ways of using the electrical pulse (1000 pulses per kWh) to record the meter's consumption figures. This turns out not to be as simple as I thought it would be, and no, I don't want to use an optical counter on the LED plus some ESP voodoo board to do something that should be much more straightforward.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay just on that point, If you can change the meter, there are meters with modbus outputs. I'm probably going to get an SDM120, as I'm not trusting my CT clamp. you have modbus sorted so reading it should be no issue for you?

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @william1066You may want to review this post from Glyn.

Yes, I agree, it is an interesting thread, and further confirms the smoke and mirrors we are up against.

Posted by: @william1066I am taking only the COP during my economy 7 cheap rate - so only first[ish] 7 hours of the day, and switched off the hot water.

This is important information! Context means a lot when interpreting COPs. As I said before, I don't really set too much store by short interval COPs, too much volatility, and in Midea's case there is also the integer problem (0.75kWh gets reported as 1kWh, the rounding errors being considerably greater over short runs when the actual numbers are small - 0.75 => 1 is a 33% over-estimate etc). I wonder is Samsung also use integers and so get the same sort of error? However, on the face of it, these rounding errors always increase to reading, yet the Midea app under-reads, so not sure how this all fits together... Consider this:

Actual kWh in/out over an hour:

0.75/2.25 (COP = 3)

Midea rounding

1/3 (COP = 3)

Actual kWh in/out over an hour:

1.25/3.75 (COP = 3)

Midea rounding

2/4 (COP = 2)

Midea thus appears to shoot itself in the foot (because the rounding is proportionally bigger on the smaller kWh in value).

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @iancalderbank@cathoderay just on that point, If you can change the meter, there are meters with modbus outputs. I'm probably going to get an SDM120, as I'm not trusting my CT clamp. you have modbus sorted so reading it should be no issue for you?

I have the SDM120 without the M suffix. M is for modbus...

I could get it changed over but it would need a qualified electrician (I don't think DIY is an option) and as you all know I am a tight wad who will never spend a penny I don't need to spend.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @iancalderbankIf you can change the meter, there are meters with modbus outputs. I'm probably going to get an SDM120

The two main manufacturers of energy meters are Acrel and Eastron.

Eastron is more commonly imported to European countries.

There are MID-certified units which have guaranteed accuracy for billing purposes, but most about £5 more.

I prefer the 2-module wide version - SDM220 (or SDM230) with Modbus

Posted by: @cathoderayI could get it changed over but it would need a qualified electrician (I don't think DIY is an option)

That depends on how/where it has been fitted.

The 'rules' for changing like-for-like aren't particularly clear to me.

Eg if I have a broken 13A socket faceplate, then it's permissible to change this for a new one without calling out an electrician.

Yes, I realise that the householder has just reconnected wires on a ring main which might not be tight enough, or might cause a 'break' in the ring.

But the alternative is that people wouldn't bother to replace broken faceplates, which is equally dangerous!

Common sense prevails, I think.

Save energy... recycle electrons!

@transparent thanks - am I right in assuming this is pretty close to your professional area of expertise? any particular reason for the recommendation? I've no hard and fast reason for suggesting I'm going to get the 120M, other than its available on openenergy monitor shop! is the 220 more accurate?

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

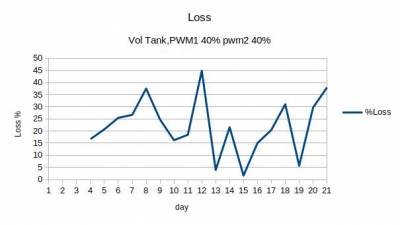

I have used a cheap "Danfoss" Water Power meter on my Radiator circuit.

My Radiator circuit is isolated from the Heat Pump water loop by an Heat Exchanger.

I have calculated the loss of energy ,

Loss = ((Energy Generated by the SAMSUNG HEAT PUMP - ENERGY READ on the HEAT EXCHANGER OUTPUT )/( Energy Generated by the SAMSUNG HEAT PUMP)x 100 per cent...........

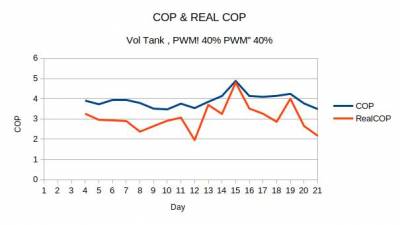

Comparing the COP from the SAMSUNG figures with the REAL COP as seen on the other side of the Heat Exchanger gives

The average SAMSUNG displayed COP is 3.9 while the average REAL COP on the other side of the Heat exchanger is 3.06!

These figures were obtained with the Heating Stopped .

I have not used the Bus outputs on the "Danfoss" water meter ( A £100 EBAY German Sharky under a pseudonym), only taking daily readings.

I will later connect the "Danfoss" to my PC.

iantelescope

You're right @iancalderbank that this is 'very close' to my area of expertise.

I have a friendly qualified electrician who's happy for me to run mains cabling.

He then does the mechanical and electrical tests when he makes the connections within my bank of three(!) mains consumer units.

I sometimes design and create components on a 3D-printer which he hasn't previously met.

For example I have adaptor-collars to connect oval-conduit within wall-plaster to a steel flush-mounted backing-box.

But he's happy to work with me like this because he knows that I

- am pedantic about selecting the correct size wire and mcb trip parameters for a circuit

- understand the insulation and leakage-current characteristics for the materials (plastics) which I use in each situation

- know and implement the rules about having both LV (240v mains) and ELV (below 75v DC) operating within the same environment

- fit more safety and surge-suppression devices than he ever gets to see elsewhere!

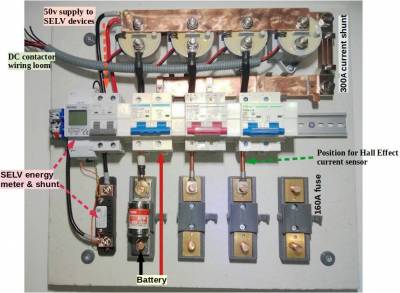

I work with micro-controllers (Arduino, AT-tiny, Raspberry-Pi) operating at 3.3 to 5v DC, using milliamps

alongside solar (120-500v DC) and battery storage (48-58v DC up to 500A)

alongside LV/mains 216-253v AC up to 40A per circuit

... so I need to have a clear grasp of what separation must be implemented, and what safety (earthing) systems should be present.

Just because I'm running appliances 'off-grid' doesn't mean that there should be any compromises on safety-margins... quite the opposite!

There may not yet be regulations which cover the equipment/systems I'm designing, but I want to develop the practices which could be adopted into 'standards' in the future.

I use a lot of measurement devices, including Modbus,

in such a way that the data-gathering continues when there is a system-failure.

There's no point trying to analyse faults if the data gets lost due to the fault occuring!

I even have volts/current/power meters which operate solely from the PV supply (fluctuating 120-500v).

So if an inverter isn't delivering a consistent output, I can see the discrepancy by comparing with the inputs.

I prefer the Eastron 2-module wide meters because the writing on the lcd is horizontal and it presents more information than the single number on the SDM120-range.

There's a DC version of the Eastron power-meter visible on the left end of the DIN rail in the following photo.

Please don't copy this design of a 4-way inverter-battery protection/combiner.

There were mistakes in the layout such that

- it didn't always 'fail safe' under fault conditions

- there are circumstances under which the inverters couldn't be restarted from the battery storage

There is a new design being built and about to undergo testing.

The work I'm doing is closely allied to the sort of issues which you're discussing here about monitoring and controlling heat-pumps.

In just the same way that you're aiming to avoid a heat-pump cycling, I'm trying to use battery storage whilst needing to know how much energy is stored.

They are equally complex issues to assess.

Save energy... recycle electrons!

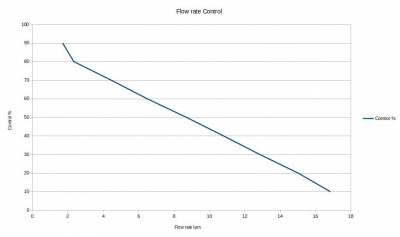

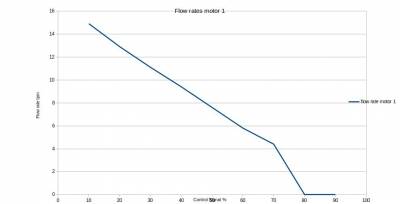

@william1066 Grundfos PUMP PWM Frequency....

I stand corrected William........

The Frequency range of the PWM signal is indeed 100 Hz to 4Khz!

I mistakenly tested both of my pumps at a 10 Khz Frequency producing .........

Grundfos PUMP PWM Frequency....

I stand corrected William........

The Frequency range of the PWM signal is indeed 100 Hz to 4Khz!

I mistakenly tested both of my pumps at a 10 Khz Frequency producing .

Perfectly linear results....

Sorry....

ian

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 607 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 25 minutes ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 1 hour ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 2 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 2 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 2 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 2 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 3 hours ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 3 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 4 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 9 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago