Whether zoning is needed depends on how the occupants use the space, the layout of the house, and how heat losses vary between areas. It’s not about the size of the house alone, it’s about diversity of use and performance across rooms.

For example, it doesn’t make sense to put a well-insulated timber-floored living area on the same circuit as a cold, uninsulated stone-walled room and expect one flow rate to suit both. That’s when balancing becomes almost impossible—one circuit needs high flow to deliver heat, and others are oversupplied, leading to energy waste and discomfort.

In systems where a single pump serves multiple zones, that pump usually has to be sized for the worst-case (index) circuit. The other zones then draw what they can from that higher flow rate, which isn’t efficient and undermines control.

Some jurisdictions are already requiring zoning in new builds and deep retrofits, and more are following suit. Personally, I think it should be case by case. A well-designed single-zone system can work brilliantly in some homes. But in others—especially where usage varies, or building fabric is inconsistent—zoning can reduce running costs and improve comfort.

So, I wouldn’t say all homes should be zoned or that none should. But I’d strongly argue that ruling it out entirely, especially in heat pump systems, is premature. Every property and every household is different — and the system design should reflect that.

As for overshooting, I meant primarily system-induced, where an area continues heating because of high ∆T or long cycling, not just from cooking or solar gain (though those matter too). It’s often a symptom of poor modulation, flow mismatch, or oversized emitters running without proper zoning or control.

Posted by: @harryreaSome jurisdictions are already requiring zoning in new builds and deep retrofits, and more are following suit. Personally, I think it should be case by case. A well-designed single-zone system can work brilliantly in some homes. But in others—especially where usage varies, or building fabric is inconsistent—zoning can reduce running costs and improve comfort.

The guidance associated with the UK building regs require separate control of each room unless it is not efficient so to do.

Posted by: @harryreaIn systems where a single pump serves multiple zones, that pump usually has to be sized for the worst-case (index) circuit. The other zones then draw what they can from that higher flow rate, which isn’t efficient and undermines control.

Please explain why a higher flow rate is inefficient and undermines control.

Posted by: @harryreaAs for overshooting, I meant primarily system-induced, where an area continues heating because of high ∆T or long cycling

Ok so how does zoning fix that assuming that the radiators or emitter circuits are balanced roughly on the lsvs or fixed loop valves.

Perhaps to clear this up you need to explain exactly what you mean by zoning in the case of a radiator based system and a ufh based system. We may be talking at cross purposes. In particular does a zone in your terminology need active control or do you still consider something with passive control a 'zone' (in which case each individual radiator is a zone because the passive control of an lsv will alter it's output and similarly each loop in a ufh is a zone provided it has at least a passive flow control valve in it so it can be balanced)

Posted by: @harryreaSo, I wouldn’t say all homes should be zoned or that none should. But I’d strongly argue that ruling it out entirely, especially in heat pump systems, is premature.

I agree with that as I say above, although i also would comment that the reason for (actively controlled) zoning needs to be thought through and validated by asking the questions: is it for comfort or cost and in either case can what is wanted/claimed actually be achieved?

The heating controls industry, at least in the UK, has encouraged us to believe that micro zoning in time and space will save money and increase comfort. So far the evidence to support this is sparse to non existent, but of course it is in their financial interest. Since there are some good thermodynamic arguments to the contrary, certainly with heat pumps, the general claims need to be regarded with due scepticism imho.

For the avoidance of doubt this does not mean that I believe that suitably intelligent control can't work, in fact I believe it can. However the key is suitably intelligent. Unless a manufacturer of controls can explain in simple terms how their system is optimised specifically for an ashp (or alternatively guarantee a level of performance or cost saving) I wouldn't personally be prepared to spend money on it, simply because there are too many out there making unproven claims. Others may of course have more faith in the heating industry.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

James,

Your questions cut right to the core of why these discussions matter.

One thing I’ve noticed over the years — and this thread really highlights it — is that we often use the same terms to mean slightly different things, especially regarding “zones” and “controls.” And it’s not just semantics — it shapes how we design and troubleshoot systems.

In a lot of current practice, zoning is seen mainly as a control-layer function — a way to open or close valves, turn pumps on/off, or modulate flow to match demand. But increasingly, I’m seeing that true system performance hinges less on the control devices themselves, and more on the physical layout and how the system behaves hydronically, particularly in terms of pressure, flow independence, and return temperature behaviour.

So, rather than viewing zoning purely as a matter of room-level control or motorised valves, I’m interested in how zones can be used as structural tools — to segment a system into independently operating hydraulic circuits. That way, each zone isn’t just passively reacting to room temperature but is set up to allow the appliance to operate efficiently and predictably.

It’s not a mainstream approach yet, and it’s not tied to any one product or brand, but I do think there’s space to separate functional control (time/temp logic) from structural control (pressure/flow design) in how we think about heating systems. Otherwise, we risk chasing symptoms—like overshoot or short cycling—with smarter controls when the issue might be baked into the system layout itself.

That might be a slightly different angle than usual, but I think these kinds of conversations are precisely where they belong.

James, On your question:

In systems where a single pump serves multiple zones, that pump usually has to be sized for the worst-case (index) circuit. The other zones then draw what they can from that higher flow rate, which isn’t efficient and undermines control.

Please explain why a higher flow rate is inefficient and undermines control.

When a single pump serves multiple zones, that pump usually has to be sized for the worst-case (index) circuit — the one with the highest resistance or largest flow requirement. That means it often delivers a higher flow rate than most other zones need. This creates several issues:

- Imbalanced flow: Zones with lower resistance end up taking more than their fair share of flow, while longer or higher-resistance circuits may struggle. That makes fine balancing nearly impossible — especially when relying only on TRVs or lockshields — and leads to uneven heating, discomfort, and inefficiency.

- Return temperature distortion: Oversupplied emitters return water hotter than necessary. That has a direct impact on appliance efficiency:

- Heat pumps suffer a loss in COP as the return temperature rises.

- If the return temperature creeps above the threshold, condensing boilers can lose their condensing effect entirely.

- Control instability: Because the flow isn’t matched to demand, the system tends to overshoot in certain areas, short-cycle, and respond poorly to modulation. You end up with symptoms like poor ∆T control, excessive boiler cycling, and a heat source that constantly hunts for the right output.

In contrast, a multi-pump system (through proper hydraulic separation or dedicated zone pumps) allows each zone to operate independently with the flow it needs. This delivers:

- Better system balance and comfort.

- Lower return temperatures and more stable ∆T.

- Improved appliance performance due to more predictable flow and return conditions.

- Often, lower total electricity usage is achieved by avoiding a single oversized pump running flat out.

To put it in real terms, a recent analysis showed that:

- A single-pump system delivering 0.54 L/s at 93.6 kPa used 50.54 W of electrical power.

- A multi-pump system, with hydraulic separation and smaller, appropriately sized pumps, consumed 42.62 W in total while improving control and comfort.

So this isn’t just about electricity at the pump. It’s about whether the system allows the appliance to operate efficiently and predictably. Even the best boiler or heat pump can’t do that if it’s fed unbalanced flows or unpredictable return temperatures.

Posted by: @harryreaIn contrast, a multi-pump system (through proper hydraulic separation or dedicated zone pumps) allows each zone to operate independently with the flow it needs. This delivers:...

Posted by: @harryreaSo, rather than viewing zoning purely as a matter of room-level control or motorised valves, I’m interested in how zones can be used as structural tools — to segment a system into independently operating hydraulic circuits. That way, each zone isn’t just passively reacting to room temperature but is set up to allow the appliance to operate efficiently and predictably.

Thanks for all the explanation that's very helpful.

In summary I think you are advocating splitting a heating into multiple circuits with separate pumps for reasons other than (or in addition to) temperature control, in order to make balancing easier/more stable/more predictable.

I am not an expert in hydronics but can imagine this makes sense. What I struggle to imagine is an installer getting it right given how blase most are about hydronic design. I can also see practical difficulties in retrofits, which make up the majority of the housing stock in which heat pump installations are necessary. So whilst I can see that theoretically this might offer some advantage I am sceptical that the practical application is widespread. Of course that doesn't mean it's not a worthwhile study, there will be applications for sure and anyway anything which illuminates the otherwise fairly poorly understood business of heating has got to be a good thing! Furthermore the exercise and learning may well trigger spin off ideas. If you were prepared to publish/discus your results here it would be worth starting a separate thread.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Thanks, James — that’s a really encouraging and fair response, and I appreciate the open-minded way you've approached it.

Yes, you’ve summarised it well: the approach I’m exploring involves separating circuits not just for temperature control, but to create more stable, predictable flow paths that align better with how modern appliances (especially heat pumps) want to operate. It’s about system behaviour, not just control logic.

You’re right that the real challenge lies not in the theory but in getting it right on-site — especially with retrofits. That’s one of the main reasons I’ve been developing a structured training programme focused specifically on these system-level principles. It's not aimed at turning installers into engineers, but at giving them reliable tools and understanding so they can get repeatable results without guesswork or overcomplication.

I’ve also been drafting a white paper to help frame these ideas more formally — not just the technical side, but also the common points of confusion and why conventional language around “zones” and “controls” sometimes leads us down the wrong path.

I’d be happy to share more as it comes together — and I agree it might deserve its own thread at some point. If there's interest, I’d welcome input from others here too. A lot of what I’ve been working on is grounded in exactly the kind of real-world feedback that’s shared on forums like this — which is probably the most honest R&D resource anyone

I agree entirely with the concept of zoning for practical purposes, especially for control of comfort. For example, I have a log burner in my lounge which is used occasionally so I don’t want to fiddle with settings each time it is used. I am an open loop sceptic. It’s fine if you can run 42C at -2C and modulate down to 25C. Running multiple pumps is fine also but not necessarily practical for modern houses. With legacy technology of radiators and fixed speed pumps in uninsulated houses there was plenty of scope for high flows and multiple pumps. The same doesn’t apply today. There are now pumps with differential pressure, constant pressure, auto adjust and even differential temperature control which can take care of many applications but even this is insufficient.

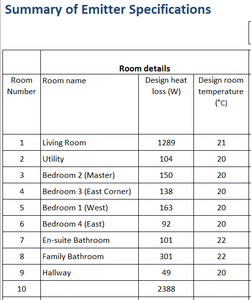

The problem arises with modern new-build houses. I attach a summary of a typical new 200 sqm house. The lounge is large open-plan with kitchen/dining and long bifold glass doors along the south wall. There are 4 bedrooms and en suite and family bathrooms to the north. The heat loss is 2.4kW at -2C OAT or average 12 W/m2 (20 W/m2 for lounge) including 80% heat recovery of an MVHR (<1kW at 15C OAT, 40:30 lounge loss to rest). The house has 15cm UHF loop spacing with flow screed giving an average System Performance Factor of 4 (tog 2 carpet). Therefore UFH DT for lounge is 5C (20/4) or average flow temperature of 26C at -2C OAT .Rest of the house is DT 3C. Peak flow rate at 5C DT is ~4 l/min for a lounge zone and ~3 l/min the rest (reduced to 1/4 at 15C OAT).

There are a number of issues arising. What size of heat pump, if it exists? Solar gain and kitchen heat will be a problem, necessitating separation from the northern part of the house. Flow requirement is very low in both temperature and flow rate. Open loop is obviously not going to work here. Multiple pumps will solve nothing. So, what is to be done here? It is a very current situation and heat pumps are a mandatory requirement here. Can you imagine the installer cockups?

Private individual. No affiliation with commercial "Heat Geeks" of same coincidental name.

@heetgeek

There are plenty of new build super insulated houses that run on ashps reported particularly on buildhub. I don't know exactly how they are configured but I guess many rely on the thermal mass of the slab in some way or another and with such low loss efficiency isn't quite so critical.

As an specific example I think @johnmo has a very low loss house which he runs on ashp. Not sure the exact details but I do know he has tried various operating modes and I think has concluded that open loop no buffer works best. Perhaps he could comment.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaAs an specific example I think @johnmo has a very low loss house which he runs on ashp. Not sure the exact details but I do know he has tried various operating modes and I think has concluded that open loop no buffer works best. Perhaps he could comment.

House is a single storey 192m² all UFH within 100mm concrete screed. Pipes are generally at 300mm spacing. Have tried all manner of buffer - 4, 3 and 2 port and volumiser. Have also had various zones and also ran with additional pump and mixer on the UFH manifold.

By far the best performance is no additional pump or mixer and no zones. Can be run in either storage heater mode (running in cheap rate periods only) or WC with decent cycling times. In storage heater mode run times are several hours, in WC a cycle per hour is typical, sometimes 3 cycles every 2 hrs.

We also run at elevated flow temps during excess PV generation. The energy just buffers into the floor room DO NOT, overheat because of it.

Posted by: @heatgeekThe heat loss is 2.4kW at -2C OAT or average 12 W/m2 (20 W/m2 for lounge) including 80% heat recovery of an MVHR (<1kW at 15C OAT, 40:30 lounge loss to rest). The house has 15cm UHF loop spacing with flow

Our house is almost as above 3.5kW at -9. We use a 6kW heat pump. Zero issues running fully open loop.

What people forget is UFH at low outputs is very much self regulated. About 4 degs here last night, running WC, floor temp 23 degs. So any room temp rise to 23 and then anything above that the floor starts to draw heat from the room, the floor cannot cause a room to be any hotter than it's self.

Also flow temp isn't floor temperature, so last night we were flowing up to 28.9 degs at peak, but floor temp never exceeded 23 degs.

Posted by: @heatgeekSolar gain and kitchen heat will be a problem, necessitating separation from the northern part of the house

We run the circulation pump on heat pump 24/7, any solar gain (we get loads) is redistributed around the house. So no separation required.

Posted by: @heatgeekOpen loop is obviously not going to work here.

I would do open loop first. Room monitoring is helpful for balancing the system, I have a an UFH controller with room sensors, but it's just not connected to heat pump. But I can see at a glance the room temps. Add that and you get flexibility to do things differently later.

Another thing to consider is when zones are employed, you still need to meet minimum flow rates for heat pump and meet minimum capacity to stop short cycling and meet defrost demand. A volumiser only fixes one a buffer fixed both, but you get distortion of flow temps and less efficiency.

Posted by: @harryreaSo, rather than viewing zoning purely as a matter of room-level control or motorisnised valves, I’m interested in how zones can be used as structural tools — to segment a system into independently operating hydraulic circuits. That way, each zone isn’t just passively reacting to room temperature but is set up to allow the appliance to operate efficiently and predictably.

Isn't this making an issue way more complex than it ever needs to be - overthinking it? A system running low flow temperature and emitter sized to room, balancing is easy and to a large degree self modulating - even a radiator system can be designed to flow low temperature.

@heatgeek Thanks for your post and for articulating a very real scenario that reflects the kind of system we’ll be seeing a lot more of: low flow rates, low ∆Ts, and heat losses so small they often feel like noise in the system. I completely agree with your observations about solar gain, MVHR, and the challenges of modern new-build loads. And yes, in setups like yours, open-loop systems quickly run out of control range.

I might offer a different perspective on how we interpret the role of “multiple pumps” and what they’re actually doing in systems like these.

Rather than using them as traditional “zones” (on/off, time/temp logic), I’ve been working on what I’d call structural zoning — separating the system into hydraulically independent circuits so the appliance receives a consistent, real-time flow and return profile, even as demand varies across the building.

The aim isn’t necessarily to give each room its own call signal, but to prevent circuits from interfering with each other. This becomes especially useful in retrofits, legacy buildings, or hybrid systems where return temperature distortion, unstable ΔT, or long loop interference cause appliances to short-cycle or misfire — even with advanced controls.

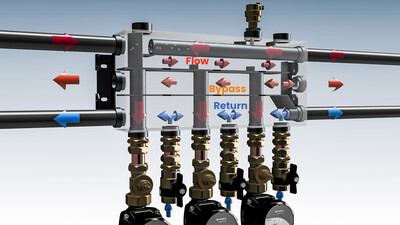

Here’s a visual of one of the manifolds, NRG Zone 5; you would use a smaller version for the job you described, we’ve developed to achieve this:

Each chamber — Flow (top), Bypass (middle), Return (bottom) — is internally separated. The bypass zone acts as a stabilising buffer (not a thermal store), maintaining a neutral point so that zone pumps can operate without pulling across other circuits or corrupting the return temperature.

This has allowed us to:

Avoid blending via buffers or LLHs

Keep return temps clean (crucial for HP COP)

Run multiple emitters without flow conflict

And modulate consistently at low loads

This particular setup wouldn’t “solve” your specific system—clearly, you’ve already dialled that in well—but it might offer resilience in cases where demand is more fractured or thermal diversity is higher.

I really appreciate your input on this, and if you’d ever like to look at the principles in more detail, I’d welcome the chat.

Posted by: @harryreaThanks, James — that’s a really encouraging and fair response, and I appreciate the open-minded way you've approached it.

Yes, you’ve summarised it well: the approach I’m exploring involves separating circuits not just for temperature control, but to create more stable, predictable flow paths that align better with how modern appliances (especially heat pumps) want to operate. It’s about system behaviour, not just control logic.

You’re right that the real challenge lies not in the theory but in getting it right on-site — especially with retrofits. That’s one of the main reasons I’ve been developing a structured training programme focused specifically on these system-level principles. It's not aimed at turning installers into engineers, but at giving them reliable tools and understanding so they can get repeatable results without guesswork or overcomplication.

I’ve also been drafting a white paper to help frame these ideas more formally — not just the technical side, but also the common points of confusion and why conventional language around “zones” and “controls” sometimes leads us down the wrong path.

I’d be happy to share more as it comes together — and I agree it might deserve its own thread at some point. If there's interest, I’d welcome input from others here too. A lot of what I’ve been working on is grounded in exactly the kind of real-world feedback that’s shared on forums like this — which is probably the most honest R&D resource anyone

Polar opposite view on system design. Totally unconvinced building complex systems is a way to go for efficiency. Split the system in to hydraulically separated systems why? Volume is king for a heat pump, having as much surface area for heat transfer stops short cycling. Your system is the exact opposite. You are promoting system distortion, so likely to add to poor system efficiency. Multiple pumps. These systems already exist via low loss headers and buffers. They are generally rubbish unless in complex commercial buildings and take careful design, in a house they are just not needed, KISS wins every day for me.

-

Bosch CS5800i 5kW - Experience So Far

4 weeks ago

-

My Octopus Cosy 6 Heat Pump Journey: From Quote to Completion

4 months ago

-

How to Zone with a Single Room with UFH

5 months ago

-

My British Gas – Heat Force ASHP Installation: A Frustrating Experience

1 year ago

-

Low shower pressure after ASHP retrofit

1 year ago

- 27 Forums

- 2,520 Topics

- 58.6 K Posts

- 569 Online

- 6,800 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

Yes, here's mine. From the service manual parts numbers...

By bobflux , 7 minutes ago

-

Had to learn the hard way 🤣 now I'm sharing T...

By bobflux , 22 minutes ago

-

RE: Issue with a Grant Air Source Heat Pump & Tado Smart Thermostat

Im assuming from your original post that hysterisis ref...

By JamesPa , 1 hour ago

-

RE: Heat Pump vs New Gas Boiler for Inherited House - Worth the Extra Cost?

Hi @fretless6 Mike, I have experience with Taggas (Re...

By Old_Scientist , 3 hours ago

-

RE: Daikin Altherma 3 LT compressor longevity question

@bobflux With my limited HA skills I can't ad...

By Ubert767 , 5 hours ago

-

RE: Underfloor Heating Installation Issues with Heat Pump

I'm going to install Thermacome ACOSI+ radiant ceiling....

By bobflux , 7 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Now seems a good time to summarise the costs and effici...

By benson , 8 hours ago

-

RE: Tell us about your Solar (PV) setup

@mk4 Charge to 100%, discharge down to 10%.

By bobflux , 9 hours ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

The simplest wired option is usually the Growatt Ethern...

By Jonatan , 15 hours ago

-

RE: Electricity price predictions

@jamespa And it seems some of the nasty public cloud...

By Batpred , 22 hours ago

-

RE: Jokes and fun posts about heat pumps and renewables

Technology is rapidly advancing. BBC News reported th...

By Transparent , 1 day ago

-

RE: Do Fridges and Freezers have COP ratings?

@editor Thank you all for your replies and submitted in...

By Toodles , 1 day ago

-

I know and yes. The secondary deltaT wont necessaril...

By JamesPa , 1 day ago

-

RE: Designing heating system with air to water heat pump in France, near Lyon

Just love the way you put it! 🤣

By Batpred , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thank you for sharing. So it seems that your Schneid...

By Batpred , 2 days ago

-

RE: Forum updates, announcements & issues

@upnorthandpersonal thanks for the thoughtful, consider...

By Mars , 2 days ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

@mk4 All 21 panels have their own Enphase IQ7a microinv...

By Toodles , 2 days ago

-

RE: Setback savings - fact or fiction?

Great, so you have proven that MELCloud is consistently...

By RobS , 3 days ago

-

RE: Mitsu PUHZ120Y 'Outdoor Temp 'error?

Thanks David & James It almos...

By DavidAlgarve , 3 days ago

-

RE: Surge protection devices SPDs

@trebor12345 - your original Topic about the right type...

By Transparent , 3 days ago

-

RE: Help needed with Samsung AE120RXYDEG

@tomf I’ve been sent this from a service engineer at Sa...

By Mars , 3 days ago

-

RE: Buying large amp bidirectional RCD and RCBO

Yes... I went through this particular headache and ende...

By bobflux , 4 days ago

-

O-oh! Let's take this as an opportunity to 'pass the ...

By Transparent , 4 days ago