I just had the 8kW EHS Mono HT Quiet (AE080BXYDEG) installed and was about to order the WiFi kit before I found Glyn and @TomC's posts about modbus.

I too have everything in the house running through Home Assistant, so I'd be very keen to experiment and contribute where possible. Modbus unit should be arriving this week.

@tomc are you adding a 120ohm resistor on the MIM-B19N between A+B terminals? I know Homely's install requires it and I see the USB adaptor you shared has a 120ohm on its A+B terminals.

How about ground, are you connecting that at both ends and if so what to?

Finally, are you using shielded/unshielded Cat5 or Beldren and what's your approx run length?

Posted by: @steven@tomc are you adding a 120ohm resistor on the MIM-B19N between A+B terminals? I know Homely's install requires it and I see the USB adaptor you shared has a 120ohm on its A+B terminals.

How about ground, are you connecting that at both ends and if so what to?

Finally, are you using shielded/unshielded Cat5 or Beldren and what's your approx run length?

I don't have a 120 ohm resistor at the moment, but I am considering adding one as I am getting some IO errors reported by the Python library that handles the Modbus comms. I'm not sure the USB adaptor does have a 120 ohm resistor installed, just solder pads incase you want to add one internally. The manual says:

Note: There is a pad reserved for 120R balancing resistance. Recommend you to weld120Ω resistors to the first and last devices if you connect many devices at the same time.

I'm using about 3m of shielded twisted pair - it's actually from an old USB cable but I'm sure Cat5 would be fine. I've got the shield connected to the ground at the USB adapter end and left isolated (i.e. cut back and taped) at the heat pump end.

I think RS-485/Modbus is pretty robust so over a short distance any old bit of cable would probably do the job! I did take care to route the cable away fom any mains volatge terminals etc. inside the heat pump case though.

Posted by: @tomcBut I'm happy to share what I've done of you are interested.

I now have the modbus connected and installed in my Samsung 16kW Gen6. I wondered if you could share your modbus config. I have all the config set for reading, but not yet for the writes. Would be really helpful to see yours before I mess something up.

Thanks

William

Posted by: @tomcBut I'm happy to share what I've done of you are interested.

I think I worked it out, I need to enable the register messages before the flow rate, and some other registers will start working. Did not page far enough in the manual. I think I can sort this out later this week.

Posted by: @tomcBut I'm happy to share what I've done of you are interested.

I think I worked it out, I need to enable the register messages before the flow rate, and some other registers will start working. Did not page far enough in the manual. I think I can sort this out later this week.

I'm still very interested in this too, would be very grateful for more details on what both of you have done. Different heat pump (Midea) but it also uses modbus-RTU over RS-485, with access to two terminals, H1 and H2, which appear to be RS-485 A and B terminals, via the wired controller in the house and also possibly the heat pump PCB outside the house. The registers in the Midea manual suggests it is possible to both read/get and set values, including the weather comp curve high/low values, which could be very useful, ie an adaptive weather comp curve.

I am planning to use a dedicated thin client/mini PC running Home Assistant to do all this so very interested to know

(a) hardware setup? I am planning to use mini PC <-> usb cable <-> usb to/from adaptor/converter <-> wire (not sure what type) <-> Midea wired controller. I intend to use wired connections rather than wifi as both more robust and less password/key nonsense

(b) software/modules in HA to do the reading/writing and recording of data?

(c) are other components eg ESP essential or desirable, or just extra clutter?

Any advice much appreciated!

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay I have been a Home Assistant for many years, and there is a bit of learning curve.

All you will need is a PC or RPi, then install the fully managed HA OS. Do the wiring, plug in the RS485 USB device.

Add the modbus entries to your config file, and it should all work. Happy to provide a much more detailed info if needed, let me know.

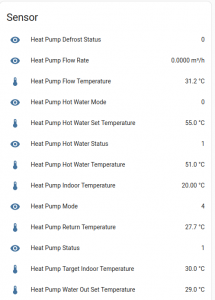

I have the module installed, just having issues (as you can see from the screen shot below) with the new registers and one existing register. Will hopefully sort during the week.

@william1066 That's very interesting to see in action. I have been using home assistant for a number of years and conveniently the pi is located beside where my cylinder is so will hopefully be easy to connect the USB adapter.

The plumbers ran a cat 6 cable to the outdoor unit and used 2 pairs for F1 and F2 so hopefully I don't have to run another cable and can just use the other two pairs for the Modbus card. I'm just waiting on delivery of this from Keroclima.

Did you use the python script mentioned earlier in the thread or are you doing this in Yaml in HA?

@william1066 Looking good, you've taken a slightly different (and probably more elegant) approach than me in using the HA Modbus integration, rather than a Python script and MQTT. I didn't want to move my HA RPi from the office (where it connects directly to the router) to the garage which is where the RS-485 comes in from the heat pump, hence a script on a separate RPi. But I'm sure there would be a way of having some kind of RS-485-TCP/IP bridge in the garage and still use HA Modbus integration as you've done.

Which registers are you having issues with?

@tomc I think I have solved my problem. If you want flow rate, outside temperature and a couple of others, it seems these are in the group of "New Modbus Registers" and need to be programmed into the MIM-B19 first. You can't program them individually [well technically you can], which I did first, if you do that, they either don't work at all, or work for a bit then stop working. Now that I have programmed them as documented, as a batch using "write multiple registers". Seems to be working. We will see, if this fixed them.

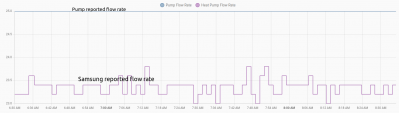

Seems to be working for the last 2 hours, which is an improvement on last night. [The pump flow rate is an estimate with published +- 10% accuracy / samsung much more accurate as per Sika specs]. Sika is about +-2% or less. [2...65 l/min: ±(1% of range + 0.5% of reading) ±2% of range - with water between 20 and 30 degC]

Posted by: @william1066there is a bit of learning curve.

All you will need is a PC or RPi, then install the fully managed HA OS. Do the wiring, plug in the RS485 USB device.

Add the modbus entries to your config file, and it should all work. Happy to provide a much more detailed info if needed, let me know.

I have the module installed,

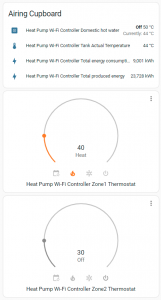

@william1066 - that's very interesting. This is what I currently have, using the midea_ac_lan module (<=link) as modified by wasilukum (<=link) inside a full (OS) version of Home Assistant.

It is done over wifi and as you can see only provides limited data, though it does have to key elements, total energy in and total energy out, with an estimated total life time (ie since installation) COP of 2.64 which I am disinclined to believe (there has long been uncertainty about rounding errors in Midea data eg what if an hourly consumption of say 2.2kWh gets routinely rounded to 3? Quite a big error over time). I think my lifetime COP is probably a little over 3.

Midea_ac_lan and it's forks are far from complete, and their developers are not very active, I suspect because doing things over wifi is excruciatingly painful. Not only is there nuclear weapon level security to get past, the data itself is wrapped up into the most contorted strings imaginable, and there appears to be no published guide on what is what. My own forays into trying various code modifications one bit at a time have got nowhere. This is what makes using modbus over RS-485 so attractive, all those obstacles removed at a stroke.

You can also see, in the two gauge cards below the airing cupboard one, that Midea_ac_lan also provides a way to set things as well as read (get) them. The currently available controls are of little/no value, because they assume you are controlling the heat pump via room stats, and they get the wrong information (the 40 degrees in the upper gauge is not the room stat setting, it's the set LWT were I to be running in constant LWT mode, which I am not. I think this is because midea_ac_lan, like so many modules out there, is primarily focused on AC (air conditioning) units, and so doesn't really cater for heat pumps, though the crossover in how Midea does things means heat pump interfacing can be done, but it is not the primary purpose.

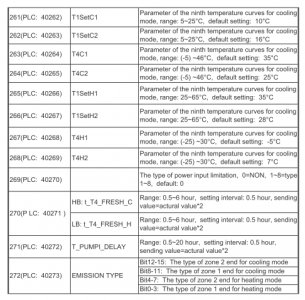

My aim is eventually to be able to monitor both important variables, and, crucially, be able to modify the infamous curve 9, ie the weather comp curve. The wired controller manual suggests this may well be possible, though there are some typos:

The top 8 rows say in column 3 they are about cooling, but if you look in column 2, the top 4 are indeed about cooling settings (T1SetC1 etc) but the bottom 4 are heating settings (T1SetH1 - T1 = LWT so this is the LWT setting for the first (left hand end) of the weather comp curve, this label is the label that also appears in a place where the sun doesn't shine, the wired controller tradesman's entrance). My aim is to be able to adjust the curve according to load/demand, eg if room temp (from a separate sensor) is a bit below desired room temp, then up the weather comp curve a bit, until the actual and desired room temps are closer together. In other words, an adaptive weather compensation curve.

"Do the wiring, plug in the RS485 USB device. Add the modbus entries to your config file, and it should all work. Happy to provide a much more detailed info if needed, let me know. I have the module installed..."

A brilliant and concise summary, but a little bit too concise for us beginners! To break it down into the various stages:

"Do the wiring, plug in the RS485 USB device." My plan is a two wire cable (twisted pair? sheathed?) onto the H1/H2 screw terminals in the wired controller (I think these mirror the same terminals on the outside unit PCB, if so, no need to run a long cable to the outside unit?) to the AB terminals on a RS-485 to USB adaptor (what about ground/earth? what about 120 ohm resistors?) such as this one (<=link), or do I need a higher spec (isolating) adaptor (<=link)? This wire will be the long one, running from the wired controller in the airing cupboard to my study where I have the mini PC with HA OS (already set up). The adaptor will either plug directly into the mini PC or sit beside it and be connected to it by a short USB cable.

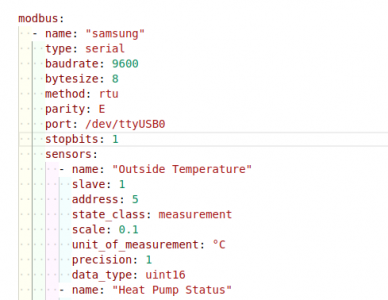

"Add the modbus entries to your config file" - I think I am right in saying HA can handle modbus natively, so presumably these are entries in \config\configuration.yaml (I have the samba add on in HA so I can see/edit its files over the network, ethernet cable between my desktop PC and the mini PC). But the 'modbus entries'? This HA page (<=link) has stuff like this

# Example configuration.yaml entry for a serial connection

modbus:

- name: hub1

type: serial

baudrate: 9600

bytesize: 8

method: rtu

parity: E

port: /dev/ttyUSB0

stopbits: 1

and stuff about how to write to controls and read sensors (registers). Is it just a case of going through that lot with a tooth comb to get the right configuration.yaml modbus entries?

"I have the module installed" - not sure what 'the module' is? A code module, or the RS-485 adaptor. or something else?

Sorry to ask so many questions, but once this is all done I want to write it up in my Beginner's Guide to Heat Pump Monitoring thread, to provide what it says, a beginner's guide. All this should be broadly applicable to any heat pump that uses RS-485/modbus using a wired set up (and possibly wifi based ones as well, if not plagued by Midea type security).

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayMy plan is a two wire cable (twisted pair? sheathed?)

There seem to be multiple views on this, simple cheap two wire, shielded and grounded at one end only, shielded and grounded on both ends. I decided to go shielded, and for the modbus connection, ground both sides. (for the internal controller to external heatpump, I grounded one side only but also used the shielded cable). Neither have comms errors. Length of each is 27.5 meters.

Posted by: @cathoderaywhat about 120 ohm resistors?

I did not put an resistors on. A conscious choice.

Posted by: @cathoderayI think I am right in saying HA can handle modbus natively,

Yes, I can share my config file, but looks like this

Posted by: @cathoderayand stuff about how to write to controls and read sensors (registers). I

I have not ventured in into the writing yet. Just getting my head around reading. Errors with reading are not likely to cause issues. For writing it is a case of measure thrice ....

To quickly test the various registers I installed mbpoll on my Linux laptop. I may try get this installed on HA, then I don't have to keep stopping the modbus service and moving the USB to my laptop.

Posted by: @cathoderayBeginner's Guide to Heat Pump Monitoring thread,

Happy share what I did, though something like github may be a better place for it, linking to/from this site.

- 26 Forums

- 2,406 Topics

- 54.6 K Posts

- 382 Online

- 6,092 Members

Join Us!

Worth Watching

Latest Posts

-

Daikin DHW Margin - what is it?

Our Daikin Altherma 3 Monoblock has DHW settings for bo...

By Pipcart , 10 minutes ago

-

RE: Considering MLCP (Multi-Layer Composite Pipe) for ASHP

@deltona I did draft a long point by point response ...

By JamesPa , 14 minutes ago

-

RE: GSHP WOES! Midland based engineer recommendations?

@editor It is indeed for servicing. My current service ...

By Morgan , 41 minutes ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

@transparent Thanks, I think I now get it. I am sor...

By JamesPa , 45 minutes ago

-

RE: Sunsynk Whole House Backup Issue

Hi @lostandconfused , I agree that topic/thread is the ...

By Batpred , 54 minutes ago

-

RE: Speedcomfort radiator fans

In case it helps Andrew Kuhne on openenergy monitor has...

By JamesPa , 2 hours ago

-

RE: Post-Traumatic Heat Pump Stress Disorder

@jamespa, we have got this topic, which all the mods ca...

By Mars , 4 hours ago

-

Things have gone quiet with you @drei. Any updates?

By Mars , 4 hours ago

-

RE: Passiv Smart Thermostat - Help & Forum Support

Thanks @tim441. Interesting timing, as Passiv are a cur...

By Mars , 6 hours ago

-

Hi everyone, I have a two year old Marlec Solar iBoos...

By Tallmarc , 9 hours ago

-

RE: Please help with the settings ecodan

Are you trying to address any particular performance is...

By Sheriff Fatman , 14 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

🤣 Well, I never managed to get the HA solis "...

By Batpred , 16 hours ago

-

RE: Experience - New Build / Complete New Heating System

Your sap clculations should give you a heat loss figure...

By JohnnyB , 16 hours ago

-

RE: Vaillant aroTherm not heating with many faults

@editor hmmm, our engineers Rae, Craig, Naz, Rob and Ry...

By ASHP-BOBBA , 17 hours ago

-

RE: I’m glad the cold spell is over!

@editor as a reply for this date the 6th of Jan in o...

By Nursethescreens , 18 hours ago

-

RE: Heat loss based on gas usage

@jamespa Thanks. The numbers posted above were jus...

By Bash , 19 hours ago

-

RE: Heat pump not reaching flow temperature

I would describe this as either a fault or a configurat...

By JamesPa , 19 hours ago

-

RE: New Daikin 11kW Altherma 3M install - is it working as it should?

I forgot to mention: Octopus measured our heat loss at ...

By Toodles , 22 hours ago