@jamespa a few thoughts

heatpumpmonitor.org is great , but in the nicest possible way something of an echo chamber - the people who've made the effort to put their systems on there are (generally speaking) the same people who've made the time and effort to make their systems work really well, because if their data shows poor performance, they'll have done something about it! So whilst they show what is achievable in practice over a decent sample size, they show the upper end of that. I'm trying to get my system on there at the mo. I'll drag their figures down ;-). Its not that easy to get your system on there, you have to be a geek and get a bunch of stuff installed and configured, as I'm sure you're aware, and is so not "joe public" suitable. data from the rest of the country's installs - those have not been tweaked and optimised by heating enthusiasts - is what you'd need to see, but that would have to come a different way.

early adopter - I disagree, we are in early adopter. NOT from a tech point of view - I accept it is mature. I mean from a people (% of users who've got one, % of the installer pool who can fit / have fitted one) and process (are installs and systems reliable and consistent) point of view.

flow rates and distribution pipework - I've a lot of respect for heatgeek so no doubt their figures are good, but there are some of the dreaded assumptions in there which won't be the case for all houses. some people's distribution pipework won't be great or as per those assumptions. almost every house is different. back to having to know whether the house is suitable or not for your "straight swap".

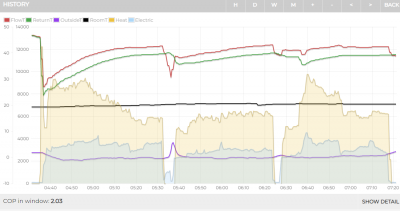

having done my own install and 1 month in, and followed all the best practices that I could ( single loop, no buffer, modulating pump, volumiser, replace emitters, long run times) I don't know yet how one gets these super high COPs. I've had at best 3.5 when its been around 7-9C. This morning, outside temps hovering around zero, I got 2.0 (see pic below) and that is not with high flow T's , I'm at 42 or 43. and I gave a damn about my install.

this thread isn't a discussion about my system but my point is that I will put the effort in to improve my system. In the "straight swap" situation that won't happen. So, IMO, the mfr claimed / spec sheet COPS will be a complete pipe dream.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @jamespauserid="4643"]

the difference is that with a gas boiler, the biggest issue is the safety risk.

Quite, so less regulation not more is required!

Sorry I have to disagree- the HP installation industry needs to be completely re- configured with powerful measures centred on performance penalties.

The central objective to the HP rollout is energy efficiency on a massive scale. If an MCS installer company installs a “Designed” system delivering a COP of only 1.5 (when it should be 4) and fails to document an energy strategy which is intelligible to the home owner then there must be heavy and ruthless penalties to the installer for failure to deliver the design performance.

In the same way that Gas Safety cannot be compromised... Today energy efficiency cannot and must not be treated as a secondary ambition.

Many other publicly funded businesses need to meet standards requiring penalty tests, why not the lucrative BUS scheme.

Posted by: @iancalderbanksome people's distribution pipework won't be great or as per those assumptions. almost every house is different. back to having to know whether the house is suitable or not for your "straight swap".

This rather suggests the industry is missing a system for characterising the flow network. I can't help but feel that with some level of "plugging in a pump into the existing system" and "manually turning the existing radiators off and on" one can fairly non-intrusively assess the flow properties. I guess that some more sophisticated boilers may even allow you to control the pump level and see the flow rate. In addition, injecting slugs of warm water into the pipes (a delta) one might be able characterise how insulated the pipes are as well as the length of pipe runs by observing when each radiator starts to heat up.

Perhaps there is a business case for some kind of a product, especially if one can shoe-horn magic pixie-dust AI in there to recognise standard system layouts to reduce the number of manual operations required. Installation risks need to be managed.

I too try to think outside the box, and have spent much of my career educating the 'but this is the way we have always done it' clan. Methods and processes can often be improved, and at the end of the day it will invariably come down to 'is it cost effective to do so'.

We both share the same desire, to help reduce greenhouse gas production by lowering fossil fuel consumption, and hopefully encouraging others to do the same. There are a number of options that could be used to try to achieve this goal.

For me, the starting point should always be to reduce demand, be that energy efficient appliances, modified lifestyle, or in the case of home heating, improved insulation. Reducing demand for most would be a win - win, since it would not only help reduce ones energy bills, but by reducing demand, can help reduce the amount of generating capacity required to be built and operated to meet that demand. Reduced generating capacity should help keep down costs for the benefit of the consumers.

A further way to reduce demand is to try to ensure that ones heating system is operating at maximum efficiency, be that gas fired, oil fired, or by means of a heat pump. This is where our thinking differs slightly, though we still champion optimum efficiency.

The redeeming factor for heat pumps, is their higher efficiency by harvesting energy from a free external source, in most cases the outside air. This unfortunately is also their Achilles Heal, since unlike other heating systems, the fuel source for an ASHP is not consistent, and reduces with falling outside air temperature. This of course occurs at the time of peak heating demand.

Even using average daily temperatures in ASHP calculations does not work well, since it is quite possible for the outside temperature to change from a low of -2C overnight, to a peak of 10C during daytime. This can have a dramatic effect not only on the heat loss experienced by a property, but also the energy source for an ASHP being used to heat that property. Making calculations based upon an average temperature of 4C, will I suspect indicate a higher efficiency than the true value achieved. The higher the required LWT, the lower the overall efficiency achieved.

At the end of the day it is down to individuals to decide what improvements they can make in their efforts to reduce energy consumption in the most efficient manner.

I attached a copy of a spreadsheet I produced quite some time ago for an Ecodan 14kW ASHP. It can be used to explore how a system is likely to respond to varying insulation levels, heat emitter capacity and indoor temperature setting. If you have any questions then please feel free to ask.

Posted by: @chickenbigThis rather suggests the industry is missing a system for characterising the flow network. I can't help but feel that with some level of "plugging in a pump into the existing system" and "manually turning the existing radiators off and on" one can fairly non-intrusively assess the flow properties.

I tried to do this with my existing system. But: my primaries to the boiler were undersized (they were replaced for the heatpump), my existing circulating pump was undersized (Arguably even for the boiler system) and certainly couldn't generate the head/flow rates needed for a heat pump circulation rates. I contemplated just replacing the circulating pump with the HP spec one , but concluded it wouldn't be worthwhile (Because any result would be invalid due to the aforementioned too-small primaries) and I literally couldn't buy the pump that I wanted to without actually buying a heat pump with it. real world houses will have any manner of similar foibles.

I think you might be able to prove a definite positive: if you set existing circulation pump to max, can you get the flow rates the HP needs (without huge noise etc), if yes, observe and measure behaviour with rads on/off one by one, but if the result is anything other than that , I think you're back to intrusive "find the pipes" assessment.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @sunandairSorry I have to disagree- the HP installation industry needs to be completely re- configured with powerful measures centred on performance penalties.

The central objective to the HP rollout is energy efficiency on a massive scale. If an MCS installer company installs a “Designed” system delivering a COP of only 1.5 (when it should be 4) and fails to document an energy strategy which is intelligible to the home owner then there must be heavy and ruthless penalties to the installer for failure to deliver the design performance.

In the same way that Gas Safety cannot be compromised... Today energy efficiency cannot and must not be treated as a secondary ambition.

Many other publicly funded businesses need to meet standards requiring penalty tests, why not the lucrative BUS scheme.

I'm halfway between the two of you.

If a system installed under the current MCS regime, only delivers COP 1.5 and it was specified as 4, and/or it just doesn't heat the house properly, then the installer must rectify or be penalised. There I agree with sunandair. But, I think we all know that doesn't work very well in practice, right?

But there's another objective to HP rollout which is arguably higher priority than "energy efficiency": Get Off Gas. here I agree with JamesPa, and why I said what I said several post back.

If heat pumps can be made to COST the same as gas (to run and to install) even for low efficiency run costs (thus requiring HP specific electricity pricing or a major price shift), that then means those installs are more acceptable to the mass user base and the take up goes up. then IMO this is still of benefit for the climate. Those less efficient installs (perhaps not under MCS ) could be still of value to the climate and the user, providing they still work (and by work I simply mean "heats the house to the user's comfort"). There's always the option then for the user to invest a little more (or be given a interest free loan to do so) to up-spec the system to make it more efficient.

note that I am not advocating that all installs should be low efficiency - far from it - I'm just saying that accepting that some will have to be - providing the joe public customer is not left financially disadvantaged or Cold - is a potential way to Get Off Gas more quickly.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

At the present time installing more heat pumps will not necessarily 'get off gas', it will just move the location where the gas is being burned.

Combined Cycle Gas Turbine (CCGT) power stations are approximately 50% efficient, so it takes 2kW of gas to produce 1kW of electrical energy. If a heat pump only has a COP of 1.5, then to operate it will entail burning more gas.

When operating in open cycle, a CCGT is only 33% efficient. I will leave you to do the maths.

Installing inefficient heating systems is therefore not the answer, and will not encourage homeowners to go through the trauma and expense of installing such a system, that will then probably cost more to run.

I feel that it is rather pointless for the Government to throw our money at the heat pump manufacturers and installers, without there being an agreed design philosophy of how to correctly install a heat pump in the different properties, correctly trained staff to install and configure such systems, and a regulator 'with teeth' who can ensure that systems are correctly installed, configured and commissioned for optimum efficiency, and take action with those companies who fail to provide an adequate service.

I'm not holding my breath. 🙄

Posted by: @iancalderbankIf a system installed under the current MCS regime, only delivers COP 1.5 and it was specified as 4, and/or it just doesn't heat the house properly, then the installer must rectify or be penalised. There I agree with sunandair. But, I think we all know that doesn't work very well in practice, right?

I'd love to see MID certified meters installed under MCS, and then a guaranteed SCOP performance from it! I appreciate the meters cost money, but I think are well worth the extra and should be installed as standard. As a bare minimum a MID certified electrical meter should always be installed, they're only £50. So far as I'm aware, electrical and thermal meters inside heatpumps are of unknown (and poor) tolerance, so cannot be used as part of a guarantee.

Thanks for all the comments. As a group we aren't currently 'converging', which is a disappointment given that this group seems to be considerate of others views and generally positively minded.

From some of the comments above I realise that I made the classic rookie error (even though I should know better) of leaping to a strawman partial solution before being certain we agree on what the objective, constraints and assumptions are. So lets take a step back and check we agree on those. We can then return to the comments above

I would suggest the following

Objective

the objective is to reduce, eventually eliminate carbon emissions while heating our houses, with a degree of urgency commensurate with the ambition to be carbon neutral by 2050.

This is subtly but importantly different to

Posted by: @sunandairThe central objective to the HP rollout is energy efficiency on a massive scale.

In this context it is worth noting (to give a scale to the problem) that we currently retrofit 1.4M gas boilers each year, and have about 23M houses. So roughtly we need to do about 1M-1.5M per year.

Constraints

the primary constraint is that it has to be affordable, not just to the few, but to the many. I would also suggest that making the assumption that it will be made affordable by ongoing taxpayer subsidies (at any material level) is dangerous, possibly foolhardy

the timescale objective means that any solution needs to be based largely on technology we have, or can be confident we will have shortly

Assumptions

I think we have to assume that an ASHP run on electricity is cleaner, and will continue to be cleaner, than gas ever can be. We further have to assume that the cleanliness of electricity will, at worst, keep pace with the demand, contrary to this comment:

Posted by: @derek-mAt the present time installing more heat pumps will not necessarily 'get off gas', it will just move the location where the gas is being burned.

The fact is that the proportion of renewables in electricity has grown every year recently. If we want to take a snapshot then the Government publishes greenhouse gas conversion factors, currently 0.18 (Kg(e) per kWH) for Gas, 0.19 for electricity. The figure for electricity has been improving year on year and, even at the current figure, an ASHP COP of 1.1 would outperform electricity in terms of carbon emissions.

For the purposes of the discussion about ASHPs we also should assume that insulation is a parallel activity, not alternative but parallel. However there will always remain a requirement to heat homes

Can we at least agree on these, and are there any which need to be modified or added?

Once we agree on these, or alternatives, I suggest we try to agree on the current state of the industry.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

I think that many on the forum would agree that there is not a simple solution, but that all reasonable options should be considered and investigated. I am not convinced that many of our politicians and their advisors fully understand the scale of the problems. Voting into law net zero requirements is not going to make it happen.

I would suggest that we consider the problems and possible solutions, and then try to convince others of the need for action.

Here is my list of suggestions.

1) Problem :- It is my understanding that many of the condensing gas boilers installed in homes throughout the land are not actually condensing. Possible Solutions :- Educate homeowners to lower the temperature setting so that condensing actually occurs, thereby reducing consumption and saving them money. Ensure Gas Engineers who install and service gas boilers are adequately trained, and ensure that gas boilers are correctly adjusted and that the homeowner knows the reason why. Savings of up to 10% may be possible, and possibly would be the simplest and cheapest to achieve.

2) Problem :- Many homes have poor energy efficiency, due to poor levels of insulation. Possible Solutions :- Encourage those that can afford to do so, to improve insulation levels whatever their heating system, financial support should be provided for those that cannot afford to do so. Highlight the energy saving and long term financial benefit of improved insulation.

3) Problem :- There would appear to be a lack of knowledge within Government, the varies ministries and regulators, about heat pumps and heating systems, which may be affecting decision making. Possible Solutions :- Insist that they have one installed in their own home, at their expense, and see if they enjoy the upheaval and fun and games getting it to work, or getting someone back to fix it when it doesn't.

I will see if I can think of more tomorrow.

Posted by: @jamespaConstraints

I would certainly add that the heat source needs to be simple to fit, probably opportunistically when the existing heat source breaks. This implies it should be quick (and low risk) to install, with a broad-base of installers trained and willing to do so.

hi @jamespa

The issue of uptake has loomed large lately and I’m sure there’s many and varied reasons. I guess inflation and the economy wouldn’t have helped.

Reputation of the HP industry and conversations over the garden wall would certainly have fuelled a lot of resistance to what is often perceived as over-complicated, unreliable and very temperamental.

You put the word “Mindset” in the title.

But who’s mindset?

Customer’s still crave NEST or HIVE type thermostats. So the industry gives them pseudo smart thermostats which don’t work.

What we need is a genuine customer lead solution to heat pump installation. One that recognises “Efficiency is King” and HPs are a delicate instrument that needs to be tailored to the property and fully commissioned… And that the End User, with their own set of limitations and knowledge is the one having to operate it.

Whereas, instead of trying trying to demistify the way a heat pump works the operatives and sales teams appear to languish in the complexity.

Step One: stop fitting the main controller in the attic, spare room or in the cellar. 😅😂

There are other steps of course…. But this is not just a science issue the “human/machine interface” is totally missing from the MCS guidelines and all most installers handbooks.

IMHO

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 394 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 23 minutes ago

-

RE: Electricity price predictions

Sorry to derail this thread ‘slightly?’ but back to the...

By Toodles , 32 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Without knowing it, @andrewj, you've laid down the gaun...

By Majordennisbloodnok , 51 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 56 minutes ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 1 hour ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 2 hours ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 5 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 5 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 6 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 10 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 21 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 22 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago