Observations on my Ecodan's estimates of energy consumed and delivered

Comments I made in the thread 'Electricity use for heat pumps - comparing homes and consumption' seemed to merit a thread of their own. So here it is, after a short break while I stripped out the bathroom (and then waited for March data).

The short version is that my Ecodan invariably overestimates its electricity consumption. But it does this inconsistently which leads me to assume it's estimates of energy delivered may also be unreliable. So unless it's estimates of energy consumed and delivered are inaccurate but consistent with each other, any Coefficient of Performance derived from either or both of them is probably also inaccurate.

I've read plenty of people observing this inaccuracy. Here I'm quantifying it (in terms of energy consumed but not delivered). I'd be interested in the experience of other Ecodan owners- especially if they have third party measurement of energy consumed and delivered.

The long version is that my 11.2kW Ecodan was installed in the Summer of 2022 with an FTC6 controller. At the planning stage I specified that I wanted a separate meter installed so I could monitor energy consumed. In February 2023 I started keeping comprehensive daily records to help me judge whether changes I made led to any improvement in performance efficiency. Up to that point I had only kept a note of the figures from the consumption meter (which is accessible- unlike the FTC6 which entails burrowing at the back of the airing cupboard to read). My daily records since then cover energy consumed and delivered as 'measured' by the FTC6 controller, consumption measured by the meter and daily maximum and minimum outside temperatures (from my home weather station which is broadly consistent with the Ecodan/Melcloud OAT reading).

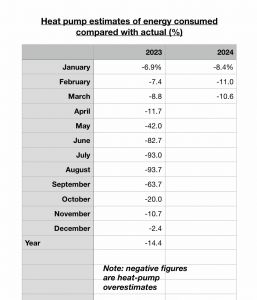

The attached table only gives the % difference between the energy consumed month-by-month as measured by the meter and by the Ecodan. In every month the Ecodan overestimates consumption. I'm not sharing energy delivered in this thread as I don't want it to become a 'how to improve efficiency' discussion- we've already got plenty of those! And I lack confidence in the accuracy of the energy delivered figures reported by the controller. Given the widely varying difference between my two sources of energy consumption data any CoP figures derived are unlikely to be reliable or accurate. Note that energy consumed by the immersion heater isn't included in these figures.

Observations and thoughts:

- consistent over-reading: Viewed at the monthly level, the Ecodan figures always overstate energy consumed. At the daily level the picture isn't so absolutely consistent but there were only 35 occasions in time covered by this data-set when the metered energy consumed exceeded the Ecodan estimate.

- data factors: The consumption meter gives figures to two decimal places while the Ecodan forecasts are all whole numbers. It naturally follows that 'if' the Ecodan rounds its forecasts (as opposed to only ever counting in whole numbers) then there will be a degree of inconsistency. But this would only ever be less than 0.5 kWh and even at the daily levels the inconsistency between the two data sources is usually greater than this.

- I turned off the heating manually for the summer. Despite this the Ecodan still 'allocated' some of its energy consumption to heating. I haven't reworked the data to explore what happens if I treat the heating consumption as zero.

- based on my temperature recording there is good correlation between energy consumed and OAT at the daily level.

Conclusion ?

The over-estimating of energy consumption is worst when consumption is low. There seem to be two main contributory factors- rounding and Ecodan estimates of consumption by the heating side when it is actually zero in the summer.

The uncertainty of reported energy consumed and delivered figures make using daily CoP figures a very unreliable way to measure the effectiveness of small changes to things like a weather compensation curve. Weekly figures are a better basis.

Surely things should be better than this!

I'm interested in your findings here. I've got the impression from elsewhere that the Mitsubishi in built monitoring is somewhat approximate.

I'm just in the process of installing an 8.5kW system and trying to work out if an independent heat meter would be a good idea (I know it would but can't really afford it). In reading the installation manual I see that there is a setting relating to the in built monitoring called 'delivered energy adjustment'. The range available is - 50% to +50%. I think it's for the purposes of allowing for the presence of glycol in the system and the associated impact on efficiency.

I'd be interested to know if you've played around with this setting to see what impact it has?

@hestia I haven't touched this setting. As I can't detect a pattern in the Ecodan overestimates of energy consumed and have nothing to use as a basis to assess if the energy consumed figures are consistent or accurate I wouldn't choose to play with it. Apart from anything else, at least the basis for my data is consistent over time.

Posted by: @glpinxitThe short version is that my Ecodan invariably overestimates its electricity consumption. But it does this inconsistently which leads me to assume it's estimates of energy delivered may also be unreliable. So unless it's estimates of energy consumed and delivered are inaccurate but consistent with each other, any Coefficient of Performance derived from either or both of them is probably also inaccurate.

I've read plenty of people observing this inaccuracy. Here I'm quantifying it (in terms of energy consumed but not delivered). I'd be interested in the experience of other Ecodan owners

If you’ve read other threads on this subject then it’s quite likely you’ve read a few of my posts on this topic also.

The first thing I’d like to suggest is that I don’t believe it is inconsistent. To my mind there are at least 2 things being added together. One figure is a fixed 24 hour add-on for circulators and monitoring and another is an actual estimate of consumption which may not be too far off.

The apparent inconsistency may be as a result of a relatively large fixed daily (electronics and ancillary circulation) estimate of say 3kwh being added to a small calculated days consumption of say 10kwh will seem hugely punishing when compared to a different days estimate of 3kwh ancillary plus 40kwh HP calculated consumption.

What I have been told is that the FTC6 monitoring system appears to use around 600watts in 24 hours and the system.

The system may also allow for frost stat to circulate system fluid. Or to also activate fluid reheat if it drops below 15c.

Furthermore the system may be allowing for anything up to 3 or 4 circulation pumps if there is hydraulic separation or zone pumps etc.

my system applies 2.8kwh to my daily energy estimated consumption even when it is set to 10c on a setback. However I know that at 12c outside ambient no pumps will be operating and no reheating will occur.

I also know that my circulation pump only consumes 49watts when operating so in 24 hours continuous operation that’s only 1.2kwh.

So even in freezing conditions my system should only have an ancillary consumption of around 1.8kwh. A realistic average consumption is probably more like 1.5kwh that means my daily estimated consumption from Ecodan is over estimated by around 1.3kwh over the actual energy consumed. We only have one circulating pump and have no secondary pump.

It would be interesting to know what other users think because I believe the figures produced by ecodan can be rationalised to a trustworthy estimate. It’s important not to be spooked into distrusting the whole estimation system.

Did you check the actual values that have been set within the FTC for the various pumps and heaters? According to the manual there is a default setting of 72W for water pump 4.

Hi @derek-m

I haven’t been able to find the exact page you referred to. Last time we spoke on this I looked through the data book and manual but couldn’t find the specific section.

Do you have a page number or section that you know of?

Posted by: @sunandairHi @derek-m

I haven’t been able to find the exact page you referred to. Last time we spoke on this I looked through the data book and manual but couldn’t find the specific section.

Do you have a page number or section that you know of?

On page B-89 of the document Ecodan_ATW_Databook_R32_Vol5.8_.pdf you will find the following Service > Energy monitor settings >Water pump input > Pump 1, Pump 2, Pump 3 and Pump 4.

Page B-110 shows the Engineers Forms which should have been completed to record the various settings that have been applied during commissioning. Detailed on these forms is the values for the possible four water pumps.

I believe that it is probable that the water pumps may not be powered directly by the heat pump control system, but merely switched on and off, hence the need to add approximate values within energy monitoring to account for the water pumps that have been installed.

Posted by: @glpinxitThe attached table only gives the % difference between the energy consumed month-by-month as measured by the meter and by the Ecodan. In every month the Ecodan overestimates consumption

Hi. Do you know if your meter is collecting all energy used by all ancillary equipment eg. Immersion heater, zone pumps (if fitted) etc?

Also how many pumps make up your system?

lastly have you ever operated your system at say 10c room temp for a full 24 hour period and at an OAT above the freeze temp, say above 8c night temp? Then taken the energy consumption for that 24 hour period? This should produce a period when the monitoring system is operating but no heating (or DHW) is called for. A MELCloud energy report should give you a baseline of how much the system is adding which should be a fixed add-on to cover what it perceives to be unmeasurable extra consumption.

The situation we have is that our immersion is fed from a separate circuit and so I guess we would need a separate meter is pick up it’s enegy use. (Not that we ever use it.... much.

Posted by: @derek-mDid you check the actual values that have been set within the FTC for the various pumps and heaters? According to the manual there is a default setting of 72W for water pump 4.

yes ours is set exactly as you stated. 72W for pump4. Zero for all others.

I may consider reducing it to 50w and see what that does to the daily standby consumption figure which is currently 2.8kwh in 24hours.

I think Occam should get his razor out on this one. The simplest explanation is that the Mitsubishi is not capable of accurately measuring the electrical consumption.

It is fairly straightforward to use a CT clamp to measure the current, though it would have to cover the current drawn from the minimum usage of around 20W up to a larger unit working flat out needing several kW, so a range from less than a tenth of an amp to 25 or so. I’m no expert on electronics but what I’ve picked up is that it requires some specific componentry to measure the voltage and calculate the actual power being drawn as this can fluctuate quite dramatically when powering AC components such as motors. I would expect that Mitsubishi have taken the easy option of just making the calculation based on assumption of a steady 240V, multiplied by a measurement for the amperage that may also be less accurate particularly at lower levels (?).

I would presume the most common way for the power supply to the FTC to be configured is for it to be connected from the outdoor unit, and for the pumps to be powered from the FTC unit. It is certainly the easiest for any installer unless there are particular circumstances. In which case the measurement of the power consumption, which must take place at the outdoor unit, is for all the heat pump’s consumption except the DHW immersion.

Mitsubishi EcoDan 8.5 kW ASHP - radiators on a single loop

210l Mitsubishi solar tank

Solar thermal

3.94kW of PV

Without delving into the delights of phase angle, true power and imaginary power, in its most basic form power is volts x amps.

The specification for an 11.2kW Ecodan states that at a supply voltage of 230V, the maximum supply current will be 28A, which gives the maximum expected power supply to be 6.44kW.

Measuring equipment has a specified accuracy, normally quoted as a percentage of Full Scale Deflection (FSD).

In the above example the measuring circuit may need to accommodate a maximum expected voltage of say 250V and a maximum expected current of say 30A, which gives a maximum expected power measurement of 7.5kW.

If the specified accuracy of the measurement system is say 1%, then the reading obtained could be within +/- 75W of the true value, which is not a major problem when the heat pump is operating at or near maximum power, but becomes more of a problem at lower power operation, particularly when the compressor is not actually operating. Of course if the accuracy of the voltage measurement is +/- 1% and the current measurement is also +/- 1%, the overall accuracy is now +/- 2%, which could be up to 150W in error.

According to the wiring diagram for the cylinder unit, the power supply for all of the four water pumps is from one of the circuit boards, but since actual power consumption values can be added within the controller, it would appear that these are not being included within the power measurement system, which seems rather strange.

I have not been able to locate a current transformer on any of the circuit boards, which makes it impossible to ascertain where the power measurements are being made.

What may be interesting is that the specification for the circuit board, which powers 3 of the pumps, (when powered from an independent source) has a power rating of 300W.

If you have a CT Clamp Meter you could try measuring the current flow to the different equipment.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 303 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 1 minute ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 10 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 32 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 8 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 24 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago