@jamespa I am not disagreeing with what you are saying and in an ideal world, what you have said would be the preferred solution.

However the practicalities in my case are:

1. The internal heat pump thermostat cannot control the backup oil boiler when active as the entire heat pump is disabled when in this mode.

2. I have an outside boiler room which houses all the heat pump equipment and oil boiler and there was no practical way to wire the HP controller that contains the internal thermostat from the boiler room to the lounge without ripping half the house a part 🙁

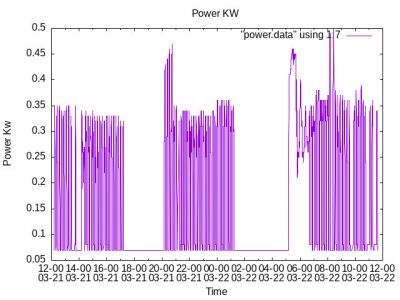

The Honeywell thermostat behaviour in both scenarios has not changed much but changing the HP field option #2092 made an impact regarding how the HP behaves, ie from 3mins on 7 mins off to "run for the length of time the Honeywell demanded heat"

So this is the solution I have and hopefully have made the best of it 🙂

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

Posted by: @technogeek@jamespa I am not disagreeing with what you are saying and in an ideal world, what you have said would be the preferred solution.

However the practicalities in my case are:

1. The internal heat pump thermostat cannot control the backup oil boiler when active as the entire heat pump is disabled when in this mode.

2. I have an outside boiler room which houses all the heat pump equipment and oil boiler and there was no practical way to wire the HP controller that contains the internal thermostat from the boiler room to the lounge without ripping half the house a part 🙁

So this is the solution I have and hopefully have made the best of it 🙂

Agreed and I wasn't trying to suggest otherwise.

The point I was trying to emphasise is that, as you have shown experimentally, a heat pump which is essentially controlled in on/off mode by an external thermostat is almost certain to work inefficiently. The efficient way to run a heat pump is for it to be on all, or almost all, of the time, delivering energy more or less continuously at the lowest possible flow temperature. Heat pump controllers (and Homely) are designed to do this, external controllers aren't (and mostly can't because they can't control flow temperature). So in general terms using a thermostat (or Hive or similar) as the primary way of controlling a heat pump is to be avoided. Unfortunately there are still a lot of people (and it seems many installers) that don't understand or don't accept this.

Its an unfortunate feature of the history of the UK heating history that we didn't implement weather compensation on gas boilers. Many gas boilers can do it, because its mandatory in some other European countries, most notably Germany where there is a strong boiler industry. However the UK didn't make it mandatory and so plumbers didn't bother and householders don't readily understand it.

Had we done so we would have been better prepared for heat pumps which depend, for efficient operation, on the concept that flow temp is varied to match load and the idea is to run the system more or less constantly at the lowest possible flow temperature matched to the demand. Instead we (the UK) bought into adding a load of complex external controls that purport to save lots of money by micro zoning or 'clever' time slicing, but in reality can only make a fairly small difference in the case of a boiler (usually at the expense of comfort), and are likely to be detrimental in the case of a heat pump.

C'est la vie!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

What is the purpose of Field bit 2091/2/3 Water Pump 3 option on Samsung Heat Pumps:

I asked a visiting Samsung engineer:

"What is the purpose of the 2091, 2092 and 2093 Water Pump 3 option ?", receiving the disarmingly honest reply

that " he did not know, but , he thought not much".

My own theory is that the Water Pump Option 3 in delaying the water pump motor pulse extends the Cycle time.

Without the Water Pump 3 cycle extension, I initially found the cycle time limited to about 8 minutes.

This 8 minute cycle was initially attributed, by Samsung themselves to the absence of a buffer.

I should add that the Samsung Engineer became very irritated at this point saying that "He Could not Read Korean!".

What do you think is the purpose of the Field bit 2091/2092/2093 Water Pump 3 ?

Volumisers (Buffers)?

My System was, after a 6 month delay, was fitted with a 50 litre buffer to increase the pipe water volume from an inadequate 6 litres, in a further attempt to limit the excessive "short Cycling".

What do you think of Buffers?

Thermostat Cycling?

I have only recently discovered the hidden Cycling rate settings within the Honeywell "Home" Thermostat later fitted by my "Installer".

The Thermostat was set to 6 cycles per hour explaining the dominant 10 minute cycle time !

I have reduced the Cycle Rate to 3 giving a cycle time of 20 minutes.

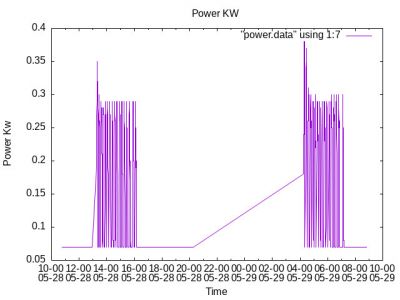

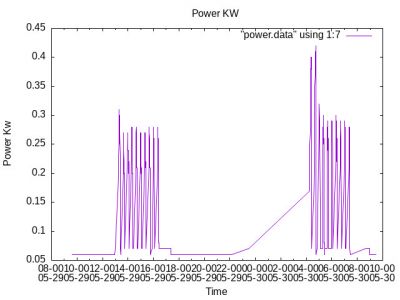

The original Cycle time, set with the Thermostat at 6 cycles per hour is shown in 5-28-9 .jpg

The Cycle time with a Thermostat set to 3 is given in 5-29-9

A vast improvement but still far from ideal.

I think that a far better Continuous , Not Switched Thermostat Temperature sensor is needed !

Where Can I get a professional Continuous, non-switching Temperature sensor , controller ?

Many thanks for your, refreshing unpretentious description of your system and your Heat Pump faults..............

Posted by: @iantelescopeI think that a far better Continuous , Not Switched Thermostat Temperature sensor is needed !

Where Can I get a professional Continuous, non-switching Temperature sensor , controller ?

Any 'old' thermostat does this, its only more recent ones that try to be more sophisticated, in a way wholly unhelpful to heat pumps.

But the real solution is to turn the thermostat up to 2 degrees above the desired room temperature, then adjust the WC curve so the desired room temperature is achieved (if necessary balancing the radiators so that the right room temp is achieved in all rooms for the same flow temp). Then its the heat pump which is doing the control, not something external. If the principal control is external (unless its specifically designed for a heat pump, like homely), the heat pump will operate inefficiently and your bills will be higher.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Could I try and express my problem in a different way?

All heat Pumps have a Maximum power output , in my case ~5 kW.

All Heat Pumps have a Minimum power output, in my case ~2.5kW .. 3kW.

If my heat pump is asked to supply, say, 1.8 kW, my Heat Pump system will produce a square wave whose average value is 1.8kW.

Therefore , any demand for an output power less than ~2.5kW will result in oscillation , otherwise called "Short Cycling".

Short Cycling produces excessive motor wear , in my case on Each of the Two motors.

Whenever the Power demanded is less than the minimum Heat Pump that the Heat Pump can Supply the system will Oscillate or "Short Cycle".

The "Short Cycling" Period can be approximately set using a buffer tank., see MCS Documentation

Buffer tanks, however, as you correctly say, increase losses, with the MCS issuing the following warnings:

Now , in my case , Water Volumes are not the only source of Short Cycling with :

1) Short cycling caused by my Thermostat setting having a lower limit of 3 Cycles per hour , or 20 minutes cycle time.

2) Short Cycling caused by the operation of the Field bits 2091,2092 or 2093 Water Pump 3 function.

No matter how I increase the demand Temperature, and I have indeed tried this , the Heat Pump still breaks into oscillation , albeit with an increased inefficiency, greater loss at a higher temperature.

Finally, My system cannot produce power less than the minimum nor ( temporarily ) greater than the maximum.

The Maximum demand should have been met by a backup heater used for perhaps three weeks in the year.

A reduced Maximum power allowing a reduced Minimum power in the remainder of the year.

ian

@iantelescope since you address me directly I will reply directly. I'm not sure what you think I don't understand, nor what you think we don't agree on!

All heat pumps (and boilers) will cycle where the heat demand is less than their minimum output.

A buffer tank can change the cycling frequency but not the on off ratio. So a buffer tank can turn short cycling into medium or long cycling, but cant change the fundamental that cycling will occur and the on/off ratio will be set by the ratio of demand to minimum output. However a buffer tank is only one way to change the cycling frequency, the heat pump controller also has this functionality. A buffer tank has side effects which may well be undesirable so, unless its positively needed for something else, leaving out the buffer tank and adjusting the cycling period using the heat pump controller is a better strategy.

Cycling will cause some increase in compressor wear (by an unknown amount) and is also less efficient thermodynamically than continuous operation by an amount that is in principle calculable, but which we haven't really calculated. Short cycling will certainly cause more wear than long or medium cycling, but is probably less efficient thermodynamically (I can explain why the latter is the case if you want to question this).

I think (hope) we agree on that. If so then so far so good.

Posted by: @iantelescopeFinally, My system cannot produce power less than the minimum nor ( temporarily ) greater than the maximum.

The Maximum demand should have been met by a backup heater used for perhaps three weeks in the year.

That's an opinion on design choices which I actually can agree with in principle. Furthermore, should I ever get planning permission, I will personally be erring on undersizing rather than oversizing, which is the essence of what you are concluding.

However we don't actually have conclusive data to prove this principle that you and I agree on (albeit that BRE has some indicative data). More significantly its not the principle on which the BUS grant is awarded, and if you want a grant then you have to submit to that principle. Equally significantly there is sufficient uncertainty in the determination of the actual demand that, even if the design principle you advocate were adopted, only a fraction of installations would actually conform to it.

So what does this all amount to? My personal view is that it amounts to an engineering conclusion that says: when sizing heat pumps err on the side of under sizing (and design in some supplementary heating) rather than erring on the side of oversizing, on the grounds of overall efficiency.

However, in the real world, the grant rules don't really permit this and the public generally wont understand this, as they expect their central heating 'to just work'. So, whilst I absolutely condemn designers who load 20%+ on an already well overengineered loss estimate and end up with perhaps double the correct size, I cant really criticise those who specify something that might turn out to be perhaps 10-30% bigger than is actually required as a result of the uncertainties in sizing in the first place.

All of this comes back to the fundamental, what is the house loss? For my money no desktop exercise based on assumed construction will ever match a (sensibly interpreted) measurement. That's why I keep advocating (for retrofits) looking at actual consumption data from the existing heating system and as a minimum using it to sense check any spreadsheet. A few on here, and a few in the industry, get this but most don't. I intend to stick to my guns on taking into account measured data wherever possible, but must concede that the trade off between (limited) over- and under- sizing is a design choice on which there is legitimate cause for dissent.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@iantelescope Hmm it does not fill me with confidence when a Samsung Engineer does not know his own product.

Before I answer your questions, I am going to offer information that I have found in manuals, through experimentation and observation of component behaviour, so apologies if something is incorrect in my information.

As you may have guessed by the size of my heat pump (12Kw), I have a fairly large system requiring 2 circulating pumps and hence I have a low loss header between pump 1 and pump 2, both pumps being controlled by the Samsung controller. Not sure of the size of the LLH but at a guess about 25 litre.

Honeywell Thermostat:

This has, as you have found, options to control the cycle rate which are primarily designed for fossil fuel heat sources. During research into the best cycle rate for a heat pump, a number of HVAC sources recommend 2 to 3 times an hour (although a number of people may disagree) and since the thermostat needs to be set to a cycle rate then 3 fits best. In my case the thermostat also needs to control the oil boiler when it is enabled and it only likes 3 times an hour. (6 cycles per hour is for gas boilers)

The thermostat also has a learning algorithm and from what I have observed, calculates the amount of "on" time per cycle based on the rate of heating. This observation was verified when the heat pump was running the thermostat was demanding heat for approximately 17 minutes per cycle, however when my ridiculously oversized oil boiler kicked in (26Kw) the thermostat reacted by dramatically reducing the "on" time per cycle down to 5 minutes.

Another observation of the Honeywell, to avoid overshooting the target temperature, the cycle "on" times are adjusted shorter to slow the rate the room is heating when it is within approximately 1C of the target temperature and although the thermostat says it is 21C for example, using a second thermometer (verified for accuracy) the room is actually only 20C. My lounge can take up to 4 hours to achieve that last 1C, so by starting the heating earlier I can actually guarantee the room is 21C for the evening.

If you are running your heat pump all day then the last item will probably have less of an impact on your comfort but is worth knowing.

In summary, to persuade the thermostat learning algorithm to demand heat for the longest times per cycle, slow the rate of heating down (lower flow temperature) to enable this but still ensuring the target temperature of the room is reached in a timely manor. A little experimentation will be needed to find the sweet spot. I found 35C @ +10C OAT and 45C @ -2C OAT to be my ideal heat curve but yours will no doubt be different.

Samsung Heat Pump Field Options #2091, #2092 & #2093:

All these options do the same thing. The differences are:

#2091 is for an external thermostat controlling under floor heating (UFH) zone 1, governed by Water Law 1

#2092 is for an external thermostat controlling fan coil units (FCH) zone 2, governed by Water Law 2 (which my thermostat is connected to)

#2093 is the internal thermostat within the samsung controller, enabled when #2091 and #2092 are both disabled. (Not sure which water law is active for this but is not important as we are not using anyway)

You will have to try and determine which Water Law is in use on your system so you will know whether to adjust field option #2091 (WL1) or #2092 (WL2).

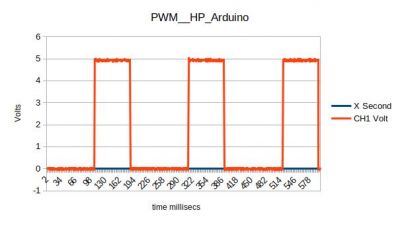

If we had a scenario where the outside temperature is +5C causing the Water Law target to be 38C and the Honeywell thermostat to demand heat ("on" time) for 16 minutes per 20 minute cycle then each of the options for field settings #2091, #2092 or #2093 would behave as follows:

Option 1:

The compressor and the circulating water pumps will run for 16 minutes and stop for 4 minutes per cycle, 3 times an hour.

Option 2:

The compressor will run until the water temperature reaches the Water Law limit of approximately 39C - 40C and stop or stop after 16 minutes whichever is sooner. If the Water Law limit is reached first the compressor will start again when the flow temperature has dropped to approximately 36C. These are the hysteresis limits but an average flow of 38C is achieved.

The circulating water pumps will run continuously for 17 minutes (1 minute overrun). To use this option you will need ensure you have some form of bypass in the system otherwise the water pump could be pushing against a closed valve (if the valve is controlled by the thermostat). I have a diverter valve so the path to the radiator circuit is always open.

Option 3:

The behaviour of the compressor is the same as option 2, however the circulating water pumps will run continuously for 16 minutes then stop. (no 1 minute overrun) (currently my setting).

Option 4:

The compressor and circulating water pumps will run for 3 minutes, switch off for 7 minutes and then run for 3 minutes etc, while the Honeywell is demanding heat. In this scenario the heat pump will only run for approximately 2 x 3 minute periods (Total 6 minutes) during the 16 minute "on" period of the Honeywell thermostat cycle. 3 minutes is not enough time to build up enough flow temperature before the system stops thus loosing all the heat during the 7 minute off period. (I cannot see the point in this option) I could never get the flow temperature hot enough with this option for the said reasons.

Buffer Tanks:

I have a small LLH as I believe it is required because of the need for 2 pumps in my system but as Heat Geeks say, whether they are needed depends on your system but should be avoided if you can design them out. So I do not have an opinion other than if they are needed then that is fine.

If you have got this far then thank you for reading. I know there is a lot of detail in this post but hopefully it gives you a better understanding based on my findings.

Let me know how you get on, cheers 🙂

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

Posted by: @iantelescopeI think that a far better Continuous , Not Switched Thermostat Temperature sensor is needed !

Where Can I get a professional Continuous, non-switching Temperature sensor , controller ?

The closest I know of of an external continous non switched thermostat is one that supports the OpenTherm protocol which the Honeywell Home does. Sadly the Samsung heat pump does not support the OpenTherm protocol 🙁

The only other option is to have your system converted to use the internal thermostat in the Samsung controller but how practical that is for your situation I am not sure

Regards

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

As you say ..........

"Hmm it does not fill me with confidence when a Samsung Engineer does not know his own product."

If the Engineer does not know his own product he should not cover his ignorance by aggressively blaming everybody else.

On the positive side , the Samsung Engineer Admitted his ignorance , something otherwise unknown in this industry.

I will not , again, recite the story of my Samsung Heat Pump installation ...............with the MCS / NIC now saying that "regrettably, Nothing can be done to repair and or replace my heat pump system."

Matters of Substance:

Many ,many thanks for the explanation of the operation of both the Honeywell Thermostat and the Samsung 2091,2092 and 2093 options,

and Yes!, I have read , and re-read your article all the way to the end.

Honeywell Home Thermostat:

Given your excellent explanation of the Honeywell Home Thermostat would it be appropriate , for me, to install a better thermostat ?

Would the installation of a Thermostat with proper variable Hysteresis settings , Run time Cycle settings , Proportional Integral damping be overkill?

System Reduction:

Heat Exchanger:

My system contains a heat exchanger installed to provide "Hydraulic isolation" between the Heat Pump and the Radiator circuits .

As such , I can completely stop the water flow around the Radiator circuit without damaging the Heat Pump .

Should I consider removing the Heat Exchanger , the pair of expensive PWM Motors with a forest of lossy pipes.

The Lossy pipes result in a 27% energy loss ( Sharky Water meter ) between the HP output and the start of the Radiator Circuit.

Buffer Tank:

My system was retrospectively fitted with a 50 l buffer acting as a volumiser.

The Buffer was recommended by Samsung-Dallium but later wrongly fitted by my then "installer".

Should I risk removing the tank or re-installing into the correct position?

Again. many many thanks for your excellent input!

ian

Posted by: @iantelescopeHoneywell Home Thermostat:

Given your excellent explanation of the Honeywell Home Thermostat would it be appropriate , for me, to install a better thermostat ?

Would the installation of a Thermostat with proper variable Hysteresis settings , Run time Cycle settings , Proportional Integral damping be overkill?

To be honest you are fairly limited with a binary ("on" / "off") thermostat and I actually think this model is good for what it does. Once you know its characteristics you can work around them like starting the heating earlier. The cycle setting tells the thermostat to cycle up to 3 times an hour. It is intelligent enough to work out if the heat loss in the house is so minimal to skip 1 or even 2 cycles in an hour. I think this is an advantage because it can actually extend the HP's ability to modulate down with low heat demand thus saving money.

You can rig the thermostat to have a target of 30C and it will put a continuous demand on the HP and providing the correct #2091 / #2092 option is set, run the HP continuously. However there is a max run time setting in the pump (#3025 default 30 mins) which will switch the pump off for a few minutes then on again. With this default value it will cause the pump to cycle once an hour but it is designed to cycle so I am not too hung up about cycling, rapid cycling is however a problem.

I would change one thing at a time and try the settings I have suggested to see if this improves your short cycling before removing hydraulic components. I am an Electrical / Software Engineer so the heating hydraulic side of things is not my area of expertise so I cannot really advise on that sorry.

Regards

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

Like you, I am more confident with the Electronics than with the Hydraulics.

My problem is, given experience with a plethora of companies , I have entirely lost confidence with the plumbers.

Designing with Saw & Hammer !:

Why does nobody measure and calculate before hammering and sawing pipes, buffers, heat exchangers etc ?

Again, many thanks for your help .....you are the first to advise with knowledge and experience without condescension .

Posted by: @jamespaSo in general terms using a thermostat (or Hive or similar) as the primary way of controlling a heat pump is to be avoided. Unfortunately there are still a lot of people (and it seems many installers) that don't understand or don't accept this.

I feel that I need to defend the use of thermostats with heat pumps, particularly in the case of heat pumps that are oversized and don't modulate down sufficiently and end up cycling if LWT goes below 33C. One of the top performing Samsungs on heatpumpmonitor never goes below a LWT of 33 because of a tendency to cycle and run times are controlled by the wired controller's thermostat. My Samsung is controlled in a similar manner, although not as efficiently. What it loses in efficiency it gains in economy. Low and slow would require a minimum of 18kWh of electricity usage even in milder weather (24 x 0.75kW), whereas I rarely use that much. Average daily usage in January was 18.1 kWh and less than 12 kWh for the other months.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 412 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

I agree incentives are needed. We are an unusual home b...

By Batpred , 7 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos interesting. I might look into that. My other op...

By benson , 1 hour ago

-

RE: Our Experience installing a heat pump into a Grade 2 Listed stone house

@robs Do you need IAT for this to work? Don’t curren...

By Travellingwave , 4 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

@goodbyegas Hi Fellow Ecodan owner here. Looking a...

By Travellingwave , 4 hours ago

-

RE: Say hello and introduce yourself

You can send private messages via the Messages (envelop...

By cathodeRay , 8 hours ago

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

With complete radio silence from Peak and no sign of th...

By DaveC , 8 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Yes, ours dropped by about 25% RH. I figured it was a c...

By Papahuhu , 9 hours ago

-

RE: The Hidden Secret to a Successful Heat Pump: Pipe Size Matters

I'm wondering if I need to do any pipe upgrades. My hea...

By Falesh , 9 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred The Pace BMS also isn't the best with it's ...

By Bash , 10 hours ago

-

I understand now what you were referring to. This look...

By trebor12345 , 10 hours ago

-

RE: What determines the SOC of a battery?

@batpred I would consider changing your balance star...

By Bash , 10 hours ago

-

RE: Setback savings - fact or fiction?

This illustrates what I am getting at, even apparent st...

By cathodeRay , 15 hours ago

-

No you arent, because you dont need any, and furthermor...

By JamesPa , 15 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

As I mentioned earlier most radiators have a power outp...

By JamesPa , 16 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 2 days ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 2 days ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 2 days ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 2 days ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 2 days ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 2 days ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 3 days ago