My ASHP is not performing as well as I’d hoped: COP just over 2

Let me start by saying I'm happy with what the ASHP does and how it keeps the house at a nice constant temperature. However, it uses an incredible amount of electricity and, even in this mild weather barely scrapes a COP of just over 2. The house has cavity wall insulation installed in the summer of 2021, double glazing throughout and good loft insulation.

The ASHP is a Mitsubishi Ecodan 11.2KW retrofitted to a 1950s 3-bed detached house. Complete new installation with new pipework to new radiators in a single zone. No wet central heating was present when we moved in. Installed in November 2021 and commissioned in January 2022. Initially with Heatmiser thermostat that I had the installer replace with the Mitsubishi wireless controller. The system is set to run 24/7 in Auto Adaptation mode. I have spoken with the original installer who is confident that his installation is sound. The system is a single zone with radiators only upstairs and downstairs.10 radiators in total. No underfloor heating.

I think, having read through threads on forums that my system can probably be made to run more efficiently and cost-effectively. Hence the consideration for a third-party overview. For example, I have read that Honeywell valves are not ideal in an ASHP environment. TRVs should only be in bedrooms. As it is all my downstairs TRVs are left wide open. I have read of similar installs obtaining a COP far exceeding my figures. My COP barely goes above 2./2.5. My usage of the heat pump is, for central heating, Auto Adaptation mode, 24/7, with the Mitsubishi wireless room controller set to 20 degrees C without any setbacks. DHW is set at 50 degrees C with a reheat at 42 degrees C. The cylinder is a Tempest 250 Litre.

It was recommended to me that I contact a certain installer who might inspect the installation and, in all probability, make physical changes to some components such as the Honeywell valves and pumps which might make the system more efficient. i.e. get a third party overview. Over the course of an email conversation, he asked for pictures.

Having seen the pictures he replied:

"I can not see a buffer, volumiser or low-loss header in the cylinder room, if it does not have one it’s incorrectly installed.

A sufficient volume of water must be made available above the system volume itself for de-frost mode.

Or it will remove pre-heated content from the system every time it does this, which means that has to be feathered again, causing additional power usage, the heat pump can also cycle too which all uses additional energy. I would be asking the installer where the volumiser is."

I have been reading the thread regarding buffer tanks and LLH (link below) as a result of which I am utterly confused.

Retrofitted 11.2kw Mitsubishi Ecodan to new radiators commissioned November 2021.

14 x 500w Monocrystalline solar panels.

2 ESS Smile G3 10.1 batteries.

ESS Smile G3 5kw inverter.

@morgan I am not qualified to comment regards the system needing a buffer/ low loss header etc, however I need to confirm have you tried checking the basic things such as are all the radiators balanced? Some installers tend to do a rough balance on radiators and let TRV's do the fine tunning, however I have found this is not good enough and balanced all radiators properly. It is also recommended that TRV's should be used as temp limiters and be set higher than the desired room temp so there is very rarely flow restriction in the system. @Toodles posted an excellent article recently for balancing rads.

The other item that caught me out was the calculation of the COP value and interpretation of the system data. COP = (Heat Generated (Kw) + Input Kw) / Input Kw. I was only getting values of 1.9, 2.1 etc until I discovered I was misinterpreting the data then my COP was over 3 once correctly established.

I do not have a Mitsubishi ASHP but is the photo showing "Delivered Energy" the total including the input electrical power or just what the ASHP has generated from the outside air do you know?

Regards

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

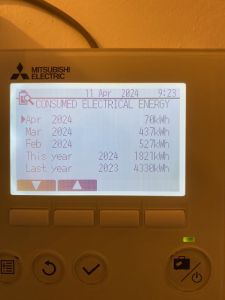

My understanding is that COP is ascertained by > Delivered electrical energy (Kw) divided by the consumed electrical energy (Kw).

For example in my case above for February 2024 1327Kw by 527Kw = COP 2.5.

I'm afraid your calculation doesn't make sense to me.

Retrofitted 11.2kw Mitsubishi Ecodan to new radiators commissioned November 2021.

14 x 500w Monocrystalline solar panels.

2 ESS Smile G3 10.1 batteries.

ESS Smile G3 5kw inverter.

Some of the manufacturers use the COP calculation method shown by @technogeek, but I don't think that is the case with Mitsubishi.

Could you please provide some graphs from MelCloud data?

How does the Ecodan electrical energy consumption compare with your actual electrical power meter readings?

@morgan For your information the calculation I gave is from here https://energyeducation.ca/encyclopedia/Coefficient_of_performance . The value of Qc in my case (Samsung) is the generated heat from the atmosphere plus the work put in (W in)(electrical energy) = QH divided by the work put in (W in)(electrical energy).

I was just trying to establish if your COP is calculated the same way or not, however if Mitsubishi details this information differently fair enough

Regards

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

I think @technogeek is looking at a Vaillant which does, I believe, present a figure for the 'free' heat generated by the pump, so the 'paid-for' input energy has to be added back in to calculate the total energy generated. I can't see how you can obtain a figure for heat from the environment in the first place except by taking the figure for the heat generated and subtracting the energy used to generate the heat!

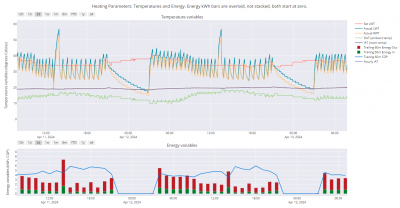

@morgan I don't follow the argument that your second opinion guy has put forward. If you have too low a volume of water available to defrost then you are going to have issues around slow and more frequent defrosts which will certainly detract from the energy efficiency of the system, but these should be issues in themselves that you can diagnose from looking at the performance record in MelCloud. However your COP for April is still low even though we (at least where I am) have not had temps dropping low enough to cause defrost cycle for weeks. Compulsory buffers seems old-school and needs to be justified for the way the system works rather than thrown in as a catch-all fallback.

I think that overall my system is somewhat comparable to yours, Ecodan, rads only, 70s house – it took around 10000kWh heat last year and so far this year has required 4400kWh. For a cost of 3100kWh last year (COP 3.2) and 1425 so far this (COP 3.4). But, as evidenced in various threads, the Ecodan reported energy used is typically way off, 3700 last year and 1690 so far this – it is only by having a meter on the supply that I know the true figure of kWh consumed. So hopefully not actually quite as bad as you fear.

What is the balance between HW and heating energy used? And how often does the tank reheat get triggered? The COP for that is always on the low side so may be dragging the overall number down if you are running a HW cycle more often than you need to. This may be affected by bad positioning of thermistors in the tank. An easy experiment is to switch the HW cycle off after it has run and then wait until the hot water is running too cold for you and check what the thermistor reading is on the controller display – you might be (should be?) surprised by how low it can get before the hot water actually runs out. Of course you might need a fuller tank for operational reasons at certain times, but a 24hr reheat is probably the least efficient setting.

I have an 8.5kW unit and I know that is larger than it needs to be for my house, so I think your 11.2kW unit is definitely too large for yours – you are keeping the house at 20° for about the same output. So I presume it only runs continuously at low temperatures. Unfortunately an issue not as simple as changing a setting or small bit of plumbing! I find the unit always likes to work to a LWE in the mid to high thirties, then just varying the cycle off periods – as much as I'd like the LWE to be lower and run with a lower COP I suspect that only increasing the rad sizes to allow for more heat output at lower temps will have an effect. So I would also suggest removing the TRV limits and allowing the upstairs rads to be part of the heating circuit at all times, otherwise you have less radiant capacity and the water temperature may be pushed up by the controller in order to deliver the heat it is expecting to.

Mitsubishi EcoDan 8.5 kW ASHP - radiators on a single loop

210l Mitsubishi solar tank

Solar thermal

3.94kW of PV

@harriup There is a Heat Geek presentation on Youtube in which Adam Chapman fitted a Vaillant ASHP in a house with poor insulation, ill fitting windows and less than ideal pipework - even so the ASHP was producing a COP in excess of 3! Just saying… Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

@toodles All those factors might result in a lot more heat being required, it can still be delivered in a very efficient way. Lack of efficiency seems to be about a mismatch between the way the pump produces heat and the way the building can extract it. I quite fancied having a Vaillant when ours was installed but ended up with an Ecodan because of supply issues at the end of the RHI grant period. And, like Morgan, I am constantly slightly disappointed by the apparent lack of efficiency which I increasingly put down to the software running it.

Mitsubishi EcoDan 8.5 kW ASHP - radiators on a single loop

210l Mitsubishi solar tank

Solar thermal

3.94kW of PV

Now people have said all the sensible long things, I have a question - can you tell how often it is coming on and off each hour, and is it possible to see what sort of temperatures it is running the water at through the radiators?

Posted by: @guthrieNow people have said all the sensible long things, I have a question - can you tell how often it is coming on and off each hour, and is it possible to see what sort of temperatures it is running the water at through the radiators?

If you search the forum, you will find countless examples of people doing exactly this. The vast majority of heat pump controllers will give you this data live (you may need to work out what parameters to watch), many will give you historical data, and, with a few mods, relatively sophisticated monitoring is possible in some cases eg where a modbus connection is available. Here is minute by minute data from my heat pump for the last 48 hours:

There is one caveat: this data (apart from indoor air temp) comes from the Midea wired controller, ie it is Midea marking its own homework, and is not verified by third party independent sensors. That said, it does not appear to be wildly inaccurate.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @derek-mSome of the manufacturers use the COP calculation method shown by @technogeek, but I don't think that is the case with Mitsubishi.

Could you please provide some graphs from MelCloud data?

How does the Ecodan electrical energy consumption compare with your actual electrical power meter readings?

Not in a position to provide those yet. Will do so when I'm back home.

Retrofitted 11.2kw Mitsubishi Ecodan to new radiators commissioned November 2021.

14 x 500w Monocrystalline solar panels.

2 ESS Smile G3 10.1 batteries.

ESS Smile G3 5kw inverter.

@harriup Does this mean your Ecodan reports electricity consumption 15% higher than actual measurements?

If we assume something similar happens with @morgan - which we of course don't know but is a possibility - the COP would be around 3 instead of 2.5 for February 2024. Not great still, but definitely better. But let's await the data.

CEO and co-founder at HavenWise

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 1,068 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That’s my pleasure, @andrewj. The only challenge now is...

By Majordennisbloodnok , 2 hours ago

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 3 hours ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 4 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 4 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 4 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 5 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 5 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 5 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 9 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 12 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 14 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago