Mixing of pipework/components' with different internal dimensions - theory vs reality/practical approach

Hi all. Consider the following scenarios to support a modest ASHP (with glycol) with a simple setup of single circulation pump through a decent 3-way diverter valve to mid-sized cylinder and two heating circuit runs with mixed emitters operating as one zone and returning through mag filter and flow sensor.

28mm copper from/to ASHP, DN25 pump, 22mm cylinder connection, 2 x 22mm push-fit to 15mm rads and UFH manifold w/ 15mm UFH loops:

- all remaining components DN25

- all remaining components DN20

- a mix (e.g. DN25 3-way, DN20 flow sensor)

Before I read John Cantor's site, my understanding was that the smallest internal diameter of just one component in a circuit essentially reduced the whole performance everywhere on that circuit to that diameter, however if I've understood his words correctly, even putting a nominal single run of larger-diameter (straight) pipework improves overall performance (by reducing head - thereby increasing flow?).

So my initial questions are:

- should one aim to put the widest pipework *wherever physically* possible, reducing to the smaller diameters at the components that cannot be changed (e.g. rads pipework under floors), OR does wider pipework only make a difference for particular components/usage/minimum distance (e.g. more than 300mm, 2m, etc)?

- are there any components in particular that would benefit from larger internal diameters - e.g. if water flows through 22mm connections for hot water and space heating, is there merit in using a 28mm 3-way or flow sensor or mag filter?

- what sort of performance improvements/limitations would one expect based on the answer?

I find this an interesting question as I did a similar thing after reading John Cantors site. I have 28mm to my 5kW heat pump which then reduces to the previously existing 22mm copper then to 22mm plastic with 15mm plastic tails to each of the radiators. I used the steel inserts in the plastic pipe as they are a lot thinner than the plastic.

The upshot is I dont seem to have any flow issues and the SCOP is currently 4.3, which I am very happy with. My take is as long as the pipe diameter can take the heat load everything seems hunky dory. I calculated the heat energy the plastic pipes could take using some simple maths and checked it with the copper figures from heat geek just to make sure I wasnt doing anything stupid

House-2 bed partial stone bungalow, 5kW Samsung Gen 6 ASHP (Self install)

6.9 kWp of PV

5kWh DC coupled battery

Blog: https://thegreeningofrosecottage.weebly.com/

Heatpump Stats: http://heatpumpmonitor.org/system/view?id=60

The hydraulic friction losses are in proportion to the square of the flow velocity x length. For example the friction loss of a given flow through 22mm dia pipe is 62% higher than through 28mm pipe. Higher velocities increase the risk of noise as do changes in velocity. Whether pipe size and friction loss affects performance will depend on if the circulating pump is controlled to maintain the flow rate needed to transfer sufficient heat.

Thanks for the reply, @bontwoody

It's no doubt me, but I've tried a handful of times and can't figure out what this means - sorry, could you write it another way so I can understand, please?with 15mm plastic tails to each of the radiators. I used the steel inserts in the plastic pipe as they are a lot thinner than the plastic.Posted by: @bontwoody

Which it sounds like yours can; well done with the SCoP!The upshot is I dont seem to have any flow issues and the SCOP is currently 4.3, which I am very happy with. My take is as long as the pipe diameter can take the heat load everything seems hunky dory.

Would you be able to share the calcs / methodology to confirm diameter/heat load compatibility?

What would your calcs have been had you replaced what 22mm you could with 28mm pipe, and/or components that had increased internal diameters?

Cheers for your post, @JohnR

Implying that wherever a larger internal diameter can be applied, the friction loss is greatly reduced and therefore a good idea?The hydraulic friction losses are in proportion to the square of the flow velocity x length. For example the friction loss of a given flow through 22mm dia pipe is 62% higher than through 28mm pipe.Posted by: @johnr

Indeed, so with larger diameters, velocities are reduced and therefore so is the noise; how does one determine when the number of velocity changes is beneficial against actual velocities, I wonder...Higher velocities increase the risk of noise as do changes in velocity.

Is this 'simply' assuming, if the appropriate pump is in place, bigger pipe size is good, or is it more nuanced than that, John?Whether pipe size and friction loss affects performance will depend on if the circulating pump is controlled to maintain the flow rate needed to transfer sufficient heat.

I just mean that from the 22mm copper or plastic pipe spine, each radiator have 15mm plastic down to it. I use John Guest plastic pipe but prefer the Hep2O steel inserts instead of the JG plastic ones.

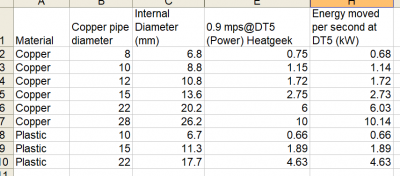

For the calculations I just took the internal diameter of the pipes and calculated the area (Pi r squared). Then calculated the volume of water passing per second at 9 mps flow (which is what heat geek recommend). The energy contained in one litre of water for a 5 degree C loss is 20900 Joules (4180 J/degree).

As I only have a 5 kW heat pump and 22mm plastic can move 4.63 kW, even with some small pipe restrictions I was pretty confident it would work, which turned out to be the case. Note that 15mm plastic can move 1.89 kW so as long as each radiator is emitting less than that it should be fine.

As the calcs are done at a flow rate of 0.9 mps there should be no problems with noise as @JohnR points out. (unless I have misunderstood something). My water pump is PWM controlled BTW so can adapt to maintain the correct flow.

House-2 bed partial stone bungalow, 5kW Samsung Gen 6 ASHP (Self install)

6.9 kWp of PV

5kWh DC coupled battery

Blog: https://thegreeningofrosecottage.weebly.com/

Heatpump Stats: http://heatpumpmonitor.org/system/view?id=60

Posted by: @rhh2348Implying that wherever a larger internal diameter can be applied, the friction loss is greatly reduced and therefore a good idea?

Less friction means less effort by the pump. The primary circuit for my 7kW Arotherm+ heat pump uses 28mm pipe and is running happily. The extra volume of water must help with the defrosting cycle.

Indeed, so with larger diameters, velocities are reduced and therefore so is the noise; how does one determine when the number of velocity changes is beneficial against actual velocities, I wonder...

One can get bogged down in calculations. There's probably a table somewhere that gives equivalent pipe lengths for bends, valves and reducers/expansion.

]Is this 'simply' assuming, if the appropriate pump is in place, bigger pipe size is good, or is it more nuanced than that, John?

My reference point is my own system which seems to be giving above average performance and I relied on the installer to get it right. There's 28mm pipe between heat pump and buffer tank and then 22mm connecting to the pre-existing radiator system (22mm pipe splitting into downstrairs and upstairs circuits). There are others here who have better knowledge of what is good practice.

@JohnR, I think I've seen something like this for plastic - in essence, each 90deg elbow/T etc creates the equivalent resistance of 0.5m of straight pipe.a table somewhere that gives equivalent pipe lengths for bends, valves and reducers/expansion.Posted by: @johnr

Are there any components in between that aren't DN25 minimum? e.g. 3-way, 2-port, pump, etc?There's 28mm pipe between heat pump and buffer tank and then 22mm connecting to the pre-existing radiator system...

To reflect on my original post, it feels to me as though 28mm through the circulation pump and 3-way to the heating circuits is most-beneficial because I could take 28mm-worth of flow to the first rads tee that splits into two distinct 22mm pipe runs therefore 28mm / 2 better than 22mm / 2 or, to put another way, with 22mm up to that tee I'd be restricting flow unnecessarily?

The flow sensor and mag filter I'm less sure - the mag filter I have apparently restricts flow very little and as the return water has been through mostly 22mm before it, I don't see much benefit in replacing with 28mm equivalents (though I'd question why 28mm/DN25 flow sensors aren't standard/easy to source).

Someone tell me otherwise!

Posted by: @rhh2348To reflect on my original post, it feels to me as though 28mm through the circulation pump and 3-way to the heating circuits is most-beneficial because I could take 28mm-worth of flow to the first rads tee that splits into two distinct 22mm pipe runs therefore 28mm / 2 better than 22mm / 2 or, to put another way, with 22mm up to that tee I'd be restricting flow unnecessarily?

That looks to me to be a sound approach: Use the bigger pipe size to where the flow splits to the two heating circuits.

Posted by: @rhh2348The question at that point is, as posed in the OP, for those to go back through 22mm flow sensors and a mag filter to the return to the outdoor unit, (what) are we gaining anything?

I've just been and checked: My 28mm pipework includes a 22mm mag filter (with isolator valves) and works fine. Think of it as a short section of single carriageway road on what is otherwise a dual carriageway. It's an impediment but much better than a lot of single carriagway road.

“Think of it as a short section of single carriageway road on what is otherwise a dual carriageway. It's an impediment but much better than a lot of single carriagway road.”

Actually that’s a terrible analogy 🙂 the cars would go no faster than the single carriageway if both lanes were full.

Can I think of a better one? Nope 😂

House-2 bed partial stone bungalow, 5kW Samsung Gen 6 ASHP (Self install)

6.9 kWp of PV

5kWh DC coupled battery

Blog: https://thegreeningofrosecottage.weebly.com/

Heatpump Stats: http://heatpumpmonitor.org/system/view?id=60

- 27 Forums

- 2,520 Topics

- 58.6 K Posts

- 449 Online

- 6,800 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Underfloor Heating Installation Issues with Heat Pump

I'm going to install Thermacome ACOSI+ radiant ceiling....

By bobflux , 14 minutes ago

-

Issue with a Grant Air Source Heat Pump & Tado Smart Thermostat

Hi all I'm having some trouble with a Grant ASHP and ...

By Renewables345 , 1 hour ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Now seems a good time to summarise the costs and effici...

By benson , 1 hour ago

-

RE: Heat Pump vs New Gas Boiler for Inherited House - Worth the Extra Cost?

*** I now see @jamespa has already posted but will stil...

By cathodeRay , 3 hours ago

-

RE: Tell us about your Solar (PV) setup

@mk4 Charge to 100%, discharge down to 10%.

By bobflux , 3 hours ago

-

RE: Daikin Altherma 3 LT compressor longevity question

This mess is intriguing: I wonder if this represent...

By bobflux , 4 hours ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

The simplest wired option is usually the Growatt Ethern...

By Jonatan , 8 hours ago

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

ASHPs do have a minimum compressor speed. The minimum h...

By bobflux , 15 hours ago

-

RE: Electricity price predictions

@jamespa And it seems some of the nasty public cloud...

By Batpred , 15 hours ago

-

RE: Jokes and fun posts about heat pumps and renewables

Technology is rapidly advancing. BBC News reported th...

By Transparent , 19 hours ago

-

What matters for flow and pressure drop is internal dia...

By bobflux , 19 hours ago

-

RE: Do Fridges and Freezers have COP ratings?

@editor Thank you all for your replies and submitted in...

By Toodles , 22 hours ago

-

I know and yes. The secondary deltaT wont necessaril...

By JamesPa , 1 day ago

-

RE: Designing heating system with air to water heat pump in France, near Lyon

Just love the way you put it! 🤣

By Batpred , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thank you for sharing. So it seems that your Schneid...

By Batpred , 2 days ago

-

RE: Forum updates, announcements & issues

@upnorthandpersonal thanks for the thoughtful, consider...

By Mars , 2 days ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

@mk4 All 21 panels have their own Enphase IQ7a microinv...

By Toodles , 2 days ago

-

RE: Setback savings - fact or fiction?

Great, so you have proven that MELCloud is consistently...

By RobS , 3 days ago

-

RE: Mitsu PUHZ120Y 'Outdoor Temp 'error?

Thanks David & James It almos...

By DavidAlgarve , 3 days ago

-

RE: Surge protection devices SPDs

@trebor12345 - your original Topic about the right type...

By Transparent , 3 days ago

-

RE: Help needed with Samsung AE120RXYDEG

@tomf I’ve been sent this from a service engineer at Sa...

By Mars , 3 days ago

-

RE: Buying large amp bidirectional RCD and RCBO

Yes... I went through this particular headache and ende...

By bobflux , 4 days ago

-

O-oh! Let's take this as an opportunity to 'pass the ...

By Transparent , 4 days ago