@mjr, you are fortunate to have found a good installer.

We questioned our installer a year later about the buffer they installed and they stood resolute behind their decision. It’s just safe from an installer perspective to fit a buffer at the expense of system efficiency. They don’t want the hassles.

This is the first time I’d heard that Honeywell valves were not great companions for heat pump systems though.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

Posted by: @editor@mjr, you are fortunate to have found a good installer.

We questioned our installer a year later about the buffer they installed and they stood resolute behind their decision. It’s just safe from an installer perspective to fit a buffer at the expense of system efficiency. They don’t want the hassles.

This is the first time I’d heard that Honeywell valves were not great companions for heat pump systems though.

Hi Mars,

It is the internals of the valve that are the important factor, not who manufactures it. The flow rate through a valve is limited by the smallest area through which the liquid is flowing. If the external pipework or pipe fittings have a smaller area than the valve internals, then the valve will have no real affect when it is sufficiently open.

Can anyone help me to find consumed and delivered energy? I followed a YouTube video but my controller didn’t have the same info as the one on there. I have the Wi-Fi unit but it’s not set up (still in the box) - do I need to install this?

Posted by: @editor@mjr, you are fortunate to have found a good installer.

The company wasn't great, the workers on site were OK (but never returned to do the final fixes) but maybe their designer had some skill!

Posted by: @hotheatCan anyone help me to find consumed and delivered energy? I followed a YouTube video but my controller didn’t have the same info as the one on there. I have the Wi-Fi unit but it’s not set up (still in the box) - do I need to install this?

No, it should be on the wired controller somewhere. On mine, it's the "i" information symbol button, then the button below the kWh readings, I think, but fuller details are buried in the Service menu: Running information entries. What youtube video did you follow? What controller do you have? Did the installer give you the manuals for it? As ultimately, that's probably the simplest way to find out.

@mjr the video I watched had it like yours but mine doesn’t. Will have to dig through and see if the manual is there!

I have a question about TRVs: I understand the logic of turning them all up to max to increase flow temp, but what about in rooms that aren’t used? Should these also be open, or fully closed, or as I’ve been doing down to about 2?

Posted by: @hotheatHi everyone, looking for a bit of friendly advice please

We have an 11.2kW ecodan, 300l hw cylinder and very basic Honeywell thermostat on a 4 bed detached house. Fairly newly installed but unfortunately installer is long gone without ever really going through the settings

We’ve been using about 50kWh a day during the cold snap, which I think is probably about right however the house isn’t that warm. The pump seems to be using a lot then a little then a lot of energy, rather than the low steady use I think we should be aiming for (looking at the half hourly usage graph from octopus).

Our settings via thermostat have been to have it warm in the mornings, middling in the day (as not in), warm again in the evenings and then low enough to be off at night. This worked well enough before the cold snap but I don’t think it’s working now as it’s getting too cold overnight. the thermostat is in the hallway which is probably coldest bit of the house, so setting it to 17 actually keeps it on most of the time.

my question is: should I just whack it up to a higher temp 24/7 and have it on all the time? Reasoning being that once it finally gets there it’ll be able to keep it there? Or if not, how low should I go overnight?

the other complication is that I have no idea how the Mitsubishi control panel works. I know the compensation curve setting is on but I haven’t seen it activated I don’t think as it would say + some degrees in these temps? I think he said it’s set to 45 degree flow temp as standard. I also don’t know how to change hot water schedule - I think currently it’s on in the mornings which can cool down the house unhelpfully, although if I sort the heating this might not matter as much.

Is there a good YouTube guide on how the control panel works? And should I get a smarter thermostat, or is what I have fine?

any advice for a heat pump newbie gratefully received! Thank you

Hi @hotheat, it’s been nearly a year since you started asking questions like the one above. I’ve seen your recent posts and looking at your system you have quite a large HP which will need a reasonable number of radiators to prevent cycling - which you may have. And as you probably know a certain amount of cycling is acceptable from the manufacturers point of view. However it would be good not to have cycling during the main season And into the colder end of the year. In the end you need to deal with what you've got or change something at probably great expense.

its a bit mild today so not ideal to experiment but you could try running your hp at a fixed flow of 38C or even 40C and see if it cycles at that temp. I think your WC curve setting of 30@15 may be giving you around 35C at today’s temp. Once you know at what temp it stops cycling you can then make changes.

I also note you have a LLH and trv thermostats and these bring their own issues. Make sure all trv’s are open and you’re room stat is above room temp which I think you already know.

But for now see if you can find a temp that the HP operates without cycling.

Do you know how many rads/towel warmers etc you have? We really need to know all their output sizes usually quoted by manufacturers as DT50 rating. If you can give this information we can work out heat distribution capacity of your system. I think that’s enough for now.

if I understand correctly you can only operate in WC curve and fixed flow temp. Is that true?

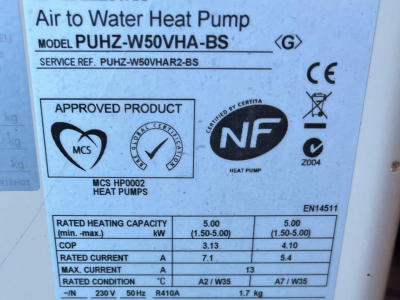

as a quick non-technical reference point you’re ouside unit will have a data plate on the right side. Here is a picture of a 5kw Ecodan. You can see in the top column it’s rated minimum output and maximum output.

It shows the minimum output that the machine must operate at, below this output the HP has to stop after a run time of 20 minutes. Min= 1.5kw Max = 5kw

So where it says A2/35W this means AIR TEMP 2C (at operating flow of) 35C WATER TEMP. So from this information you can see at 2degC the HP has min operating output of 1.5Kwh which is quite small. ** I would imagine your 11.2 kw heat pump will have a much higher minimum output closer to 4 kw.

Hopefully it’s now clearer that A7/35W can be interpreted as the same flow but at 7C.

So I’m suggesting that if you can photograph your data plate you will know the minimum KWh output of your Heat Pump at a nominal operating temperature of 35C.

Am I right in thinking you don’t know your existing COP because the main controller isn’t displaying consumed and delivered energy?

@sunandair yes, hopefully I’m a bit savvier than I was in that first post!

all your assumptions are basically correct. Minimum output is 4.2kw, all my trvs are open and thermostat set high (except overnight). No SCOP data because of the controller issue - I have emailed Mitsubishi on this but not heard back yet.

attached is the rad schedule, and we have added one more k2 1200x600 since during some renovations. Sorry I don’t have the DT50 data though. Before I started using pure WC I was considering increasing the size of some upstairs rads as it wasn’t warm enough up there so if that would help things it wouldn’t be the end of the world (although it is now warm enough).

our heat loss was 8.15kw which was within 10% of the 8.5 unit which is why we got the 11.2 unit. But that is probably why it is oversized most of the time!

hi, I’ve worked out your T50 heating capacity of your radiators and added the extra rad you’ve had fitted. You have approx 25.3 kWh T50 capacity based n the Stelrad charts.

this needs to be corrected down to the flow temperatures you might be using in order to establish what flow temp will be above your minimum output of 4.2 kWh.

At 35C the correction factor I use is 0.165 so 25.3kwh X 0.165 = 4.17KWh

At 30C the correction factor is 0.085 so 25.3 X 0.085 = 2.15KWh

so perhaps you can see that 35C flow temperature you are just below the minimum capacity for your heat pump. It may well operate without cycling at 35C.

whereas at 30 you will be well below the minimum heat transfer.

maybe 36 or 37 would operate more comfortably without cycling.

hope that’s of interest

There are certain assumptions that other things are behaving correctly such as the Low Loss Headder and that pipe sizes are not restricting circulation and flow rate.

@sunandair thank you that’s very helpful! Appreciate you doing the calcs for that, feels like there is always something new to learn.

I’ll definitely increase the min flow temp, but my question is if a certain amount of cycling is ok according to Mitsubishi, do I need to increase it all the way to 35? Assuming energy used is about the same with and without cycling (some savings from the few mins off, but a small peak when it starts back up vs the constant flow), 32 would be more comfortable heating wise - and most of the time when heating is needed this would be above 35 in any case.

next thing for me to learn is what the LLH actually does…

@hotheat The answer to your question would almost certainly be provided if you had access to the energy data which is missing. If you had the opportunity to see what a particular flow temp delivered in terms of COP you could make a judgement from what you see. But you are right in trying to get the flow temp as Low as possible but preferably without cycling more than 1 cycle per hour as a reasonable target IMO.

PERHAPS PRESS MITSUBISHI TO RECTIFY YOUR FAULTY FTC CONTROLLER. They knew they were supplying them with incomplete functionality due to short supply of microprocessor components. So the supply issue should now be over. If we were told the correct story.

@sunandair yes I will press them! Last time I called and was 7th in the queue and didn’t have the energy to wait (no pun intended), but I will push to get a replacement now I see how useful it would be for me.

Posted by: @hotheatthe way to 35? Assuming energy used is about the same with and without cycling (some savings from the few mins off, but a small peak when it starts back up vs the constant flow), 32 would be more comfortable heating wise - and most of the time when heating is needed this would be above 35 in any case.

In theory energy used shouldn’t be the same since longer operation should be more efficient and less wear on the compressor. What would be really worthwhile from a feedback point of view would be to test the 36C fixed flow temp on your system. It would help to know if the calc delivers on outcome in practice. Could you do that and give feedback? At a time to suit?

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 298 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

@skd I think your guess might well be right - unfortuna...

By Toodles , 2 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 13 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 1 hour ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 4 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 7 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 24 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago