Massive Electricity Cost for Running My Air Source Heat Pump

I don't think the insulation around those four external pipe runs is adequate.

Although I can't see how they arrange themselves to pass through a 100-125mm outer sleeve, the pipe clips have already compromised the wall thickness before the flow even gets there.

I also wonder if the installer has used Split-Insulation.

If so, then the split will be gaping open on the side which faces into the wall.

The approved method is to use adhesive to join the splits,

and for all bevel-cut ends around pipe elbows.

This then gets an outer layer of 'tape' to further cover the joins.

Armaflex and Kaiflex both manufacture UV-resistant external insulation.

It's usually sold as "solar insulation" because it gets used on roof-mounted solar-thermal collectors.

Save energy... recycle electrons!

As for the steel shed, I would expect to see around 100mm thick insulation sheet for the roof,

and around 75mm for the walls and door.

It must be draft-proof,

which may require neoprene rubber gaskets to be cut and glued around the pipe-exit holes.

I can provide further construction details if required.

The adhesive will be a 'contact' type such as this from Screwfix

Pipe insulation is usually best undertaken as a DIY task...

... preferably by someone with OCD!

Save energy... recycle electrons!

@transparent Hi, I spend most of my time on international travel through work.

However, I have taken some time to check what you guys are saying and you're entirely correct.

See pics!

My first avenue was simply to get it all corrected, however I see now I will have to find the time to do most of it myself if I want it done well.

If I posted pictures of the horrific work they did in my house I think you guys would turn up with pitch forks outside their office!

If you're going to take a DIY route to fixing the pipe insulation, then you should be asking for a rebate from the installer.

To calculate this, first ask them how long it will take them to remove what's there and do it again properly.

Then use £45/hour per person and add in the cost of buying the insulation yourself.

That should provide you with a good starting point.

They'll be super busy and wanting to get on with their next job rather than fix yours.

So the option of repaying you in cash will be tempting for them.

One possibility for you to consider is to make a rectangular box around those external pipes and seal them in...

... at least for the main vertical run.

There are PVC parts used by window-fitters and firms who clad facia boards, which could be fashioned into suitable boxing.

Save energy... recycle electrons!

@transparent I couldn't agree more, my first idea when looking at it was to box it in.

There isn't enough clearance between the pipes and wall to insulate it much better.

My sons arm was recently injured quite badly, but as soon as he is fit I will lob him up in the loft to check the pipe insulation in there. I wouldn't be at all surprised if it is just the rockwool!

Absolutely!

Child labour is well suited to the task of pipe insulation in confined spaces.

To seal where pipes enter the steel shed, I'd be using offcuts of EPDM rubber roofing material.

It's excellent for shaping around joins, and easy to cut.

You can glue it directly onto existing vertical surfaces.

So it's also a good choice to seal the top of your boxing.

Save energy... recycle electrons!

I know I'm late to this but I thought it would be worth pointing out that insulation of pipe runs outside the thermal envelope of the house is a building control matter. The installers should be responsible for complying with those regulations.

The relevant sections are 4.24 to 4.26 of approved document L:

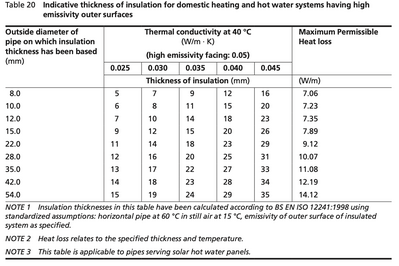

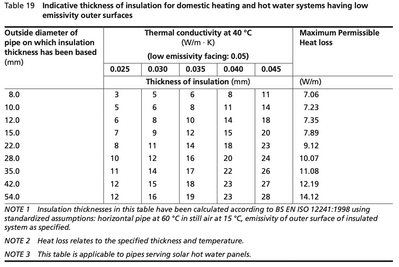

It's worth noting that the insulation thicknesses described in that document are for very high quality insulation (i.e. very low thermal conductivity and low emissivity). The building regs defer to BS 5422 for lower performance insulation, and that can have a huge influence. See the attached two tables for low and high emissivity insulation, cribbed from a verv old copy of BS 5422.

If we take 22mm pipe as a reference. The really high quality insulation would require only 8mm thickness, but if it was high emissivity then that would increase to 11mm and if it then had high thermal conductivity typical of the sort of neoprene like insulation (~0.04 W/mK) then you'd need 23mm insulation to meet the regulations. That's a big jump from 8mm!

As an aside, the building regs are a great source in some areas like this. IMHO they're easy to read and a model of clarity.

I agree @mark-h The Building Regs are now very readable...

... although I do miss the sections of 'advisories' and illustrations of acceptable practices which used to be present.

There's an additional problem when selecting external pipe insulation because it has to be UV resistant of course.

The range of sizes available for installers to choose from is therefore reduced,

and especially so if they wish to use larger bore insulation around valve bodies.

Pipe Lagging offer a selection of 'solar' pipe insulation online, but it's expensive once you opt for sizes outside the common pipe diameters.

Another option is to swathe UV-resistant tape around the odd-sized sections and bends.

But my own experience with this approach is that the adhesive on the tape isn't good enough to hold firm around tight corners.

It needs supplementing with contact-adhesive at the edges.

There are also anti-UV paints which can be applied on top of existing insulation...

... provided it hasn't already been degraded of course!

Save energy... recycle electrons!

Currently viewing this topic 4 guests.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 453 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 52 minutes ago

-

RE: What determines the SOC of a battery?

Thanks. It is not clear how @bash concluded the chargin...

By Batpred , 1 hour ago

-

Struggling to get CoP above 3 with 6 kw Ecodan ASHP

I've been using this heatpump for two winters now and a...

By GoodbyeGas , 2 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That would make sense. I've found the effects are prett...

By Majordennisbloodnok , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 3 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 5 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 15 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 17 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 17 hours ago

-

RE: Electricity price predictions

@judith Thanks for sharing, and nice to see how the ...

By Batpred , 18 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 20 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 21 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 21 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 22 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 23 hours ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

I don't know about Solis inverters. It isn't a featur...

By Transparent , 2 days ago