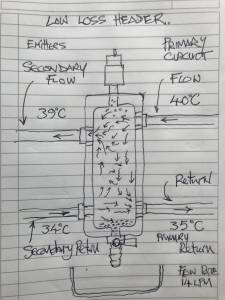

Low Loss Header is losing 1.5c from flow temperature

@iancalderbank thanks Ian

yes there is a drop in flow temp across the LLH but there is a more or less equal rise in return temp across the LLH. These were tested with a separate thermistor…

I don’t know if there is a way of working out a quantifiable energy cost for the increased generated DT to create the desired DT at the emitters but perhaps it isn’t as big as I’m thinking it might be?

thanks for your insights on this

Posted by: @sunandair@iancalderbank thanks Ian

yes there is a drop in flow temp across the LLH but there is a more or less equal rise in return temp across the LLH.

doesn't matter. check the datasheet 2 posts up. the higher the flowT, the worse the COP. same for any heat pump.

also you are talking about loss of DT, but in your sketch, DT is the same both sides, which it would be if flow rate is the same. heatgeeks explanation is pretty good as they usually are https://www.heatgeek.com/low-loss-headers/

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @iancalderbankDT is the same both sides,

hi Ian,

here is my sketch again what do you mean that the DT Is the same both sides? The sketch shows a 1degC drop in one direction and a 1degC rise in the other direction…. Is that what you mean?

the Heat Geek info looks interesting

Will look in due course… thanks

Posted by: @sunandair@iancalderbank thanks Ian

yes there is a drop in flow temp across the LLH but there is a more or less equal rise in return temp across the LLH. These were tested with a separate thermistor…

I don’t know if there is a way of working out a quantifiable energy cost for the increased generated DT to create the desired DT at the emitters but perhaps it isn’t as big as I’m thinking it might be?

thanks for your insights on this

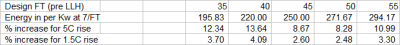

Assuming I understand the question correctly (which I may not) then yes there is. Plot COP vs flow temperature, then work out the COP (at some representative OAT eg 7C) for the two 'alternative' flow temperatures required to achieve the same FT at the emitters (ie with and without the LLH, or more simpl the original design FT and that plus the reduction in FT across the LLH). Then use that to work out the change in energy consumption due to requiring a higher FT from the ASHP.

So for example with a Mitsubishi R32 11.2kW the COP at 7/40 is 4.55 and its 5.11 at 35/40. That translates to a 12% increase in consumption for a 5C rise in Flow temp, so about 4% for a 1.5C rise.

Here is a quick table for the 11.2kW Mitsi

This accounts only for the reduction in thermodynamic efficiency of the heat pump, not for any energy losses in the LLH (which, assuming its well insulated, should be negligible). It also assumes that the pump speeds (l/s) both sides of the LLH are approximately equal (if they aren't then youare forcing mixing which is a bad idea)

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa perfect….

thanks James

Added

(We tried a number of secondary pump settings until we got the lowest change in DT but we couldn’t do much better than 1degC. At least we are dealing with constant flow rates…. )

Ive already built my secondary pump bypass….

DT is a phrase used too much in HP discussions, one needs to be clear about between what points the difference is being measured. Its normal that DT is used to refer to the difference between flowT and returnT. In your case, DT on the left side is 5C. (39-34). DT on the right side is also 5C (40-35). DT times flow rate gives you the heat energy transfer rate, which has to be the same each side - there is no input or output of energy in the LLH. If the flow rates are different on each side then DT would be different each side, but the energy transfer would still be (MUST BE) the same. The LLH isn't "losing" energy (it can't, its not an emitter - assuming its well insulated).

But what the LLH does, is force mixing to happen, which MUST reduce the flowT on the emitter side. this reduces the efficiency of the system as a whole, once you consider how the energy input device (the HP) works. To get an emitter temp of 39C, you have to run your HP at 40C. This costs you x% in HP efficiency - its guaranteed, for any HP, the higher the HP flowT, the less efficient it is. (as per jamespa, probably around 3% for 1C). If your drop in FlowT is worse, this % gets higher (= worse).

If you have a poorly balanced LLH - widely differing flowT's - then the drop in flowT would be worse, thus increasing the need to run the HP at an even higher temperature OR leading to too-cold emitters that don't warm the house - thus giving an even less efficient system with an even worse COP.

If you've already got it down to only a 1 degree drop in flowT across the LLH, by tweaking your secondary pump, thats pretty good - implies you've got it down the least amount of mixing that you can (whilst still keeping the LLH). the only way to get better will be to repipe without it. additional benefit of that is you only need 1 pump, and you can also potentially use a variable circulation speed (either a CP or PP pump , or a PWM pump controlled by the HP, or a DT-targeted pump), starting point for that discussion should be what is the pump within your ASHP capable of.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

- 27 Forums

- 2,520 Topics

- 58.6 K Posts

- 641 Online

- 6,800 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Heat Pump vs New Gas Boiler for Inherited House - Worth the Extra Cost?

@fretless6, where are you based? I might be able to con...

By Mars , 26 minutes ago

-

RE: Underfloor Heating Installation Issues with Heat Pump

I'm going to install Thermacome ACOSI+ radiant ceiling....

By bobflux , 1 hour ago

-

Issue with a Grant Air Source Heat Pump & Tado Smart Thermostat

Hi all I'm having some trouble with a Grant ASHP and ...

By Renewables345 , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Now seems a good time to summarise the costs and effici...

By benson , 2 hours ago

-

RE: Tell us about your Solar (PV) setup

@mk4 Charge to 100%, discharge down to 10%.

By bobflux , 4 hours ago

-

RE: Daikin Altherma 3 LT compressor longevity question

This mess is intriguing: I wonder if this represent...

By bobflux , 5 hours ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

The simplest wired option is usually the Growatt Ethern...

By Jonatan , 9 hours ago

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

ASHPs do have a minimum compressor speed. The minimum h...

By bobflux , 16 hours ago

-

RE: Electricity price predictions

@jamespa And it seems some of the nasty public cloud...

By Batpred , 16 hours ago

-

RE: Jokes and fun posts about heat pumps and renewables

Technology is rapidly advancing. BBC News reported th...

By Transparent , 20 hours ago

-

What matters for flow and pressure drop is internal dia...

By bobflux , 20 hours ago

-

RE: Do Fridges and Freezers have COP ratings?

@editor Thank you all for your replies and submitted in...

By Toodles , 23 hours ago

-

I know and yes. The secondary deltaT wont necessaril...

By JamesPa , 1 day ago

-

RE: Designing heating system with air to water heat pump in France, near Lyon

Just love the way you put it! 🤣

By Batpred , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thank you for sharing. So it seems that your Schneid...

By Batpred , 2 days ago

-

RE: Forum updates, announcements & issues

@upnorthandpersonal thanks for the thoughtful, consider...

By Mars , 2 days ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

@mk4 All 21 panels have their own Enphase IQ7a microinv...

By Toodles , 2 days ago

-

RE: Setback savings - fact or fiction?

Great, so you have proven that MELCloud is consistently...

By RobS , 3 days ago

-

RE: Mitsu PUHZ120Y 'Outdoor Temp 'error?

Thanks David & James It almos...

By DavidAlgarve , 3 days ago

-

RE: Surge protection devices SPDs

@trebor12345 - your original Topic about the right type...

By Transparent , 3 days ago

-

RE: Help needed with Samsung AE120RXYDEG

@tomf I’ve been sent this from a service engineer at Sa...

By Mars , 3 days ago

-

RE: Buying large amp bidirectional RCD and RCBO

Yes... I went through this particular headache and ende...

By bobflux , 4 days ago

-

O-oh! Let's take this as an opportunity to 'pass the ...

By Transparent , 4 days ago