@derek-m Good work! I will try to take a look over the next few days. Im presuming its a linear WC curve defined by the figures in K5/6. If that's not the case perhaps you could explain.

What I cant quite get my mind around is that your previous version had variable flow temperatures as well, which were related to the load amongst other things. Although you explained that this had the effect of modelling the emitter actual demand, I was never quite sure how it worked. Perhaps you could just clarify the logic of how you work this out ie the steps taken to get from the various variables to the flow temperature and energy delivered in any one period. I can follow some of it but the length of the formulae, on which I congratulate you, makes it quite challenge to reverse engineer!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@josephiah For what its worth modelling done completely independently by @derek-m and me, and using completely different approaches, tends to suggest that setback may be more likely to save money (if at all) when the OAT is moderate, than when its really cold. Its also (obviously) more likely to yield a comfortable result when the OAT is moderate than when its cold.

This assumes that the house cool down time is fairly long (half a day or more); a house with a very low thermal mass would defeat this (very tentative) conclusion.

So your tentative real world data tends to support the modelling output and, for once, comfort and cost-saving probably tend towards adopting the same behaviour.

Our house is occupied during the day and, for the past couple of years, in prep for fitting a HP, I've been running my gas boiler, on which I have limited the the max o/p at 8.5kW (as opposed to 28kW which it is capable of) and the FT to 50/55 as follows:

a) 24x7 when its really cold

b) 6am-10pm in the shoulder season

c) 6am-8am and 4pm-10pm at the ends of the season

Altogether leading to a really comfortable result, much more comfortable than my previous regime with high temperature radiators and timed operation even during the very cold periods. So far as I can tell consumption has dropped not increased, although I suspect this is due to reducing FT so that it actually condenses as its supposed to!

I have a growing feeling a-b (or similar) may well be the way to operate a HP in my house also, once my District Council finally stops getting in the way of me fitting one!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

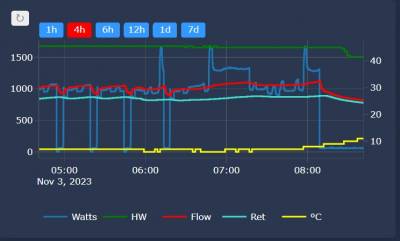

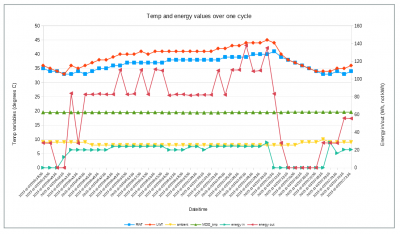

Anatomy of a cycle: here is a single cycle from my heat pump, from around 0640 to 0720 this morning. This has been the pattern for the last few days, just under two cycles per hour. In addition, the LWT/RWT delta t is less than 5 degrees. I presume both, the cycling and the lower than expected delta t, are the heat pump's way of reducing output to match low demand. Each 40 minute cycle has four roughly 10 minute phases, (1) initial ramp up, (2) steady state, (3) another unexplained ramp up and (4) cool down. I am still baffled by the second ramp up - why not stay at steady state once it has got there?

Once again, the effect of the compressor running/not running on the OAT can be seen, as the OAT rises a degree or two when the compressor is off during phase 4, the cooling down phase.

The energy in and out are remarkably steady during the whole cycle (ie no hills and valleys) but I think this is most likely an artefact of the way I record the data. The temp readings are recorded every minute, but the energy readings are only determined every hour, that is, once an hour, the amount of energy in and out is calculated for the preceding 60 minutes. This means the minute by minute energy in and out could vary substantially, but we never see that, instead, we just see the average over the hour. I did it like that because the idea of a minute by minute COP seemed at the time rather absurd, but in fact it may not be. I will see if I can tease out minute by minute energy in and out (and COP) and then chart that.

The thing is, a cycle is a hill and valley pair - ie a setback and recovery boost. We may already have the experiment running under our very noses. More later...

Midea 14kW (for now...) ASHP heating both building and DHW

It would be useful to see the real-time energy going into the pump from a Watt meter, it might show something. I attach one of mine below, mine also cycles about twice an hour until the OAT gets below about 6C, this charg shows a couple of cycles and a longer run, but the minute-by-minute energy of the pump is interesting.

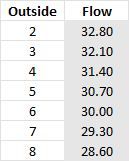

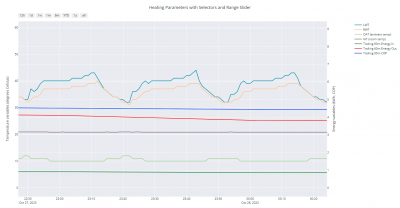

I should add that it's in full weather comp mode against full house flow with no thermostats atm, the flow temp settings calculated by s/sheet are below, I have no idea why the pump chooses in some cases to cycle and others to run on, there's clearly something going on in its internal algorithms but I have seen other comments from other Ecodan users that this kind of cycling with very short off-times as the pump gets towards fully-on runtimes/OATs is not unusual. Our pump (PUZ 11.2) is slightly oversized for the house, but we intend some building work so live with that for now.

@rod - I do have a separate third party kWh meter that supplies only the heat pump but maddeningly it is not modbus enabled, meaning I can only get readings manually, and I draw the line at standing on steps reading the damn thing every minute for an hour! However, I have established that my modbus derived and then calculated kWh/energy in values are pretty close to the separate meter values, at least over longer time frames (one hour or more). The minute data does have everything needed to calculate energy in and out every minute, and I am doing that at the moment, and will post the results once I have them.

Midea 14kW (for now...) ASHP heating both building and DHW

I use one of these with the device in a fused-spur surface-mounted box next to the consumer unit, and the sensor clamp around the live to the pump in the consumer unit - my pump has a dedicated circuit. Could be put around the live anywhere, it's wifi enabled and gets picked up by Home Assistant to do the monitoring.

https://shellystore.co.uk/product/shelly-em-2x50a/

Here are the minute by minute energy values alongside the minute by minute temp values I posted earlier. Note they are Wh, not kWh, and, as a sanity check, I summed the values over the entire 44 minute period and got 762 Wh in and 3055 Wh which equates to 1.04 kWh in and 4.17 kWh (and a COP of 4.01) over the hour which are consistent with the hourly values shown in the earlier chart. MD02_tmp is the room temp:

Interestingly, the first ramp up isn't associated with a disproportionate increase in energy use (energy in). In fact, it (energy in) is pretty stable throughout the on phase, while the energy out rises a bit during the on phase, suggesting a slight increase in efficiency over the on phase (which I suppose could also be worded as it starts off a bit less efficient). But, overall, as I see it, nothing world shattering to see here, no obvious cycling penalty.

Midea 14kW (for now...) ASHP heating both building and DHW

I suspect that the second increase in LWT occurs after your heating system and heat emitters are fully up to temperature, hence the RWT starts to increase which in turn pushes up the LWT.

Posted by: @derek-mI suspect that the second increase in LWT occurs after your heating system and heat emitters are fully up to temperature, hence the RWT starts to increase which in turn pushes up the LWT.

That sounds very plausible, except for the fact the LWT rise appears to start just before the RWT rise, see at around 0703h. The four phase pattern is ubiquitous at the moment, here is another random selection from late October, and again the LWT starts just before the rise in RWT in two of the three cycles (in the other, the left hand one, they change at the same time). That said, we are relying on the Midea sensors being spot on...

Midea 14kW (for now...) ASHP heating both building and DHW

We have some towel rail radiators which are connected directly to the HP flow/return and mixing valves ar the underfloor manifolds - I would expect that the returning water temp would climb pretty fast as some hot water will not have far to go before coming back to the pump. This would then be followed by water passing through different parts of the UFH system and contribute to phased rises as each one pushes out the colder water and returns the new warmer flows.

Possibly contributing?

Hi James,

You are indeed correct, the WC 'curve' is a straight line calculation based upon the values in cells I5 and I6 and K5 and K6.

Energy Demand : This is calculated from the standard heat loss as set in Initial Data and the temperature difference between IAT and OAT.

Energy Supply : This is an awkward one to calculate since it needs to limit the value when the heat pump reaches maximum output and cannot go any higher. Whilst the heat pump is operating within its normal range, energy supply is a measure of how much thermal energy the heat emitters can accommodate at the given LWT. It also takes account of changes in Delta T and variations in IAT, such that as IAT increases, the heat emitters can dissipate less thermal energy for a given LWT. The problem was trying to limit the maximum value of energy supply, since this varies with LWT and OAT, so in the end I took the simple solution of only calculating the limit for the energy supply, when energy demand exceeded 14000W. This approach works okay unless the OAT is above -4C, and a large positive WC offset is applied when energy demand is below 14000W. If you can think of a solution I will be 'all ears'.

Duty Cycle : This is a measure of when the energy supply falls below the minimum continuous output of the heat pump, so will likely start to cycle.

PI (Power Input) : This is derived by dividing the energy supply value by the COP value.

LWT : This is calculated from the WC curve values and the WC offset.

COP : This is obtained from the Detailed Data tables via the Lookup Table and the Intermediate Table and should be the value at the given LWT and heat pump loading.

Building Thermal Capacity : This was added to investigate how different thermal masses could affect how a system responds. The effect is seen in the Actual IAT (finish) calculation, where the change in energy balance affects the IAT.

Obviously the green highlighted cells are the ones that can be varied.

One thing that became apparent is that although the WC curve may be linear, the actual response in thermal energy output is not. I believe this due to the fact that the thermal energy output of the heat emitters is not linear, so although LWT may change linearly with OAT, the quantity of thermal energy being supplied is not linear. I adjusted the WC curve settings to be balanced at 0C and 15C, but this balance is not maintained at other OAT values. I would welcome your thoughts if my assumptions are correct.

Posted by: @derek-mI believe this due to the fact that the thermal energy output of the heat emitters is not linear, so although LWT may change linearly with OAT, the quantity of thermal energy being supplied is not linear. I adjusted the WC curve settings to be balanced at 0C and 15C, but this balance is not maintained at other OAT values. I would welcome your thoughts if my assumptions are correct.

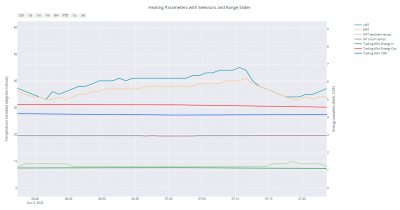

I can respond to this straightaway as I played around it when I did my WC simulation model (a very focussed model designed to test that one thing only - attached).

As you say the 'ideal' WC (with rads) is not linear and a linear WC will lead to slight mismatches in output vs demand. In my model I looked at several variants on possible linear and non linear wc curves, to see if they made much difference (answer - a percent or two in energy use). You can see the variants in the tables. A 'best fit' linear approximation is one of the options, as is that jacked up by a degree or two to ensure that the house is always warm enough.

Oddly enough this is where HPs that do not modulate the flow rate for constant delta T may be slightly better. Linear WC with constant flow rate' is a bit closer to the 'ideal' weather compensation curve than is 'Linear with fixed delta T'.

Thanks for the explanation, very helpful, I will give it a look over and try some breaking tactics.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 364 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

i only know about Intelligent Octopus Go ToU, where acc...

By SKD , 21 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 55 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Without knowing it, @andrewj, you've laid down the gaun...

By Majordennisbloodnok , 1 hour ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 1 hour ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 2 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 2 hours ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 5 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 5 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 7 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 10 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 21 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 23 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago