Grant Aerona Setback

Posted by: @derek-mIn the right hand chart did you vary the Target LWT or was this done by the controller?

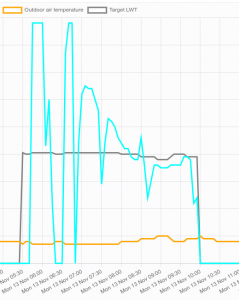

It's being varied by the controller's WC - see below where I've just shown the 'Target LWT' vs OAT (and compressor freq) for that same time period; the Target LWT just reflects the OAT. On the Grant, as you know, the WC curve is just a straight line.

For clarity, all values are coming directly from the Grant HP, apart from 'Target LWT' which I calculate based on the OAT and WC curve (line) as defined by the 4 control parameters. I'm confident the calculation is correct given the observed modulation of compressor frequency when LWT reaches the Target LWT. My long-term plan is to modulate the LWT based on IAT as well, but that's down the line - I have flow rates and zoning to work on first.

Grant Aerona 3 10kW

Posted by: @cathoderay@mikefl - a useful comparison, even if it is, I agree, a rather busy chart! There is a more marked spike, but there is also a notable dip after the spike, meaning we may want to consider the area under the curve, rather than moment by moment values. And, although it is a bigger spike, it isn't huge, eg the added area under the curve in the left hand chart caused by the spike isn't that large compared to the total area under the curve.

I was vaguely under the impression that modern compressors have a slow start up, ie they wind up slowly, rather than jamming straight away into top gear, precisely to limit start up current draw (and perhaps other things as well). That's why I think the 'start ups carry a heavy current penalty' thing may be a hang over from the older heat pumps, that no longer applies to newer ones.

I think that you will find that the 'soft' start for an electric induction motor is only over a period of seconds, to limit the current inrush.

The compressor will probably start unloaded, so running at full speed will only draw slightly higher current. The loading increases as the pressure within the system builds, making the compressor work harder.

Posted by: @mikeflMy long-term plan is to modulate the LWT based on IAT as well, but that's down the line

I'm already doing that, and most of the time it works, but I still have to iron out a bug, running my hourly auto-adaption script, which varies the LWT depending on the difference between the actual and desired IAT, terminates the DHW heating if it happens to be on when the script runs. I've just adjusted the code so that it will only run if the DHW is off, generally not a limit as the DHW, which is on a timer, usually only comes on between 1300 and 1400 daily.

Posted by: @derek-mI think that you will find that the 'soft' start for an electric induction motor is only over a period of seconds, to limit the current inrush.

The compressor will probably start unloaded, so running at full speed will only draw slightly higher current. The loading increases as the pressure within the system builds, making the compressor work harder.

I don't currently collect compressor frequency, but it appears to be available over modbus. I will add it, and we should then be able to see how amps and compressor frequency are related. That said, are we right to assume compressor frequency is a direct measure of how hard it is working?

Midea 14kW (for now...) ASHP heating both building and DHW

No and yes, compressor frequency denotes how fast the compressor is running. How hard it is working is dependent upon the pressure within the condenser.

Think of pumping up a bicycle tyre using a hand pump. When the pressure is low it is quite easy to operate the pump, but as the pressure builds, so does the amount of effort required to move the pump.

I have noticed with our A2A heat pump, when it first starts the compressor run quite fast, but the quantity of electrical energy being consumed is not too high. As the heat pump gets to the point of supplying thermal energy, the compressor slows, but the amps increase.

Obviously as the amount of thermal energy being produced increases, the compressor speed also needs to increase, since it is moving more refrigerant gas around the system.

It will be interesting to see how the compressor speed varies with thermal energy output.

Posted by: @derek-mIt will be interesting to see how the compressor speed varies with thermal energy output.

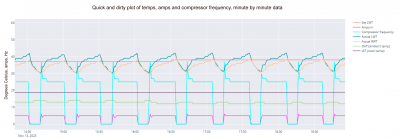

Here we go, data from the last few hours since I added compressor frequency to the data, as it happens a period of relative stability in OAT, though it has been breezy (wind chill and, in my case drafts):

I suppose it is pretty much as expected, high compressor frequency at start up, slows as it comes under load, with the small uptick in amps at startup? I haven't included the energy in/out bar chart because that is hourly data, minute by minute variations will be lost. In the above chart, given the flow rate remains constant, as does the specific heat of the fluid, the LWT/RWT delta t can act as a proxy for the thermal energy output.

Midea 14kW (for now...) ASHP heating both building and DHW

-

Thermostat for Ideal Logic Air with 3 zone support

6 months ago

-

Grant Aerona Setback

2 years ago

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 289 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 9 minutes ago

-

RE: Electricity price predictions

i only know about Intelligent Octopus Go ToU, where acc...

By SKD , 50 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 1 hour ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 2 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 4 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 7 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 24 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago