The problem with looking at the flow and return temps on the controller is that they are constantly changing, so it might look good at one moment (and a deltaT of 13 would be great, but unlikely), and be completely different 5 minutes later. e.g. when first turned on, the return temp will be low, in comparison to the Leaving Water Temperature (LWT); but once up to speed they'll move together, and eventually even out as the heat demand from the house reduces.

I think that it's best to focus first on getting the mechanical bits understood/sorted, then go on to look at the settings and efficiency. Easy to end up chasing your tail. With a Grant you have a fixed flow, so in the design you should have a figure for kW required for the house (which ought to then be capable of being delivered by the heat emitters), and that will relate to a flow in litres/min - see the calculation in Chapter 9 of the installation guide.

As this is a new install, your installer should be following the appropriate building regs (part L is the one I believe), so all pipework should have been insulated in any unheated space, and I'm sure that includes your pump room. Hopefully someone else can confirm this, but lack of insulation is a sign that appropriate regulations have not been followed.

Grant Aerona 3 10kW

A = Secondary circulation pump

B = Magnetic filter

C = Low Loss Header

D = Flow Regulator?

E = Diverter Valve?

The question marks are because I'm not sure I can make things out from the picture, and I'm guessing they are that. Specifically:

- what make/model is A and what setting is it on?

- C doesn't look like a standard Grant LLH. If it's a new install, is this a new model LLH or was a different make used for some reason?

- D should be on the return flow, as should B, so I'm assuming that's the return pipe to the HP, and D might be where I've marked it. Can you check and read off the flow rate if that's what it is? Again, look at Section 9 of the Installation Guide

- I think E is a diverter valve by A. There should be something that swaps between the DHW and CH and be before the flow reaches the secondary pump

Grant Aerona 3 10kW

Posted by: @mikeflThe problem with looking at the flow and return temps on the controller is that they are constantly changing, so it might look good at one moment (and a deltaT of 13 would be great, but unlikely), and be completely different 5 minutes later. e.g. when first turned on, the return temp will be low, in comparison to the Leaving Water Temperature (LWT); but once up to speed they'll move together, and eventually even out as the heat demand from the house reduces.

I think that it's best to focus first on getting the mechanical bits understood/sorted, then go on to look at the settings and efficiency. Easy to end up chasing your tail. With a Grant you have a fixed flow, so in the design you should have a figure for kW required for the house (which ought to then be capable of being delivered by the heat emitters), and that will relate to a flow in litres/min - see the calculation in Chapter 9 of the installation guide.

As this is a new install, your installer should be following the appropriate building regs (part L is the one I believe), so all pipework should have been insulated in any unheated space, and I'm sure that includes your pump room. Hopefully someone else can confirm this, but lack of insulation is a sign that appropriate regulations have not been followed.

Thanks Mike, I'll get back to you on all this later today when get home.

For the heat requirement looking at the heat calc doc it states:

When the external temperature is -2.7°C

The total heat source required to heat the building must provide an output of 7.86 kW

I've not had official handover from the plumber yet, hence scrambling to sort this beforehand (to avoid extra cost) so I don't have the installation guide as yet.

Plumber is coming tomorrow and I'll report back what's been done/said etc incase of any use for others.

I've messaged plumber the temps of the zones (19.5 kitchen/diner, 17.5c downstairs, 18c up stairs) and he's saying he probably needs to put in a warranty claim to Grant now as doesn't seem right at all.

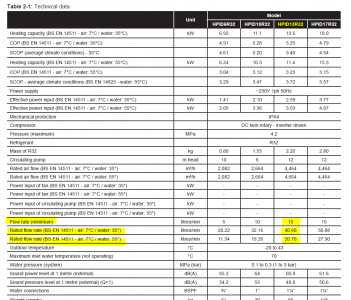

Most Grant Aerona ASHPs work on a DT of 5degC, they will push up to 8degC, but seem happiest with a low DT. If you are in the habit of turning the heating off overnight, and starting the system from cold, it's important to consider the small delta T. The supply water temperature will never be more than 5 or 6degC higher than the return when the ASHP is working flat out, so it can take a long time for supply and return temperatures to both rise. Supply can't rise until return starts to rise, which will only be once the house starts to warm and less heat is lost at the emitters. An ASHP cannot put large amounts of heat energy into the system from cold, they work 'low and slow'.

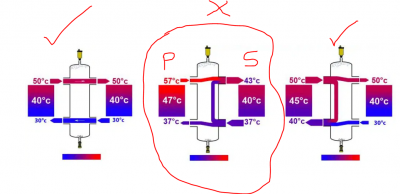

About 8kW calculated heating sounds low for a building of 220m2, but a 13kW source should easily manage, provided the emitters are large enough. You have a low loss header, so there will be at least two pumps, the one in your picture on the secondary side and the one built into the Aerona ASHP. Their flow rates should balance, the way to check this [with no flow gauge on the secondary side] is to measure the temperatures across the LLH in and out. The top pipes in and out and the bottom pipes in and out should be equal temperature with the same delta T. Check this with all zones and radiator circuits open. If you find on the return side (bottom of the LLH) there's a difference between inlet and outlet, then the primary and secondary flows are not balanced, usually it's the secondary circuit flow that is too low. That can often explain poor performance of an ASHP which is sized OK, if it can't get heat energy generated at source to be released emitters, either because the emitters are undersized, and/or the flow rate is too low, then it's never going to operate to full capacity.

As MikeFl has pointed out, not a single pipe is insulated in your plant room. Hopefully this is because it's a new system and the plumber hasn't finished yet. You'll have a lovely cosy plant room no doubt, but I'm sure you would prefer lovely cosy house rooms. Let's hope the external piping is insulated in suitable weather and UV protected insulation.

It's a good point about pipe insulation, will raise that (it is lovely and warm in there lol). Outside is insulated after randomly a decorator on site questioned why hadn't they done it (they said they just hadn't got to it yet, tbf the insulation was sitting next to the ASHP so wasn't that they hadn't though to).

I haven't got a way of measuring the temp but will pass on all these queries to plumber tomorrow.

In terms of set backs, I've got the zones pretty much higher in their 'off' state than what they are so I don't think it's that - it's just simply not hitting any temps. E.g. just to see if downstairs got higher, it's at 23c on, 21c off effectively, and never hits either.

I do wonder about the calcs, as I've checked with the architect on the project asking, if worse case rads etc undersized, who's liable, it's in the plumber's court as their contracted to design the heat system. She re-flagged that she was very unhappy with the lack of support from the plumbers - getting rads sized was a pain in the neck, I ended up using their calculations to suggest radiators, which they then confirm would suffice - one real challenge was windows in living rooms are very low, so they were suggestion rads far wider than the windows, hence going for the higher/albeit way more expensive Eskimo rads. They however signed off all the radiator choices, and using delta 20 which was suggested they all pretty much met the room requirement - one bedroom was 20w off I believe. On that however, upstairs fairs a lot better temp wise, but we don't ever push it too high as not something we like. I'll see if upping it to 22c, if it gets anywhere.

The project to the house was very much heat being a priority (it was cold before). So all walls that are external were insulated internally with 75-100mm celotex. Roof was re-insulated. There's side roofs that sit partially on the living rooms (they extend further out than bedrooms above them) - those were completely re-roofed and insulated. All windows are Velfac triple glazed with low u values throughout. So insulation was definitely a priority.

@crimson - is that flow rate photo taken with the ASHP running? It's showing a flow rate about 9 litres/minute. If so, that's way below Grant's minimum flow for the 13kW unit of 15litres/min. That's an absolute minimum, I would be expecting around 37litres/min based on 5degK between LWT and RWT 13KJ/s / 5 / 4.2 kJ/kg = 0.62l/s x 60 = 37l/min. Even at 8degK between LWT and RWT, which is the largest deltaT for the Aerona, you need 13KJ/s / 8 / 4.2 kJ/kg = 0.386l/s x 60 = 23l/min.

I don't know what the black 4 port valve is on your last photo, but it's not something Grant supply or specify for their installs. Got any more info?

@allyfish Afraid don't have more details, will ask plumber about the black 4 port valve.

That flow rate, seems to be same atm and it's definitely running. I'll periodically check that and raise with plumber. Thanks again!

Posted by: @crimson'll periodically check that and raise with plumber.

Hi @crimson, the flow rate is constant for Grant systems, as they have a fixed speed pump in the ASHP. If your primary flow rate is 9l/min, and the flow valve isn't sticking [give it a gentle tap, but you can usually see it moving slightly] then something is very wrong with the primary flow. There will be nothing wrong with the Grant Aerona unit, they are very reliable and dependable, nearly all issues arise from poor installation and deficiencies or shortcomings there.

It looks to me like the primary flow rate on your system could be seriously deficient. If it is much lower than the secondary flow rate, what happens is return water from your radiators going back to the ASHP mixes with the heated flow from the ASHP in the low loss header, lowering the supply temperature to the radiators and emitters. Then you've got a shortfall in heating capacity. It's easy to check these things, and a competent plumber should not need to be prompted to do so. Ideally, systems are best without low loss headers, but Grant specify them as do other ASHP manufacturers to give a little wriggle room in system design and make flow rates less critical.

A bit of info for you, and maybe your plumber too if they are not up to speed: https://www.heatgeek.com/low-loss-headers/

Lower primary flow compared to secondary flow produces the effect circled, it needs to be fixed and balanced up. Grant ASHPs have pretty good primary flow pumps, and the piping route is usually very short between the unit and the low loss header, so this problem is rare. There will be a cause; such as a closed valve (maybe the flow setting valve), or that strange black 4-port mystery valve (the function of I have no idea) or the pump speed setting on the ASHP control PCB. They are normally supplied set to max speed, and usually need turning down not up.

As @allyfish has pointed out, that flow rate is an issue - the 'square-headed' screw-like thing below the gauge window on the regulator is what controls the flow, but 6 o'clock is "fully open", and you only have a 90 degree clockwise turn available (i.e. 9 o'clock would be most restrictive). It looks close to vertical from you picture, but even just off vertical will only drop by a few litres/min. There are dip switches on the outside unit which lets you set 1 of 3 flow rates, but the HP will have come set to maximum (level 3) and I doubt if your plumber has changed it, although you could check (or ask your plumber to).

If everything is at 'max' and you're not getting decent flow that suggests a blockage somewhere - air or dirt or whatever. With a new install I'd hope everything would be clean and new, but there are some things on your first picture that confuse me now I've looked at it a bit longer. Firstly, I counted about 7 bits of duct tape stuck on various pipes - is the plumber using these to signify something? Having duct tape on new copper seems a bit weird to me. And secondly, I counted 4 or 5 lever valves that are in the closed position. Why are parts of the system shut off? Typically valves are in the open position and only closed for servicing or when there's a problem.

If possible could you upload another picture 6 (the one before the secondary pump, of the DHW cylinder) but from further back, to show that white box with Grant and the yellow warning sticker on it, and down as far as the floor. Thanks.

Grant Aerona 3 10kW

Thanks both, picture attached (apologies if I'm not addressing all queries, perodically looking at this whilst working so not my full attention today.) Let me know if need further pictures etc.

I'm flummoxed he overlooked the flow rate, unless whilst he last attended it wasn't like that.

What's frustrating is this isn't a small time plumbing firm, they're working with the builder and architect on multiple projects, what is a concern is some of them have been sloppy with mistakes etc, so I could see someone turning something off to do something then forgetting. Much like when someone installed the delayed radiator downstairs and left the cap off the LLH, which overnight caused a lot of water to come from there and into the utility (just happened that was one day we didn't go in the utility). There's been many different plumbers from the firm on site (I've seen 4 or 5, and know someone else did this pipe work) so there's no continuity all the time.

I messaged him the flow rate photo and he said that is very low. I'm concerned on expertise here though. The one I'm chatting with from the firm is supposedly their ASHP specialist (he numerous times has changed the settings etc).

I'll query everything raised, especially the LLH model as it's not Grant (does seem odd that).

Someone leaving the small cap and a lot of water loss (well to a layman, a lot on the floor to point took a lot of mopping up a dehumidifier to clean up, in a couple hours it 2/3 filled a 2L bowl when I left it under there until plumber turned up). Could that have instigated an issue? This was really when things started to be a problem. Before that the settings weren't set as high, so rads weren't that hot, but we also hadn't really setup temperatures to be decent on/off rates (I think for example it was 21c on, 16c off, and numerous times in day so maybe didn't have a chance). Just wondering if there's a coincidence here.

I'll query the shutting off of valves. The duct tape I heavily suspect is for identification purposes (they're not fully wrapped round etc), but will query too.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 795 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That’s my pleasure, @andrewj. The only challenge now is...

By Majordennisbloodnok , 6 hours ago

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 7 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 7 hours ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 8 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 8 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 8 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 9 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 9 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 9 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 13 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 16 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 17 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 2 days ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 2 days ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 2 days ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 2 days ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 2 days ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago