Ecodan - is there actually such a thing as a 'minimum' flow temp to avoid cycling, and why if so?

A difficult topic for me to explain lucidly but I hope the following makes enough sense:

I note @gary has written a number of times about this, advising his minimum flow temp is 32C before his Ecodan cycles (though I've also seen him mention use of a thermostat to stop his system above desired indoor temp, so there may be more to it).

At a stable, decent (16L/min) flow rate, I've seen mine run for one and two hour cycles over one or two days at 30C flow temp setpoint then the next day cycle every 17 mins at between 31 and 34C, then cycle every 20-30 mins at 30C again the following day - there doesn't seem to be any consistency to it.

OAT is probably being factored into the Mitsubishi outdoor unit power 'algorithm' (though I doubt it's finessed enough to be warranted being called that) so the stable flow temp of each unit may vary based on local conditions at runtime?

I've also seen it modulate as low as 0.7kw (and 0.8 and 0.9) for one - two hours in succession, but then see it struggle to maintain 20+ mins at a tickover at 1kW.

The bigger picture is, I have the compensation curve almost perfect for indoor temps but it invariably cycles, and therefore creates stress on components and reduces efficiency. I'd like to find out why this is so. The only way it seems I can reliably avoid cycling is running flow temp at +5C above said comp curve, which then means I have to reduce the flow rate to maintain comfortable temperatures which in turn likely causes overshoot cycling!

Am aware that Mitsubishi controllers with auto-adaption seem to avoid cycling - may have to use if I can't resolve otherwise.

Any thoughts welcome.

32C is the lowest my system will go without cycling but at that flow temp the heat input is higher than the heat loss so the thermostat has to cut in to prevent overheating.

Posted by: @rhh2348A difficult topic for me to explain lucidly but I hope the following makes enough sense:

I note @gary has written a number of times about this, advising his minimum flow temp is 32C before his Ecodan cycles (though I've also seen him mention use of a thermostat to stop his system above desired indoor temp, so there may be more to it).

At a stable, decent (16L/min) flow rate, I've seen mine run for one and two hour cycles over one or two days at 30C flow temp setpoint then the next day cycle every 17 mins at between 31 and 34C, then cycle every 20-30 mins at 30C again the following day - there doesn't seem to be any consistency to it.

OAT is probably being factored into the Mitsubishi outdoor unit power 'algorithm' (though I doubt it's finessed enough to be warranted being called that) so the stable flow temp of each unit may vary based on local conditions at runtime?

I've also seen it modulate as low as 0.7kw (and 0.8 and 0.9) for one - two hours in succession, but then see it struggle to maintain 20+ mins at a tickover at 1kW.

The bigger picture is, I have the compensation curve almost perfect for indoor temps but it invariably cycles, and therefore creates stress on components and reduces efficiency. I'd like to find out why this is so. The only way it seems I can reliably avoid cycling is running flow temp at +5C above said comp curve, which then means I have to reduce the flow rate to maintain comfortable temperatures which in turn likely causes overshoot cycling!

Am aware that Mitsubishi controllers with auto-adaption seem to avoid cycling - may have to use if I can't resolve otherwise.

Any thoughts welcome.

Cycling will occur if the heat demand (measured in kW) from the house is less than the minimum output of the heat pump (also measured in kW), which is basically a property of the compressor. For any given heat pump the flow temperature at which this occurs will vary from house to house. So (in broad terms) if I have a tiny house with only one radiator, it will cycle even at high flow temperature. If I have a massive house with 30 radiators it will cycle at a very low flow temperature. Even for any given house/heat pump combination it will vary depending on outside temperature and how warm the house is.

You can increase the heat demand artificially (and thus delay the onset of cycling) by increasing the flow temperature, (because the emitters will emit more heat as the FT increases), but of course this also increases the house temperature.

Im not sure how autoadaption helps because minimum output is an intrinsic property of the compressor. It may play games with flow temperature and time or it may modulate the compressor more gently. I have seen diagrams where, even when operating at min output, compressor frequency is increased above minimum on start up in each cycle, which of course raises the FT to target more quickly, but then also inevitably overshoots target more quickly, if that were suppressed it might do better. This 'autoadaption' effect is Mitsubishi specific and I dont have a Mitsubishi!

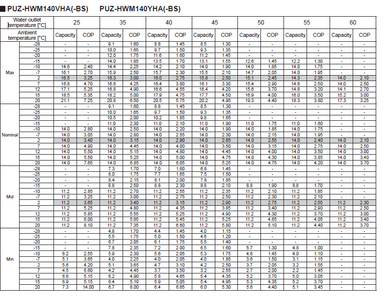

Hope that helps a bit at least. Mitsubishi publish performance tables with min and max output as a function of flow temperature and outdoor temperature, the detail they give is some of the most comprehensive of any manufacturer. Below is an example

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

On an Ecodan the std compensation curve mode only allows the flow temp to drift by 1 or 2C before it shuts off on auto adapt the allowable drift is programmable upto +5C.

So you are correct James it just delays cycling by allowing the flow temp to increase above the set point

... which presumably will reduce the cycling frequency but not materially change the on/off ratio (which is determined by the ratio of demand to minimum output)

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Yes it’s really there to allow the heat pump to vary the flow temp above the set point if the room temp is significantly below the set point and then to back it off so it doesn’t overshoot but does help with cycling at the expense of on and off periods

Is that the basis for all cycling - for example, if dT between LWT and RWT is too high, it means the house can't/doesn't need to absorb more - or are there other separate reasons (excluding defrosting) why it would; if the HP is stable for 75 mins why does it cycle then go for another 90 mins?Cycling will occur if the heat demand (measured in kW) from the house is less* than the minimum output of the heat pump (also measured in kW), which is basically a property of the compressor.Posted by: @jamespa

I've often (but not consistently) seen that when the curve flow setpoint and/or OAT changes (independently, the former doesn't change immediately as a result of the latter), it cycles - which feels clumsy (why not just reduce compressor freq - and also see below). Do others see the same?

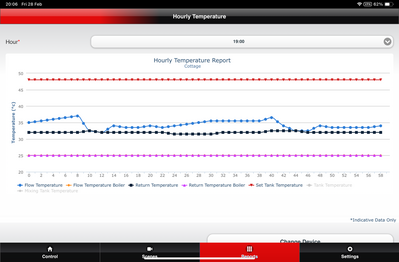

Looking at my charts for last night, at a temporary elevated flow setpoint of 38C and reduced flow rate of 9L/min, and OAT of 2 and 3C, it ran for 3 hours without cycling with the flow temp starting at 39 and finishing at 41C (maintaining a dT of 6). I suspect it calculated the next flow temp it had to go to at that point and probably thought 41.5 / the dT would be too much so it cycled**? It then ran for another 50 min cycle*** before the curve setpoint dropped 1C (to 36.5) and then it was back into shorter cycles.

* does this usually manifest in the dT rising too much?

** that being the case, why didn't it try to modulate down a little

*** so I assume the heat demand from the house was still there, in which case why did the first cycling occur?

The databook for my 6kW shows the capacity at 2C OAT and min load is 3.4 at 35C-40C and 3.8 at 25C - indicating a flow setpoint/temp of 30 needs a capacity of around 3.6(kW?). For the two long runs, output power was at or slightly above those once it had settled, so I don't think that caused the cycling in these instances.

So in the case of Gary's 32C, and my tentative 36C, these are just the mode values - they won't work every single time due to the variables you've stated?So (in broad terms) if I have a tiny house with only one radiator, it will cycle even at high flow temperature. If I have a massive house with 30 radiators it will cycle at a very low flow temperature. Even for any given house/heat pump combination it will vary depending on outside temperature and how warm the house is.

This implies my experiences aren't as a result of low volume but perhaps instead of undersized rads?

One of the (many) things I feel Mitsubishi's HP does badly is the balancing of modulation and its ferocity thereof - at the merest (0.5C) drop in flow temp, I see it go from low modulation/comp freq at 4 CoP to mid frequencies over 20 mins then overshoot/cycle/give up, when it should just apply a little more compressor and ease off when it returns to the previous flow temp it was happy with!Im not sure how autoadaption helps ... It may play games with flow temperature and time or it may modulate the compressor more gently.

Ref off/on vs cycling, I do see mine infrequently switch the compressor off for longer periods of time whilst continuing to circulate the previously-heated liquid - I'd have to look at previous occasions to see if I can see any patterns as to when it does this, but annecdotally off/on seems to happen more frequently in higher OATs.

Posted by: @rhh2348Is that the basis for all cycling - for example, if dT between LWT and RWT is too high, it means the house can't/doesn't need to absorb more - or are there other separate reasons (excluding defrosting) why it would; if the HP is stable for 75 mins why does it cycle then go for another 90 mins?

To the best of my knowledge demand < minimum output is the only reason for cycling other than defrost, unless of course there is something else (eg a thermostat) controlling the heat pump, someone may correct me. However heat pumps do vary in their precise control strategy so how this manifests may vary.

Posted by: @rhh234838C and reduced flow rate of 9L/min, and OAT of 2 and 3C, it ran for 3 hours without cycling with the flow temp starting at 39 and finishing at 41C (maintaining a dT of 6). I suspect it calculated the next flow temp it had to go to at that point and probably thought 41.5 / the dT would be too much so it cycled**

The heat pump will have some hysterisis limits, ie the max excursion of FT before it cycles. Sounds like its 3-4C in your case. It will also have a minimum 'off' time.

Posted by: @rhh2348* does this usually manifest in the dT rising too much?

The most likely trigger for it to switch off is flow temperature going too high. DT rising (at constant water flow rate) would indicate an increased demand not a reduced demand.

Posted by: @rhh2348** that being the case, why didn't it try to modulate down a little

perhaps it was already running at min compressor frequency.

Posted by: @rhh2348

This implies my experiences aren't as a result of low volume but perhaps instead of undersized rads?

Low volume will increase cycling frequency but wont materially affect the on/off ratio (but see comment below). Undersized rads will result is a colder house at any given flow temperature. Upsizing the rads will allow you to reduce the FT but, unless you increase the house temperature, wont fix cycling because the house demand (at any given ITA/OAT combination) is the house demand (ie the loss from the house)

Posted by: @rhh2348but annecdotally off/on seems to happen more frequently in higher OATs.

of course it does, house demand is less when the OAT is higher and so the minimum output is more likely to exceed demand.

Posted by: @rhh2348One of the (many) things I feel Mitsubishi's HP does badly is the balancing of modulation and its ferocity thereof - at the merest (0.5C) drop in flow temp, I see it go from low modulation/comp freq at 4 CoP to mid frequencies over 20 mins then overshoot/cycle/give up, when it should just apply a little more compressor and ease off when it returns to the previous flow temp it was happy with!

I have observed this in some mitsubishi plots. Increasing system volume would help with this, possibly quite a lot. Add a volumiser.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

At the time of the example I gave, it seemed to be <= 3C, yes - however I think that Mitsubishi's algo varies this depending on other readings; flow rate and/or setpoint - at a higher rate and lower setpoint, I've seen it only allow for flow setpoint + 2C, for example, and when it does the silly ramp ups, it gives up at +5C!The heat pump will have some hysterisis limits, ie the max excursion of FT before it cycles. Sounds like its 3-4C in your case.Posted by: @jamespa

Yes, however I'd question their algo again here - the compressor should modulate down a little rather than pushing the flow temp up to chase the dT.The most likely trigger for it to switch off is flow temperature going too high.

It should, however I imagine it's actually just a too-aggressive algo; logic would say that the unit should stay at the maximum flow temp to keep it running rather than cycle in that situation - i.e. if demand is still there, give what heating it can rather than none!?DT rising (at constant water flow rate) would indicate an increased demand not a reduced demand.

Nope, it had two steps down of wriggleroom...perhaps it was already running at min compressor frequency.** that being the case, why didn't it try to modulate down a little

For clarity, I assume here that cycling refers to unhandled/unexpected stops rather than off/on is a controlled stop (in Mitsubishi's case, usually as the flow temp is high enough to continue heating by circulating only).Low volume will increase cycling frequency but wont materially affect the on/off ratioThis implies my experiences aren't as a result of low volume but perhaps instead of undersized rads?

I understood it to be that if you upsize a/the rad(s) then the effective output (room temp) would go up at a constant flow rate thereby increasing the house temp.Undersized rads will result is a colder house at any given flow temperature. Upsizing the rads will allow you to reduce the FT but, unless you increase the house temperature, wont fix cycling because the house demand (at any given ITA/OAT combination) is the house demand (ie the loss from the house)

Similarly, increasing the flow rate without replacing rad(s) does the same and reduces the likelihood of overshooting / dT getting too large. This invariably means lower flow temps and the reason for this post, however, volumiser comments below...

I was referring specifically to off/on vs cycling and the unit going again shortly after, but yes, thinking about it again now, off/on happening naturally at higher OATs is fairly obviously more likely.of course it does, house demand is less when the OAT is higher and so the minimum output is more likely to exceed demand.but annecdotally off/on seems to happen more frequently in higher OATs.Posted by: @rhh2348

Was on the list as a possible option. Initially I decided not to install as I'd calculated system volume and felt it was significantly-more than Mitsubishi state is needed (9 -> 34L, average/warm climate -> "colder climate") and therefore not needed.I have observed this in some mitsubishi plots. Increasing system volume would help with this, possibly quite a lot. Add a volumiser.One of the (many) things I feel Mitsubishi's HP does badly is the balancing of modulation and its ferocity thereof - at the merest (0.5C) drop in flow temp, I see it go from low modulation/comp freq at 4 CoP to mid frequencies over 20 mins then overshoot/cycle/give up, when it should just apply a little more compressor and ease off when it returns to the previous flow temp it was happy with!Posted by: @rhh2348

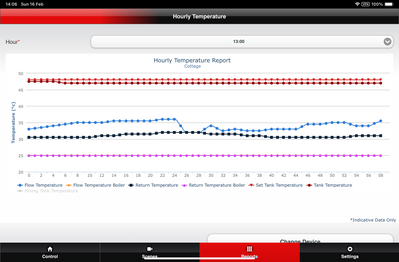

So, taking another example from a couple of weeks ago: OAT of 5C, setpoint 32C, flow 16L/min, dT 4 = short cycling* when flow = setpoint + 2C. (* which I'd suggest is anything < 75 mins - on my setup, it is usually approx 30 mins).

When the OAT went down to 4C, setpoint went up 0.5C to 32.5C, flow = setpoint + 2.5C, output was good at 4+kW, CoP around 4 - went for nearly 2 hours before cycling, seemingly only because the OAT dropped briefly to 3C then back to 4C.

Three days before that, same conditions and it short-cycled again when flow = setpoint + 2C. (* apart from when OAT briefly toyed with 3C and I got 40 mins!)

- Would a volumiser or some other alternative reduce cycling to a minimum at OAT c. 4-7C, or is this the algo, do we think.

- Moreover, I'd say OAT or setpoint changes account for 35% of cycling - if this is also the algo's reaction, I doubt there's much that can be done

- One extreme alternative is perhaps to invest in a pump that can change flow rate based on flow setpoint or dT...

Posted by: @rhh2348

The most likely trigger for it to switch off is flow temperature going too high.

Yes, however I'd question their algo again here - the compressor should modulate down a little rather than pushing the flow temp up to chase the dT.

It can't once it has got to minimum frequency. If it isn't already at mine frequency then I agree.

Posted by: @rhh2348; logic would say that the unit should stay at the maximum flow temp to keep it running rather than cycle in that situation

That would overheat the house. If house demand is less than min output it must either cycle or overheat the house.

Posted by: @rhh2348Was on the list as a possible option. Initially I decided not to install as I'd calculated system volume and felt it was significantly-more than Mitsubishi state is needed (9 -> 34L, average/warm climate -> "colder climate") and therefore not needed.

Yeah that's a minimum to guarantee defrost which, unlike cycling, is a bit fatal if it goes wrong. More system volume will reduce cycle frequency, but you need a fair amount.

Posted by: @rhh2348Would a volumiser or some other alternative reduce cycling to a minimum at OAT c. 4-7C, or is this the algo, do we think.

That's the best way to increase system volume so it will reduce cycling frequency (greater on time, greater off time). However, other than possibly in marginal cases near the onset for cycling,it won't materially affect the temperature at which it cycles because that is determined by the minimum output.

Posted by: @rhh2348One extreme alternative is perhaps to invest in a pump that can change flow rate based on flow setpoint or dT...

That won't necessarily help. The key is not DT it's min compressor output. You need either a heat pump with a wider modulation ratio or one with a max output better matched to your house if cycling is to reduce

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

First thought is that cycling is a designed in process. And Mitsubishi appears to to have a 20 minute minimum run time for normal operation with 3 to 5 minute off time between cycles.

this means that at 30c flow temp the temps are gentle on the compressor. And if the restart is only 3 to 5 minutes away the restart temp is still up at around 26c. So it is generally believed that cycling at these low temperatures and low temp differences is less stressful than perceived.

Regarding whether the operating system is inconsistent or consistent this can be very disconcerting at times for us all since, in the beginning, we don’t know what “consistent” actually looks like.

whether shortish cycles or longer cycles I think I see a degree of consistency in how the compressor responds to the return temperature and adjusts compressor output.

it may not adjust in a conscious way( if it were you or I in control.) but the algorithm appears to be searching for the best flow temp based on WCC is asking for. And if it can’t sustain operation at the flow temp requested it deliberately raises its flow temp for 6 or 8 minutes before shutting down. To me this is consistent behaviour.

But you’re right- total radiator volume is crucial to operating at lower flow temps because you need to be able to ditch the minimum kw of 3kw or 3.2kw in your HP size case. And system volume is also very important to carry it and overcome defrost scenarios in colder weather.

If the radiator cannot lose the required heat then the return temperature comes back too high, squeezing the DT until the Lowish flow temp cannot be maintained any more. So it has to cycle. If you have a large enough emitter capacity then the minimum HP output can be satisfied at the lower temperature flow temp you are looking for. The lower flow temp also means your room temperature is not going to be reached too quickly, so avoiding room stat shutdown.

Does this make any sense?

Can you list your total system volume and DT50 rating of all your radiators/UFH? This might help clarify if you’re light in capacity.

Posted by: @sunandairbut you’re right- total radiator volume is crucial to operating at lower flow temps because you need to be able to ditch the minimum kw of 3kw in your HP size case.

Aren't you potentially confusing two things here. OP could of course increase rad size/ volume and reduce ft but that won't change the minimum output required because that's determined by the house. So unless the min output of the heat pump reduces with reduced ft, or he allows the house to get warmer, this doesnt help with the range of temperature over which cycling occurs, although the increased volume should reduce the cycling frequency (but on off ratio won't change)

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 451 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 4 minutes ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 6 minutes ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 40 minutes ago

-

RE: What determines the SOC of a battery?

The answer from Fogstar was crisp. My hypothesis, su...

By Batpred , 1 hour ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 1 hour ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 1 hour ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 4 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 4 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 7 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 23 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago