OK, I've set all the TRVs to 30 degrees, permanent, and will see what happens.

If it starts getting too hot, I'll reduce the weather curve "offset" temperature a little.

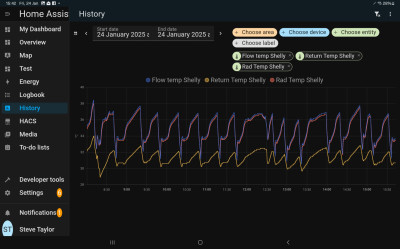

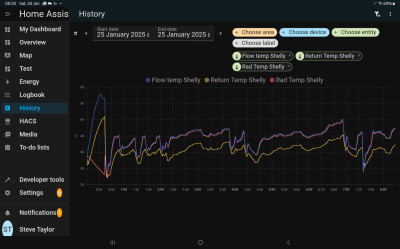

I've had it running with all the smart TRVs set to 30 degrees since 08:45 this morning, and it's still cycling.

Lockshields are set pretty much right, as all the rooms are more or less at the right temperature.

All the radiators are pretty even - all taking heat from the water, no cold ones.

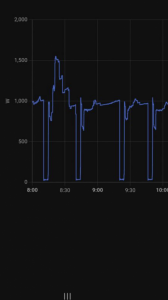

I don't understand why the heatpump just keeps running at 900 watts as it approaches the setpoint, rather than modulating down to the 650 watts that it occasionally manages to run at.

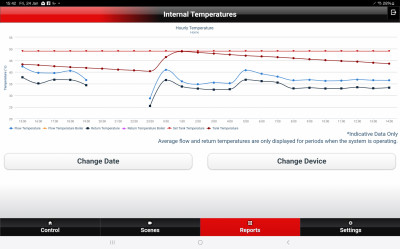

The data from MelCloud looks pretty smooth, but the hourly average data disguises what's really happening.

Just a thought, but would the Mitsubishi wireless thermostat and receiver control the heatpump differently in WC mode, or it it basically an on-off control device. I know that the wireless thermostat has a room temp sensor for use in room adaptive mode.

Is my issue just that the heatpump is missing some data that would make it modulate, because I'm using a basic "on-off" relay that's currently permanently on?

Posted by: @clockworksI don't understand why the heatpump just keeps running at 900 watts as it approaches the setpoint, rather than modulating down to the 650 watts that it occasionally manages to run at.

The data from MelCloud looks pretty smooth, but the hourly average data disguises what's really happening.

@clockworks can you confirm is the 900w you refer to consumption or is it output? If it’s consumption then that’s about right… assuming a cop of 3 which is quite likely.

also your graph showing power is only showing 2 cycles per hour. Which ain’t too bad. Has your cycling improved?

what was the outside temp when this graph was recording?

Outside temperature as reported by the ASHP sensor during the period of the graphs, 8 or 9 degrees.

Yes, 900watts is the consumption. Measured by a Shelly EM clamp, on the mains supply from the CU to the heat pump, so it includes the controls and pumps.

This does seem to be it's "preferred" low power setting, but, as you can see on the full graph, it will sometimes drop below 700watts. Odd that it nearly always dips to 700watts near the beginning of a cycle, but only very rarely in the middle or end.

The cycling does seem to vary in frequency. Mostly every 20 minutes, sometimes 30 minutes, occasionally an hour.

Having all the rads "open" has reduced the frequency somewhat - with some rads closed, it was mostly 20 minutes, with some of just 15 minutes.

Looking more closely at the graph posted the other day, I can see that the minimum rated output is over 3kW from this unit, so maybe it really can't go much below 900watts input for any length of time?

Thing is, pretty much everyone says "cycling is bad" and "run it slow and low".

Do they really mean "don't keep powering off and on with a thermostat or programmer" and "keep the radiator temps low and steady"?

This is what it's doing now, back to 20 minute cycles

Posted by: @clockworksHaving all the rads "open" has reduced the frequency somewhat - with some rads closed, it was mostly 20 minutes, with some of just 15 minutes.

Looking more closely at the graph posted the other day, I can see that the minimum rated output is over 3kW from this unit, so maybe it really can't go much below 900watts input for any length of time?

Thing is, pretty much everyone says "cycling is bad" and "run it slow and low".

Do they really mean "don't keep powering off and on with a thermostat or programmer" and "keep the radiator temps low and steady"?

The first thing I have seen in your graphs is that opening the TRVs has allowed the emitters to offload more heat, making your home somewhat warmer. In turn this has improved cycling to 30 minutes which is within the Mitsubishi accepted tolerances of cycling.

The second thing I’ve noticed is that consumption of 900 watts at a cop of 2.8 to 3 and a ambient temp of between 8 to 15c puts your HP on the borderline of cycling because of its minimum output limit of circa 3kwh. (900w X cop3 = 2.7kw) As you’ve acknowledged in your comments above.

(FYI I believe the HP operating system has a minimum ‘on’ time of 20 minutes. It will try to operate for a minimum period of 20 minutes before shutting down. It appears to do this by raising the flow temp briefly for 20 minutes and then close down for a short pause if it cannot operate at the target flow temp.)

So you may be able to continue to improve and refine your system by just fine adjustments to your WC curve to reduce or even eliminate rapid cycling in mild weather.

An important take-away from this is that a small amount of cycling is acceptable and often inevitable in milder weather.

Cycling every 15-30 mins is not ideal for wear and tear on the unit, no, but your efficiency is 'ok' by most standards which is the key impactor of running costs.

It sounds like the system is struggling for volume as others have said only at certain points in operation, if the TRVs are closing and restricting flow to the rads. It often comes around that these smart TRVs fight the heat pump's own temperature programming or at least interfere with it, especially if it is running in weather comp mode.

Ideally when the system was fitted the installer should have provided/conducted room by room heat losses and sized the radiators according to the temperature requirements in each room and the respective heat loss with flow restriction being used only in places like bedrooms where the required temperature may change over time (for example where occupancy varies). As others have commented a heat pump works best with minimal controls.

If you could confirm if this sequence of events looks correct:

When heat pump turns on and runs until room temperatures are satisfied, the TRVs shut down flow to the radiators more or less all at the same time, eg you set the smart TRV to 21 degrees c room temp, the heat pump satisfies this, the TRV closes and the heat pump begins to cycle?

How many smart TRVs do you have, one in each room, and what are these set at in terms of temperature?

Heat pump consultant and designer at Cirrus Energy.

Thinking about installing a heat pump? Or already have one but it’s not performing as it should? Book a one-to-one session with Rob to discuss things here.

The graphs I posted yesterday were with all the smart TRVs permanently set to 30 degrees, so the rads were all "open" from about 09:00.

This did reduce the cycling somewhat, but by mid afternoon it was back to doing 20 minute cycles. All the rads were still open.

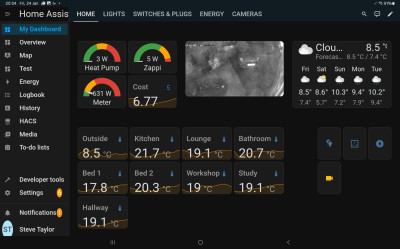

This is the room temps just after 20:00 yesterday, after 11 hours of running with the smart TRVs open in all rooms.

Leaving the ASHP to just do what it wanted, with no outside controls, most of the rooms ended up where I wanted them, so the flow temp set by the WC curve is about right.

The exception is the lounge, whis is a degree or so low. I think this is down to poor insulation in the loft space above, and is being addressed soon.

The kitchen/diner is a tiny bit warmer because of cooking around 18:00.

The "workshop" and "study" are the 2 small bedrooms in the dormer.

Bedroom 2 is running with the lockshield fully open, so gets a bit too warm without the TRV operating.

Bedroom 1 is running cooler on purpose, restricted with the lockshield.

Note that these temps are all with the smart TRVs set to 30 degrees as an experiment, so the TRVs were permanently fully open.

There are 10 radiators being used - the lounge and kitchen/diner both have 2 rads - and 9 of them have smart TRVs.

All except one (bedroom 2 which is undersized) of the radiators are sized to the design calcs.

There are 2 more rads - conservatory and upstairs shower room - but these are permanently off.

The heating schedule turns off the ASHP at 8pm, and back on again at 11:30pm when the cheap rate period starts.

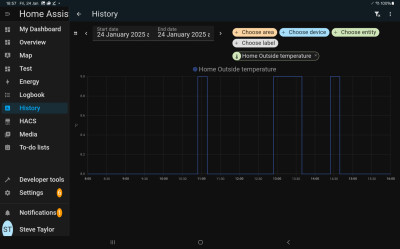

Overnight, the outside temperature dropped to 2 degrees, having been 8 degrees yesterday:

As you can see, cycling was reduced dramatically because the room temps had all dropped by a degree or 2 in the 3.5 hours the heating was off - just 2 degrees outside, which is pretty much as low as it gets here in Cornwall. ASHP sensor is actually reporting 1 degree.

It really does look like the house can't lose heat fast enough for the minimum output of the heatpump, unless the outside temp is below 5 or 6 degrees.

Although the heatpump was sized to the heatloss calcs (6kW heatpump, 5.8kW heatloss), in reality the house just doesn't need that much heat.

I think I posted earlier that the ASHP consumed 29kWH on the coldest day ( zero all day, an exceptionally cold day for this area), which works out at less than 4kW of heat per hour, averaged across the day.

Part of the problem was they used HDD numbers for Plymouth - around 1800 HDD. Actual HDD from my local weather station (Culdrose) is just over 1400.

I also think the calcs use excessive air-change figures. There's only 2 of us in the 4 bed house, so far less door openings, etc.

Also DHW consumption figure used is way too high, as we have electric showers and a dishwasher. DHW was calculated at something like 8kWH a day, and we are using less than 2kWH.

Undoubtedly all to MCS spec to qualify for the grant, but it looks like we've ended up with an over-sized unit that just can't run low enough much if the time.

Having said all that, the running costs seem OK - on par with oil, for a warmer house.

Posted by: @clockworks

Thing is, pretty much everyone says "cycling is bad" and "run it slow and low".

Do they really mean "don't keep powering off and on with a thermostat or programmer" and "keep the radiator temps low and steady"?

"cycling is bad" - cycling can either indicate the inevitable result of the heat demand falling below the heat output of the pump or it can be a failure of the interaction of the heat pump and the heating system and controls (eg a thermostat turning the pump on and off because it is fluctuating around its hysteresis settings). If this occurs several time an hour it is undesirable, and known as short cycling, but as this term is not really defined anywhere it does cause uncertainty as to whether that is what is happening.

Your cycling is in the first category and the wave forms shown in the first graph are very familiar to me as they look just like the way my EcoDan ran under WC, although there was also a room thermostat involved. There are always fluctuations in the power draw which seem odd, particularly the dip as it restarts but it is always like that so must be a result of the way the process gets going. I rarely get an even, sustained power draw.

As OATs rise your heat demand will fall, eventually to zero, so at some temperature point ALL units will start cycling - unless they are run hotter but within such time restrictions so the house isn't overheated over a period - in practice this depends on the thermal inertia of your particular house.

However, I found Room Mode, aka Auto Adapt, to be both more efficient and reduce cycling. It is not just a limiting thermostat, it provides the system with the actual and target room temperatures allowing it calculate the effects of adding quantities of heat. In situations where minimum pump output exceeds heat demand it can choose to run for longer and allow the FT to get hotter by calculating how much 'extra' heat is being added compared to the instantaneous requirement, then follow this by having a longer off period afterwards. My system went from typically cycling four or five times an hour to once. As OATs rise the off periods just get longer.

Mitsubishi EcoDan 8.5 kW ASHP - radiators on a single loop

210l Mitsubishi solar tank

Solar thermal

3.94kW of PV

Thanks for confirming that what I'm seeing is just "how it is" with the design of the Ecodan.

It puts my mind a rest to a degree - not perfect, but there's nothing I can really do about it - except for maybe trying Auto Adapt. I did wonder if the unit would allow more overshoot, or modulate down better if it knew what was going on in the house. It seems like it would work that way.

When my system was installed, it came with the Mitsubishi indoor wireless thermostat and the matching receiver. It wasn't fitted, just left here with me.

I've found a video showing how to fit the receiver and pair it with the wireless unit, so I guess I could just disconnect the Honeywell boiler relay, and fit the Mitsubishi unit - one plug into the FTC, change a DIP switch, pair, and it's done.

I could then just use some of the Honeywell Evohome TRVs as programmable limiters on the bedrooms, but leave the Mitsubishi wireless unit to handle the "call for heat".

The only problem will be - where to site the wireless unit? I'm guessing the kitchen would be best, as that's the room that's currently running with pretty much zero external controlling. I just hope the wireless signal will go that far - 15 metres through several solid walls

If you want to use auto adapt then you will either need to get the main controller sited somewhere where it can get a good temperature reading or as you say install the wireless thermostat.

Autoadapt is better at predicting demand and it does allow more freedom in terms of flow temp deviations from the baseline so it’s worth exploring.

The wireless controller will modulate the HP and reduce output as the HP approaches the target room temp- but only when in Auto Adapt mode.

When operating in WC mode the wireless controller just acts as an upper temp limiter. In weather compensation mode you are relying on the accuracy of your own weather curve to gently feed heat into your home and to stay mostly below the set temperature.

Other features include instant push button DHW reheat

half-degree increment temp adjustment and reporting. Rather than 1 degree increments on the main controller.

Some questions. Is your property upgraded with insulation? Walls, ceiling, windows, loft? Do you have old plumbing and upgraded or existing rads in your 1960s dormer bungalow.

Do you have any micro-bore piping or plastic piping? This might be one reason for fitting a Low Loss Header based on a degree of provision for unknowns from the designer.

Posted by: @sunandairThe wireless controller will modulate the HP and reduce output as the HP approaches the target room temp- but only when in Auto Adapt mode.

When operating in WC mode the wireless controller just acts as an upper temp limiter. In weather compensation mode you are relying on the accuracy of your own weather curve to gently feed heat into your home and to stay mostly below the set temperature.

Other features include instant push button DHW reheat

half-degree increment temp adjustment and reporting. Rather than 1 degree increments on the main controller.

Some questions. Is your property upgraded with insulation? Walls, ceiling, windows, loft? Do you have old plumbing and upgraded or existing rads in your 1960s dormer bungalow.

Do you have any micro-bore piping or plastic piping? This might be one reason for fitting a Low Loss Header based on a degree of provision for unknowns from the designer.

It has cavity wall insulation, and reasonable loft insulation over most of the rooms. All widows are double-glazed. Windows are quite large, but we have thermal curtains which get closed. I'm looking to get someone up in the loft to add more over the lounge and bathroom - the 2 rooms that suffer the biggest temperature drops when the heating is off. The dormer is quite small - around 18sq mt - and appears to have rigid insulation between the plasterboard and marine ply skins. Not sure about the flat roof over the dormer, but heatloss overnight from these 2 rooms seems not too bad at around 2 degrees in 9 hours when it's 2 degrees outside. One 500x600 and one 600x600 T22 radiators can keep them at 19 or 20 degrees.

EPC done for the grant came back as D. Just one point off getting a C. It should've got a C, but the chap doing it missed the fact that the old vented cylinder had a thermostat on the immersion element.

When it was built, it had an open fire in the lounge, and an oil Rayburn with back boiler and one radiator in the dining room. A neighbour with an identical bungalow, completely as-built, still has the Rayburn.

Central heating was added by a previous owner in the late 1990's. Oil system boiler in the attached garage, 22mm copper up into the loft, and 15mm copper to all but one radiator.

Some time later, the separate toilet and bathroom were knocked into one, and the bathroom radiator was added in 15mm plastic.

No microbore anywhere.

The installer said they always fit LLH now, as they had issues in the past educating users not to rely on too many TRVs to close down the heating. Makes the system idiot-proof, so I can see why they fit them.

Edit to add:

2 additional radiators were fitted, lounge and kitchen/diner, as part of the ASHP install. All the others were deemed up to spec.

The one in the "workshop" will get upgraded at some point. The existing one is fine for a bedroom at 18 degrees, but needs to be bigger for me to work in there at 20 degrees.

- 27 Forums

- 2,520 Topics

- 58.6 K Posts

- 404 Online

- 6,800 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Daikin Altherma 3 LT compressor longevity question

@bobflux With my limited HA skills I can't ad...

By Ubert767 , 30 minutes ago

-

Hi all I'm having some trouble with a Grant ASHP and ...

By Renewables345 , 51 minutes ago

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

You are absolutely correct that the capacity table MUST...

By JamesPa , 58 minutes ago

-

RE: Heat Pump vs New Gas Boiler for Inherited House - Worth the Extra Cost?

@fretless6, where are you based? I might be able to con...

By Mars , 2 hours ago

-

RE: Underfloor Heating Installation Issues with Heat Pump

I'm going to install Thermacome ACOSI+ radiant ceiling....

By bobflux , 3 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Now seems a good time to summarise the costs and effici...

By benson , 4 hours ago

-

RE: Tell us about your Solar (PV) setup

@mk4 Charge to 100%, discharge down to 10%.

By bobflux , 5 hours ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

The simplest wired option is usually the Growatt Ethern...

By Jonatan , 10 hours ago

-

RE: Electricity price predictions

@jamespa And it seems some of the nasty public cloud...

By Batpred , 18 hours ago

-

RE: Jokes and fun posts about heat pumps and renewables

Technology is rapidly advancing. BBC News reported th...

By Transparent , 21 hours ago

-

What matters for flow and pressure drop is internal dia...

By bobflux , 22 hours ago

-

RE: Do Fridges and Freezers have COP ratings?

@editor Thank you all for your replies and submitted in...

By Toodles , 1 day ago

-

I know and yes. The secondary deltaT wont necessaril...

By JamesPa , 1 day ago

-

RE: Designing heating system with air to water heat pump in France, near Lyon

Just love the way you put it! 🤣

By Batpred , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thank you for sharing. So it seems that your Schneid...

By Batpred , 2 days ago

-

RE: Forum updates, announcements & issues

@upnorthandpersonal thanks for the thoughtful, consider...

By Mars , 2 days ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

@mk4 All 21 panels have their own Enphase IQ7a microinv...

By Toodles , 2 days ago

-

RE: Setback savings - fact or fiction?

Great, so you have proven that MELCloud is consistently...

By RobS , 3 days ago

-

RE: Mitsu PUHZ120Y 'Outdoor Temp 'error?

Thanks David & James It almos...

By DavidAlgarve , 3 days ago

-

RE: Surge protection devices SPDs

@trebor12345 - your original Topic about the right type...

By Transparent , 3 days ago

-

RE: Help needed with Samsung AE120RXYDEG

@tomf I’ve been sent this from a service engineer at Sa...

By Mars , 3 days ago

-

RE: Buying large amp bidirectional RCD and RCBO

Yes... I went through this particular headache and ende...

By bobflux , 4 days ago

-

O-oh! Let's take this as an opportunity to 'pass the ...

By Transparent , 4 days ago