Posted by: @derek-mI don't just spend my time manipulating data within spreadsheets, I also observe, monitor and even record some of the changes occurring within our home. I have found that with the correct control system and using the correct control philosophy, it is possible to keep our indoor air temperature, certainly in the central hallway, at a constant 21C +/- 0.1C, with the occasional deviation to +/- 0.2C when the OAT is changing more rapidly than normal. All of this without measuring and using an OAT value.

It's good to know that this is possible. I suspect, however, that the people best able to devise a central heating control system don't work for central heating manufacturers, because there are other systems where accurate control is more important. Thus the perfect ch control system is only available to talented hobbyists.

Posted by: @kev-mI also think that the factor that has most impact wrt setback in an ASHP system is how quickly you reheat, to the point that almost nothing else matters. I have some data from when I allowed the Ecodan AA to unleash most of its power to heat the house up and I think the savings I've mentioned here were all but wiped out if not worse. I'll post the data when I get a minute.

I agree 100% which is why the 'boundary conditions' (or assumptions) to the question really matter and also why the experiment is difficult. In the limit (including some of the posted experiments) the system is never properly reheated in which case the 'prime time' temperature settles to a new 'normal' and I get lots of 'saving', but I'd possibly save as much by simply turning down the thermostat.

For what it's worth my only hesitation about your results is that you assume the setback energy equals the no setback energy after quite a short time (ie a fairly short fabric revovery). Before I had confidence in this I would like to know that the fabric has in fact been restored. I'm not suggesting you don't see a saving, just that it might not be quite as large as your simulation/experiment suggests. Of course all that really matters (unless cost is the dominant driver) is that a) you are comfortable and b) the saving is positive not negative.

Posted by: @kev-mI think you are right in that the air/house are not always in equilibrium. I've never been in one but we were always told at school that it's toasty warm inside an igloo (where thermal mass and OAT are both less than 0 degrees C). Although I suppose the walls melt rather than warm up.

It would be interesting to understand what effect the non equilibrium has. I don't think its as simple as a delay, I think it may be a combination of an accelerated heating of the air when the heating system responds, plus a delay when the outside conditions change. Doubtless it can all be described by some relatively simple differential equations (that's 'simple' relative, eg, to modelling the weather).

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

I feel certain that the Engineers who designed many of the heat pump controllers were highly capable, but the major problem is the range over which the heat pump controller is expected to operate.

My industrial type controller may require manual intervention when it goes outside it specified operating range, though it does have capabilities that I have not fully seen yet it heat pump controllers, such as the ability to be 'fine tuned' and a very useful 'ramp' capability.

If one thinks about the tasks that a heat pump controller is required to perform, it is probably more capable than a basic industrial controller.

A heat pump controller may be required to measure the OAT and calculate the required LWT, to do this it will need to control the compressor speed and possibly the water pump speed. It may also be controlling the fan speed to optimise thermal energy absorption by the Evaporator.

It may also have to be capable of scheduling heating and DHW production, along with providing the Human - Machine Interface, to hopefully keep the Humans happy.

The missing link in all this, is often the installer does not have the necessary knowledge and capability to optimise the functionality of the heat pump controller.

Posted by: @derek-mI feel certain that the Engineers who designed many of the heat pump controllers were highly capable, but the major problem is the range over which the heat pump controller is expected to operate.

My industrial type controller may require manual intervention when it goes outside it specified operating range, though it does have capabilities that I have not fully seen yet it heat pump controllers, such as the ability to be 'fine tuned' and a very useful 'ramp' capability.

If one thinks about the tasks that a heat pump controller is required to perform, it is probably more capable than a basic industrial controller.

A heat pump controller may be required to measure the OAT and calculate the required LWT, to do this it will need to control the compressor speed and possibly the water pump speed. It may also be controlling the fan speed to optimise thermal energy absorption by the Evaporator.

It may also have to be capable of scheduling heating and DHW production, along with providing the Human - Machine Interface, to hopefully keep the Humans happy.

The missing link in all this, is often the installer does not have the necessary knowledge and capability to optimise the functionality of the heat pump controller.

... and when it's all ticking over nicely, one of the Humans in the house hangs the washing on all the radiators!

Posted by: @kev-mPosted by: @derek-mI feel certain that the Engineers who designed many of the heat pump controllers were highly capable, but the major problem is the range over which the heat pump controller is expected to operate.

My industrial type controller may require manual intervention when it goes outside it specified operating range, though it does have capabilities that I have not fully seen yet it heat pump controllers, such as the ability to be 'fine tuned' and a very useful 'ramp' capability.

If one thinks about the tasks that a heat pump controller is required to perform, it is probably more capable than a basic industrial controller.

A heat pump controller may be required to measure the OAT and calculate the required LWT, to do this it will need to control the compressor speed and possibly the water pump speed. It may also be controlling the fan speed to optimise thermal energy absorption by the Evaporator.

It may also have to be capable of scheduling heating and DHW production, along with providing the Human - Machine Interface, to hopefully keep the Humans happy.

The missing link in all this, is often the installer does not have the necessary knowledge and capability to optimise the functionality of the heat pump controller.

... and when it's all ticking over nicely, one of the Humans in the house hangs the washing on all the radiators!

I remember you sending a post providing details about your system, but I don't seem to be able to find it. Would you mind posting the details again?

Posted by: @derek-mPosted by: @kev-mPosted by: @derek-mI feel certain that the Engineers who designed many of the heat pump controllers were highly capable, but the major problem is the range over which the heat pump controller is expected to operate.

My industrial type controller may require manual intervention when it goes outside it specified operating range, though it does have capabilities that I have not fully seen yet it heat pump controllers, such as the ability to be 'fine tuned' and a very useful 'ramp' capability.

If one thinks about the tasks that a heat pump controller is required to perform, it is probably more capable than a basic industrial controller.

A heat pump controller may be required to measure the OAT and calculate the required LWT, to do this it will need to control the compressor speed and possibly the water pump speed. It may also be controlling the fan speed to optimise thermal energy absorption by the Evaporator.

It may also have to be capable of scheduling heating and DHW production, along with providing the Human - Machine Interface, to hopefully keep the Humans happy.

The missing link in all this, is often the installer does not have the necessary knowledge and capability to optimise the functionality of the heat pump controller.

... and when it's all ticking over nicely, one of the Humans in the house hangs the washing on all the radiators!

I remember you sending a post providing details about your system, but I don't seem to be able to find it. Would you mind posting the details again?

I PMd you but this is what I sent:

Heat Loss 8.5kW @ -3 OAT LWT 50

Rad output 18500 at DT50

Room temp 21.5 throughout

Flow rate not sure I think about 25l/min average

DT is fairly consistent at 5

Thermal mass is going to be low - much lower than Cathoderay's

Thanks Kev, I don't seem to be able to locate the PM'd messages.

What are the WC settings and do you have anti-freeze, and if so, at what concentration?

CR's thermal mass came out at 246kWh, so would you think 150kWh would be okay for your home?

Do you have any IAT data?

Posted by: @derek-mA couple of further questions.

When do you heat DHW?

How much other electrical energy do you use that may be adding to the heating?

WC is 45@-2 / 30@25

Glycol 25%

flow rate is specified as 27l/min (I think I said 25 before)

DHW 15:00

other electrical - not much. Washing machine, dryer and fridge freezer are in an unheated utility room. It is joined to the (heated) kitchen though. Not much else.

IAT _ I can get IAT only when I've been running AA. That's one of the 3 days I sent you. It's quite easy now to get more sample days if IAT is important. Let me know.

K

Posted by: @kev-mMy method of calculating savings is as follows: (1) Measure energy consumption actuals with a setback. (2) Estimate energy consumption without a setback. (3) Subtract (1) from (2).

We are in effect using the same method, observed with setback vs expected without setback. The general method of comparing observed vs expected is widely used in epidemiology, and despite the fact biological systems are probably far more complicated than physical systems, the generally method works well, provided the necessary precautions (usually standardisation) are taken, to ensure apples are being compared with apples not oranges, and unjustified extrapolation is avoided. This last point is why we have to repeat time and again the caveat that my results only apply to my heating system in my house.

The only difference between our methods is that I have 'refined' the method used to determine the estimated/expected energy use by plotting the energy use against the OAT, and fitting a regression line/equation, and then using that equation to generate the expected values. These plots (see posts passim) have high R squared values, meaning the variation in OAT explains most of the variation in energy use, and while I have great admiration for and welcome @derek-m's and @jamespa's sterling efforts to derive a model, I do think - and this is critical - all of the necessary variables are baked into that regression equation. What I am suggesting is that the empirical result necessarily includes all of the variables, even if we don't know what they are, or how they work. This observational approach - observing an outcome without yet knowing every detail of the underlying variables and equations - has served medicine well, and I see no fundamental reason why a similar approach cannot be applied to a physical system. The key point is that all the key variables are baked into the observed result, even if that process happens invisibly.

Here is the last week's minute data for my system in my house, running without setbacks:

This is useful, insofar as it shows at least two periods of relatively stable OATs that correspond with relatively stable energy in values, again suggesting that it is not unreasonable to use the OAT to predict the expected energy use. Note also the generally stable IAT - the house is in 'energy balance'. It will be interesting to see what happens over the next few days, given the forecast is for significantly lower OATs. I suspect the IAT may dip a little (heat pump can't quite cope), and energy use will almost certainly rise sharply, partly because lower OATs need more energy in to maintain IAT, but also because lower OAT means higher LWT and that in turn means lower COP, and then of course there are those devilish defrost cycles. The lower OATs also mean I will not use setbacks, as previous experience shows the IAT struggles to recover, at lower OATs. That's OK, I just make a point of avoiding setbacks in cold weather, but that doesn't mean I can't use them to save some energy/cost in milder weather. I only have to move one slider one notch to turn setbacks on or off (change the main room stat from manual (no setback) to program (with setback) mode and back again).

Lastly, I do find it interesting that both of our observation based findings suggest saving of the order of 20%. Is this just mere coincidence, or is it in fact the tip of an unseen iceberg of more general findings? I don't know the answer, and that is why I have tried to encourage, unfortunately without much success, others who have the data to post their findings. All the more thanks to you for posting yours!

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayWe are in effect using the same method, observed with setback vs expected without setback. The general method of comparing observed vs expected is widely used in epidemiology, and despite the fact biological systems are probably far more complicated than physical systems, the generally method works well, provided the necessary precautions (usually standardisation) are taken, to ensure apples are being compared with apples not oranges, and unjustified extrapolation is avoided. This last point is why we have to repeat time and again the caveat that my results only apply to my heating system in my house.

Comparing observed vs expected is in fact comparing a model which has been created in one set of circumstances with the observations experienced in another set of circumstances. This is, to my mind, a technique of last resort. I can absolutely see why it would be used in epidemiology because

a) you cant ethically do the control experiment in many cases

b) you can't model and have little theoretical knowledge of the system, and there are no laws tested over several centuries on which you can fall back to test the sanity of what you think you are seeing

c) so long as the results show a significant enough difference, they are worth a go because you have no practical alternative other than allowing the patient to die!

Im not sure we are really in this situation here, so Im yet to be convinced of its validity in establishing a clean answer to the question, but before you react, please read on....

Posted by: @cathoderayI do think - and this is critical - all of the necessary variables are baked into that regression equation.

No they are not in when the temperatures are dynamic, at least not to the accuracy needed to measure with certainty the relatively small effect you wish to measure. Specifically variation in IAT and the heat capacity of the house (a significant effect in a dynamic situation compared to the heat loss) are not baked in. The only situation in which these are 'baked in' is if the OAT is constant for several days in a row and all the measurements related to setback at least are taken towards the end of that period, or possibly if you run experiments throughout the season so that the dynamic effects 'average out' because you get them in both directions and with a variety of magnitudes.

Also its worth bearing in mind that correlation does not equal causality! Savings of 20% due to a couple of degrees setback for 6-9 hours alone alone are simply not plausible (on the grounds of conservation of energy alone ) unless

1. you are taking significant advantage of it being warmer in the daytime than at night (in which case the savings only apply to those days and if the timings are well tuned, not to the more general case) or

2. your system is not properly tuned in the first place (in which case savings would almost certainly be larger if the system were first to be tuned, if of course that is possible, which I grant it may not be)

3. you allow the general OAT to fall (which means that that element of the saving is due to reduction in IAT not setback alone)

4. some other effect applies which is triggered by setback

As a broad brush on the results so far presented by you and others, I do not recall seeing convincing experimental evidence of 20% savings due to setback alone, but I have seen experimental evidence perhaps of savings of ~10% due to setback (which is fully consistent with the models) and perhaps a further 10% due to a general reduction in IAT or sub-optimal initial tuning, which setback, because it changes the system operating conditions, happens to improve.

Of course none of this matters provided nobody else thinks that, just by applying setback, they will get 20% savings. They might or they might not. You have clearly stated that the results apply to your home and your system only, so you have tried hard to ensure that nobody thinks that it applies elsewhere.

Posted by: @cathoderayLastly, I do find it interesting that both of our observation based findings suggest saving of the order of 20%. Is this just mere coincidence, or is it in fact the tip of an unseen iceberg of more general findings?

Having said all of that and looking at some of the data I do now think its quite possible that a fair few systems are set up in a way that means that setback will deliver savings, albeit that greater savings could possibly be had through better tuning (which may or may not be possible). A system where the WC curve isn't properly set up or which is oversized (which a large proportion of systems almost certainly are) may well benefit from being run part time, effectively stressing the otherwise underworked unit more and reducing the cycling because the amount of energy required remains, for more of the time, within the modulation range. We have seen one concrete example where this appears possibly to be the case, and one piece of evidence that cycling is worth perhaps a 5% efficiency penalty. That's hardly conclusive but is definitely food for thought.

So maybe, just maybe, setback and the associated effects on non-optimal systems will, on perhaps a majority of occasions, deliver benefits, and on some/many occasions the benefits may be bigger than one might attribute to setback alone. That's about as much as I would be prepared to say for now and we definitely need more data.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

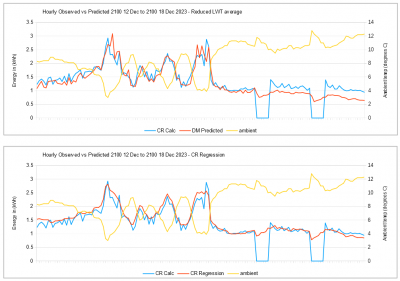

Posted by: @derek-mPlease correct me if I am misinterpreting the graphs, but the upper one appears to indicate that the Energy In would appear to be reduced, by NOT initiating a 6 hour setback.

The two charts together are intended to compare the energy in predictions from your model (upper chart) and my regression equation (lower chart) against actual energy use. The charts are identical except for the red prediction lines, with my regression equation predictions (lower chart) getting closer in this (limited time frame) chart to the actual energy use (the blue line, CR Calc means my calculated actual use, as calculated from volts times amps in). Here's the chart again for ease of reference:

Midea 14kW (for now...) ASHP heating both building and DHW

- 26 Forums

- 2,372 Topics

- 53.8 K Posts

- 229 Online

- 6,053 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Forum updates, announcements & issues

@editor — thank you @editor, and a Happy New Year to yo...

By cathodeRay , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@majordennisbloodnok — you may well be onto something. ...

By cathodeRay , 2 hours ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

2025 energy total: 7.4mW produced, 5.4mWh exported, 3.0...

By jamespetts , 13 hours ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

Thanks folks. I had tried googling an ethernet lab adap...

By z8lccda , 14 hours ago

-

RE: Data Accuracy Problem: Daikin 8kW Heat Pump's Onecta App vs MMI Power Consumption

@toodles Good evening. Thankyou for the response I...

By Nursethescreens , 15 hours ago

-

RE: Changing from 4-port buffer to volumizer

@toodles I'm not concerned that the behaviour is not no...

By Andy1618 , 15 hours ago

-

-

RE: Setback savings - fact or fiction?

I agree, and I think there are two things in play here....

By cathodeRay , 19 hours ago

-

RE: Water Hammer After Heat Pump Install

That's really helpful. Yor last sentence confirms it'...

By JamesPa , 1 day ago

-

RE: Help needed with Grant Aerona 3 issues

First time posting so bear with me. Some bits that have...

By Adamp , 2 days ago

-

RE: Mitsu PUHZ-SW120YHA + EHSC-VM20Uk - Performance

All understood. Obviously its a bit house de...

By JamesPa , 2 days ago

-

RE: Who's your electricity provider and what's your tariff?

@majordennisbloodnok This may be a better thread to ...

By Batpred , 3 days ago

-

RE: Best Heat Pump Brand in the UK

Last Call to Vote & Win! Haven't voted for your Hea...

By Mars , 3 days ago

-

RE: Solis S6-EH1P8K-L-PLUS – Why I Chose It and What I’ve Learned So Far

Interesting question. To be frank, since I have no inte...

By Majordennisbloodnok , 3 days ago

-

RE: New Fogstar 15.5kWh upright solution

The video shows the JK balancer, but the connection of ...

By Batpred , 4 days ago

-

RE: Ecodan unable to hit legionella target temp - what's the consensus?

@9jwr9 Hi, yes this is the issue with every (stand alon...

By ASHP-BOBBA , 4 days ago

-

RE: Help me keep the faith with my air source heat pump installation

@adamk FWIW I managed unintentionally to 'coax' mine in...

By JamesPa , 4 days ago

-

RE: Octopus Cosy Heat Pump Owners & Discussion Thread

You are in essence right. Adia only works with selecte...

By JamesPa , 4 days ago

-

No, you haven’t missed out, @batpred. This thread’ll st...

By Majordennisbloodnok , 4 days ago