Is this a bad installation and is there something wrong with my Samsung heat pump?

@david999 out of interest what was the heatloss figure for the property?

46lpm is correct for a 16kw heatload, however the Samsung can only output around 12.5kw at most design conditions so is not as black and white as Samsung would make out.

Did you sort your defrost issue I have seen in older posts?

@david999 I asked a few installers to look at your question regarding pipe sizes. The general consensus is that the length of the primary pipes from the heat pump to the system is crucial, as pressure loss is the main concern. A 35mm pipe results in a flow velocity of about 0.9m/s with a pressure drop of 320Pa/m, which can accumulate with other components. If the circulator doesn’t have enough residual head to meet the system's needs, you might need to use 42mm copper pipes and increase the size of some secondary pipes, or consider a circulator with a larger head.

From our personal experience adding more pumps (and more powerful pumps) adds covertly to running costs, and it can make the system noisier as the majority of these pumps will be indoors.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

@david999 - since you need this information in order to decide whether to challenge your installer, I think you'll need a regulation/directive that you can point to.

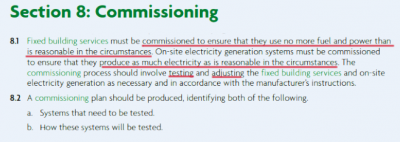

Part-L, sect-8 of the current Building Regs provides you with a valid foundation on which your argument can be based.

As @editor has stated, under-sized pipes cause greater pressure loss. That can be compensated for by using more powerful pumps (or running a pump at a higher velocity), but that uses more electricity. It's that additional electrical energy which reduces the overall efficiency, and hence fails Sect 8.1

I will also add that elbow bends cause significant pressure loss. Newton's 1st Law of Motion states that an object will remain at (rest or...) a constant velocity in its direction of travel unless an external force acts on it. The tighter the angle of a bend, the more energy is required to change the direction of a given mass of water.

Swept bends (long radius) are preferable to tight right angles.

Bends formed by using a pipe-bender on a straight length of pipe are better still.

Everything about the design of a heat-pump installation must be founded on the principle of it using as little energy as possible.

Save energy... recycle electrons!

@transparent thanks for that, at the minute since they moved a pump to the correct location its chucking up e911 error codes and since it’s warm outside I think it’s only when it gets chilly and it tries to heat the house.

samsung was talking to me initially and I made no mention of my installer but now since my installer got involved with samsung they won’t discuss anything with me.

Well your contract is with the installer, so the withdrawal of Samsung from direct discussions with you simply puts more pressure on him.

If he can't resolve error codes and malfunctions which are possibly related to external temperature, then it's he who should be requesting help from Samsung Tech Support.

Should there be a dispute which comes down to arbitration under the Consumer Rights Act, the less communication you've had with Samsung, the better.

Save energy... recycle electrons!

@transparent thanks for that, I fear I have a long way to go yet but if installations like this are the norm then MCS will need to step up to the bar or step down and have someone like building control regulate it. My installer took numerous photos during and after and my impression was that these went to MCS for review as you do with building control. But if so then it was so obviously installed badly that it would have been noticed and no commission report was ever completed which I would have thought mandatory.

perhaps the governments necessity to meet targets means they lower standards, or my installer sent other photos.

I suspect it was all meant to be run in copper, and perhaps I’m wrong but I thought it strange they ran it in plastic then the areas visible in copper. Plastic is generally frowned on in that the inside diameters are much smaller and more friction, and flow is everything with these pumps.

how hard it it to get this right.

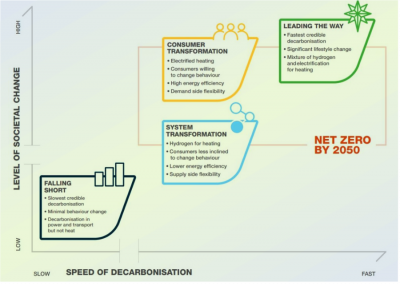

MCS is the delivery route for Net Zero oriented technologies favoured by BEIS/DESNZ.

Ofgem is a non-ministerial Government Department... which is a problem,

... but they've have just authorised the formation of the new Independent System Operator and Planner (ISOP) with its main remit being to "reach Net Zero by 2050".

ISOP is recruiting engineers from National Grid ESO and the GDOs of very great experience.

These guys could actually get us to Net Zero faster than 2050, provided that

- the strategies are based on the laws of physics rather than government favour

- the community sector (us consumers) get inspired and mobilised to play our part in the Future Energy Scenario (diagram below)

- we reverse the trend for private companies with foreign shareholders to 'invest' in the UK's energy future

If MCS doesn't fit within the energy strategies wanted by the next Government, then it will either be required to change, or it will be axed.

I'm busy communicating with PPC (Prospective Parliamentary Candidates).

To get elected, they need to informed (by us) of what's happening and how to solve it.

My message is that they must reduce the politicisation of energy, and instead embrace the physics.

It's being well received.

MCS' days of unenforced 'standards' are numbered.

Save energy... recycle electrons!

@david999 if it's an MCS registered install you must be given a copy of the heat loss calculations which should be your starting point.

29lpm is roughly around 10kw with a DT5, if the heat loss is less then 35mm could be considered overkill and it's the heat pump size that's questionable. Any more than 11kw and you would really need to be at 35mm (or more dependent on index circuit pressure drop etc.). And ofcourse remember your heat pump is not capable of 16kw at design temperature so I'm not sure it could handle 45lpm @ DT5. I think it would max out at around 36lpm.

I was speaking to a homeowner not long ago and a 12kw was installed, Samsung stated it needed 35lpm to operate... however the house heat loss was only 6kw... and so needed around 18lpm (hence why the house was never cold but the heat pump cycled all year round).

With the heat loss calcs you can the determine flow/pipe size/heat pump size etc. Etc. It might be worth having a quick go yourself if you are unable to get them from the Installer, I know there's quite a few excel sheets available on here.

@ant87 I have asked a couple of heat pump suppliers, both with a tech department what components I need to convert my 28mm pipes to 35mm and they have come back saying they can’t supply and don’t know anybody who could. If you are selling 14 and 16kw ASHPs then how can that be so. Perhaps we are ahead of ourselves in terms of this tech.

@david999 Hi David, sorry I'm not quite sure what you mean? Heat pump systems can go into 100's of kw, even megawatt systems.

If your heat loss is infact "12kw say" then it might be that your primary pipework would need increasing to 35mm (or more) which would mean 35mm copper, maybe swapping the 3 port valve for an ESBE or a Belimo valve. This is all to reduce velocity and reduce the pressure drop across the index circuit, increasing flow rate.

The likelihood hood with most Samsungs is that the primary pump is too small with most being installed on a 15/60 pump. There are installers who increase the primary pump size but you are limited to around 100w, adding an additional pump on the return to increase head OR using a relay and a larger pump.

This is all dependent on the heat loss of the building which will determine your flow rate required to deliver said heat. And the flow rate determines velocity, pressure drop and so on.

Your velocity should be around 0.9m/s but can be upto 1.5m/s which is the maximum. With modulating heat pumps this varies wildly dependent on load and is always changing, with Samsung it's fixed unless you use their PWM signal (although I am under the impression it only works when the flow temperature is above 45degC but might be wrong).

The only way to determine all of the above is via the heat loss calculations and working from there, theoretically your 16kw Samsung can only deliver 12kw, the heatloss might only be 10kw and so 28mm would be OK... however the pump needs increasing.

Equally due to the small pump it might mean that you need 42mm to reduce pressure drop thus increasing flow rate, however both giving the same end result but in a different way. A pump would likely be far easier to change, but could cost you a small amount more in electricity.

If the heat loss was infact a theoretical 14kw, your velocity would be around 1.25m/s on 28mm copper, however the pressure drop would be very high, so 35mm would be the better solution as the pump would be huge 🙂

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 431 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 20 minutes ago

-

I cannot see the complete rcbo, since the photo is cut....

By Batpred , 33 minutes ago

-

RE: What determines the SOC of a battery?

The answer from Fogstar was crisp. My hypothesis, su...

By Batpred , 42 minutes ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 52 minutes ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 1 hour ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 1 hour ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 4 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 7 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 8 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 23 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago