Lacking the technical skills to set up my own monitoring of heat pump efficiency I've contented myself with daily recording of kWh used (overall for the house as ASHP not separately metered) and Max/Min air temperature. They are a good way of at least monitoring any untoward changes in kWh.

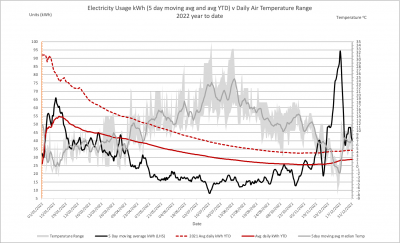

I now have 2 years of daily readings so can compare dates with the same period last year. As the attached spreadsheet shows, outside air temperature overwhelmingly drives kWh used. The spreadsheet also shows that 2022 was much better than 2021 when the timer was not correctly set to heat only the water or UFH, but not both at once. It also shows that the system performs extremely badly when the temperature drops to Zero and below. I'm sure on these occasions it would be cheaper to use the immersion heater for hot water and fan heaters for space heating.

What the spreadsheets don't tell me is if this poor performance at low temperatures is due to:

i) Inherent to the Grant Aerona heat pump

ii) Badly designed overall installation of the system

iii) Some remaining incorrect settings which I could change through the control panel.

Of these iii) is really the only one that I could do anything about - if I knew what to look for.

Mike

Grant Aerona HPID10 10kWh ASHP

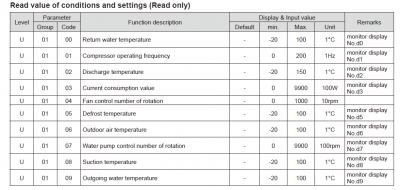

@mike-patrick I have the same Grant Aerona 10kW unit. You can used the controller to access some real-time data, but it's approximate and rounded. That includes leaving water temperature, return water temperature, and power consumption. These are user access level parameters in the controller, you can't muck anything up at this level.

Press and hold the 'back/return' button for 3 seconds to enter user level data, then use the 'up' and 'down' arrow buttons to select from data number from the list above, then the 'tick' button to select & enter. Press and hold the 'back/return' button for 3s to exit and get back to the home screen. (Apologies if you know this already)

If you know your system flow rate (which is constant for Grant ASHPs) you can fairly easily estimate the kW heat output using Q=flow(l/s)x4.18x(flow temperature - return temperature)

Dividing that value in kW by the power consumption will give you a rough CoP. Take readings when the unit is operating at steady state. The power consumption, to nearest 100W, is the whole ASHP, including compressor, water pump, evaporator fan motor and, where operating, evaporator drain tray heating. Any external secondary pump and control power is not included.

CoP will vary hugely depending on, primarily; the outdoor temperature and the required heating flow temperature. The bigger the difference between these, the lower the CoP and the greater the power consumption by the ASHP. Adding in defrost cycles to that just makes for an even lower CoP as the ASHP has to work extra hard to put back heat energy taken from the heating circuit to defrost the evaporator coil. It's not unique to Grant, all ASHPs work the same way and, for all they are very efficient heat sources, have the same limitations.

If you have climate compensation enabled with appropriate settings, and your ASHP runs continuously and is not starting and stopping due to a room thermostat, and no other external controls that are disrupting flow, or imbalanced low loss headers with different primary and secondary flows, then you're probably as well set up as you can be.

Grant CoPs and SCOPs are, for reasons known only to them, 20% higher in their literature than the OEM Chofu's literature. Make of that what you will. I have more faith Chofu's values not Grant's!

Posted by: @soniksHave you installed flow meters in your install so you can see flow rates through your system?

Well, the flow meter comes with the heat pump and I installed an interface into the heat pump to monitor this. My flow rate is currently impacted by having zone valves and a filter that is not heat pump compatible. I somewhat got around that with a 10mh2o pump so get 27 lpm, but am replacing the zone valves and filter, with [almost] full bore diverter and heat pump compatible filter and I should bet able to get to the max flow rate of 58 lpm, though nominal is 46 lpm once that is done.

@allyfish Thanks for this. I'll give it a try. With Derek's help last year I did learn to explore the menu system when I was adjusting the weather compensation.

Mike

Grant Aerona HPID10 10kWh ASHP

Posted by: @allyfish@soniks have you details of the second circulation pump fitted? Maybe a photo or something? Have you a flow setter / gauge on the system or any way of checking and setting the flow? It's quite a fundamental item for ASHP. The Grant Aerona range don't measure flow, and the internal pumps are fixed speed, but can be pre-set to one of 3 speeds. Most simpler central heating pumps these days are the same. Based on the very high flow and return temperature you have of 12degC, I'm pretty sure a fundamental issue is lack of flow, for reasons not clear. Let's check out what pump is fitted, and see if it's man enough for the job. If it is, there's another issue to tease out. I have a 24 radiator single zone system with 28mm, 22mm and 15mm copper pipes, and no problem getting flow with the built in Grant pump and a secondary small Grundfos (UPS3) fixed speed circulating pump.

Until there is adequate flow to all radiators, balancing them up is not really going to provide much benefit. You are robbing Peter to pay Paul. If there isn't enough circulating water flow, you'll never balance them properly.

The main pump in the Grant unit should be up to the job on it's own, but you also have a booster pump. OK, let's assume the secondary pump is up to the job. So why the high deltaT temperature drop over the system and the low flow? One other likely reason is a blockage.

The Grant unit does not have an inlet strainer to the plate heat exchanger which warms the water in the circuit. For that reason there should be a magnetic filter and strainer on the return to the ASHP, Grant's version that comes with the ASHP is 'Grant Vortex Max One' but Adey Magnaclean and other similar items do the job. They are low pressure drop items, great for removing ferrous contamination, but they don't stop small particles of contamination from blocking your ASHP plate heat exchanger however, which is why system flushing before commissioning is so important. This is especially so when ASHPs are retrofitted to older heating circuits where the pipework and system cleanliness can be poor. You explained your system had a faltering install in stages, do you know if it was properly flushed out & cleaned before being commissioned?

Plate heat exchangers can be reverse flushed and unblocked, it's not a disaster. Has anyone checked this for you? (installation manual page 66 item 29)

It's been a while and thought I would give you all an update.

I went forward with using one of the heat geek installers to perform the remedial work on my Grant ASHP install increasing the primary pipe sizing from HP to main plant area to 35mm copper. There are then 4 32mm MLCP pipes run from the plant room to the main plant room(garage) to the manifold and upstairs radiator circuit. We are installing UFH downstairs too.

We are going to replace the upstairs radiator circuit with 25mm mlcp as the ceilings are down but we haven't completed that yet.

The heat engineer did a test of the system at least for the hot water circuit and noticed a flow rate of 18-19lpm significantly lower than expected. The expectation was double that at least particularly with the increased pipe sizing. This points to heat exchanger being blocked or circulating pump not working at the rate required. It is already set at the max speed setting.

@allyfish would be curious to understand the reverse flush instructions as I couldn't find the instructions in the installation manual. Would you be able to share the manual you were referring to.

Would a blocked heat exchanger be covered under the Grant warranty if this is identified as the root cause.

Is there any way to test the performance of the circulating pump in the HP in isolation?

Any other thoughts/suggestions on what to do to resolve?

Has anyone had experience of performing a reverse flush on a heat pump. I've been told the power flush was already performed with FC2 and DS3(I think) cleaners but this hasn't helped.

Now the suggestion is to use a stronger cleaner/acid DS-40 and also alternatively try using a pressure washer on the heat exchanger directly in reverse flow to agitate any build up. Has anyone tried this before with any success?

Otherwise I'm told this is looking like a new HP after 3 years which is a complete joke.

@soniks Ohh I've watched that, I've asked if he flushed both ways, didn't reply.

I don't have experience but it only makes sense to flush in the opposite way of the flow as the debris pile up with the flow, if you first flush with the flow you just jammed them even more.

I remember @editor having to deal with errors from the filter getting blocked often, I suppose better that than your case.

It's hard to tell what works, you would only know for sure if you changed the heat exchanger and see what is inside.

The only thing extra I can think of, is to fill the heat exchanger with the cleaning substances and leave it like that for a day/week and see what dissolves/come out, repeat.

Hi @Soniks, that's really bad news. Has the ASHP installation been installed by a Grant G1 approved installer? If it has, and is has been serviced and maintained thereafter with no modification, then I would expect you would have a case for a warranty claim? Failing that, could Grant signpost you to a specialist repairer of ASHPs? They will need to be F-gas registered and experienced with Chofu kit. The plate heat exchanger is a replaceable spare part, but replacement is a refrigeration de-gas and a specialist job and would be an involved and lengthy job to strip out the unit to access the heat exchanger. The labour content alone never mind the parts cost might make it prohibitively expensive.

Grant use their 'Mag One' magnetic in-line filter, but Adey Magnaclean or similar all do the same job. What's the history of the filter? Does it get regularly sludged up with a lot of build around the magnetic core? There should be almost nothing with suitable corrosion protection. Just checked mine 8 months after installation, 22 rad system retrofit, 12 new rads, some older rads were original and I knew they were sludged previously as the bottom 1/3 always stayed cool - almost nothing and system water clear. The system got a good flush out when it was converted to ASHP.

One of the problems with retrofits it potential for the higher flows and velocities of low delta T heating systems to disturb sludge and sediment deposits built up over many years in lower velocity higher delta T piping systems. They get carried around the system and, in sufficient quantities, can cause problems elsewhere. A thorough powerflush of the complete system at the time of retrofit is essential.

Other stuff: Presume there is no other issue with the primary pump that could cause really primary low flow like cavitation, damaged pump impeller, etc.? These would tend to generate noise or vibration from the pump, which should otherwise be almost quiet in operation.

@soniks Szymon from Urban Plumbers by chance? He's just re-piped a badly installed Grant unit...

Off grid on the isle of purbeck

2.4kW solar, 15kWh Seplos Mason, Outback power systems 3kW inverter/charger, solid fuel heating with air/air for shoulder months, 10 acres of heathland/woods.

My wife’s house: 1946 3 bed end of terrace in Somerset, ASHP with rads + UFH, triple glazed, retrofit IWI in troublesome rooms, small rear extension.

Thanks for your suggestions @Fazel/@Allyfish.

I was told power flush performed on both directions with the pump connected to the primaries.

One of the options is to leave the chemicals in overnight and apparently drainage cleaner works well but the unit would have to be left on the floor horizontally. We would then have to wait 48 hours with the unit standing vertically for the compressor oils to settle before turning on the unit.

Filter had debris on it maybe 0.5cm thick last time it was cleaned and completely clear at the moment. I was told if the heat exchanger needs replacing you might as well get a new heat pump.

Grant will not do anything they lay the blame with the installer even through he was an ex Grant installer! They won't do anything for a blocked heat exchanger. They have offered to replace the pump in case it's a lazy pump.

I will be following up with MCS and RECCS again because after paying for the install twice and still not have a working system has got to be unacceptable. This industry really needs to be regulated better to prevent these types of installs. I was very keen on going the renewable route but I have to say after my experience I would definitely wished I hadn't.

Perhaps there's still something to salvage from the situation if the flushing works or a new pump fixes the issue but as a consumer there needs to be better protection.

@soniks I watch all his video's, he's a smart guy... Hopefully when he gets his f-gas certificate later this year he'll be in a position to de-gas/re-gas your unit and swap the blocked PHX...

Off grid on the isle of purbeck

2.4kW solar, 15kWh Seplos Mason, Outback power systems 3kW inverter/charger, solid fuel heating with air/air for shoulder months, 10 acres of heathland/woods.

My wife’s house: 1946 3 bed end of terrace in Somerset, ASHP with rads + UFH, triple glazed, retrofit IWI in troublesome rooms, small rear extension.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 301 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 1 minute ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 10 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 32 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 8 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 24 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago