Posted by: @cathoderayEstimates of heat pump energy out vary, but they are of the order of 26,000 kWh per annum.

The paradox still remains, and it remains gross, at about 3 (heat pump needs to pump out 3 times more heat to achieve broadly the same comfort level).

As I indicated in my previous post, I simply don't believe this. I think its an apparent/real SCOP problem not house needs 3 times as much energy to heat. However we may be able to prove that I'm wrong from the HP data! Although I dont believe it I'm also open minded, don't believe in magic, and do believe in the physics.

I think my previous post accounts for some of the anomaly but certainly not all (I, like others, think this is a combination of effects). I ask some questions which, hopefully you may comment on when you read them. This is an interesting case study relevant to many but not all, so its worth trying to get to the bottom of it to the extent possible.

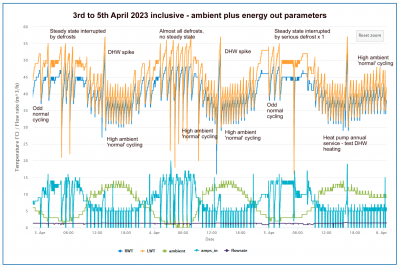

Posted by: @cathoderayVery briefly: the 'all over the place' current/LWT bit of the chart shows defrost cycles. At least I am pretty sure that is what they are, because (a) the OAT is cold enough to imply defrosts will happen (b) the LWT goes below the RWT (probably the most reliable diagnostic marker of a defrost cycle) and (c) current in drops because it is not heating during the defrost. The charts are based on minute data, and so have good temporal resolution.

fair enough between 04:00 and 06:00 but not earlier on. Having said that I am still not sure if this matters or not, probably not.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa - I wrote that before I read your rephrasing the question suggestion. It was my way of phrasing it as an anomaly/paradox/whatever you want to call it! Like you, I simply don't believe what the data appears to be telling us either, it doesn't make sense, which is why I have posted it - to try to get an answer.

Going back to basics, if a sanity check (I often use the sanity checks as well) suggests something is wrong in a case like this, either (a) the data is wrong - not measuring what we think we are measuring (using proxies is a red light here), the measuring instrument is out, etc, or (b) the data is right, but we are doing something wrong with it, which includes not comparing like with like, a definite suspect in this case, but also the 'unknown unknowns', which are what they say, yet they are part of the picture, and by their nature are the hardest ones to deal with. Of course, (a) and (b) are not mutually exclusive, both may apply.

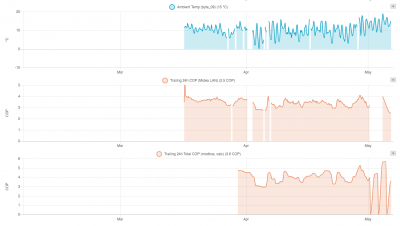

Before I answer your questions, here is some 'interesting' data taken from the History Explorer page in Home Assistant (which I haven't dumped yet, but as can be seen its data collection is patchy). Nonetheless, the charts (all data comes from Midea) show, at the top in blue, ambient temp for context, and below, in beige, trailing 24 hour COP determined (a) (Midea LAN) by using the current minus previous lifetime total energy in/out (this is done entirely inside HA using its statistics and templates or whatever they are called) and (b) (modbus, calc) by calculation (LWT/RWT delta t x 4.02 (for some glycol) x flow rate) pulled in by HA from my python generated csv data. Here they aren't the same, the calculated COP is always higher, but neither are embarrassing. Note the current COP (in brackets after each chart title) is meaningless, HA has made it up, as the heating is currently off, and the COP is zero. On its own terms, the Midea unit is doing just fine, but it is of course marking its own homework. The paradox/problem only appears when the heat pump performance is compared to another form of heating.

Posted by: @jamespaThe next place I would go (based largely on the suggestions of others above) is:

- look at plots when OAT is around 0, 5 and 15 (or the max OAT at which you heat) just to see what these tell us (if anything). Also when its (supposedly) not heating at all (is there a quiescent demand, ie is the Midea drawing current when its not heating?)?

- check your electrical power meter, compare it with what the Midea is saying. Do some 'sanity checks'

- measure DT across the HEX and between HEX and Pump to see if losses are contributing significantly

- confirm, for the avoidance of doubt, whether water heating is included in either oil or ASHP figures and any relevant characteristics of same.

Plots at OATs of 0/5/15 or in my case prob 16 degrees: because the data is observational, it relies on Mother Nature to set up these conditions so we can observe them, and MN doesn't always oblige. That said, an expanded three day plot from early April does include some highs and Lows (of OATs) and so gets close. Here is that plot with some annotations:

The obvious standout to me is the amount of 'normal' (as opposed to defrost) cycling, even when it is relatively cold outside. If it is the case that cycling is ruinous to efficiency, then some of the answer may lie here. I will see if I can get actual hourly energy out (in kWh) on the same plot, tricky to do as that data is hourly and this chart is minute data, and manually lining up the hourly data with the minute data is a recipe for rapid insanity.

Quiescent demand and external meter vs Midea data - difficult to establish the former, as the external meter only knows what is going in in total (and I don't yet have automated monitoring of that meter, I have to read it manually), what I need is the external meter readings during a period when I know the heat pump has been not heating. The external meter and Midea energy in data are close, on average the Midea kWh in data is ~3% less than the external meter data. That might be the quiescent use, but as I have no way at the moment of marrying up minute by minute external meter energy in data with actual heating activity, I can't be sure. I will however take some external meter readings, and then retrospectively check the heating has remained off (it is currently off), and that use should be the quiescent use with the heating off.

The drop as measured using my basic IR thermometer/thermocouple across the plate heat exchanger is usually about 5 degrees, ie a primary flow in of say 45 degrees in will give a secondary out of 40 degrees. They are difficult to measure, partly because the instruments are poor, and partly because they are are very volatile. At some point I will probably get some of those D???? sensors and hook them into my modbus setup (but not rushing as heating season is now over).

Although I do have some data that breaks down heat pump space and DHW heating use, all the heat pump data presented here is combined use, ie includes both. The oil period I am less sure about. I'm fairly certain it doesn't include DHW heating, because I recall using the immersion heater in the summer (to give the boiler a rest), what I am less sure about is what I did in the winter, left it on the IH, or switched to the boiler. That said, as noted previously, my DHW use is very low, it is never a significant percentage of total heating use. If the Midea app is to be believed, DHW heating currently accounts for only 2.04% of total energy in.

Midea 14kW (for now...) ASHP heating both building and DHW

Frist reactions (more considered ones later...)

Posted by: @cathoderayThe obvious standout to me is the amount of 'normal' (as opposed to defrost) cycling, even when it is relatively cold outside. If it is the case that cycling is ruinous to efficiency, then some of the answer may lie here. I will see if I can get actual hourly energy out (in kWh) on the same plot, tricky to do as that data is hourly and this chart is minute data, and manually lining up the hourly data with the minute data is a recipe for rapid insanity.

Indeed so. Cycling is said to be ruinous to efficiency but I have never seen the extent to which it is 'ruinous' quantified. However one would expect, with a decent control algorithm, little or no cycling once the heat demand exceeds the minimum the unit can modulate down to. Because of this and the previous clip I'm beginning to wonder about the control algorithm. You seem pretty clued up so I expect you may have some understanding of control loops and how they can become unstable if not correctly tuned. Maybe this is the case here. As a matter of interest do you know your system volume. Assuming that the controller has a 'proportional' element then it will be optimum at a certain system volume. If your is significantly smaller, then oscillation (which is what you are seeing) is inevitable.

Posted by: @cathoderayI will however take some external meter readings, and then retrospectively check the heating has remained off (it is currently off), and that use should be the quiescent use with the heating off.

definitely worth taking some readings now, with the unit switched on but (presumably) little or no heating demand. On another forum some older LG and Mitsi models are found to consume 250W doing nothing, thats not insignificant when added up over the whole summer (solution- switch it off).

Posted by: @cathoderayThe drop as measured using my basic IR thermometer/thermocouple across the plate heat exchanger is usually about 5 degrees, ie a primary flow in of say 45 degrees in will give a secondary out of 40 degrees. They are difficult to measure, partly because the instruments are poor, and partly because they are are very volatile. At some point I will probably get some of those D???? sensors and hook them into my modbus setup (but not rushing as heating season is now over).

If that's a flow (in) to flow (out) measurement then it will add roughly 10% to the consumption, according to my modelling of weather compensation.

Your 'paradox' is due to a combination of causes for sure. Different heating profile, PXE losses, probably cycling losses, and some others we don't yet know about. Tuning will likely improve but there is a lesson here which is generally applicable.

Of course, back in the 'real' world all people actually care about is cost. Sadly the comparative cost of different energy sources is almost a wholly political construct. A couple of years ago oil (well diesel oil anyway) was about the same price as it is today and electricity a third the price, so others might have been relatively happy, if perplexed. In a couple of years time maybe the same will be the case again. Gas vs electricity prices are wholly political, green subsidies are loaded onto electricity to keep heating bills low, not because it makes any logical sense (particularly if you are trying to pursue a 'green' agenda. I for one think that selling heat pumps on cost saving (unless the existing system is resistance electric) is mis-selling, they should be sold on the basis that over the long term they are likely to be about similar, but at any given time the price may be very different, because of the politics, in either direction.

Please do let me know if I interpreted your PHX delta T measurement correctly, if so then thats another 10% to bank.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaIf that's a flow (in) to flow (out) measurement then it will add roughly 10% to the consumption according to my modelling of weather compensation.

Quick remark: yes it is, but I'm still trying to get my head round what the detrimental effects of a PHE are. I've tried seeing them as a sort of obstruction, perhaps even as a sort of resistance, in two circuits thought of as one, and while I can see how they can restrict flow or transfer across the plates, I am not sure how that translates into lost efficiency. Even if we took the analogy further, and thought of it as a resistor in an electrical circuit, then all it would do is heat up a bit, but the heat then gets lost inside the house, so it is not lost, it just ends up in not quite the right place, eg airing cupboard in my case, rather than in a rad.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay My simple view is this: They have losses, so they increase the flow temp required at the ASHP to achieve a given flow temp at the emitters (as well as losing energy to the outside world, if any). For each degree increase in flow temp at the ASHP reckon on 2% degradation in efficiency (based on modelling of Mitsubishi weather compensation/COP). 5C deltaT across = 10%, very roughly of course. Its a false assumption that, because energy is conserved, there is no loss in efficiency. The second law of thermodynamics takes care of that!

Posted by: @jamespaAs a matter of interest do you know your system volume. Assuming that the controller has a 'proportional' element then it will be optimum at a certain system volume. If your is significantly smaller, then oscillation (which is what you are seeing) is inevitable.

Added to this, if system volume is 'low' (whatever that means) it would also explain the excessive defrost cycles.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaAs a matter of interest do you know your system volume. Assuming that the controller has a 'proportional' element then it will be optimum at a certain system volume. If your is significantly smaller, then oscillation (which is what you are seeing) is inevitable.

I don't. It also depends on whether system means entire system (primary and secondary circuits combined) or just the primary circuit, but then that doesn't operate in isolation, the secondary circuit is removing heat from the primary circuit. If it is the entire system, both circuits, I have ten rads, all K3s bar three K2s spread across a small three bedroom house, and so i guess a reasonable circulating volume. That said, my installer suggested at a recent service visit that a volumiser on the primary circuit might reduce the cycling. I can certainly see the logic of how it might.

I'm beginning to wonder whether the cycling is indeed the heat thief. I wonder if others, both with Midea and other brand heat pumps, has data with enough temporal resolution to see how much cycling they have. The other key question as you say is how ruinous is cycling to efficiency? If for example, it means the heat pump has a COP of say one at the start up of the cycle, then I have a lot of periods when the heat pump is running at a COP of 1. But this gets complicated: a situation where the data 'shows' 3kWh of energy out but in fact only 1 kWh actually arrives for each kWh in.

At the moment, I am stuck with Midea marking its own homework data. I do have that analog flow meter, and ad hoc readings suggested the Midea flow rate, which is normally remarkably static, is about right. But what about the LWT/RWT? Reporting a delta t of eight when it was actually four would double the apparent energy out...

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayI don't. It also depends on whether system means entire system (primary and secondary circuits combined) or just the primary circuit, but then that doesn't operate in isolation, the secondary circuit is removing heat from the primary circuit. If it is the entire system, both circuits, I have ten rads, all K3s bar three K2s spread across a small three bedroom house, and so i guess a reasonable circulating volume. That said, my installer suggested at a recent service visit that a volumiser on the primary circuit might reduce the cycling. I can certainly see the logic of how it might.

When I asked the question I was thinking secondary. A 3 bed house may be quite a lot smaller than the designers of a 14kW unit were thinking. I have a distinct suspicion that your house is 8-10kW not 14.

More significantly perhaps ,it has since occurred to me that the very small volume in the primary circuit is potentially an issue, unless the flow rates are correct in relation to the secondary circuit. I have been wondering all along how the flow temp could possibly plummet quite so fast when heating is switched off, and now I can see how it could. Basically, once heating is switched off, if the transfer from secondary to primary doesn't keep up with the loss from the primary, the primary circuit temp will drop like a stone, which is what the plots show. This would also explain the oscillation and the constant defrost cycles.

What controls the pump speed in the secondary circuit?

I think that, between the temp drop across the PHX and the cycling, we may easily have another 20%, on top of the intermittent heating effect.

A volumiser in the primary, together with a good insulation of the PHX to reduce delta T to around 1C maybe, might well help, but its a sticking plaster. The real question is - why bother with the PHX at all? Its introducing uncertainty, a loss in flow temperature, and reducing the volume directly available to the HP which has got to be a bad thing. What value is it adding?

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

One further comment occurs.

We know that cycling is bad news, but we cant quantify how much effect this has when the unit is below minimum output.

But cycling once the unit is above its minimum output is also bad news, and we can at least understand, if not precisely quantify that. So for example if it cycles with a 4:1 mark-space ratio, then during the 'mark' it will need to deliver 25% more energy per unit time (ie power) than if it were on constantly which, given that the flow rate appears to be constant, presumably corresponds to achieving a higher flow temp (& possibly delta T). And every 1C increase in flow temp equates to 2% loss in efficiency. You don't get anything for nothing is thermodynamic systems.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

CR was advised to consider removing the PHE quite some time ago. I think that Batalto followed the advice and achieved quite considerable improvement in the performance of his system. On calculations I made using a spreadsheet I created for CR's system, based upon the Midea standard data from the data manual, increasing the LWT by 5C at an outside temperature of 10C, would incur a 30% increased in the electrical input power, to achieve the same thermal energy output.

The other thing to consider is the difference in operation between the oil boiler and the heat pump. The oil boiler was operated twice per day, no doubt at high LWT and high output power, whilst the heat pump is being operated continuously (with cycling), for the full day. Consider the analogy of a bucket with uniform pinhole leaks, which in the oil case is being filled quickly, twice per day, so is fairly full whilst people are active, but leaks less as the level falls. In the heat pump case the bucket is being kept full all day by drip feeding at a rate that matches the leakage, but of course leaks more because there are always more pinholes within the water level.

Concerning the cycling, this again was discussed in detail quite some time ago, and I believe can be expected if the volume of the primary circuit is small compared to the output capacity of the heat pump. The LWT increases quite quickly, particularly if the PHE is not transferring the thermal energy efficiently, and in doing so reaches the calculated temperature and stops the compressor. As you correctly stated, the small volume of water cools relatively quickly, restarts the compressor and repeats the cycle. Milder weather conditions are also a frequent cause of cycling.

I have an A2A ASHP, which I have noted starts up at quite a high compressor speed and loading, but produces no actual heat output for several minutes as it increases the pressure and temperature of the refrigerant gas, it is only then that the indoor unit starts to operate. Once the indoor unit does start to operate, the compressor loading is still quite high for a period of time, until the system is fully warmed through and the indoor temperature starts to increase. I believe this may be even worse with an A2W heat pump since the time delays can be much longer.

With regard to the cycling:

Exactly what controls do you have? I understand you have a manufacturers weather compensation system, and TRVs (on full so not used). Is there somewhere a simple thermostat kicking in and out ? Apols for stating the obvious!

Cycling is usually only ‘very bad’ at more than 6x per hour. It drops efficiency slightly - mostly though what heat energy you lose on startup you gain back on pump overrun afterwards. It fatigues the compressor and joints around it, so is a cause of system failure, mostly an issue with older non inverter systems.

@cathoderay, not all original but these are my thoughts on your conundrum.

- your ASHP runs 24/7; your oil CH didn't

- your house was colder with oil but your radiators were hotter so you didn't notice

- your PHE is losing you a lot of energy

- your ASHP needs to defrost when it's less than 3 or 4 degrees outside; your oil CH didn't

- your SCOP is not 3; with your flow temperature it could be nearer 2. If you don't have a calibrated heat meter that records the energy delivered to your radiators, you're really just guessing.

IMO cycling is a red herring. It has an effect but in itself it's not significant; I measured it myself and posted on here a while back.

If you don't believe me, John Cantor did this video

https://www.youtube.com/watch?v=0oszaqP0TI4

Look at this the other way around; is 8800 kWh reasonable to heat a leaky old building to 19-20 degrees or so 24/7? I heat my quite-well-insulated and very airtight newish building to 21 deg 19/7 for about 6500 kWh per annum. It sounds like we're in the same ball park.

Reading the above I think there is a large measure of agreement that

- the difference in operating conditions vs the oil boiler, and

- the adverse effects of the PHE,

are major contributors. @derek-m comments that the PHE has to go and cites a much larger measured degradation than I had crudely calculated; my calculation considered degradation due to flow temp increase only, it ignored the effect of a low volume primary, so its not implausible that you may see a larger increase than the basic 10% due to flow temp.

Posted by: @kev-mIMO cycling is a red herring

Im not, however, convinced that cycling is a red herring yet. I grant that the effect on wear and tear is dependent on the frequency of cycling, but there is another effect which is dependent on the mark-space ratio. If the mark-space ratio is say, 4:1 (which it was in the only plot where it could be measured), then the heat pump must deliver 25% more power when on to than would be necessary (for the same total energy delivered) if it were operating continuously. It can only do this by operating at a higher flow temp/delta T or a higher flow rate, either of which increases the required refrigerant temperature, which makes the heat pump less efficient. This is consistent with the John Cantor video referred to above so far as I can see.

At high OATs cycling is inevitable, my concern is that this may be happening at lower OATs. Your most recent plot doesn't really give us enough to go on to tell whether this is occurring or not (it suggests it might, but its not conclusive). However I don't think we can yet rule it out.

To be certain we need a plot from a time when the OAT was around say 0, around say 5 and around say 10 for a longer period (I realise that this is difficult, mother nature doesn't oblige). Based on all the numbers from the oil heating, I remain suspicious that your building is in fact an 8-9kW building to which a 14kW heat pump has been fitted and which, at least according to the specs, doesn't modulate well, so its cycling over a much wider temperature range than it should. If so, the PHE is making this worse, both because it reduces the volume in the primary and because it increases the required flow temp at the HP, which according to the spec (over the range of interest) also increases the minimum output of which the unit is capable.

Posted by: @kev-m

- your ASHP needs to defrost when it's less than 3 or 4 degrees outside; your oil CH didn't

Your defrost looks pretty bad to me, presumably due to the low primary (and possibly low secondary) volume. It really would help to know what controls the secondary pump and how the primary and secondary flow rates are related, to assess whether there is likely to be good transfer during conditions such as defrost. The plots definitely suggest not, or alternatively that your overall system volume is too low (which is very plausible given you have a 3 bed house with a unit that the designers probably thought would be used in a house half as large again.

You could of course try putting a volumiser in the primary as your installer (who is presumably determined to retain the PHE) suggests. if its big enough it may well fix the defrost issue but it wont address any of the other matters.

Im not sure further staring at the data (with the exception of the specific data mentioned above) is going to help a lot more. It needs some experiment, if you are brave enough to do it of course. Otherwise I think you are going to have to live with a SCOP of perhaps 1.5-2 most likely due, it would appear, to a system the configuration of which is, sadly, sub-optimal.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 334 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 8 minutes ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 17 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 39 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 8 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago