Posted by: @transparentI think those wooden stairs would benefit from having fire-resistant boards screwed below each tread anyway. It makes the escape route safer!

Yes, certainly something to do. Fortunately no-one has done this in the past; I'm told that under the stairs is a good hunting ground for asbestos! The stairs do have a bit of play when I walk up and down, so I wonder whether the carpet is now structural.

Posted by: @transparentHardieBacker board (for tiling) is brittle.

Thanks for the tips regarding the cement boards.

Posted by: @transparentI would use Unistrut-style metalwork, but with verticals bearing directly onto the concrete floor below.

I don't suppose you've seen examples of this on the internet? I tend to work best by following and modifying examples when in the unknown. Otherwise I may have to fall back to somewhere with off-the-shelf shelving like bigdug.

here's an interesting utube concerning EVE 280 battery compression:

It's a short vid, well worth watching - I learned:

The ideal cell compression is 12psi (300kgf)

Cell lifetime is enhanced by compression

Cells expand by 0.5mm when charging (I think even if compressed as above)

Cell terminal stress is a more important issue than bloating itself. The vid wondered if a stressed terminal could cause a catastrophic internal fault?

Lifetime due to cycling for home use is huge - it's likely cells will die of old age rather than cycled to death.

@Transparent - agree that flexible terminals seems an excellent idea. Also that the major fire/heat related issues are associated with cables, crimps, terminals, fuses. I think when the bank is first used, cautiously increasing the current, and checking temperatures of all joints is crucial.

I think BigBug shelving has a minimum depth of 400mm. You need about 220mm.

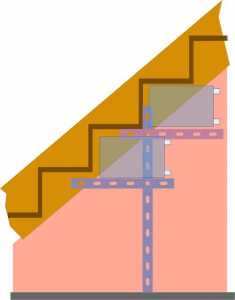

I'd imagined you using Unistrut (or equivalents) something like this:

The slot-distance is 50mm, which won't exactly match what you can do because the risers won't be a multiple of 50mm of course.

You'll see that the upper horizontal is cantilevered by quite a lot, but you can cut it longer, move it to the left and screw it to the wall-side string further back.

I've omitted the bars beneath each row of cells (end-on to the viewer's eye) for clarity, but I hope it still conveys the idea.

Here's my next photo:

I've used 9mm thick buffalo-board bolted to the two steel Unistrut bars below. Buffalo-board is birch-ply with a slip-resistant phenolic-resin upper face. I had a couple of spare pieces just the right size.

Note that the rear flange of the Unistrut wall backet would prevent the cells on each end being pushed right back against the wall. I will fix an additional 10mm-thick wall-board behind the double-row of cells, enabling them to be pushed back against it equally. If you can't rely on a firm rear-face, then it's difficult to align the terminals at the front. That can mean you end up with copper-busbars not sitting flush against the terminal surround.... a potential hot-spot.

No buffalos were harmed during the construction of this shelf.

Save energy... recycle electrons!

LiFePO4 cells balancing on the shelf... in both senses of the phrase 😉

The first photo shows two strips of Cembrit 8mm board used to ensure that the cells are evenly pushed against a firm back-board.

The second photo shows a DC-DC converter drawing power from the operational battery on the left (at 52v DC) and delivering it at 3.6v, 20A to the new cells on the right.

As with the previous power-supply I've used for top-balancing, the constant-voltage supply is digitally programmable. Accidentally turning the silver knob won't result in the voltage being raised above the set 3.6v and damaging the cells. Programming requires rotating the knob in conjunction with two buttons to the left of the LCD screen.

Save energy... recycle electrons!

Thinking about the overall layout some more, under the stairs (at the back) is probably least intrusive, and I'm leaning towards having all 4 rows in vertical alignment rather than offsetting under each stairs. This is mainly for ease of construction and maintenance. The plan is to have 4 shelves of 8 cells each, overall in a 2p16s pattern. This layout is somewhat awkward as the connections between rows are of differing lengths (two shorter and one longer). This is where wire crimping skills will be tested.

I'm considering going with a key clamp and pipe system, provided there is sufficient space under the stairs. The 27mm pipe ought to be strong enough for the 200kg total battery weight. £150 to get sufficient pipes and fittings to make the frame seems reasonable. As for the shelves, the Buffalo board looks good (if pricey)!

Well that's two of us thinking about 'overall layout'!

Once you need to install more than one battery, consideration has to be given to the protection mechanisms and the board layout which links wires from inverter(s), chargers, batteries and sensors.

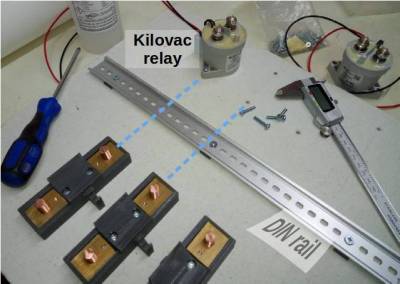

Here's the approach I'm using, whereby the required components are bolted to a backboard using brass 'Nutserts'

The vertical paths on the board are separated into lanes, one for each battery. The lanes are 72mm apart, dictated by the spacing of the DIN-rail mounted components. A standard DIN module is 18mm wide, and the double-pole 125A trips I'm using each take up three module spaces:

The fuse-holders have a side-clip into which the red +ve wire from the battery is placed. That aligns it with the right terminal for each 2-pole MCB.

Save energy... recycle electrons!

@transparent It seems like you are thinking along the same lines as the 3-phase switch gear (like the photo you linked in another thread). My plans for a single 2p16s battery is going along slightly a different path; should I be worried about it being poorly lit?

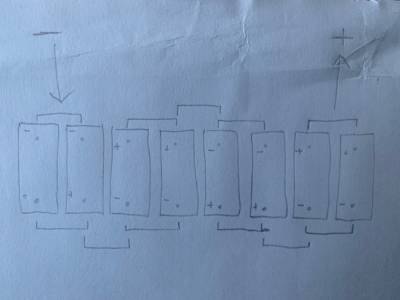

The basic unit of the system is the row of 8 cells connected in a 2p4s manner (see diagram underneath). They will be linked together by standard copper bus-bars. Note that the entry and exit connections are on the same side, and that 4 orientations of the unit are possible (reflections in the horizontal and vertical axis).

These basic units can be combined together to form a 2p16s system. For instance the following configuration has 2 short inter-row connections (51mm + depth of shelf) and one long inter-row connections (297mm + depth of shelf). Pleasingly it uses all 4 possible configurations of the row, although for maintenance purposes this may be less pleasing.

Inter-row connections are very much the weak-point in the scheme. I'm guessing I'll need to use 35mm^2 or 50mm^2 wire and crimped connectors, running as two parallel wires. 50mm^2 wires may be preferable to counteract the long cable run length. 250mm extra 50mm^2 wire means an extra (0.4mOhm/m * .025 m =) 0.1mOhm, although actual resistance difference will be half of this due to running two wires. Looking back at the post about NH00 fuses, 0.05mOhm is the same order of magnitude as the NH00 fuse holder. Still of concern is the way in which Seplos BMS has two voltage sensors between cell 8 and 9; per BMS manual "CELL8+ and CELL9- connected with the positive terminal of 8th cell and negative terminal of 9th cell to provide sampling accuracy of cell."

As a first design, the entry/exit connections will be layered as cell terminal -> terminal lug -> (inter-cell) bus-bar -> serrated flange nut, although I worry that the flange nut will work its way loose over time ("Hello Loctite 243!"). The rationale for the ordering is that most of the current (100A) will be inter-row, so the lug should pressed against the (welded) battery terminal.

Ah... thanks for clarifying, @chickenbig - So you're using all 32 cells within a single battery which has one BMS unit to protect it.

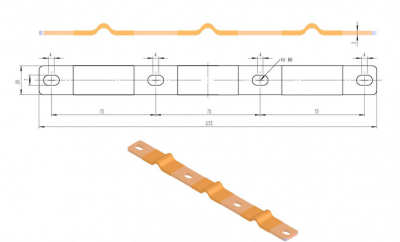

The standard copper bus-bars which get supplied with these 280Ah cells are 20mm wide and 2mm thick. That 40sq.mm is rated at 270A.

Unless you are intending to buy extra bus-bars to "double-up" the thickness, then there's little point in using 50sq.mm cable (345A) for the inter-row connections.

35sq.mm battery cable is rated 240A, so that will probably suffice.

As for the in-shelf connections of each 2p4s section, you could consider purchasing three 4-unit-long busbars per shelf, or even a thicker (3mm) flexible bar which is rated 300A.

Beyond 300A I think you'll be buying raw copper strip, 250mm long, and cutting your own slots from 4x20mm or 4x30mm bar.

But let's just note, at 300A you'd be able to completely drain your 28kWh battery in 1h45m.

It equates to 115A at mains voltage 230-240v AC, which is more than can be delivered through the Service Fuse for a single-phase domestic property!

There are very few (legal) home-based activities for which such a current-carrying capacity would be needed!

Save energy... recycle electrons!

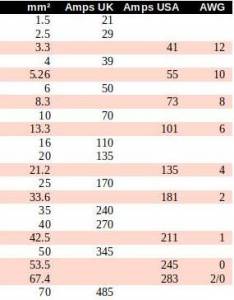

Mainly for the benefit of others who will arrive here in future, may I present the following chart showing Extra-Low-Voltage (ELV: 12-60v DC) cable sizes and the maximum current they are designed to carry:

Here I have combined the European standard, using square millimeters, and the USA standard in AWG (American Wire Gauge).

Each data-set in the table is derived from wire suppliers in the relevant continent.

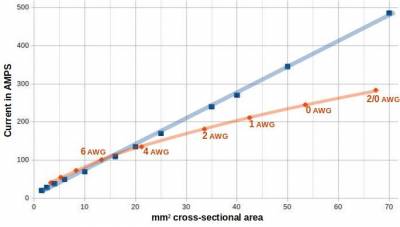

There's a good reason for this which becomes apparent if I plot the current capacity as a graph

It's not just that the cable sizes are different on each side of the Atlantic, but the manufacturers' specifications differ.

Cables for the US market are deemed to have a lower current capacity above 6AWG.

USA cable-charts tend to be more complex. There are often additional parameters, showing how the current capacity must be de-rated according to the length of the circuit and the ambient temperature.

The above charts and explanations can be freely copied into any other relevant discussions here on the Forum and beyond.

Save energy... recycle electrons!

Posted by: @transparentUnless you are intending to buy extra bus-bars to "double-up" the thickness, then there's little point in using 50sq.mm cable (345A) for the inter-row connections.

I was pushed down this road by the Orion2 BMS Operational Manual page 44 - 46. The conclusion is

Although busbar compensation is able to compensate out extra resistance from short cables, for best results, we recommend placing any cables between cell groups whenever possible.

The additional 0.05 mOhm (or 0.075 mOhm for 35mm^2, or 0.035 mOhm for 70mm^2) resistance is similar to the internal resistance of the cells (measured as 0.19 mOhm on arrival). I suppose that "more research and experiments must be performed".

Posted by: @transparentAs for the in-shelf connections of each 2p4s section, you could consider purchasing three 4-unit-long busbars per shelf, or even a thicker (3mm) flexible bar which is rated 300A.

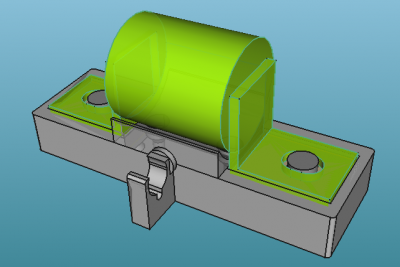

Yes, I think flexible bus bars would be a good idea, and the 4-unit-long bars will keep the connections more uniform. In your opinion does the shaped copper version provide sufficient flexibility to avoid significant strain on the cell terminals? I suppose this depends on the flexibility of the bus bar, whether it stays that flexible and how the cell terminals react over the 6000+ cycles of its life. Braided bus bars would reduce the strain on terminals close to zero; however finding a 2p version of these is proving difficult.

I'm back at home and have re-measured the under-stairs space at the back of the cupboard. It is approximately 670mm wide and 860mm high (well, the height can be selected but the width is pretty much non-negotiable).

The height makes it pretty much impossible to fit 4 rows of cells when each row is on its own 27mm pipe and 9mm board (4 * (27 + 9 + 174) = 840mm). It would be possible to have two rows of double stacked batteries in the style of Transparent's shelf solution, although I'd like to put some horizontal restraints on the upper level of cells.

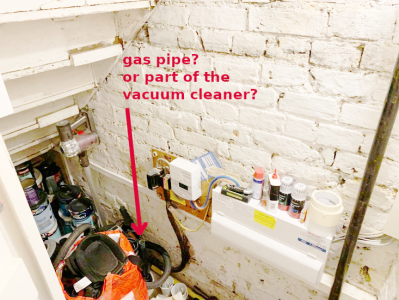

The width is also somewhat problematic (8 * 72 + 2 * 27 = 630mm), although I think I can wangle an extra 20mm by having the old gas pipe removed.

An alternative would be to have the shelf run to the left of the door (next to the tongue and groove wall). This might take up half of the width of the room, and make access to the cells rather challenging.

Another alternative would be to adopt the @transparent solution and put some shelving brackets into the party wall and brick wall underneath the T&G, but I believe this would only hold 16 cells (so only 14kWh). The stairs and T&G would not be up to (partially) holding 100kg additional weight of another shelf. I suppose key-clamp vertical post on the left and wall mounted system on the right might work, getting it back to a 32 cell system.

All for the lack of 100mm!

I'm somewhat struggling to picture these shelves with your dimensions @chickenbig

Graphics would make it a lot easier to follow - either the sort of hand-drawings you did above, or possibly on top of a photo.

For example, to show where the old gas pipe is located, I'd use a software package to 'lighten' all colours and then write on top like this:

27mm pipe sounds overkill to me.

The Unistrut horizontals I'm using are only 21mm thick.

Copper busbars: I've never previously used either of the two types of flexible busbar, so have no experience to make suggestions.

I have just bought a set of the braid-type, but they'll have to produce some sort of stunning outcome to convince me to buy more.

Although I will soon have 40kWh of storage here, the nature of the experimental trials I'm doing means that these are always used within the 20-80% capacity range.

I haven't seen any cell expansion nor found a reason why the cells would benefit from being compressed.

We must remember that the majority of experienced online commentators are from one of two backgrounds:

- off-grid farmstead or crofter

- caravan or RV owner

They will habitually be taking their cells outside the envelope where us home-storage users expect to operate.

As such they will have solved problems which we may not be facing.

Save energy... recycle electrons!

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 259 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 31 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@editor, this is now an example of greenwashing in the ...

By Majordennisbloodnok , 41 minutes ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 2 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 2 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 3 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 3 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 4 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 6 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 8 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 19 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 20 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 24 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 24 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago