Watch Where Your Installer Fits Motorised Valves

I’ve just had a frustrating experience with a Honeywell valve failure, and it’s left me wishing I’d been more involved in checking the placement of all components during installation. I empathise and apologise to my next heat pump installers in advance because we’ll be hellish clients! 😂

The valve was fitted behind the hot water cylinder, with less than 15cm of space between the wall and the cylinder. To say it’s a tight fit would be an understatement - it’s nearly impossible to access.

To make things worse, there’s no isolation valve to shut it off, meaning we’ll likely have to drain the entire system just to replace it. All in all, this setup could have been avoided with a bit more thought during the installation process. Just more shoddy installation work. 🤠

So, here’s my advice:

1. Check Placement of Valves During Installation

Don’t assume your installer will automatically think about future accessibility. Speak up and make sure components like zone valves or motorised valves are fitted in locations where they can be easily accessed for servicing or replacement.

2. Ask About Isolation Valves

Make sure isolation valves are fitted wherever practical. They’re a small addition that can save you a lot of hassle down the line when maintenance is required.

3. Inspect Before Signing Off

Before the installation is completed, do a walkthrough with your installer to confirm everything is in an accessible location. It’s far easier to fix these issues during the initial setup than to live with the consequences.

It’s small details like these that can make a huge difference in the long term. Learn from my oversight, and save yourself the stress if something goes wrong in the future!

Have you encountered similar issues? Please share.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

@allyfish the valve is working, and when called upon, opens and/or closes. Apparently there's a microswitch inside these valves, and that's what's not promoting the boiler to come as a redundancy in our system. It usually takes care of defrosts and some heating when we drop below 0C.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

Unfortunately, it’s the nature of the system we have to work with. The index circuit consistently struggles to reach target temperatures when the outdoor temperature drops to 0°C or below.

In this setup, the boiler only runs intermittently – primarily to assist with defrost cycles or provide a temperature boost when needed. While it’s far from ideal, it’s how the system is configured to operate. One of the reasons why RHH was born. An expensive system to install that has been butchered.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

@editor I see. I knew there would be sound reasons. My ASHP is barely big enough, and I've seen aveage room temperatures drop a couple of degrees overnight with the ASHP running when outdoor air temperatures drop below freezing. Basically, below a certain ambient temperature without supplementary heating, my ASHP seems to track ambient outdoor temperature. There are several factors causing this I think:

1. Undersized unit delivering maximum heat output. When it's defrosting however, it's not delivering 10kWh, more like 8kWh due to intermittency of operation and heat lost for defrost cycle.

2. Return temperature of radiators typically about 5degC lower than supply, which at primary flow rate of 22l/min means the ASHP is, more or less, maxed out: 5x(22/60)x4.2= 7.7kW. It can't reach target WC temperature because it can only raise the circulating water by around 5.5degK.

So it could really use some supplementary heat input 3-4kW. I can energise the 3kW immersion in the LLH, which raises the LWT by a couple of degrees, but that's a very expensive option, even with load shifting most imported electricity off-peak to low tariff. I have the setting for this set to -5degC, by which time I know the house won't be warm enough to be comfortable and will never warm up with around 8kWh of heat input. I could raise this to 0degC, but then I'm guzzling around 6kWh of energy with ASHP & supplementary 3kW direct electric heating together. So I light the stove and burn some wood, which can quickly boost downstairs, and it filters upstairs.

I have a bit of the same issue:

However, this is DIY so I can only kick myself. The TWV is crewed on press fittings on three sides with no possibility to losen just one. So if there ever will be an issue, it will be a pretty big operation to get it all sorted.

@editor - what surprised me most about your picture, is that your piping is completely uninsulated. Although the forum community did actually nominate you for the Nobel Prize for sustainability, this ruined your chances forever 😆.

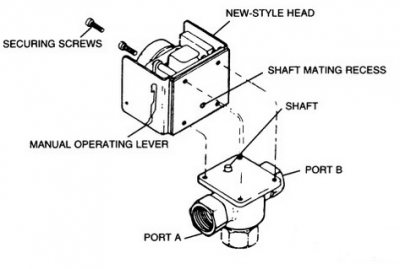

For reference, here's the classic motorised valve wiring diagram:

If the valve body itself is still operating, then you just need to exchange the head.

The white wire is only provided on valves which have ports to accept 28mm diameter pipe (or larger).

The common 22mm valves (Honeywell V4043 etc) have a 'single throw' switch.

In the case posted here by @editor it's possible that the Auxiliary Switch has stopped working because debris has fallen in through the slot from which the manual lever protrudes.

He might be able to recover the valve's operation by cleaning it out with a vacuum nozzle.

It's odd that Mars' valve malfunctioned on a Thursday evening.

They normally wait until Friday, when the stores have just closed.

Keep a spare on the shelf!!

Save energy... recycle electrons!

Posted by: @transparentHe might be able to recover the valve's operation by cleaning it out with a vacuum nozzle.

The 2000W Karcher will be out shortly!

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

As an update, we vacuumed the valve out, but unfortunately, it’s still not working. Worth a try.

The valve motor moves to the open position when requested but doesn’t function beyond that. Here’s the part that’s driving me mad: the company we called initially charged a £65 call-out fee, which included fixing the issue if it could be resolved during the visit (plus the cost of any parts).

They later called back to schedule the repair, and on a whim, I decided to confirm the cost – mainly because we recently got stung by a plumber. That’s when they informed me that, in addition to the £65 call-out fee, there would now be a charge of £200 + parts for the actual repair. When I questioned the price hike, they insisted that was their policy and pricing, which I find absolutely bonkers.

Am I being unreasonable here? I don’t know. If the valve was in a more accessible spot, I’d absolutely do it myself. I’ve replaced the motor on our UFH valve that failed two years ago without any issues, but it was fully accessible and at chest level. But this one is in such an awkward position that I can only fit one arm in at a time, making it impossible to work safely or efficiently.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

But it's only the motor head you need to replace.

You leave the valve body in situ and therefore the job is electrical.

First move the lever to the MANual position (valve open).

The steel cover is usually held in place by a single bolt at one end.

Remove that with a Pozidriv size-2 and the cover can be lifted off.

There are two or four bolts which you can then access inside.

They hold the entire head (motor and aux.switch) onto the metal plate below, and are usually slotted (not Pozidriv).

If you move the lever on the new Head into the MANual position before putting it in place, then the shaft from the valve will align with the socket at the base of the motor.

Save energy... recycle electrons!

Having just revisited your earlier photo, the tricky bit in your case is retrieving the bolts when you accidentally drop them down between the pipes.

I would use scrunched-up newspaper to fill the gaps and make a 'platform' below the valve, just above the black corrugated conduit.

Then 'borrow' a thin aluminium pie-dish from the kitchen and wedge it between the pipes on top of the 'platform'

That will catch the bolts when they fall.

To re-insert the internal bolts when fitting the new head, either use a magnetic screwdriver, or else put a blob of grease on the end to 'stick' the bolt to it.

Save energy... recycle electrons!

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 222 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

@transparent Triggered by the various commen...

By JamesPa , 10 minutes ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 40 minutes ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 46 minutes ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 1 hour ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

I've found that generally the humidity in the house is ...

By IRMartini , 1 hour ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 5 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 6 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 17 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 19 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 19 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 22 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 22 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 22 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 24 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago