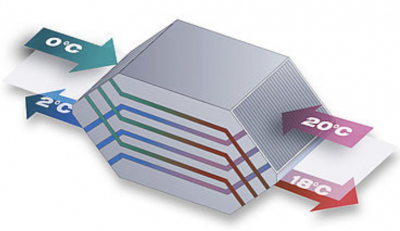

Plastic heat exchangers are usually used inside MVHR units. For an air:air heatexchanger, there's not that much heat transfer needed across that plastic barrier (as the air conductivity is poor) so thin plastic is ok. Along the heat exchanger material we want low thermal conductivity, from the hot to cold end - so for this reason, plastic is preferred over metal. Piccy of I think what's in our MVHR core.

It does sound as though your unit is in permanent bypass then, so the heat exchanger core isn't being used. Some flaps open up inside the MVHR box, bypassing the core entirely. I suggest that you get a copy of the installation and user manuals, perhaps they can help. Certainly our own Vent Axia Sentinel Kinetic can be easily told not to use summer bypass ever, irrespective of temperature sensors - it's a user adjustment not installer on ours.

What unit do you have ?

Posted by: @roblFor an air:air heatexchanger, there's not that much heat transfer needed across that plastic barrier (as the air conductivity is poor) so thin plastic is ok.

Along the heat exchanger material we want low thermal conductivity, from the hot to cold end

Can I ask what is the purpose of a heat exchanger?

@dandee A heat exchanger is used to transfer (in this instance anyway) warmth from the air that is about to be exhausted from the house (stale air) and that energy is used to heat the colder air being introduced to the house as fresh air from outside before it is distributed in the property. Basically a surface conducts the heat from the exhaust air and applies it to the incoming fresh air. Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Posted by: @fazelCan I ask what is the purpose of a heat exchanger?

That question is a great leveller. 🙂

It shows the rest of us how we quickly descend into the technical depths!

In general terms a heat exchanger transfers heat between two fluids (liquids or gasses), whilst keeping those fluids separate.

The radiator of a car is a simple heat-exchanger.

Heat from the engine is passed into cooling water.

That water is pumped through the radiator, which has thin metal fins to transfer the heat into a stream of air.

The water and the air don't come into direct contact.

Within a household ventilation system (MVHR) there is a heat exchanger with a much larger surface area.

Hot, humid, sticky air is sucked out of shower/bath-rooms and kitchens.

As it passes through the heat exchanger, the heat is passed to fresh air being drawn in from outside the home.

The separation between the two streams of air means that the cooking smells from the kitchen, and the humid atmosphere from a shower cannot pass into the fresh air.

Save energy... recycle electrons!

Posted by: @fazelPosted by: @roblFor an air:air heatexchanger, there's not that much heat transfer needed across that plastic barrier (as the air conductivity is poor) so thin plastic is ok.

Along the heat exchanger material we want low thermal conductivity, from the hot to cold end

Can I ask what is the purpose of a heat exchanger?

Ohh boi, it was a rhetorical question, see the bold highlighted statements about the heat exchanger.

Placing the quoted phrases in a bold font was too subtle for me @dandee

I'd need at least one smilie to grab my attention. 🙂

As a member of a Community Energy group, I'm not daunted by receiving very basic questions from members of the public (or politicians!).

Save energy... recycle electrons!

The heat exchanger material conductivity is actually a compromise. Through the material, the thin way, we want high conductivity. Along the material there is a parasitic loss mechanism, for which we want low conductivity. Plastic is a better compromise of these two competing requirements than Aluminium is for an Air:Air heat exchanger - as the air boundary layer has an effective conductivity which is quite low there's little point using Aluminium or Copper as it won't improve performance noticeably, while the parasitic losses would shoot up. For a water:water heat exchanger plastic would be a poor choice, and a metal would generally be chosen.

Discussion on a forum is actually a compromise. Through this medium we actually want high transmissivity of information. Along the discussion there is a inherent loss-mechanism, through which we experience periods of low communication...

... which is why @robl is still posting coherent technical descriptions of the physics behind the design of heat exchangers, 25-hours after @dandee told us it was a "rhetorical question". 🤣

But hey... it's Friday!

and I've just enjoyed reading an erudite explanation of parasitic losses. 😉

Save energy... recycle electrons!

Posted by: @roblThe heat exchanger material conductivity is actually a compromise. Through the material, the thin way, we want high conductivity. Along the material there is a parasitic loss mechanism, for which we want low conductivity. Plastic is a better compromise of these two competing requirements than Aluminium is for an Air:Air heat exchanger - as the air boundary layer has an effective conductivity which is quite low there's little point using Aluminium or Copper as it won't improve performance noticeably, while the parasitic losses would shoot up. For a water:water heat exchanger plastic would be a poor choice, and a metal would generally be chosen.

Sorry I'm struggling to understand this. I'll try to play back what I've got from you: We want to conduct air from the outgoing (warm) side to the incoming (cold) side. For this, we need a thin material that has high conductivity in the perpendicular direction, to allow transfer across the interface. However, because the air passage is quite long, we don't want the material itself to be leeching heat away from the warm air and transporting it laterally along the length of the material: we want it transfering perpendicularly across the interface only. So plastic is better for this.

However, I still don't feel like I really "grok" the explanation. Nor can I explain why we want plastic for air:air but metal for water:water.

If you don't want to explain it again (which is totally understandable!) do you have any suggestions for where I can look this up?

ASHP: Mitsubishi Ecodan 8.5kW

PV: 5.2kWp

Battery: 8.2kWh

@scrchngwsl You have already noted that for efficient counter-current heat transfer, you want to avoid heat transfer within the fluid streams. In each fluid, there is a laminar boundary layer which constitutes the major resistance to heat transfer to the interface. There is then the heat transfer perpendicular through the exchanger surface as well as that within the plane of the exchanger surface. The exchanger plate thickness is minimised (and length of exchanger maximised) to maximise flow across plate rather than along it. Flux through plate is proportional to delta-T across plate surface while flux within plate is proportional to temperature gradient along plate.

However, the boundary layer in air poses at least an order of magnitude more resistance than water and heat flux through an air boundary layer is going to be correspondingly lower. At this lower heat flux, the delta-T across the plate will be also correspondingly reduced but the gradient along plate will not (I still want to shift that amount of heat in that distance). The lateral flow of heat within the plate will therefore start to dominate, particularly if the plate has a high conductivity. I am therefore willing to use a lower conductivity plate material (which will result in a higher delta-T) to shift the balance back towards transfer across plate.

It was just yesterday that James posted

Posted by: @jamespipeHello! I'm not a tech-savvy person. I'd like the moderators and other members to dumb down the complex subjects to my level. 😀

Have we achieved that yet, James? 😉

Save energy... recycle electrons!

@ronin92 thanks a lot, that cleared it up for me!

ASHP: Mitsubishi Ecodan 8.5kW

PV: 5.2kWp

Battery: 8.2kWh

Currently viewing this topic 13 guests.

Recently viewed by users: MairiA 29 minutes ago.

- 26 Forums

- 2,426 Topics

- 55.1 K Posts

- 366 Online

- 6,104 Members

Join Us!

Worth Watching

Latest Posts

-

RE: R290 Heat Pump and Foundation Air Bricks

@l8again Manufacturers will support R32 for quite a lon...

By ASHP-BOBBA , 9 minutes ago

-

RE: Heat pump not reaching flow temperature

Agree, the figure is given for SCOP not COP

By JamesPa , 23 minutes ago

-

Exploring the role of alternative clean heating solutions - Government Consultation

I just came across this current consultation, which may...

By Rusty , 25 minutes ago

-

RE: Vaillant aroTherm not heating with many faults

@anon67 Pleased they are replacing it for you and I am ...

By ASHP-BOBBA , 44 minutes ago

-

RE: Is it normal to use power from the grid when running off the battery?

@johnnyb This is ours and is very similar for most d...

By Bash , 44 minutes ago

-

RE: Daikin Wireless Thermostat

Thanks @toodles I had a good dig around the internet...

By Bash , 52 minutes ago

-

RE: Octopus Cosy 12 Heat Pump Regret: Incredibly Loud, Poor Heating & Constant Hum - Help!

Thats very unlikely to be anything to do with the heat ...

By JamesPa , 1 hour ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

A domestic 3ph Smart Meter operates in Vector Sum Mode....

By Transparent , 1 hour ago

-

I am again trying to optimise my DHW settings taking in...

By DavidAlgarve , 2 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

@johnnyb The noise of the Solis is nothing very sign...

By Batpred , 12 hours ago

-

RE: Is my Samsung gen6 outside air temp sensor missing a sheath/sleeve?

@papahuhu Yes, good information is often hard to find, ...

By Old_Scientist , 12 hours ago

-

RE: The good, the bad and the not that great – my heat pump installation

@toodles ahhh no trouble yeah probably won't mess with ...

By Burtis , 13 hours ago

-

RE: Post-Traumatic Heat Pump Stress Disorder

Some more examples of those that really should be benef...

By Jeff , 15 hours ago

-

RE: Installer Fitted 9kW Instead of 11kW Heat Pump and Changed MCS Paperwork - What do I do?

I've now had an interesting email from a Complaints Res...

By MairiA , 17 hours ago

-

RE: Reliable, easy to use home battery options

Correct. LiFePO₄ cells mustn't be charged if their te...

By Transparent , 17 hours ago

-

RE: Water outage in the the south-east

Indeed!Any contamination in the well water would be tra...

By Transparent , 19 hours ago

-

Are split ASHPs with R290 refrigerant coming soon?

Question. Are there any (or likely to be in the near t...

By iotum , 21 hours ago

-

RE: Setback savings - fact or fiction?

Indeed. In many ways, a defrost is a setback, with the ...

By cathodeRay , 21 hours ago

-

RE: How to use my Hanchu battery storage for home without it feeding back into the grid?

@countryman-helmsley In that case is there a button ...

By IRMartini , 22 hours ago

-

RE: Ideal HP290 14kW ASHP - how to optimise

Great. It’s not bad is it, though I agree it may repres...

By Davesoa , 24 hours ago