@grantmethestrength it was literally just out of the box plug and play. I'll email him and see what he says.

Posted by: @grantmethestrength@benson can you post an example of your automation please

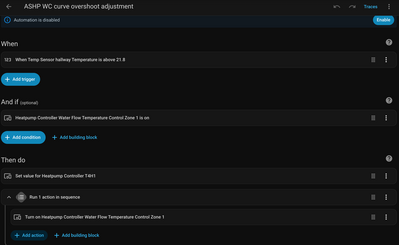

sure. Here's the automation sequence, so pre requisite is that heating must be on (this is what Control Zone 1 entity is). T4H1 is the OAT value at the colder end of the curve so if it was set back from -2, to -1, this would lower the curve sufficiently so it gradually reduces IAT, I found. The last action to run in sequence is then to turn CH back on again:

Here's the code behind it as well, if this is what you meant:

alias: ASHP WC curve overshoot adjustment

description: ""

triggers:

- trigger: numeric_state

entity_id:

- sensor.temperature_humidity_sensor_temperature

above: 21.8

conditions:

- condition: device

type: is_on

device_id: d3224b34c0e7484c771e1543c8252132

entity_id: 8116be08f573f5dc01bb0d508392cfb3

domain: switch

for:

hours: 0

minutes: 5

seconds: 0

actions:

- device_id: d3224b34c0e7484c771e1543c8252132

domain: number

entity_id: 6a61ed3c9f83ad929967dfabfd642b17

type: set_value

value: -3

- sequence:

- type: turn_on

device_id: d3224b34c0e7484c771e1543c8252132

entity_id: 8116be08f573f5dc01bb0d508392cfb3

domain: switch

mode: single

@benson - you are doing this the counter-intuitive way to me, shifting the line (curve) left and right on the x axis, rather than moving up and down on the Y axis.

Posted by: @bensonpre requisite is that heating must be on

This rings a distant bell, the unit can't be in DHW mode for some reason, and looking at my code, I do have a 'is unit in space heating mode' test before running the rest of the auto-adapt script. But if you are adjusting the curve, you will be in space heating mode anyway (unless the DHW happens to be on, which as I say you can check). I am not sure you need all the on/off stuff - I just write to the register anyway (runs once an hour).

Midea 14kW (for now...) ASHP heating both building and DHW

Edit: just had a look at some of my automations and it looks like it is home assistant creating the random entity id’s still worth checking in the non yaml version that the entities are correct. It turns out Home Assistant creates its own id in the background so that even if you rename the entity it still has the same unique id for that entity.

Kind Regards

Si

——————————————————————————

Grant Aerona3 13kW

13 x 435w + 13x 480w Solar Panels

Sigenergy 10kW Inverter

16kW Sigenstor battery

Home Assistant also has an auto-entites card so you can have a card that shows all of the entities of a device this is quite useful for finding the exact entity, its current state and its history.

Kind Regards

Si

——————————————————————————

Grant Aerona3 13kW

13 x 435w + 13x 480w Solar Panels

Sigenergy 10kW Inverter

16kW Sigenstor battery

Thanks @grantmethestrength and @cathoderay .

The reason I set it up to only run the automation when the heating was on, was to try and minimise the alteration of serviceman settings when the heating was off- for the very reason that changing the settings causes the issues that it does.

I did email Sven and he replied really quickly, with a very detailed reply. He is suggesting, as has been mentioned previously, that I just turn off WCC and set the flow temp according to OAT as one workaround. He does mention the use of a helper entity which I am not familiar with but will look into it.

Aside from all of this, the WCC that I set had been working really well without any tweaking so I can just leave it be and it will probably be fine. It was just overshooting a small amount when temperatures dropped. I have slightly altered my cold end parameters from 47c at -2, to 47c at -3 to see if this improves things. The house is back to a stable 21, and when the temp drops again this might just drop the flow temp the tiny amount that I need to stop the overshooting.

Posted by: @bensonI feel like this is another stupid question but could he apply a firmware upgrade remotely to all of his devices, if it was an issue with the coding? How would I know if the device is firmware upgradeable?

Hi, Sven is not able to update the heat pump controller remotely. The controller’s firmware can be updated using the OTA update method described on https://shop.svenar.nl/support/?q=ota_update. Another, but more involved method is to use ESPHome builder which allows to upload a new yaml configuration to an esphome device via the wifi connection. An even more involved method is to build the firmware yourself (using esphome builder) and flash the firmware using an esp32 programmer like https://shop.svenar.nl/product/?p=espprogrammer

But in normal situations an update of the firmware is not likely to be needed.

Posted by: @benson@mosibi thanks for confirming, and describing the various options.

It’s a great little device you’ve developed 🙂

Thx, but Sven did the hardware development. My role (as his father) is that I am guilty of purchasing an Airwell (Midea clone) heat pump that left us/me with a lot of questions, which resulted in the end in the device you also have 😁

Hi again all,

Just to update on this...

I've now added some energy monitoring using the built in HA Energy dashboard. This is really easy to use, and all I've done is used the modbus registers relating to energy consumption, and heating output as two devices I'd like to individually monitor. I can then just change date ranges to show day, last week, last month etc:

What I then wanted to do was set up a gauge to show rolling COP using these figures. The registers themselves are cumulative so they show total consumption, and output, since commissioning of the unit. They don't separate heating and DHW unfortunately but the combined COP is still very useful.

To this end this I used what I think is quite a new feature in home assistant which are 'helpers'- one use of which is for statistics. This is where I needed to use ChatGBP to help set them up, tell me the right options, and write a short bit of yaml code for me, which was largely successful aside from making one or two mistakes with some options. ChatGBP is a bit odd- when you go back and ask it to check something as it doesn't work, or ask "is that really the right option?", it will correct itself and say things like "good catch..or you're right! Here's what you need to do".

I then just used a simple gauge card to display it on one of my dashboards. This is for last 24hrs:

In terms of early conclusions and moving away from homely and just using Svenar combined with HA to set up a simple WCC and monitor it, I'd comment as follows.

- efficiency wise for the month of November thus far my COP (according to energy metering on the control panel) is 4.9. This is slightly better than homely managed in this sort of weather last year. It's quite close though so probably fair to say no discernible difference.

- comfort wise, this has definitely been better for us. No overshooting outlet flow temps and the steadiest IAT we've experienced, now that I've tweaked my curve to the right settings. Regarding my earlier comments about wanting to adjust the curve to compensate for over shooting, I've come to realise that it probably isn't even worth it. The only time it overshoots is when we get a short burst of solar gain in the morning (couple of big windows and patio door at back of house, east facing). It soon settles down though. In milder weather the WCC generally provides an IAT of 20.5, and during colder periods this rises to 21 which is perfect for us.

- on occasions homely failed to reheat our cylinder during set times and I now believe this is due to the issue with entering serviceman settings and turning everything off. The benefits of the above approach is that cylinder reheats are now 100% reliable.

- I now have total flexibility and control over my heating, and I can do this without having to go to the cumbersome control panel. To give one example where this is handy, I fitted a new radiator in one of the bedrooms a couple of days ago as our existing one was slightly undersized (another boo boo by the original installers). Once fitted I wanted to just have the heating run continuously at a reasonably high flow temp to test for leaks etc. I could quickly do this by turning off weather comp on my dashboard and I just ran it at 40 for an hour or so to make sure no leaks, everything heating up correctly etc.

- As above, I can set my HA dashboard up with whatever options and controls I want, and it is a super easy app to use. e.g. hot water boost, quick view of outlet and inlet temps, weather comp settings.

The Svenar controller has been an absolute revelation for us to allow us to easily do this (thanks again to Sven and his dad). Cost wise the total outlay even including the ready made home assistant green is much cheaper compared with Homely.

I do think Homely, Havenwise etc really come into their own if the ashp user is exploiting TOU tariffs. We're not doing this directly with the heat pump as we have 13.5kW battery storage so just set the battery up to exploit the Cosy dips, and then the ashp just runs 'normally'.

Thanks for everyones help, and it was I think one of JamesPas replies on another thread that introduced the concept of pure weather comp to me which I had not heard before. I was naturally inclined to think I would need some form of intrusive IAT influence but I now know that this isn't really the case to have a system that works well. I hope this is of interest to others, or if nothing else writing it all down will help remind me of what I did and how.

@benson — excellent work! You now have access to all the data in the modbus registers, plus a way of displaying that data in useful ways.

For the benefit of others, you may have skipped over a stage: how you record the data. Maybe HA or the Sven/Mosibi add on just does that anyway. But, obviously, there needs to be a way the data ends up in a database that is then used to provide the charts etc.

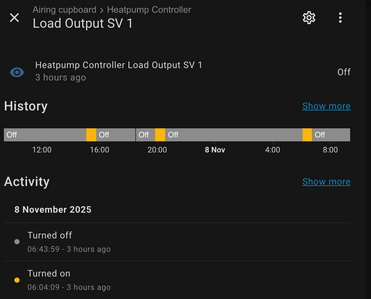

Posted by: @bensonThey don't separate heating and DHW unfortunately but the combined COP is still very useful.

There is a way to do this. One of the registers holds the position of SV1, the main three port two way valve, which indicates whether the heat pump is in DHW or space heating mode. The position of that valve is the only reliable way to tell which mode it is in. The data is in one of the 16 bits in register address 129. How you get that bit is somewhat obscure - the data arrives (over modbus) as an integer, which you then have to convert to its binary representation, and then extract the relevant '0' or '1'. I can go into more detail if you want to do this.

Posted by: @bensonThis is slightly better than homely managed in this sort of weather last year.

I think it has been quite a mild autumn so far, and even just a degree or two difference in outside air temperature can make a visible difference. My 24 hour rolling COP (South UK) is typically between 4 and 5 at the moment. Your 4.9 vs 5 is I agree effectively the same.

Posted by: @bensoncomfort wise, this has definitely been better for us.

A well tuned WCC will achieve this, except during well understood exceptions (eg solar gain, strong cold wet winds, entertaining guests). If you want to tweak the curve, it is easily done over modbus. Instead of reading the relevant addresses, you write to them.

Posted by: @bensonif nothing else writing it all down will help remind me of what I did and how.

Very true! I have been remiss in this. It is very easy to get carried away making and testing changes, and then forgetting all the steps you took to get where you are now. Notes, notes and then more notes!

Midea 14kW (for now...) ASHP heating both building and DHW

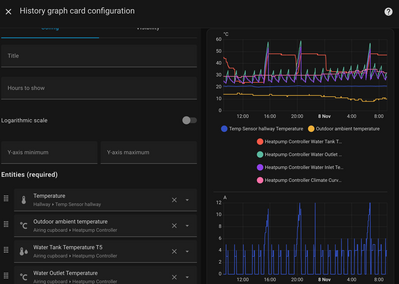

@cathoderay yes I did rather gloss over the graphs.

I think the inbuilt functionality of home assistant is really good, and it's always being updated. I thought I needed add ons (hence why I started looking at plotly add ons, and others) but there's actually so many native dashboard cards that cover the majority of scenarios any average user would want.

I one I used is "History graph card". All you do is list the modbus registers you want to plot for the last 24hrs.

Below my main one I've got a separate graph for current, and another for flow rate.

Posted by: @cathoderayThere is a way to do this. One of the registers holds the position of SV1, the main three port two way valve, which indicates whether the heat pump is in DHW or space heating mode.

Ah great! Sounds like this is something where I could potentially use the HA helpers again and I can indeed see SV1 in my list of 200 odd entities I can monitor (and on and off history which seems to tally up with our DHW reheat set times).

I now have a kitchen to fit as my next project but when I have a bit more time I can look into it 🙂

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 258 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 12 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@editor, this is now an example of greenwashing in the ...

By Majordennisbloodnok , 22 minutes ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 2 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 2 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 2 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 3 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 4 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 6 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 8 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 18 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 20 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 23 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 24 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 24 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago