Posted by: @cathoderay@derek-m - if I read the table on that page correctly, the default setting for S2 positions 3 and 3 is 11 ie on/on which equals variable speed Wilo (pump brand) with 9.0m head (quite punchy, more than enough to make your ears pop). The m^3/h seen in the wired controller does vary, I think I have seen it as low as around 1m^3/h, but only very rarely, most of the time it is around the 1.4 mark. I think it can vary, but isn't being varied very much.

To know for certain which water pump is installed and the correct settings for DIP Switch S2, you would need to look inside the heat pump unit.

It may be possible to carry out a quick check by requesting more heat energy, either by increasing the LWT setting in fixed LWT mode, or increasing the offset in weather compensation mode. Dependent upon how the heat pump is programmed to respond it should increase the flow rate for a period of time.

If this method does change the flow rate then carry out the reverse to see if the flow rate falls.

To transfer more heat energy whilst maintaining the specified DeltaT requires a greater flow rate.

Posted by: @derek-mIt may be possible to carry out a quick check by requesting more heat energy, either by increasing the LWT setting in fixed LWT mode, or increasing the offset in weather compensation mode. Dependent upon how the heat pump is programmed to respond it should increase the flow rate for a period of time.

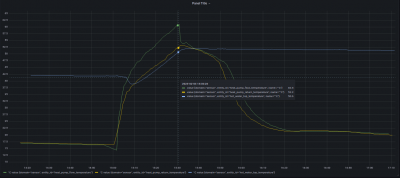

I've just tried temporarily increasing the warm end of the weather comp curve by ten degrees. Flow rate effectively remained unchanged, at 1.41 to 1.42m^3/h. It was also 1.4 something just before I did the test, when the compressor wasn't running. I looks like it's a fixed flow rate, but as I said before, I do recall seeing it at a lower figure once or twice. Next time I open the outside unit, I'll have a look at those dip switches, also what the actual pump in there is.

Midea 14kW (for now...) ASHP heating both building and DHW

I ordered a Samsung gen6 8kw ashp and a pre-plumbed cylinder online. The seller included "Freedom heat pumps" installer instructions which had incomplete instructions and didn't quite match with the plumbing arrangement of the pre plumbed cylinder. This resulted in six months of immersion heated water!

The instructions also led to the burning out of the pump relay on the samsung circuit board as it omitted to mention the need for an auxilliary relay between the board and the pump (Samsung book mentions this though) so I ended up hacking in a SSR direct to the circuit board in the middle of winter, goodbye warranty 🙂

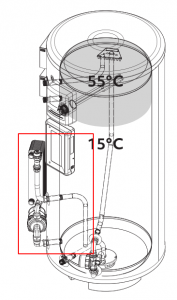

The pre-plumbed cylinder has a plate exchanger separating the heat pump from the pre-plumbed cylinder. The exchanger was mounted on its side which doesn't help it to be air free and the direction of flows were the same, resulting in a poorer heat exchange (I re-piped and re-orientated it). Other than saving a wee bit of antifreeze I don't really see much point in the plate exchanger at all.

The set up instructions used external room thermostats and excessive water temperatures for my house.

The Samsung manual assumes a PWM pump and the pre-plumbed cylinder came with a normal pump (one on each side of the plate exchanger). I am currently agonising over whether I should get a PWM pump and whether to ditch the plate exchanger alltogether.

D

Posted by: @derekdeleonI am currently agonising over whether I should get a PWM pump and whether to ditch the plate exchanger alltogether.

I have the 16kW Samsung Gen6. As I was going to reuse my vented indirect solar thermal store, so I put in a heat exchanger for the hot water, with some modifications simerlar to the mixergy layout. (required a wireless camera in the cylinder - which was challenging given the cylinder is Faraday cage)

To cut a long story short, seems to be working ok, at least on heating the cylinder - an additional coil between the cylinder and the shower, means I need a couple degrees hotter than with a direct cylinder . A cylinder recharge cycle looks as below. (30 mins, approx)

That's an interesting way to do the hot water, sounds like you like a challenge 🙂 I just went with an unvented 250l cylinder with a 3m2 coil. Reckon I'm going to take out the plate exchanger as it isn't big enough to do the duty anyway. I looked it up on the manufacturers website and they even make it clear that it probably won't be good enough for heat pumps! Wrongly specced by the supplier 🙁

https://nordictec-store.com/gb/62-ba-16-serie-0016mplate-1-thread Mine is the 24 plate version.

I'm not really sure where to add this in the forums, but this seems like a suitable thread. My latest post about our installation this time last year is about after sales support - and in the main I've been very happy. The post, and others, is available here: https://world.hey.com/alastair.graham

Hope that it's of use to some of you thinking about getting more home energy tech installed.

@william1066 ever since installing a Mixergy, i went home and with bits i had laying around converted my own cylinder to a heat pump plate loaded. which it has now been for nearly 3 years.

Heat pump installer

@derekdeleon It looks like they got the connections right, but you probably don't have enough surface area.

The BA-16-24 has a Heat Exchange Area: 0.384m² - which seems a bit small - as you found out.

Mine is the Ba-23-70, which seems to do the job (Heat Exchange Area - 1.610 m² about 4x the BA-16-24). [not comparable with finned tube surface area, of course - if anyone has a ratio to calculate equivalent plate vs finned tube surface area, please share as I am interested in that figure]

At the time I chose this plate heat exchanger, I basically "guessed" the size by looking at pictures of the mixergy plate heat exchanger, counting the plates and estimating approx size. Mine seems to work pretty well.

At the moment I can get 12kW of heat transfer rate through this setup to the cylinder.

I would be very interested in hearing more about your conversations with the trade about ASHP installations. We have had the original installers back at least 6 times and the Daikin engineers out 3 times since installation last October. I am beginning to wonder if the unit (Altherma 3H HT) is still faulty. The most recent engineer (from Daikin) told us that he had replaced the broken booster heaters and checked that the software was up to date. He did wonder if we had a big enough unit for the size of house. The unit can still only manage to heat the circulating water to about 35-40C when the spec claims that 65C can be achieved.

@william1066 after installing our first Mixergy a few years back, I was unimpressed.

Since then we have installed/converted older invented cylinders to plate loaded with heat pumps. Including my own.

Heat pump installer

@timatheronwood sounds undersized, or short of refrigerant. Or could be poor design. Most of the Daikin engineers don't really know about heating design. I should know I used to work for Daikin.

Heat pump installer

Hey all, a big thank you to all you kind forum-ers who offered advice during choosing/pre-install of our baby 8k Midea last year.

It has been running for a full year now.

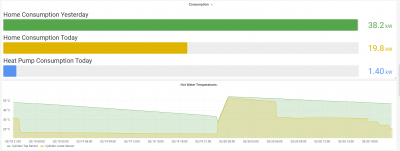

HW set at 45deg (65 weekly immersion boost) and weather comp at 41-25.

It handled the -7C temps with aplomb and, most importantly, helped contribute to a satisfying 70% reduction in our energy use. We are an electric-only house (econ10) & used 5600kW total.

Recently had small solar install, that is helping too (maybe 15-20%?). No battery tho.

Quick Q to people who have solar - is there any reason you wouldn't have a smart meter? We don't have one yet &, as we don't have batteries, would probably be interested in getting a little back from the SEG.

Cheers!

-

Is this ASHP install OK?

7 months ago

-

My Journey to Finding the Best Heat Pump for My Home in France

12 months ago

-

What is the most important factor for you when choosing a heat pump brand?

2 years ago

-

Mid terrace - ASHP Install location

2 years ago

-

Any installer recommendations for Samsung ASHP?

2 years ago

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 329 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Having consulted with the plant wrangler in chief, it w...

By AndrewJ , 9 minutes ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 19 minutes ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 41 minutes ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 1 hour ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 3 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 3 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 4 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 5 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 7 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 19 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 21 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago