@cathoderay I thought a bit more about the flow rates thing. with a Buffer / LLH it matters to get them balanced, as that minimises the effect of mixing (as much as is possible, anyway) and thus minimise the reduction in flow temperature across the unit. But in a PHE , there can be no mixing. So I'd expect flow rate tuning to make minimal or no difference to the overall system behaviour in terms of throughput. The heat transfer is governed only by the input and output temps and the physical size of the PHE. If you move the 2ary side water slower, the hot out will come out at at a temperature closer to that of the hot input, but you won't get more heat energy through it. The only way to increase the capacity of the same PHE is to put vastly hotter water into it. which in a way you are doing with the high LWT's you're running at.

So I kind of expect that the measured heat throughput that you have won't be changed (certainly not by much) by your flow rate tweak? as its the PHE thats the constraint.

Every single one of the best practice installers and industry experts out there now says "open loop" . I have no idea what currently goes on in Freedom heat pumps. But if you read the collected works of grahamh, who was Mr Freedom back in the day, buffers and LLH are definitely no longer "mandatory".

the science on this point isn't evolving any more, its reached stable state I think: if you follow some of the experts you will learn that HP's are bench tested always in "open loop". As that is how you get the "databook" best performance numbers. Maybe LLH/Buffers were needed back in the day I don't know, I have zero knowledge of HP's more than 2 years ago! ask grahamh...

some bits of the industry are doing it right. heacol. the heatgeeks. But it seems we are in constant situation on this forum of trying to help those who've been installed by the parts of the industry who don't (do it right).

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @glpinxitI guess that you may need to tinker with your pump speeds to determine what your situation is

Unfortunately, neither provides any way to control their speed externally, beyond the push button control on the secondary pump. The primary one has it's speed controlled by the heat pump, with no manual setting that I have found, at it appears to run at a mostly steady rate whatever the demand.

Having said that, see @iancalderbank's posts, and my reply below, I think we have a consensus that the PHE acts as a throttle, we already have the maximum possible heat transfer, and changing flow rates isn't going the change the amount of heat transferred.

Posted by: @iancalderbankSo I kind of expect that the measured heat throughput that you have won't be changed (certainly not by much) by your flow rate tweak? as its the PHE thats the constraint.

Very possibly, but the flow rate tweak was your suggestion! I did seem to me at the time reasonable that if the secondary circuit fluid flowed faster, then the amount of heat transferred to the rads, and so away from the PHE, would increase, indeed it is predicted by the flow rate x delta t x specific heat equation, as long as the secondary delta t stays constant, may not have done, before the change to CC3, it was 8-9 degrees, vs 6 now. Correct me if I am wrong, but I suspect this fits with the PHE being a throttle theory, flow rate may have on up on CC3, but the delta t has dropped, because only so much energy can get across the PHE.

GH as I understand it wrote the Freedom Installation manual that my installer used, the one that says you must have a LLH/buffer/PHE, otherwise your warranty is history. My question about the 'science' being primitive was rhetorical - surely heat pumps have been around long enough for the principles to have been established quite some some ago? Why were they ever a requirement (leaving me and others lumbered with something they not only don't need, but is actually harming performance)? And if it has been reversed, what were @swanny's installer doing when the did install a LLH on a recent (2023?) installation?

The point I am making is that it is a serious nuisance to end users to have to put up with all this lack of clarity/inconsistency, when there really is no excuse for it. I'm certainly not going to take my system down in January (what could possibly go wrong) even if it is mild at the moment, but if when I do remove the PHE, who is going to pay for it. Perhaps Freedom should pay, they insisted on the PHE in the first place? I don't think it should be my installer, he was just following Freedom's instructions, believing they knew what they were talking about.

Midea 14kW (for now...) ASHP heating both building and DHW

GH has been involved in heat pump installs since the early days, he knows his stuff. He also had to come up with workarounds for flow rate issues that were the bane of early installs.

LLH/Buffers are there purely to ensure there aren't flow sensor/flow rate issues on retrofit installs.

Off grid on the isle of purbeck

2.4kW solar, 15kWh Seplos Mason, Outback power systems 3kW inverter/charger, solid fuel heating with air/air for shoulder months, 10 acres of heathland/woods.

My wife’s house: 1946 3 bed end of terrace in Somerset, ASHP with rads + UFH, triple glazed, retrofit IWI in troublesome rooms, small rear extension.

@cathoderay flow rate tweak - yes my bad, I had it in my head we were balancing flow rates with an LLH. It hadn't occurred to me that it wouldn't make a difference with a PHE until I worked through it. fair enough you were being rhetorical - didn't pick up on that sorry!

systems being installed badly : At least you know what the issue is and the path to a solution on your system. Albeit it'll probably be you that ends up paying, which will hurt. I think the only possible grounds you've got is by proving the PHE is undersized by getting its spec.

whats more of a concern to me is whats happening from now onwards, I don't know how it gets fixed. The bad press that results from "my heat pump won't heat my house" stories that arise from all of these crap installs and what that results in , in terms of people not switching over.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @iancalderbank@derek-m maybe thats not the right technical term. I'm just telling you what it does. If you stand by the heat pump its a LOT colder when its running. I had to do some minor property maintenance the other day in the full blast. 7 layers on and still numb in 5 mins, had to give up. Ok so the sensor isn't directly in the blast - its on the upper back . but it doesn't surprise me it drops a bit at all. Not sure how many people actually graph this level of detail from a sensor that is physically on the unit.

You, as a warm blooded human, will feel the effect of wind chill, so if air is flowing around you it will feel chilly.

The actual sensors are relatively small so that they give a reasonably quick response, but also need to be protected from damage, hence their location.

Here are some possible causes of temperature variation as measured by the OAT sensor.

There could be sunlight on the heat pump or ground nearby that is raising the temperature of the air around the OAT sensor when the heat pump is not operating.

When the heat pump first stops, there could be warmer air coming out of the rear area for a period of time.

When the heat pump restarts, any warmer air will be displaced, hopefully by fresh air at normal ambient temperature.

@derek-m I suppose that accuracy of the measuring of ambient temoerature in the locale of the heat pump will partially depend upon the frequency of the ‘polling’; if the sensor is polled every few seconds or several minutes or ten minutes for arguments sake might produce very different reports, perhaps a measurement that tells the pump to start needs to be followed just seconds later to sense that true OAT as seen when ‘new air’ surrounds the sensor. Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Just thought that a little cheerier results might be welcomed; this is today’s performance with an OAT of 10 degrees C. We have gone from approx 1.75 kw/h when we had -6 degrees C to 0.75 kW/h today. Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

If I may offer a little advice from observations about your system and those of others.

It is my considered opinion (and I think that there are others who will also agree) that the heat pump is not the determining factor as to how energy is supplied to the home. The heat pump merely tries to supply sufficient energy to meet the demand.

Please consider the following:-

The heating demand is set by the heat loss at the prevailing IAT and OAT. If your calculated heat loss is as specified 12.4kW, then at an OAT of -5C, the probable heat loss will be 11.3kW at an IAT of 16C, 11.9kW at an IAT of 17C, 12.4kW at an IAT of 18C, and 12.9kW at an IAT of 19C.

To meet this heating demand the heat emitters will be required to emit this quantity of thermal energy from the water into the home. The quantity of thermal energy being emitted will be dependent upon the heat emitter capacities, the 'average' water temperature, the flowrate and in your case the transfer capacity of the PHE. For the heat emitters to meet the heating demand at the above IAT values, the corresponding LWT's would be required, 52.5C @ 16C, 53.5C @ 17C, 54.6C @ 18C, and 55.6C @ 19C.

But of course the above values do not include having a PHE within the system.

I would suggest that you measure the flow and return temperatures at each radiator as accurately as possible, to see if they are each receiving the full flow temperature and to see if the system is correctly balanced.

I would also suggest that you ask Freedom to provide details of the PHE, its make and model. It should then be possible to ascertain if it is actually capable of transferring 12.5kW of thermal energy from primary to secondary, without placing a large burden upon the operation of the heat pump.

Don't forget for thermal energy to be transferred through a heat exchanger, there must be a temperature difference. If the thermal energy being supplied by the heat pump cannot be adequately transferred, then the heat pump will throttle back or may even stop for a period of time.

I forgot to ask. Did the OAT actually increase by something like 9C over a 3 hour period?

Posted by: @hughfGH has been involved in heat pump installs since the early days, he knows his stuff. He also had to come up with workarounds for flow rate issues that were the bane of early installs.

LLH/Buffers are there purely to ensure there aren't flow sensor/flow rate issues on retrofit installs.

I know GH has been around for a long time, and generally knows his stuff, though sometimes he does make typo type errors. That said, I am personally grateful to him, because he was the one that first pointed out the Midea 12/14/16kW models are all the same hardware, output is just controlled in software by flipping dip switches (note I have not done this, it is just useful to know it is an option, as the original spec for my system was for a 16kW unit, but they were out of stock, and there was a pressing grant deadline). My point is that for a novice or even partially self-educated end user, it is confusing to be told we must have a LLH/buffer/PHE on pain of losing our warranty, and then be told, whatever we do, don't have a LLH/buffer/PHE, it is ruining out system.

On your second point, they are there to preventing flow sensor/rate problems, given that my heat pump is a retrofit to an old leaky building, can you comment on whether removing the PHE might have a downside, ie I might end up with flow sensor/rate problems if I remove it?

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayOn your second point, they are there to preventing flow sensor/rate problems, given that my heat pump is a retrofit to an old leaky building, can you comment on whether removing the PHE might have a downside, ie I might end up with flow sensor/rate problems if I remove it?

this needs qualifying.

The "install a system that won't get any complaints or callbacks but we don't care about efficiency" approach installs an LLH / Buffer. because there's no possibility for low flow rate on the radiator side to cause a low flow rate alert on the heat pump side. I think that's why they do it. They could also use 2x smaller cheaper pumps rather than 1x larger.

A properly engineered single-loop system with no LLH / buffer, with low resistance pipework and components , and an appropriately sized pump, will not have flow rate errors either.

In your case with a PHE there's an added feature / complication that you have a different fluid on each side. outside could be glycol , inside not.

To change your system to a single loop, as well as removing the PHE you'd have to consider

- glycol or not. If not, then antifreeze valves. If yes, lower heat capacity of glycol, more glycol, more expensive to fill.

- what is the flow resistance of my system as as whole (end to end, heat pump and radiators) and what pump do I need for that?

- If that gives an overly large pump size, what pipe works need to be upgraded in size to reduce resistance?

- do I also need to upgrade some components (such as diverter valves or filters) to minimise flow resistance

your other possibility is to fit a much larger PHE. as that is where we think the constraint is on your system as it stands.

My system is also a retrofit ( but to a less leaky building than yours) with a single loop. it can be done.

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

Posted by: @derek-mThe heat pump merely tries to supply sufficient energy to meet the demand.

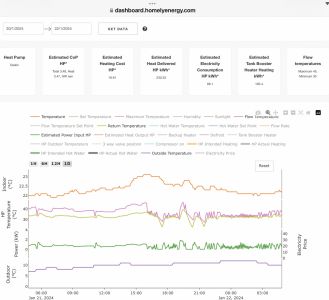

@jamespa I think I am right in saying is of this view, and I do get this point: the heat pump responds to the feedback contained in the RWT. Indeed i was looking into this earlier today, in the context of cycling, trying to discern what triggers the cycle:

On first glance it makes sense that it is the LWT going over a certain point above the set LWT, but in fact it may be the RWT reaching the set LWT. Comments welcome.

Posted by: @derek-mI would suggest that you measure the flow and return temperatures at each radiator as accurately as possible, to see if they are each receiving the full flow temperature and to see if the system is correctly balanced.

I would also suggest that you ask Freedom to provide details of the PHE, its make and model. It should then be possible to ascertain if it is actually capable of transferring 12.5kW of thermal energy from primary to secondary, without placing a large burden upon the operation of the heat pump.

Measuring the flow and return temps on the rads is far from easy or reliable, I have tried. Access problems, being consistent with where the IR thermometer is pointing, and with or without black masking tape? More to the point, although the balancing is good enough for me, it is far from perfect, but I am well into diminishing return territory if I do any more to try and balance them. Furthermore, two rads are stubbornly cooler, even if I close off all the other rads, they are reluctant to warm up. It is probably no coincidence they are bother at the ends of their respective pipe runs. The pipework was power flushed, in an attempt to get those remote rads to warm up, but it is still the original pipework, decades old.

I will certainly ask Freedom, nothing to lose, and I might strike lucky.

Posted by: @derek-mI forgot to ask. Did the OAT actually increase by something like 9C over a 3 hour period?

Not sure which period you are referring to? If it was on a chart, then that is what the OAT sensor says happened.

Midea 14kW (for now...) ASHP heating both building and DHW

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 612 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That’s my pleasure, @andrewj. The only challenge now is...

By Majordennisbloodnok , 9 minutes ago

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 54 minutes ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 1 hour ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 2 hours ago

-

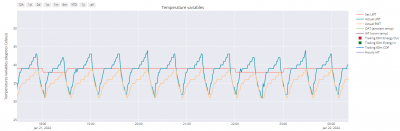

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 3 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 3 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 3 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 3 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 4 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 10 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 12 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago