Hi Derek,

1: The Sharky is installed across the beginning of the Radiator circuit , the purpose being to measure the losses by comparing the Power , Energy output from the Samsung with the Power , Energy at the start of the Radiator circuit.

2: Yes, the DT across the primary of the Heat Exchanger ,PHE is approximately 2C to 3C and the flow rate in the region of 16 to 17 lpm.

3: The term Flow Water Difference Temperature is the difference between the Flow and return Temperature sensors on the Sharky , i.e on the Radiator pipe circuit..

4: I was advised , by the French Samsung Engineer that the energy losses were caused by the "excessive flow rate in the primary of the Heat Exchanger" . His "solution" was to reduce , or control, the flow rate in the primary ports of the Heat Exchanger.

5: The "Short Cycling " has been apparent from the start of the "installation" with my "installer" spending days trying, unsuccessfully , in reducing the, then ( August 2022), 8 minute period Short cycling.

6: I was advised " that if I reduced the flow rate in the primary ports of the Heat Exchanger that the Delta_T would increase.

7: I used the unused Pulse Width Modulation , PWM motor ports to limit the flow rate in both the primary and secondary circuits.

8: I have reduced the primary ports of Heat Exchanger to flow rate of 16 lpm.

9: Being very sceptical about my own, or the "experts" advice, I test the results both with and without flow rate reducing in the primary .

10: The Delta_T across the primary Heat Exchanger does slightly increase but at the cost of increased instability.

11: As usual I have followed the advice of the "experts" at Samsung, Samsung-Dallium , Samsung-France ,the NIC , my "installer" with increasing scepticism.

12: My , probably mistaken, understanding of my flow rate problem

The thermal power in a hot water pipe is given by :

Thermal Power ,kW = Specific_Heat_of_Water X Flow Rate X Delta_T Across the primary ports of the Heat Exchanger

Given that the power is fixed, controlled by the Samsung inverter :

Flow_Rate X Delta_T = constant

As the French Samsung engineer pointed out

a decreased flow rate will increase Delta_T.

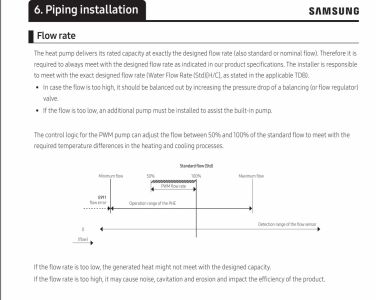

13: I have reduced my flow rate using the Motor Pulse Width Modulation ports set to the 50% to 70% values given in the Samsung manual for the Pulse Width Rate Control.

Please , Derek, don't be offended by my obvious inexperience.

I have, with increased scepticism , tried to follow the advice of the "experts".

Could you please provide the model number of your heat pump so that I can ensure I have the correct manual. Also the make and model of the PHE if possible.

Do you know the concentration of anti-freeze in the primary circuit?

Hi Derek,

Please find all the serial number , Field parameters et al in the attached Samsung-Controls.pdf ......

The options I have selected, and used , are shown with an asterisk.

I have tested most of the Field settings in my pursuit of a solution avoiding moving the Buffer tank to the other side of the motor, with the attendant risk of further increasing the losses and decreasing the effective REAL-COP.

The user manual is given by:

Air to Water Heat Pump

User manual

Control kit MIM-E03CN / MIM-E03EN

Warning! , the manual was probably, originally , written in Korean being translated "automatically" by a computer.

A newer version was produced where the changes to the flow rate PWM are better discussed:

Notes

1) The water motors may be controlled in either of two options , case 1 & case 2:

a) Case 1 Using On-OFF motor switching. this was the method used by the French Samsung Engineer.

b) Case 2 , Using a continuous Pulse width modulation,PWM signal from the Samsung Control board.

2) The PWM output signal from the control board does not work on my heat pump!

3) The French Samsung Engineer "did not know , or understand How the PWM control works", that being only known to the Germans".

4) I have made my own PWM signal generated by an Arduino. The Actual flow rate is here controlled as a function of the Delta_T across the primary Heat Exchanger ports.

5) I have just bought a replacement control board hopefully giving a working Samsung Generated PWM Signal.

ian

Many thanks for your input.

I use the Open-office Calc spreadsheet sourcing and producing CSV files.

I use GNU PLOT for DATE_TIME extraction .

Date -Time Format handling?

I have tried several graphical programs for producing graphs from odd Date - Time formats but have run into a fundamental problem.

My Data logger, for example, produces the DATE-Time in the form Year-Month-Day--Hour-Minute-second

eg "2024-02-17-34-35-12"

This has proven to be difficult or unreliable for many programs in handling and generating a time base from a plethora of DATE-TIME FORMATS.

Except for "GNUPLOT" which can process most Date-Time Formats.

My Sharky produces another text embedded version with "start script" hour-min-sec-Year-Month" " end script".

Again , only GNUPLOT extracts the date /Time from the text often producing an excellent graph in the process.

Can you recommend a Graph making program replacing GNUPLOT for it's ability to read most Date/Time formats?

ian

The serial number is not the same as the model number.

You will find the model number on the nameplate on the side or rear of the outside unit.

The type number on the tank is

AE050RXYDEG/AE00RNWMEG

The 2091 Field settings reflect several of my attempts when changing all the parameters in the 2091,2092 ans 2093. Just in case.

I initially thought , just like Craig , that my 8 minute Short cycling period was set by the fourth option.

When asked, the French Samsung Engineer said that he did not understand any of these options having no background in Electronics or Electronic logic.

He added that , in any case, these options did not do very much, again saying that "only the Germans understood the PWM and the 2091 options".

Franco Prussian War of 1871 is still , apparently , being fought !

ian

So what is the actual setting of 2091?

I am aware of the competence of some french 'engineers', having worked with a number in the past.

Where are you located by the way?

Hi Derek,

I have mostly used 2091 with "Water pump App no 3 " the fourth option.

This option produces a temperature surge some 7 minutes after the start of the cycle.

This surge was presumably designed to increase the Cycle time .

This option also produces a 2 C Hysteresis , again, designed to further increase the Cycle time.

The Samsung Software is here deigned to mimic the behaviour of the best hardware Thermostats.

My cycle time is increased slightly when using 2091 ,Water Pump App no 3.

This morning I changed the setting to Water Pump App no 2 , for experimentation again.

Hi Derek,

I am located in Inchinnan ( The INCH , or Island of St Innan ) a town between the Cart and the Clyde although no longer an island.

Officially, Inchinnan is part of Renfrew.

Underneath my house , are the remains of "Criegiehall" a former croft owned by the Scottish Knights Templar from 1158.

ian

@iantelescope - date-time formats can be very tricky, especially with software that likes to be 'clever' - and then gets, for example, month and day mixed up, or tells you the date time is 456930 and then just for a joke tells you the 4th of January is April Fools Day. Spreadsheets can be especially creative in this way. There are various options:

1. Treat the date-time stamps as categories not date-time. They need to be in order, and equally spaced, which of course they are often not.

2. Process the date-times into an acceptable format in a spreadsheet. This is an option that works well for folks that don't get out very often. For example, force the date-time into a string (eg add spaces/text characters) and then do string extraction to get the various parts eg chars 1-4 are year etc.

3. Use python. This is what I do. You can tell python what format your date-time strings should have:

>>> from datetime import datetime

>>> now = datetime.now()

>>> print(now)

2024-02-23 15:48:51.027361

>>> print(type(now))

<class 'datetime.datetime'>

>>> now = now.strftime("%Y-%m-%dT%H:%M:%S")

>>> print(now)

2024-02-23T15:48:51

>>> print(type(now))

<class 'str'>

which takes a python datetime and coverts it to a string of my choosing.

You can also (this can be very useful) tell python what format your existing date-time strings have (I have changed the hour from 34 to 14), and make them into datetimes:

>>> telescopeTime = '2024-02-17-14-35-12' >>> print(type(telescopeTime)) <class 'str'> >>> telescopeTime = datetime.strptime(telescopeTime, '%Y-%m-%d-%H-%M-%S') >>> print(telescopeTime) 2024-02-17 14:35:12 >>> print(type(telescopeTime)) <class 'datetime.datetime'>

Note the key methods are very similar, only one letter different: strftime and strptime.

The above examples are for single variables to show the conversion process. In practice, you read the CSV data into a pandas dataframe (in effect an internal invisible spreadsheet inside python) and do the manipulations on columns. Pandas also has it's own datetime conversions.

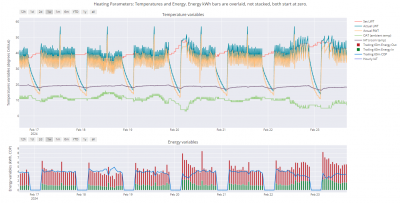

The best plotting system I have found so far that produces pleasing charts without needing painfully complicated code is python's plotly express module, which I use to produce charts like this (last weeks data) from CSV files via pandas dataframes:

BTB for those who notice the slightly slow recoveries after recent setbacks, I suspect these are wind/rain chill: my house does not like the wet windy weather it has been subject to of late.

Midea 14kW (for now...) ASHP heating both building and DHW

Great stuff , I will have to try python for my graphs.

I would still recommend you try GNUPLOT with it's old fashioned 1970's Shell script format.

But , Thanks , I will have a look at python again, having tried several different programs, languages and apps with my DATE/TIME Problem.

ian

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 225 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos, please do try to concentrate. That is the oppos...

By cathodeRay , 31 minutes ago

-

RE: What determines the SOC of a battery?

Thanks, so the consequence is Fogstar either do not kno...

By Batpred , 40 minutes ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Thanks for checking and sharing! It is odd that Fogs...

By Batpred , 46 minutes ago

-

RE: Electricity price predictions

My apologies for slow responses. I seem to have found a...

By Transparent , 2 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

I said I wouldn’t mention them, @jamespa. So I won’t ...

By Majordennisbloodnok , 2 hours ago

-

RE: Our Experience installing a heat pump into a Grade 2 Listed stone house

@mk4 Thanks for your interest. If the existing oil boil...

By Travellingwave , 2 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Thank you for the kind introduction! No, sadly not...

By GoodbyeGas , 4 hours ago

-

RE: Setback savings - fact or fiction?

This illustrates what I am getting at, even apparent st...

By cathodeRay , 4 hours ago

-

No you arent, because you dont need any, and furthermor...

By JamesPa , 5 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

As I mentioned earlier most radiators have a power outp...

By JamesPa , 5 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 17 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 18 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 2 days ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 2 days ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 2 days ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 2 days ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 2 days ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 2 days ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 3 days ago