Hi James, nice to talk to you again.

Measuring the Temperatures of my heat exchanger ports?

I will indeed take your advice and install another pair of DS18B20 's to measure the Radiator facing ports of my Heat Pump.

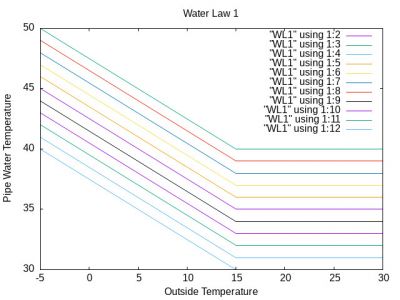

Weather compensation Settings

I have extensively used the Water law compensation.....

By Adding the Water Law Graph setting to the Water Law thermostat offset control on the Samsung I can , to some degree , control "Short Cycling".

With the Water -Law graph set to a pipe Water Temperature of 45 C | 47 C | 50 C when the outside temperature is -5 C | -6 C I can reduce the "short Cycling" by arranging the Heat Pump NOT to Cycle at All!

Stopping "short cycling" by stopping All cycling!.

Yes, I know it is not recommended , and is very inefficient and costly , but, stops the endless "Short Cycling".

I was asked by Telford , the tank manufacturer, to examine the pipe water only to discover the costs of "short Cycling".

The MCS Article on Buffers and Volumisers gives the standard fix for Short cycling as calculating and fitting a buffer tank .

but, gives a warning about the cost of "Short Cycling" and the potential efficiency costs of Buffer tanks.

The Pipe Water was a jet black ink colour completely failing the BS7593:2019 Water quality test.

I had the pipes cleaned by a professional , at a cost of £600 only to discover that my "installer" had never cleaned, or tested, the pipe water under BS7593:2019 .

Samsung settings

I have recorded , and adjusted ,all of the 80 Controls within the Samsung, discovering that the Motor Pulse Width Modulators are faulty.

The Heat has been configured to use switch ON OFF Motor switching rather than PWM continuous control.

I have used an Arduino to supply and control BOTH PWM Motors from the Delta_T Temperatures across the Heat Exchanger primary ports.

The Temperatures are indeed increased slightly by reducing the Water flow rate using the PWM motors.

Again, many thanks for your advice .........it is appreciated.

ian

I would suggest that you have a read through the following post from page 13 onwards: https://renewableheatinghub.co.uk/forums/renewable-heating-air-source-heap-pumps-ashps/12kw-samsung-gen-6-short-cycling/paged/19#post-18238

The idea is to check that the short cycling is not due to incorrect controller settings before making any physical changes to the system and pipework.

Do you have any thermostats within your system? If so, what is the make and model.

It would be useful if you could post details of all the controllers internal parameters.

Posted by: @iantelescopeWith the Water -Law graph set to a pipe Water Temperature of 45 C | 47 C | 50 C when the outside temperature is -5 C | -6 C I can reduce the "short Cycling" by arranging the Heat Pump NOT to Cycle at All!

That's quite a high flow temp, what flow temp was the system designed for.

Generally the starting point is to adjust WC as low as possible consistent with the house getting warm enough with trvs and thermostats fully on and the system operated 24*7. Increasing the flow temp to reduce cycling is likely to decrease efficiency not improve it.

My suspicion is that the flow is primarily through your low resistance buffer tank which short circuits your phe hence depriving the heating circuit of energy (which is why your system doesn't heat up as much as you need). The recirculation alone will cause losses, exacerbated by the uninsulated pipes. Because of this you are having to operate at a higher ft than is required by the emitters, further reducing efficiency. Short cycling won't be helping but turning up the WC to eliminate it only leads to one-off control which isn't helping. Together these would explain many of the symptoms you report.

Please post the four temperatures from the phe so we can see how much damage that is doing and also the information @derek-m has asked for about the control systems.

Most likely the right way forward is to replumb the buffer as a volumiser in the return, set all the external controls so they have effect only in extreme situations (eg solar gain) turn down the WC as far as you can, and maybe tweak the phe. Then if necessary play with a couple of parameters other than the WC setting to control cycling. However until we have the answers to the questions above we can't be sure.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Hi Derek,

Have a look at the Samsung controls on my Heat Pump.

I have adjusted , and reset almost ALL of the settings in innumerable attempts at getting a compromise between stability, meaning reasonable Short Cycling and Efficiency , meaning reasonable Real COP. Be warned, this is NOT light reading!

The Thermostat , a Honeywell Home Thermostat was fitted some three weeks after the start of the "installation".

Again, I have adjusted , and reset the Thermostat to accommodate reasonable, and safe, living room heating conditions with cost and "Short ?Cycling".

My best "compromise" is

1) Start heat pump at 700 running until 0900 attempting, but never succeeding to reach 21.5 C.

2) Reduce the temperature to 16C between 0900 and 1200.

3) Start heating at 1200 running until 1400.

4) Reduce room temperature to 16C between 1400 and 1700.

5) Start Heating at 1700 with an attempted temperature of 21.5 C.

6) Reduce heating to 16 C between 000 and 0700 the following morning.

The thermostat has been programmed to mimic the Outward Settings of the Samsung Heat pump itself.

Balancing

I have attempted , without success, in balancing the living room Radiators against all the others.

I have resigned myself to only heating my living room with the Hot water Switched OFF.

Hi James,

Again , many thanks for your patience.

Samsung Controls

I have attempted to "adjust" almost every Samsung control setting in my attempt at reconciling "short Cycling with COP".

The Buffer tank compromise

The Buffer tank, being , at my insistence , selectable with a valve, makes very little ( 10%) difference to either the efficiency , or the stability ( absence of Short cycling ).

The Buffer tank , does , however, provide a provable protection against ice.!

During the winter I open the buffer valve to protect against frost.

Outwith Winter I have switched the Buffer tank OFF.

As an aside, I am NOT using Glycol on the outdoor water circuit , allowing the pipe water a higher Specific Heat.

Losses

The Heat Exchanger, the buffer tank and the "pipework" are loosing ~ 22% of the Heat Pump generated Energy.

With the Hot water switched on the losses approach ~48%.

Adjustments

I have adjusted everything in an unsuccessful attempt at a compromise between Short Cycling and Efficiency/Cost.

Measurements

After two years I now have a heat Pump covered in Sensors, but, still without explanation or progress.

ian

How many thermostats do you have and are they the type that switches on and off a set number of times each hour?

What is the temperature setting of the thermostats?

Posted by: @iantelescopeThe Heat Exchanger, the buffer tank and the "pipework" are loosing ~ 22% of the Heat Pump generated Energy.

I think that the recipe is fairly clear then

Insulate the pipework where you can

Remove the heat exchanger and secondary pump

Switch off the buffer tank

Turn up trvs and thermostat to max so they have no effect

Adjust WC (IE flow temp) to min poss to keep the house at the desired temp

Review the control settings

Then and only then start tweaking further

Before next winter replumb the buffer tank as an inline volumiser

Or

Leave it as it is in which case it will be as it is.

All subject of course to any comment @derek-m wishes to make.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Ian appears to have had problems for a couple of years, so rather than rush ahead I think that it is best to go through each item one step at a time. Craig1980 had similar short cycling problems that were being caused by incorrect settings within the controller, so that is one avenue to explore.

It is best not to try too many things at the same time. As Shakespeare stated "Many strokes, though with a little axe, hew down and felled the hardest timbered Oak".

Posted by: @derek-mIan appears to have had problems for a couple of years, so rather than rush ahead I think that it is best to go through each item one step at a time. Craig1980 had similar short cycling problems that were being caused by incorrect settings within the controller, so that is one avenue to explore.

It is best not to try too many things at the same time. As Shakespeare stated "Many strokes, though with a little axe, hew down and felled the hardest timbered Oak".

I agree with the principle, however I'm also concerned that we are starting at a place which has drifted so far from optimal that @iantelescope is at risk of chasing 'local best' and ending up in another attempt to tweak from the wrong starting point.

But yes, doing it in a sequenced way pausing at each point and looking at results is of course sensible, so long as there is no expectation that any one change will 'fix it'.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Hi James,

The "Designed" Flow temperatures provided by three different "installers " were:

1) MP Group , Warm flow Heat pump , first estimate 50 C

2) MP Group , Samsung 5Kw Heat Pump , second estimate , 50 C

3) MP Group , Samsung 5Kw Heat Pump , third estimate, 50 C

4) CMS Group, Midea 7.3 kW , first estimate , 55 C

5) Quarterion, Mitsubishi 8kW , estimate , 50 C

The NIC engineer with two other "engineers" from my "installer" attempted, unsuccessfully , in setting the flow temperature to 35 C on my Heat Pump when the flow temperature was controlled by the Water Law Thermostat resulting in Heat Pump failure.

The NIC "Engineer " then discovered that "he needed some fresh air" disappearing into my garden leaving the pair of "engineers" from my "installer" trying , again unsuccessfully, to repair the Heat Pump.

My "Installer" was STRUCK_OFF again after this demonstration.

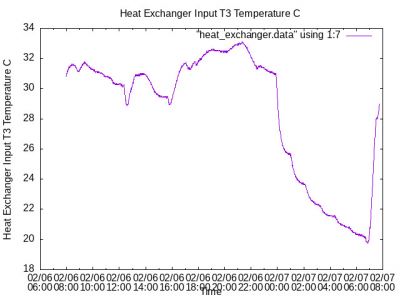

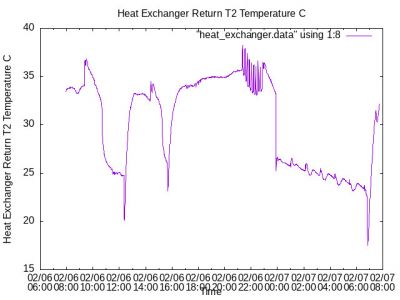

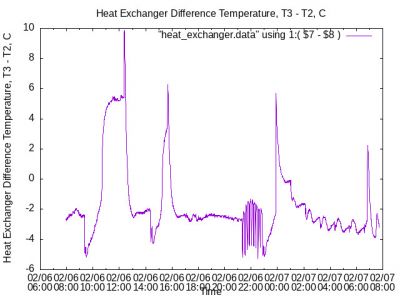

The Primary Heat Exchanger Temperatures.

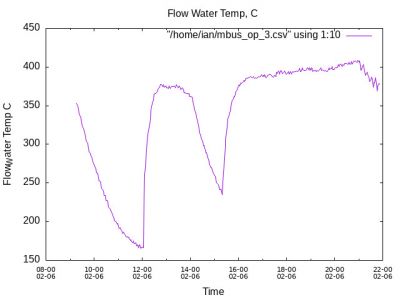

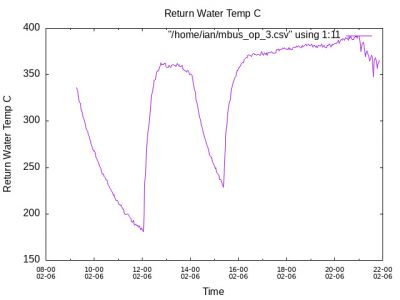

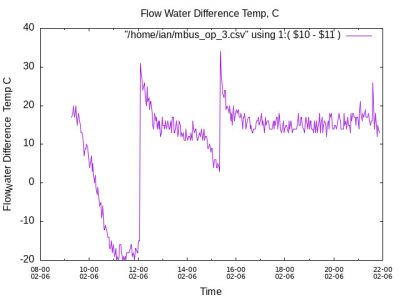

Please find the Primary Heat Exchanger Temperatures in the following graphs of the Input , output and difference Temperatures across the Heat Exchanger on 6th Feb 2024

The DS18B20 sensors, being high speed serial devices are plainly sensitive to noise!

I do not have DS18B20 fitted to the PHE output ports but the Sharky Water meter is nearby giving a more accurate, if confusing picture:

The Sharky In-Water Sensors are here relatively noise insensitive.

The Temperatures are here altered by Modulating the Pulse Width Modulation motor ports on BOTH Motors.

The PWM Modulation is here controlled by the Delta_T across the Primary ports of the Heat Exchanger.

ian

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 222 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Testing new controls/monitoring for Midea Clone ASHP

My auto-adapt script only makes infrequent changes. If ...

By cathodeRay , 3 minutes ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Thank you for the kind introduction! No, sadly not...

By GoodbyeGas , 4 minutes ago

-

RE: Setback savings - fact or fiction?

This illustrates what I am getting at, even apparent st...

By cathodeRay , 29 minutes ago

-

No you arent, because you dont need any, and furthermor...

By JamesPa , 1 hour ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Can you link them to Home Assistant so they can be inte...

By JamesPa , 1 hour ago

-

RE: Electricity price predictions

I have often thought the same. In Italy (I am told) th...

By JamesPa , 1 hour ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

As I mentioned earlier most radiators have a power outp...

By JamesPa , 2 hours ago

-

RE: Our Experience installing a heat pump into a Grade 2 Listed stone house

@travellingwave Looking forward to hearing the rest ...

By MK4 , 2 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

As a side note I observed the the charge/discharge time...

By Bash , 2 hours ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 13 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 14 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 14 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 2 days ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 2 days ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 2 days ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 2 days ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 2 days ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 2 days ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 3 days ago