Posted by: @iantelescope

Temperature Drop and flow rate

Again, James you are probably correct.

However, my "intuition" is still basically that of an Electrical/Electronic Engineer.

I , and I suspect the French Samsung Engineer, would , instinctively, consider a pipe Temperature drop to be proportional to the flow rate.

So much for intuition!

To use an Electrical Engineers analogy, think of the pipes as being wires, the thinner they are, the more voltage drop (pressure), to push the current (quantity of water) along the wire (pipe).

Only a small amount of power (thermal energy) is lost in the wire (pipe), with the vast amount of power (thermal energy) being dissipated in the load (heat emitters).

Yes, I now appreciate that I was misinformed by the Frenchman.

However, my "intuition" still insists that the pipe Friction loss will surely increase with the flow rate?

Also , the pipes , in question were repaired, and repositioned , on numerous occasions to get the Sika Flow sensor working , while NOT issuing Flow Errors..

Also, the pipes have 16 right angle bends between the Heat Pump and the Cylinder in my kitchen.

Surely, these right angled bends and repaired pipe sections must consume more energy , and thus decrease the End pipe Temperature?

Surely, the friction losses will increase with the internal pipe surface area, and hence pipe length ?

Sorry, as you can see I am still influenced by my instinctive electrical/electronic background.

ian

My intuition tells me that a pipe of a given diameter that is required (under pressure) to carry a given throughput of water will exert greater friction and resistance to the same volume of water flowing through a pipe of a greater diameter (which will require less pressure to do the same amount of moving of material). Therefore, at this lower pressure, there will be less friction / pressure in the larger diameter pipe. Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Posted by: @iantelescopeHowever, my "intuition" still insists that the pipe Friction loss will surely increase with the flow rate?

Also , the pipes , in question were repaired, and repositioned , on numerous occasions to get the Sika Flow sensor working , while NOT issuing Flow Errors..

Also, the pipes have 16 right angle bends between the Heat Pump and the Cylinder in my kitchen.

Surely, these right angled bends and repaired pipe sections must consume more energy , and thus decrease the End pipe Temperature?

Surely, the friction losses will increase with the internal pipe surface area, and hence pipe length ?

Yes but this reduces the remaining voltage (pump head) available not the current (flow).

And friction losses don't cause a temperature drop they cause a drop in head (pressure).

None of this decreases the pipe temperature at the end, in fact friction will very slightly increase it!

Pipe temperature at the end is reduced only by conduction through the walls of the pipe and thence heat transfer to the outside world.

Unfortunately you are conflating two energy stores, the thermal energy contained in the water which powers the radiator, and the potential energy available due to the pressure difference caused by the pump, which is converted to the kinetic energy of the flowing water. The latter is attenuated by friction and of course ends up as heat, but its a tiny amount of heat. Its the former which powers the radiators and is simply transported from place to place by moving the water. All this does is leak slowly into the rest of the house, and the faster you move it the less leaks. The circuit analogy works for the potential/kinetic energy, but not for the thermal energy.

Posted by: @iantelescope" Only the Germans REALLY understand How the PWM System works!".

If the Frenchman said that then Nicolas Léonard Sadi Carnot is turning in his grave! But clearly this Frenchman didnt understand even the basics of plumbing.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Thanks James, I was not aware that the result of the Water friction was to reduce the pressure drop , not the Temperature.

At least I now have a new "intuitive" appreciation of Water pipes.

"intuition " is valuable , but sometimes misleading !

Cost ?

Electronic Measurements are cheap and accurate !

Water measurements are Expensive and inaccurate?

How do You measure Water Temperature, Pressure and Flow rate inside water pipes?

Modelling?

Electronic/Electrical modelling is cheap and accurate!

Water measurements are Expensive and inaccurate?

How do you model the Water flow,Temperatures ,pressures in the pipe system?

I know that very advanced modelling is available at cost, but,

I am looking for a Model suitable for the pipes , heat exchangers, buffers external to the Heat Pump Compressor itself.

ian

Cycle Period ?

What is your current "Cycle Period "?

Currently my own cycle period is 10.5 minutes with up to 110 cycles per day in Winter.

Is this excessive?

Measurements?

How do you measure Temperature and Flow rates within copper pipes?

My own system uses 4 K type sensors and a "Sharky ", in Water, power meter.

The Sharky was installed to measure the actual COP , not the COP displayed on my Samsung Heat Pump.

ian

Posted by: @iantelescopeModelling?

Electronic/Electrical modelling is cheap and accurate!

Water measurements are Expensive and inaccurate?

How do you model the Water flow, Temperatures ,pressures in the pipe system?

There are various online calculators for flow and pressure.

Temperature loss in pipes should be either negligible or within the insulated envelope of the house (or both) so, other than for a very long outside pipe run where it might be a degree or so, is simply not worth modelling.

Individual plumbing elements can often be reduced to simple assumptions either about impedance, if you want to know about flow/pump head, or temperature loss, if you want to know about efficiency.

Heat pumps can be crudely modelled for some purposes using just the published COP curves as f(OAT, FT). I for example have used this to model in excel the effect of weather compensation, which has yielded some useful insight (well useful to me anyway).

If you want to look at the effect, for example, of on/off vs continuous working, you need to know more about the start up penalties (beyond those solely due to flow temperature). These are more difficult/impossible to get a handle on (their engineering, unlike COP which is essentially physics).

Modelling the load is more challenging, for many purposes it can just be modelled as a continuous load varying according to OAT, but again if you want to know about the effects of on/off operation you need to consider the thermal mass of the load, which is not generally known (but can be estimated if you measure the time it takes your house to cool)

Then there is the perception dimension. The objective is to feel sufficiently warm at lowest cost/lowest carbon footprint. Feel is not one dimensional!

So far as I know no one has attempted a whole system model, and certainly not one which includes the human at the end of the chain. I don't intend to either. Until they do its a case of identifying what parameter/variable interests you, and creating a model sufficiently good to isolate that parameter/variable alone, which almost invariably requires information only on a small part of the system.

My personal interest would be to get a handle on the effects of on/off operation (eg night time set back/switching off during the day). Conventional wisdom says 'operate 24/7' and in mid winter I don't doubt that is right in most practical scenarios unless the occupants are away for at least a couple of days. However there clearly are scenarios where its better to switch off/turn down, but there is absolutely no quantitative (or even general qualitative) information on this. I did start a model aimed at this but got bogged down instead with challenges with my own installation, scheduled for mid October!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

I actually created a model some time ago for Ecodan and Midea heat pumps, that shows how the system operates at various outside temperatures, along with the effect of improved insulation and installing larger heat emitters.

It also allows hour by hour assessment of the probable effect of changes to the desired indoor temperature (setback), and recovery after setback. As you have pointed out it cannot take account of the effect of thermal mass, which would need to be assessed for each individual property.

I need to modify some of the algorithms to cope with when the calculated LWT goes outside that possible from the manufacturers data, after which I can provide a copy.

Excellent clear Technical writing James!

I accept, reluctantly , that a whole system model is impractical.

My immediate problem is simply to get a measurement of an acceptable Cycle Time.

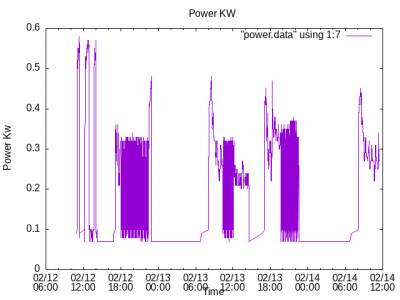

The Power Graph , taken on 12 /02/23 shows that the Cycle time is changing , however, the long periods where cycle time is 10.5 mins I find disturbing.

The Cycle time will reduce during Spring and Autumn given that the Compressor is operating at minimum power.

Should my cycle time still be at minimum , however, during Winter ?

The 10.5 minute cycle time is set by a Samsung bit setting.

ian

Thanks, Derek

An Excellent display of Simple clear Technical writing .

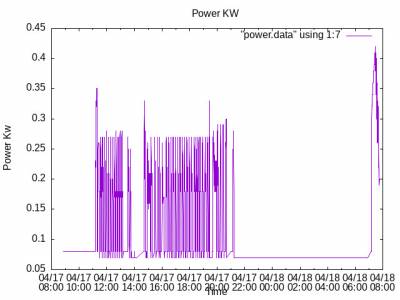

Can you define "Short Cycling"?

Is this short Cycling , acceptable , during April , during the prime Short cycling month of April?

The minimum cycle time , of 10.5 minutes, is set by a Hardware bit set in the Samsung controller.

ian

I believe that the definition of short cycling is more than 6 times per hour.

Cycling will occur when the thermal energy output from the heat pump is greater than the demand presented by your heating system.

Are you operating your heat pump in water law mode and if so what the settings?

Do you have any thermostats or TRV's on your system and if so what are their settings?

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 453 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 4 minutes ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 6 minutes ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 40 minutes ago

-

RE: What determines the SOC of a battery?

The answer from Fogstar was crisp. My hypothesis, su...

By Batpred , 1 hour ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 1 hour ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 1 hour ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 4 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 4 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 7 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 23 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago