Derek,

from what I can see the meter is receiving and recording data; flow rate, flow and return temps and kWh. Just not the right data and the temp sensors are definitely wrong at the moment. I'll see if I can record some real time numbers and I'll also have look at the (non-MMSP) sensors.

Hi Kev,

For clarity, could you please identify which readings you think are incorrect, is it the ones on the MMSP or the FTC controller? A set of readings from both would be useful. It could be that the FTC controller has not been correctly configured to match the signals coming from the heat meter and/or electricity meters. I have seen this time and time again in the past when I have been commissioning industrial systems.

Hi guus

How do I work out relative heat loss/ usage based on m2? I'm wanting to work out whether my house insulation is performing well or not

Thanks

Posted by: @hr_3Hi guus

How do I work out relative heat loss/ usage based on m2? I'm wanting to work out whether my house insulation is performing well or not

Thanks

Hi HR_3,

I'm afraid it is not quite as simple as watts per m2. Your heat loss will probably vary from room to room, rooms with larger window area will have a higher heat loss than rooms with a smaller percentage of glass. There is a spreadsheet that can be downloaded from MCS, that will help you to calculate the heat loss room by room.

@hr_3 do you know your current heating use in kW? You can just divide this by the total area of your house and that's your w/m2. However this will vary depending on the temperature outside - so you would need to do it at multiple temperatures to generate your own heat loss estimations.

Posted by: @derek-mHi Kev,

For clarity, could you please identify which readings you think are incorrect, is it the ones on the MMSP or the FTC controller? A set of readings from both would be useful. It could be that the FTC controller has not been correctly configured to match the signals coming from the heat meter and/or electricity meters. I have seen this time and time again in the past when I have been commissioning industrial systems.

I've just had a look. The MMSP heat meter is showing 37C flow, 33C return. I think the flow is correct; it corresponds to my reading from the inlet to a radiator that is a few feet away from the heat meter flow temp sensor (this one is correctly installed in a pocket). The return sensor isn't installed correctly but it shouldn't be far off as it's taped to a copper pipe.

Melcloud, which gets its info from the Ecodan, is showing 31/27 (ish). I think therefore it's under-reading by 6C or so - at the moment. So I think when my compensation curve asks the ASHP for 31C, it heats until it reaches what the sensor thinks is 31C, except it's really 37C. I also don't know whether the under-reading is linear; i.e. if it's the same % at different temperatures.

it's good that my house is nice and warm at 37C flow/2C ambient but it makes it quite hard to control the system using flow temps. It really needs to be sensing them correctly. I could have go at fixing this but I want to speak to the installers first. Having said all of this, I'm still very pleased with the system.

Posted by: @derek-mHi Kev,

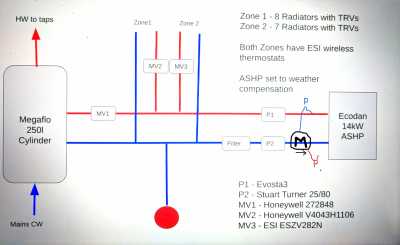

I think that you said before that you don't have a buffer tank, but do you have a low loss header?

Do you have any pumps in addition to the one inside the ASHP?

For the sensors that are zip-tied to the pipework, once we find out what type they are it may be possible to either ask for them to be replaced by your installer with pipe clamp type or the installation of thermowells. First it is necessary to find the best location, so that they are providing both accurate and consistent measurements. See if there is any writing or labels on the sensors connected to the FTC controller to identify them. They could be a PT100 or PT500, which can easily be sourced at quite reasonable cost.

No buffer or low loss header. Two additional pumps.

The Ecodan sensors would be a 300mm to the right of the heat meter on the same pipe run on this diagram.

@hjd ,

thanks, yes there is, I saw that yesterday. You can adjust the flow and return up/down by 10. I'm not sure whether to tinker with that or leave it to the installer. Wouldn't do any harm I suppose and I can always put it back.

Hi Kev,

Having ambient air temperatures around 2C is not very good for ASHP operation, because it will increase the number of defrost cycles.

Adjusting the calibration setting of the temperature measurements probably will not improve efficiency, and could make matters worse. Calibration of a measuring system involves making an adjustment at the lower end of the range (zero), when testing against a known standard. A further adjustment would then be made at the upper end of the range (range) against the same standard measurement device. Since there may be interaction between the 'zero' and 'range' adjustments, this process would be repeated until both measurements are correct without further adjustment. The overall calibration would then be checked at 20% steps over the full range. Making adjustments to a systems calibration to correct for poorly installed sensors is not the correct way to resolve the issue.

To reduce overall energy consumption to the absolute minimum requires correct operation and optimisation, rather than just offsetting readings.

What are the settings of your weather compensation curve? Do they match those shown in the modelling tool after allowance for incorrect temperature indications has been made?

Reduce the indoor air temperature to the minimum acceptable level, using the weather compensation offset.

Consider lowering the indoor air temperature by 1C overnight.

Lower the DHW tank temperature to the minimum acceptable level, and set the controller to heat the water during the mid to late afternoon period, when the ambient air temperature is probably at a maximum for the day.

Derek,

that was my worry about just offsetting the thermistors; it might correct it at one end but not the other.

My weather comp curve says 33.3C at 0C. I've got it offset to -2, so that's 31.3C at 0C. Melcloud was showing exactly that last night. The model suggests I need 39C to heat my house to 21C and will use c. 2.2kW. That's close to what I'm seeing.

I suppose it doesn't really matter that the sensors are under-reading as they are still doing a good job of controlling the room temperatures.

I've now got the curve about right on an offset -2 so I'm happy enough. As you suggest I may bump it down a notch overnight and see what happens. If all is OK I'll recalibrate the curve it so it runs with zero offfset.

I do need to look at the HW timer as it's coming on at random times. It could also come down a bit as 50C is a bit hot.

Kev

Hi Kev,

One further area were it may be possible to reduce energy consumption by a few percent, would be by tightening the 'heat pump thermo. diff.' setting during the Winter period. I mentioned the upper and lower settings before when you were concerned about the cycling during milder weather conditions.

If you look at your MELCloud graphs showing the water flow temperature, you may see that the temperature goes above the required weather compensation value and then falls below for a period of time. If this is the case, then lowering the upper setting and increasing the lower setting should reduce the variation, and may improve efficiency. I may be wrong, in that when the ASHP is running continuously during colder weather, the water flow temperature is controlled and does not reach the limits.

I would be interested to see that graphs and also the frequency and effect of the defrosting cycles.

- 26 Forums

- 2,396 Topics

- 54.3 K Posts

- 223 Online

- 6,077 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Setback savings - fact or fiction?

No need to create a new thread, @sheriff-fatman. You do...

By Majordennisbloodnok , 5 hours ago

-

RE: Power outages and storms: A surprisingly good DNO experience

Well done to Scottish Power for doing a good job. Well ...

By Majordennisbloodnok , 5 hours ago

-

RE: Advice for a novice on Mitsubishi Ecodan 6kW

Fair point. The highest frequency of defrosts I'd seen...

By Sheriff Fatman , 6 hours ago

-

RE: Heatpunk Floor plan issues

It's usually the complete opposite... seldom that Safar...

By Mars , 6 hours ago

-

RE: RDSAP10 effect on existing heat pump EPC rating?

@mike-patrick interesting update - thanks.I've been thr...

By Tim441 , 8 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

I remember reading in some inverters. They mandate a se...

By Batpred , 8 hours ago

-

RE: Fan is clipping ice build up from the front of unit.

@majordennisbloodnok I’ll not go there thanks! Toodles.

By Toodles , 9 hours ago

-

RE: Running from backup generaor in powercut?

@majordennisbloodnok Back in the 80’ or 90’ we had a te...

By Toodles , 9 hours ago

-

RE: Running my new Nibe ASHP efficiently

I'm new to the forum. Did you get a reply to this last ...

By Mike @ Camelot , 11 hours ago

-

RE: ASHP Energy Consumption: Aira 12kW heat pump

@grantmethestrength MCS requirements for DHW capacity h...

By Toodles , 11 hours ago

-

RE: New Mitsubishi Ecodan 11.2kW installation - L9 errors and maybe more

Great to hear! I just figured this out a day or tw...

By anotherdaveuk , 13 hours ago

-

RE: Help me keep the faith with my air source heat pump installation

@adamk I'm observing my own system at low temperatures ...

By dr_dongle , 18 hours ago

-

RE: Free Ecoheat Heat Pump Install

@deltona Yes older houses are problematic like that, bu...

By bontwoody , 2 days ago

-

RE: Radiator sizing sanity check

As I mentioned early on the cost of supplying and fitti...

By JamesPa , 2 days ago

-

RE: Electricity price predictions

Great point, one of the key ones in my chat with Octopu...

By Batpred , 2 days ago

-

RE: New Fogstar 15.5kWh upright solution

Let me point out that there are many Chinese suppliers ...

By Transparent , 2 days ago

-

RE: Weather compensation- why you should use it

@majordennisbloodnok — The Two Ronnies Mastermind sketc...

By cathodeRay , 2 days ago

-

Just realised that this image of the cylinder cupboard ...

By Sheriff Fatman , 3 days ago

-

RE: Rodents! A word of warning for heat pump owners

Two thoughts: 1: Let's ask @david-s if Primary Pro in...

By Transparent , 3 days ago

-

RE: Solis S6-EH1P8K-L-PLUS – Why I Chose It and What I’ve Learned So Far

In the diagram below, I describe my understanding of th...

By Batpred , 3 days ago