Posted by: @newhouse87@derek-m suppose instantaneous as in ever over a day period to keep house at 22 from 7am to 10pm, difference between 21 and 22 for the day kwh?

When I have checked the actual figures, it would appear that my original estimate was a little on the low side. Taking a typical home, the following may be expected over a 24 hour period.

Indoor Temp 21 22 21 22

Outside Temp 5 5 10 10

Energy In (kWh) 85.171 92.351 43.309 47.763

COP 3.04 2.98 4.11 4.07

Energy Out (kWh) 259.126 275.649 178.214 194.233

If the outside temperature was a constant 5C, and the indoor temperature was increased from 21C to 22C, the Energy Out would be 6.38% higher, but the Energy In would need to increase by 8.43%.

At an constant outside temperature of 10C, the Energy Out would increase by about 9%, while the Energy In would increase by approximately 10.3%.

It is always necessary to be careful when using averages with heat pumps, since their efficiency can vary quite considerably with changes in outside air temperature.

Taking the above example, if the outside temperature were to be 5C for 12 hours and 15C for 12 hours. This would give an average outside temperature of 10C for the 24 hour period, but compared to the constant 10C outside temperature values, the results are quite different.

Indoor Temp 21 22 21 22

Outside Temp 10 10 5-15 5-15

Energy In (kWh) 43.309 47.763 52.125 57.343

COP 4.11 4.07 3.42 3.39

Energy Out (kWh) 178.214 194.233 178.087 194.417

Although the Energy Out figures are approximately the same, the Energy In is about 20% higher, which is due to reduced heat pump efficiency at lower outside temperatures.

So to answer your original question, an increase in energy consumption of 8% to 10% should be expected when raising the indoor temperature from 21C to 22C.

Maybe you should buy your wife a mink coat to wear around the house. 😋

@derek-m thanks man, think i can live with 10% to keep her happy. Obviously be more then 10% the few days we have below freezing most of the day, will be switching off at 9pm to 5am though.

Its trying to get her to wear less not more i do be 😆

Posted by: @newhouse87@derek-m thanks man, think i can live with 10% to keep her happy. Obviously be more then 10% the few says we have below freezing most of the day, will be switching off at 9pm to 5am though.

Its trying to get her to wear less not more i do be 😆

She doesn't have to wear anything underneath the mink coat. 😎

I have now received and installed the replacement XY-MD02 temperature and humidity sensor and it appears to be working. Here are a few recent lines from the minute data csv file, the last two entries on each line are the temperature and humidity values received from the XY-MD02 (the other values are from the wired controller, as detailed in posts passim):

2023-09-19T16:04:31,00000000,1,0,18,18,17,25,41,0,249,14,35,0,0,12883,35964,18.8,73.5

2023-09-19T16:05:31,00000000,1,0,18,18,17,25,41,0,248,14,35,0,0,12883,35964,18.8,73.7

2023-09-19T16:06:31,00000000,1,0,18,18,17,25,41,0,246,14,35,0,0,12883,35964,18.8,73.6

2023-09-19T16:07:31,00000000,1,0,18,18,17,25,41,0,245,14,35,0,0,12883,35964,18.8,73.5

2023-09-19T16:08:31,00000000,1,0,18,18,17,25,41,0,246,14,35,0,0,12883,35964,18.8,73.6

2023-09-19T16:09:31,00000000,1,0,18,18,17,25,41,0,248,14,35,0,0,12883,35964,18.8,73.7

I haven't turned the heating on yet, holding out as long as possible, but when I do turn it on, I should have all the data I need to control the weather compensation curve settings based on the actual room temperature vs desired room temp (basically, boost the LWT if the room is a little cooler than it should be, drop the LWT if the room is a little warmer than it should be). The two large numbers before the temperature and humidity values are the lifetime energy in/energy out in kWh values, meaning I can track actual use over time (subtract kWh one hour ago from current kWh gives use in last hour etc). For some reason the lifetime COP (LCOP?) is rather poor, I think possibly because it includes kWh used while commissioning the system, over shorter time periods the COP is normally greater than 3.

I can then run the system 24/7 with no boost, and then with a setback and recovery boost, and compare the energy used for each on days with similar weather/OAT to determine which mode of running uses more energy overall.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayI have now received and installed the replacement XY-MD02 temperature and humidity sensor and it appears to be working. Here are a few recent lines from the minute data csv file, the last two entries on each line are the temperature and humidity values received from the XY-MD02 (the other values are from the wired controller, as detailed in posts passim):

2023-09-19T16:04:31,00000000,1,0,18,18,17,25,41,0,249,14,35,0,0,12883,35964,18.8,73.5

2023-09-19T16:05:31,00000000,1,0,18,18,17,25,41,0,248,14,35,0,0,12883,35964,18.8,73.7

2023-09-19T16:06:31,00000000,1,0,18,18,17,25,41,0,246,14,35,0,0,12883,35964,18.8,73.6

2023-09-19T16:07:31,00000000,1,0,18,18,17,25,41,0,245,14,35,0,0,12883,35964,18.8,73.5

2023-09-19T16:08:31,00000000,1,0,18,18,17,25,41,0,246,14,35,0,0,12883,35964,18.8,73.6

2023-09-19T16:09:31,00000000,1,0,18,18,17,25,41,0,248,14,35,0,0,12883,35964,18.8,73.7I haven't turned the heating on yet, holding out as long as possible, but when I do turn it on, I should have all the data I need to control the weather compensation curve settings based on the actual room temperature vs desired room temp (basically, boost the LWT if the room is a little cooler than it should be, drop the LWT if the room is a little warmer than it should be). The two large numbers before the temperature and humidity values are the lifetime energy in/energy out in kWh values, meaning I can track actual use over time (subtract kWh one hour ago from current kWh gives use in last hour etc). For some reason the lifetime COP (LCOP?) is rather poor, I think possibly because it includes kWh used while commissioning the system, over shorter time periods the COP is normally greater than 3.

I can then run the system 24/7 with no boost, and then with a setback and recovery boost, and compare the energy used for each on days with similar weather/OAT to determine which mode of running uses more energy overall.

will you be able to write your own algorithms/routines to do this, i.e monitoring and adjusting in real time?

If you wish to have a PID type control system I should be able to help with the algorithms, if you wish.

I assume that you can only change the values of the WC curve as integers?

Posted by: @kev-mwill you be able to write your own algorithms/routines to do this, i.e monitoring and adjusting in real time?

That's the plan. I already have the monitoring in place, adding a working MD02 sensor to get the room temp data was the final step. The Midea controller does have internal room temp data, but as it is in the airing cupboard it does not reflect room temps in used rooms (curiously, I don't live in my airing cupboard, despite the fact it has the Midea controller in it).

Adjusting in real time: I was going to set the LWT directly, but I suspect the Midea wired controller will reset it using its own logic (or otherwise), and I now think it will work better if I set the weather comp curve (WCC) high/low points. Let's say my standard WCC points are 55@-4/35@16. The core bit of code, which will run at intervals, maybe every 15 mins, will boil down to:

if desired room temp - actual room temp > 2 then WCC = 57@-4/37@16 else WCC = 55@-4/35@16

if desired room temp - actual room temp < -2 then WCC = 53@-4/33@16 else WCC = 55@-4/35@16

with actual settings to be determined empirically. The else bit does the reset when the room temp has got closer to the desired temp, and no doubt there will be mods and improvements along the way.

I've already established miminalmodbus, the python package I use to do modbus communications, can write to ie set the Midea registers, see here. I'm going to go carefully though, don't want to set up some form of positive feedback loop and have the heat pump do a Krakatoa number on me.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @derek-mIf you wish to have a PID type control system I should be able to help with the algorithms, if you wish.

I assume that you can only change the values of the WC curve as integers?

We cross-posted. Thanks for the offer to help, please see my cross-post above for my current thinking.

When queried, the WCC temps come back as integers, meaning they probably are stored as integers as well, but that shouldn't be the end of the world.

Midea 14kW (for now...) ASHP heating both building and DHW

+/- 2C seems rather coarse for control purposes, but I suppose it depends how accurate you wish the temperature control to be.

A PID control system compares the actual temperature to the desired temperature and makes periodic adjustments until the desired has been achieved. As actual becomes closer to desired, the adjustments made are be smaller.

Posted by: @derek-m+/- 2C seems rather coarse for control purposes

2 was just a number off the top of my head, what I was trying to do was show the logic, with the actual numbers decided empirically ("with actual settings to be determined empirically...and no doubt there will be mods and improvements along the way"). In all likelihood I will start with 1, but that is actually quite small in percentage terms (55 to 56 is only a 1.8% increase): it will of course depend on how volatile/reactive the system is.

PID is I guess just the industrial term for what I, being medically trained, think of as homeostasis, or more generally a feedback loop that keeps something stable.The first question to be answered is what to use for the loop, ie its structure. My thinking is that the thing to be kept stable is the room temperature, kept stable at the desired room temp, and the thing used to adjust the room temp is the LWT, with that in turn controlled by adjusting the end points of the weather compensation curve. I'm going to use the WCC end points because directly setting the LWT (a) may not be possible and (b) if it can be set, the Midea wired controller will almost certainly over-ride any changes I make. In effect, I will set up a python script that will do what I would do if I were to manually read a room thermometer and manually adjust the weather compensation curve depending on whether the room temp was above or below the desired value. As I said, the best intervals of measurement and increments of change will have to be determined empirically. It is all too easy to have overactive feedback loops that over steer, swinging too far one way and then too far the other way. For example, the later 'smarter' (actually dumber, too clever by half) autopilots used on boats are notorious for over steering.

The python language has all the necessary components to do this: a timer to set the interval for the checks, if clauses to do the checks and initiate action if needed, and the minimalmodbus module to read the room temp sensor and get and set Midea register values. I already have the data logging system running, meaning I will have real time and historical data on relevant parameters, including energy in and out, with the ability to produce meaningful stats and useful charts. Above all, at least in concept, it is simple. None of that HA YAML mumbo jumbo with cavernous code meaningless to man.

Midea 14kW (for now...) ASHP heating both building and DHW

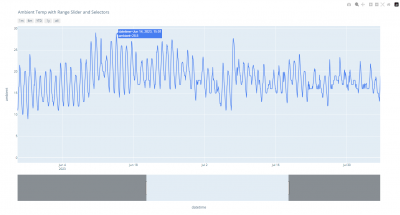

I have also been experimenting with plotting options, and it looks as though plotly in python does pretty much what I need. Here is a proof of concept snapshot (ie this image isn't interactive, but the real thing is) plot of ambient outdoor temp with selectable date ranges and a date slider, with a data point value popup when hovering over the line, zooming in on June/July this year:

It needs tidying up, formatting and better labelling, but the basics are there.

Midea 14kW (for now...) ASHP heating both building and DHW

Hi Ray,

Now that I have almost completely recovered from a heavy dose of flu, which I suffered even before I received my annual flu jab, I have managed to work up sufficient enthusiasm to perform a hefty dollop of 'whatiffery' with regard to that burning question, to setback, or not to setback. Results to follow shortly after completing some final tests.

With regard to controlling the indoor temperature using an 'offset' of the WC curve, there are various aspects that you may wish to take into consideration.

1) Do you wish to keep the indoor temperature constant, or be able to make changes within a specified range?

2) What degree of accuracy would you like to achieve?

3) Would you be happier with a more rapid response (but less efficient), or a slower response with better efficiency?

Below are some ideas that you may wish to consider.

Using the Midea data that you supplied some time ago, it would appear that a 1C change in LWT will cause a 6% to 9% change in thermal energy output, which could vary the indoor temperature by between 0.45C to 0.9C. Since the effect appears to be greater at warmer outside temperatures, I would suggest only changing the cold end of the WC curve, the 55C @ -4C end. It may be necessary to adjust the warm end setting to allow adequate control during warmer periods.

To perform Proportional Action (Gain) control will require measuring the room temperature and comparing this with the desired temperature, the difference being the error signal. This error signal would then need to be multiplied by an adjustable gain setting. The PA value will need to be calculated and stored for later use.

Integral Action (Reset) is required to reduce the error to zero, so that when the system is balanced, room temperature = desired temperature. The IA value is again derived from the error signal, but is integrated over time.

The new WC curve setting will therefore be given by:-

Original WC curve setting + PA value + IA value = New WC curve setting.

I think that an example may help with the understanding.

If the desired room temperature is 20C, but the actual room temperature is 20.4C, there is an error of 0.4C, but since the error is the result of desired room temperature minus actual room temperature, the derived error will be -0.4.

The calculated PA value will be -0.4 x gain factor (which lets say is 1). The PA value is therefore -0.4.

The calculated IA value will be -0.4 x reset factor (which lets say is 0.01). The initial IA value is therefore -0.004. This value is stored for later use.

The new WC curve setting is therefore given by:-

55 + (-0.4) +(-0.004) = 54.596C

Because the WC curve setting is an integer, the new WC curve setting will need to be rounded to the nearest integer, which in this case would be 55C, so no change.

The above program would need to be run every 5 or 10 minutes with the possible following results.

Run. Desired Room Temp. Actual Room Temp. Error. PA value. Old IA value. New IA value. New WC curve setting.

1 20 20.4 -0.4 -0.4 0.0 -0.004 (54.596) 55C

2 20 20.4 -0.4 -0.4 -0.004 -0.004 + (-0.004) = -0.008 (54.592) 55C

3 20 20.4 -0.4 -0.4 -0.008 -0.012 (54.588) 55C

26 20 20.4 -0.4 -0.4 -0.1 -0.104 (54.496) 54C

As can be seen above, the PA value will vary with the error and its effect can be adjusted using the gain factor.

The IA value will add to or subtract from the WC curve value, and will continue to change until the desired and actual temperatures are equal.

The response of the control system can therefore be optimised by setting the gain factor and the reset factor.

If you have any questions please feel free to ask.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 260 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 31 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@editor, this is now an example of greenwashing in the ...

By Majordennisbloodnok , 42 minutes ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 2 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 2 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 3 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 3 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 4 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 6 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 8 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 19 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 20 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 24 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 24 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago