Posted by: @davewPosted by: @gotaashp

As an aside - this installer video has the case off at 29:30, no mention of an internal pump whilst discussing the internal gubbings.

@gotaashp, @derekm

I have a total package ecodan 8.5kw pump and packaged cylinder and I have three pumps pre plumbed by mitsubishi on the indoor unit....looking at the schematic for my system (See page 5) it shows the 3 pumps , one for the DHW, one on the primary heat pump return and one on the heating circuit (not sure how this works I think it is something to do with the magical hydraulic separation in the low loss header.....however I think this confirms the heat pump has no internal pump.

I am still not sure which of the two heating pump I have been adjusting using the FTC setting but I am down to 1 (currently showing 11l/min) and everything seems okay but still only achieving DT of 3.

Still trying 24 HR trials on AA with tweaks and getting 3.2 to 3.4 cops... today's test is no setbacks and 20c set point.

Still running repetitive with one cycle per hour.

Hope this helps

You are indeed correct that the Ecodan does not have an internal water pump. My bad. 🙄

So I must assume that when you change the pump speed on the controller it is varying the speed of, probably, the return pump, which must therefore be wired to the controller.

What I fail to understand, is why you are having to manually change the speed of the water pump, if the speed is being controlled from the controller? Why does the controller not vary the speed automatically to control the DeltaT?

Edit.

The only other way to increase the COP would probably be to reduce the LWT, but I would also suggest checking that the temperature sensors are actually installed correctly, are making good thermal contact with the pipework, and are adequately insulated.

Posted by: @derek-mPosted by: @davewPosted by: @gotaashp

As an aside - this installer video has the case off at 29:30, no mention of an internal pump whilst discussing the internal gubbings.

@gotaashp, @derekm

I have a total package ecodan 8.5kw pump and packaged cylinder and I have three pumps pre plumbed by mitsubishi on the indoor unit....looking at the schematic for my system (See page 5) it shows the 3 pumps , one for the DHW, one on the primary heat pump return and one on the heating circuit (not sure how this works I think it is something to do with the magical hydraulic separation in the low loss header.....however I think this confirms the heat pump has no internal pump.

I am still not sure which of the two heating pump I have been adjusting using the FTC setting but I am down to 1 (currently showing 11l/min) and everything seems okay but still only achieving DT of 3.

Still trying 24 HR trials on AA with tweaks and getting 3.2 to 3.4 cops... today's test is no setbacks and 20c set point.

Still running repetitive with one cycle per hour.

Hope this helps

You are indeed correct that the Ecodan does not have an internal water pump. My bad. 🙄

So I must assume that when you change the pump speed on the controller it is varying the speed of, probably, the return pump, which must therefore be wired to the controller.

What I fail to understand, is why you are having to manually change the speed of the water pump, if the speed is being controlled from the controller? Why does the controller not vary the speed automatically to control the DeltaT?

Edit.

The only other way to increase the COP would probably be to reduce the LWT, but I would also suggest checking that the temperature sensors are actually installed correctly, are making good thermal contact with the pipework, and are adequately insulated.

Think I’ll claim the no pump in the heat pump thingy 😉😂😂

Davew have you tried a DT check while your system is in DHW mode? That will be a shorter return loop to the heat pump and so may give you a higher delta T. That should also switch off one of the other pumps… I’m guessing the CH return pump will de activated.

Edit- I know this isn’t a solution in itself but it may explain where heat exchange is poorer.

Also. The Mitsubishi pre plumbed cylinder assemblies are the only ones guaranteed to have ftc linked speed control. If an installer assembles their own pipework they may install different pumps with manual adjustment. Availability has been cited as a reason!?

Also endorse what Derek Said about checking the thermistor placement and contact is good. Make sure they are on the Primary Flow and Return and not on the CH flow and return.

Our story so far

we’ve got our daily COP up to 3.75, 3.4, 3.73, 3.72, 3.67, 3.58, 3.72 for the past 7 days. This is taken from our daily consumption update on screen.

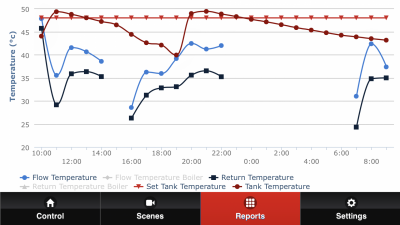

Our Problem area is : Reporting graphs.. Not sure how good MELCloud is? What’s the best-simplest-low cost system people are using?

morning. an update....

i have WC curve set to 45 @ -3c, 25 @19c. before I went to bed last night I offset the LFT by -3c on the FTC panel, so not to have it so warm during the night. WRT was showing 20c.

at 8am this morn, WRT was still showing 20c. (it hasn't fluctuated hardly at all from this since I started WC (72 hrs ago)). interestingly, because of the lower outside temps the LFT was at 40 and the RFT was at 36, so a DT of 4 - the best I have seen it since observation started 3 days ago. this suggests that I can achieve a better DT with higher LFTs but struggles with lower (~32) LFTs (DT2). any thoughts why this might be?

Derek - I haven't tried your suggested trial yet or checked the temp sensors. I'm not sure what I'm looking for but I'll figure it out 🙂

EDIT: also wanted to ask, how are you calculating your COP? is this number readily available on the MELCLOUD app? (something I don't have).

Posted by: @si-filloalso wanted to ask, how are you calculating your COP?

I’m sure MELCloud works it out once you’re familiar with it.

The quickest way I’ve been using is off the FTC main screen. Press the right menu button and you should get 4 rows of options. The right one is the daily consumption and generation rate. This is updated daily at 11.59pm and gives you a running total for the current month. I then subtract yesterday’s number from todays total to give me the last 24 hours stat.

to work out the cop divide the big number by the small number.

example :

total generated 206kwh

total consumed 56kwh

206 / 56 = 3.68 COP

@sunandair ah, thank you. I had seen this numbers but didn't realise it was a cumulative (monthly) number. So yesterday I had COP of 2.64. current month...2.52. could be better I feel.

I had a look at temp sensors on flow/return pipes. Contacts look ok, but no insulation as Derek suggested should be present. Do I need to lag them with something?

You can drill down further on those energy figures, but they only go as granular as monthly. For daily you'll have to do as @SUNandAIR suggests (subtract the number from the day before). Have a watch of the video below.

Mitsubishi Electric Ecodan FTC5 - Using energy monitoring - YouTube

If you go to melcloud and click on reports tab then select energy usage.....set the start and end dates for period you want ...for a single day use both dates the same....it gives a pie chart showing total consumed and below that a bar chart for consumed and delivered...you can deselect the hot water by clicking on the orange bit under the bar charts if you want just heating consumption.

All said on my melcloud it does not show cop which I would have thought was very easy to do but as you said it's just delivered/ consumed.

You can of course look back to any date or period this way.

Posted by: @sunandairAlso. The Mitsubishi pre plumbed cylinder assemblies are the only ones guaranteed to have ftc linked speed control. If an installer assembles their own pipework they may install different pumps with manual adjustment. Availability has been cited as a reason!?

Ah-ha that makes a lot of sense. Ours isn't pre-plumbed and like @si-fillo we don't have a large number of rads with long runs - so likely the installer deems a fixed flow rate sufficient (and it seems to be tbh) so no need for any speed control. Thanks

Posted by: @davew

I will investigate tomorrow and finally determine what is happening and report back.

Hi Dave,

Thank you so much for the feedback, not everyone provides it, which makes ensuring that we are supplying correct, meaningful, help and advice more difficult.

It is also helpful for future forum readers to see that the problems were actually correctly identified and resolved.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 1,075 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That’s my pleasure, @andrewj. The only challenge now is...

By Majordennisbloodnok , 2 hours ago

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 3 hours ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 4 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 4 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 4 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 5 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 5 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 5 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 9 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 12 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 14 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago