Posted by: @roblWhile you could defrost without using energy, it’s difficult. You could vibrate the coils, and get ice to fall off intact. I’ve seen an ashp designed to be manually hit with a hammer to get the ice off! Don’t do this with a conventional one, it will break it. Otherwise, I think the efficiency loss is less if you use heatpump created thermal heat rather than a straight electric heater, and slightly less the faster it is - if you did it too slowly, it might use heat but never actually defrost. What’s usually happening is that the ice is being melted off - which takes a fixed energy.

Here is one suggestion.

A second small heat pump that can provide hot water into a coil type heat exchanger, which is mounted just before, but not touching, the evaporator coils on the main heat pump. When the larger heat pump is approaching the point where a defrost will become necessary, the smaller heat pump is started to produce water at say 50C. The larger heat pump would need to stop its compressor and probably reduce the fan speed, but keep drawing air through its evaporator coils. The smaller heat pump would now supply hot water through its heat exchanger to provide the thermal energy required to melt the ice buildup on the main evaporator.

Because the smaller heat pump is only operating intermittently, it should not ice up and require a defrost.

Of course this is all added complexity and expense, which may be better spent insulating the building to reduce the heat demand, which in turn means any heat pump installed would not have to work so hard, so would be less likely to ice up in the first place.

What's that saying, 'putting the cart before the horses'. 🙄

@derek-m I’m sure that Mr. Emmit (sp?) would have liked such a project - just supply countless lengths of copper piping and joints…Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Posted by: @derek-mI think that a GSHP would have been a better option in your situation.

Possibly, but I am not sure I have the space needed, plus very very disruptive, and very very expensive (plus no grant at the time?).

My situation isn't that unusual round here, or I expect in a lot of non-urban settings, old small and sometimes listed buildings, with varying garden space. You may recall one of my reasons for having a heat pump (air source) was to see if it could be done effectively, when many said it couldn't, and the answer is yet it can be done, but it will be expensive to run, because the building will be expensive to heat whatever the fuel. The current heat supply deficit isn't down to it being a heat pump, it is down to it being an under-sized heat pump. I'm still on the fence about flipping the dip switches, more heat, but higher costs, which are already very high at current usage, four to five times what it was in the recent milder past, and still that nagging warranty concern.

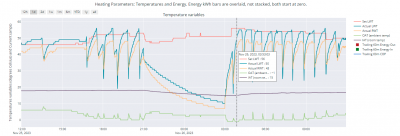

By the way, I think today's chart (last 24h data) shows the auto adaption script is working. The baseline curve, without any adaption applied, is 56 @ -4 / 34 @ 15. The script then checks the actual IAT against the desired IAT (19) and for every degree of difference above or below, adjusts both ends of the WCC one degree down or up, respectively, up to a maximum of a three degree increase or decrease. Here's the data shortly after the end of the setback:

The OAT is -1, and with the baseline WCC that would give a Set LWT of around 53 degrees. However, the actual IAT is 15.0, f degrees below the desired IAT, and the script has responded by pushing up the WCC endpoint by the max amount possible, 3 degrees, pushing up the Set LWT by 3 degrees, to 56 degrees. But, even with that boost, it still can't cope. At the moment the IAT is 16.7, better than 15.0, but still not even approaching the desired 19 degrees.

@derek - a secondary heat pump is an intriguing idea, and would get the needed heat more effciently, but as you say at the cost of adding complexity and expense. It would however give you the opportunity to spend many a happy hour modelling the effects of the secondary pump on the primary pumps efficiency 😉 .

I'm already doing what I can to improve insulation, but it is a long and winding road, with many an unexpected and unwelcome turn. The latest saga involved some high tech glazing putty that turned out to be anything but high tech: it is water soluble until it has fully cured, which can take weeks, with the end result that it got washed away in the rain. When I suggested to the manufacturers that making a water soluble glazing putty for external use in our climate was on a par with making a chocolate teapot, they merely rattled up a load of legal BS, end use not our responsibility, circumstances beyond our control etc etc. I then said rain may be beyond our control, but its certainty is beyond doubt, and then gave up. There are some battles that it is simply not worth fighting.

Midea 14kW (for now...) ASHP heating both building and DHW

I am sorry to hear that your system is failing to keep your home warm, but I am not surprised, now that the design problems are becoming apparent.

Your system is now defrosting quite frequently, which of course only makes matters worse.

I would suggest that you try the following to try to reduce the number of defrost cycles, and also to get your heat pump to operate in a more consistent manner.

Put your system into fixed LWT at a setting of say 45C. Monitor the actual OAT and compare this with the reading from the OAT sensor. The eventual aim being to find the lowest LWT at which the heat pump runs consistently, and also gives the minimum DT between the actual OAT and the sensor OAT reading.

Don't carry out any further setbacks, since they are probably just making matters worse.

Try installing some form of temporary barriers to prevent the cold air coming out of the heat pump from being drawn into the intake. If this proves successful then see if it would be possible to re-arrange the shrubbery/hedges so as to create a barrier between exhaust and intake.

In the longer term it may be necessary to discuss these problems with the relevant parties as far as being 'listed' is concerned. For optimum efficiency you need to achieve a supply of warmer air to the heat pump, while dissipating the colder exhaust air as effectively as possible.

Posted by: @cathoderayPosted by: @kev-mIMO defrosts are the Achilles heel of current ASHPs...I don't think there is anything unusual about my ASHP of set up; they all do it.

I absolutely agree. It's like having an internal combustion engine that throttles itself when you put your foot down - madness! The heat pump becomes a heat thief! I can see why icing happens, but what I can't understand is why such a self defeating solution to the problem has been used, with no apparent effort applied to finding a better solution. Perhaps they need to get ChatGPT on the case. A different material, or maybe a coating, for the coils, that resists icing? How do ships and planes deal with icing these days? An alternative way of generating warm air to do the deicing that doesn't suck heat from the house and at the same time pushes the heat pump to operate at it's most inefficient - maybe a separate heater element, which although it has a COP of 1, is at least not a heat thief?

Hi Kev and Ray

Our heating was on a low setback so it was inactive for heating purposes. This allowed us to see the auto-reheat for defrost purposes.

Fistly we have noticed it doesn’t reheat the circulating water every defrost. In many cases we think the existing hot water already in the pipes has enough energy to complete the defrost cycle.

What appears to trigger the reheat is when the flow temp drops below 15c. Secondly the reheat only tries to raise the flow temperature to around 22c and at what appears to be a very low compressor output. This reheat to only 22c appears to be a minimal cost esp since the system can’t afford the circulating fluid temp to drop to freezing point before the exchanger itself is fully defrosted.

My theory is:

If the system is operating in normal heating mode then it is quite likely that the system will not require a reheat at all since there will already be enough heat in the circuit to instigate and complete a defrost. So the only times a short reheat might be necessary would be on a night time extra low setback when the system is on a virtual shutdown for half the night. Since on most setbacks the pipe temps shouldn’t drop below 18c until a few defrosts have occurred.

I would like to know you’re thoughts on this and whether it is as big an issue. Or is it more a perception issue?

Add :(A similar energy boost for a different reason is a water re-heat and circulation when the Outside Ambient drops below the freeze stat temperature limit which is necessary if there is no antifreeze)

Posted by: @cathoderayPosted by: @kev-mIMO defrosts are the Achilles heel of current ASHPs...I don't think there is anything unusual about my ASHP of set up; they all do it.

I absolutely agree. It's like having an internal combustion engine that throttles itself when you put your foot down - madness! The heat pump becomes a heat thief! I can see why icing happens, but what I can't understand is why such a self defeating solution to the problem has been used, with no apparent effort applied to finding a better solution. Perhaps they need to get ChatGPT on the case. A different material, or maybe a coating, for the coils, that resists icing? How do ships and planes deal with icing these days? An alternative way of generating warm air to do the deicing that doesn't suck heat from the house and at the same time pushes the heat pump to operate at it's most inefficient - maybe a separate heater element, which although it has a COP of 1, is at least not a heat thief?

Unfortunately most heat pumps are either a) direct descendants of air conditioners originally designed to cool or b) not designed for a mild but damp climate like the UK, where defrost is likely to be a problem for many days in the year. I do remember seeing one manufacturer claim that they had a new coating on the fins/blades to reduce icing, but I guess that until heat pump manufacturers see the UK (or another country with a similar climate) as a priority then innovative ways to deal with the problem might be few and far between. This is where a far-sighted government that understood tech (or trusted and acted on the advice of those who do understand tech) could help.

in fairness though to heat pump manufacturers they do declare both COP and max power including the effect of defrost cycles, they don't attempt to hide the facts, so if anyone has been caught out by this then its down to poor specification by their installer.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @sunandairOur heating was on a low setback so it was inactive for heating purposes. This allowed us to see the auto-reheat for defrost purposes.

Thank heavens you posted this, it reminds me of another can of worms which you dicuss, frost protection. In normal running, the heat pump as you say provides its own frost protection, but during a setback everything cools down, and last night my RWT dropped to 7 degrees...

Doctor to patient: I'm terribly sorry, I've got very bad news

Patient: Oh my God, how long have I got?

Doctor: Seven...

Patient: What? Weeks? Months?

Doctor: Six...five...four...three...two...

I thought heat pumps had frost protection built in, as in they come on even when off, when the heat pump internal temp drops below say ten degrees, driven by a 'frost stat'. Now I am not so sure. My system does have antifreeze, which will provide some protection, but I thought that was for the even worse scenario of an extended power cut in freezing conditions.

I will probably leave the setback in place for tonight, when it is forecast to be a bit less cold, for setback data collection, and then remove the setback from tomorrow onward, as it is forecast to get colder again. Removing the setback also fits with @derek-m's suggestion.

Posted by: @sunandairI would like to know you’re thoughts on this and whether it is as big an issue.

I certainly think we should make sure one way or another the system isn't going to freeze up.

@derek-m - I did try a period of fixed LWT running in early 2022, soon after the heat pump was installed, but it greatly increased energy in, by about 50% if memory serves. I am reluctant to try that again when current running costs are already very high.

Ducting: rather than ducting warmer air to the rear of the heat pump, I might be able to rig up something that will duct the cold exhaust air away from the machine: maybe some sort of temporary poly tunnel for use in cold weather. I will look into possibilities.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayThank heavens you posted this, it reminds me of another can of worms which you dicuss, frost protection. In normal running, the heat pump as you say provides its own frost protection, but during a setback everything cools down, and last night my RWT dropped to 7 degrees...

AFAIK they all do have frost protection built in, just like fossil fuel boilers. It should override any set back (again just like fossil fuel boilers) but of course not if you have set back by cutting the power to the HP.

In addition most recommend either

a) fitting anti freeze valves at the lowest exterior point - these gently leak water from the system thus depressurising it if they get below about 3C.

b) running with a glycol/water mix in the circulating fluid

one of these is normally fitted to protect against freezing during power failures

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaI do remember seeing one manufacturer claim that they had a new coating on the fins/blades to reduce icing

That is one thing i wondered about, either non-stick, so the ice doesn't get a hold, or some surface that causes the water before it actually freezes to bead up so that it's weight causes it to drop off, the same sort of idea as is used in a diesel fuel agglomerator which agglomerates water to large droplets that fall to the bottom of the filter bowl.

Midea 14kW (for now...) ASHP heating both building and DHW

I am not suggesting to run permanently on fixed LWT, but to try to get better control over the vicious circle that the heat pump is in. You need to aim for the low and slow running regime.

Reducing the LWT should make the heat pump more efficient, possibly making the exhaust air warmer, which in turn should make the intake air warmer, which should make the heat pump more efficient, and so on and so forth.

Yes, directing the exhaust air out of the area may also work.

Posted by: @jamespaAFAIK they all do have frost protection built in

That's what I thought, but I haven't been able to find any documentation for it in the (obtuse, that may be the reason) Midea manuals.

Posted by: @jamespajust like fossil fuel boilers

Not all do, my oil boiler didn't, I had to add a separate frost stat. It remains possible my heat pump doesn't have a unit is off frost stat, until I see documentation that says it does have one, or the data I record shows the unequivocal operation of a frost stat.

As I said, I do have currently have glycol in my system, but how much, and how depleted it is, I do not know. The problem is that a little bit of frost can do an awful lot of damage.

Frost valves don't strike me as a particularly elegant solution. Their protection will I suspect be very local, and when I looked for an answer to what happens after your frost valves have de-pressurised the system, I didn't really find one.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @derek-mI am not suggesting to run permanently on fixed LWT, but to try to get better control over the vicious circle that the heat pump is in. You need to aim for the low and slow running regime.

Reducing the LWT should make the heat pump more efficient, possibly making the exhaust air warmer, which in turn should make the intake air warmer, which should make the heat pump more efficient, and so on and so forth.

I will try briefly tomorrow. I have infinitely better monitoring now than I did when I last set a fixed LWT, and should be able to see what is happening fairly quickly.

Midea 14kW (for now...) ASHP heating both building and DHW

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 577 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 33 minutes ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 1 hour ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

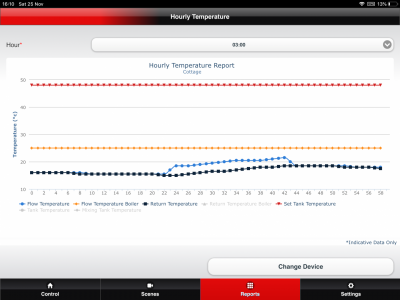

Here’s a current graph showing a bit more info. The set...

By benson , 2 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 2 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 3 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 3 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 3 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 4 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 10 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago