Posted by: @larrySo, reviewing all that has been discussed above, what do we think should be the most basic steps forward?

Not looking to revolutionise MCS in one swoop, but optimising all the info that is available and accessible - incl. A blower test for example

I'm thinking of suggestions that could be reasonably implemented within the skillset of a typical design and installation company, and would undoubtedly improve the system design and product spec'n mistakes that are still seeding doubt in the industry.

I think a room by room heat loss is a first step but with authority/discretion to include known upgrades without full documentation (one idiot would-be installer said the MCS process meant I had to prove exactly how good our elderly insulation was-clearly not possible). This includes owner upgrades, which must be in writing to protect both parties. If occupants have results of tests then these MUST be used in preference to assumptions.

A sanity check of using bills must be mandatory.

What won’t work is custom testing since it would be more expensive than the installation (shame but not viable for all, just research labs).

It can’t be made more technically difficult since it’s clearly challenging to get right for many installers.

The main change to MCS must be to protect the customer not go round in “not my fault mate” circles.

2kW + Growatt & 4kW +Sunnyboy PV on south-facing roof Solar thermal. 9.5kWh Givenergy battery with AC3. MVHR. Vaillant 7kW ASHP (very pleased with SCOP 4.7) open system operating on WC

Posted by: @judithPosted by: @larrySo, reviewing all that has been discussed above, what do we think should be the most basic steps forward?

Not looking to revolutionise MCS in one swoop, but optimising all the info that is available and accessible - incl. A blower test for example

I'm thinking of suggestions that could be reasonably implemented within the skillset of a typical design and installation company, and would undoubtedly improve the system design and product spec'n mistakes that are still seeding doubt in the industry.

I think a room by room heat loss is a first step but with authority/discretion to include known upgrades without full documentation (one idiot would-be installer said the MCS process meant I had to prove exactly how good our elderly insulation was-clearly not possible). This includes owner upgrades, which must be in writing to protect both parties. If occupants have results of tests then these MUST be used in preference to assumptions.

A sanity check of using bills must be mandatory.

What won’t work is custom testing since it would be more expensive than the installation (shame but not viable for all, just research labs).

It can’t be made more technically difficult since it’s clearly challenging to get right for many installers.

The main change to MCS must be to protect the customer not go round in “not my fault mate” circles.

I agree with all this.

I do think an approved method to practically integrate the results of a blower test would give the best bang for buck.

There's no other simple, repeatable test that could reduce the errors inherent in the existing method better than this; in such a short time at low cost.

It could be offered by installers or commissioned by the customer and become part of the "EPC" :o( ..... Don't get me started on these!!!

Here we go again, messy data making monkey plots! What I have, and can and can't do:

(1) minute by minute recorded data for all variables of interest, stored in a large csv file

(2) calculated hourly totals from the minute data recorded each hour at one minute past the hour for energy in and energy out, broken down by total, space heating and DHW, plus calculated COPs for these, plus mean OAT and IAT for that hour. Each value is in effect a trailing 60 minute value, the values for 1200 today cover the period from 1101 to 1200 today. This data is in a second csv file. This file provides the data for my recent week in October hourly OAT vs energy delivered plot.

(3) calculated 24 hour totals for the energy variables and COPs recorded each hour. Each row is the trailing 24 hour data for that hour. This data is in a third csv file. Using text-as-data sql queries, I can extract say all the midnight hour rows, and that gives me a data set with daily values. Most unfortunately, this file only has OAT data, not IAT data, meaning I can't select periods when the IAT was stable, which I need to do. If I just plot 24 hour energy in vs average OAT, I get nonsense, because there are many periods when the IAT was not stable, ie my house in equilibrium requirement is broken.

I am trying to find a way to get the IAT into the third data file so I can select only rows when the IAT was relatively stable.

The data runs from late March 2023. All the data files are subject to very occasional drop outs eg from power cuts and the general vagaries of nature.

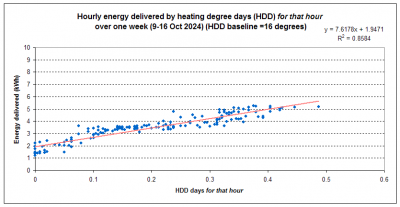

I have also done an hourly energy delivered vs heating degree days (HDD) plot, calculating the the HDD for each hour as the baseline temp (16 degrees) - OAT divided by 24 (to get the hours HDDs, if OAT is 16 or above this gets set to zero) for last week (a period when the IAT was stable:

But I am not sure how much more it tells us, except that, as expected, energy delivered rises as HDDs rise. It may even complicate things. Assuming I have got these HHDs right - the extreme right data point, at 0.5 for the hour, is 12 for the day (0.5 x 24), or an OAT of 16 - 12 ie 4 degrees at which OAT the the energy delivered is just over 5kWh for that hour (which is the same as shown on the energy out vs OAT plot). But using HDDs adds the extra layer of complexity, having to convert back and forth between OATs and HDDs, at least in my weak and feeble non-numerate brain. Maybe they don't add anything for hourly plots, because the detail is already in the data, but maybe they come into their own for daily plots, where an 24 hour average can obscure significant variability.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayHere we go again, messy data making monkey plots

Im not entirely sure what this comment is intended to convey.

My analysis is as follows -

- there are various ways of getting at essentially the same information, which way is 'best' depends on the data available to you. That will vary from case to case

- the focus of this discussion is ASHP sizing. So we need to start with the assumption that we have a fossil burner

- by far the most common fossil burner is a gas boiler

- gas boilers dont feature weather compensation in the UK, they respond only to IAT

So given the above, the data available to our target audience is

- gas consumption, half hourly if there is a smart meter or rather less often if there isnt.

- degree days for their nearest or most appropriate weather station (hourly/half hourly OAT is not downloadable for free on any website I have found)

- average daily temperature for the nearest or most appropriate weather station, which is essentially the same thing

- a few other daily measures such as sunshine hours etc

So the task is to find a way to create something useful from this.

If we have only gas consumption quarterly then the available method is to do something based on total gas consumption/total degree days

If we have gas consumption daily or more frequently then we can plot gas consumption vs average OAT or degree days (it doesn't matter much which, although they are not quite the same because on a day when the temperature goes above and below the degree days baseline they do differ)

Unless we have hourly OAT readings we cant plot hourly/half hourly consumption vs OAT and anyway such a plot might be deceptive given the averaging effect of the fabric (with the exception of systems with WC which excludes most of our target audience).

In any case boiler efficiency, heating pattern and IAT are unknowns.

We can make some estimate of the former given information about the boiler.

If we have half hourly meter readings we can get the heating pattern. In a house that doesn't cool too much it wont so big a difference that we cant compensate to within say 10%

In a house that is allowed to cool materially or where the IAT is materially different from the design IAT but is not known, we are a bit snookered with any simple analysis of the type one can do on a spreadsheet. However its at least plausible that a more sophisticated analysis might help, taking into account rates of change from which other factors can doubtless be estimated/measured.

From the above one can, I think, come up with some propositions depending on the data available. Im not going to enumerate them all but the central one is to plot daily fossil fuel consumption vs degree days (or average temperature) and to plot average consumption over say 3, 6, 12 hours vs date. Together these give complementary views which, suitably interpreted, should help in many but not all cases. Obviously if this data is not available you cant use it and if other data is available you may well want to use that.

Posted by: @larryI do think an approved method to practically integrate the results of a blower test would give the best bang for buck.

I think I agree with that, so long as a blower test is sufficiently cheap which, given that it need not take much time, it could be. In fact perhaps every MCS fabric surveyor should carry a blower, some hardboard (or whatever they use) and some tape to do the test as part of the survey.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@judith , @larry , @cathoderay

Posted by: @larrySo, reviewing all that has been discussed above, what do we think should be the most basic steps forward?

Not looking to revolutionise MCS in one swoop, but optimising all the info that is available and accessible - incl. A blower test for example

I'm thinking of suggestions that could be reasonably implemented within the skillset of a typical design and installation company, and would undoubtedly improve the system design and product spec'n mistakes that are still seeding doubt in the industry.

I think a room by room heat loss is a first step but with authority/discretion to include known upgrades without full documentation (one idiot would-be installer said the MCS process meant I had to prove exactly how good our elderly insulation was-clearly not possible). This includes owner upgrades, which must be in writing to protect both parties. If occupants have results of tests then these MUST be used in preference to assumptions.

A sanity check of using bills must be mandatory.

What won’t work is custom testing since it would be more expensive than the installation (shame but not viable for all, just research labs).

It can’t be made more technically difficult since it’s clearly challenging to get right for many installers.

The main change to MCS must be to protect the customer not go round in “not my fault mate” circles.

Collecting the above together with my comments and those from @cathoderay

- A room by room fabric spreadsheet

- A blower test done by the surveyor for the room by room fabric spreadsheet

- A questionnaire for the householder about heating patterns, IAT and invisible fabric upgrades (which form pat of the contract)

- An analysis based on either total gas consumption annually and degree days or, where available, smart meter readings and degree days.

Its a bit more work than the spreadsheet alone, but with suitable automation not much more. 1, 2, 3 taken together should come close to eliminating the fabric uncertainties, except for properties where upgrades have been done which the current householder doesn't know about (which will certainly occur, but hey that's life).

4 provides a check, or in some cases will trump, what you get from 1-3.

Some of the above can be dropped for

- relatively new properties where the fabric is known

- low loss properties (say 4kW or less, or according to existing pipe sizes) where an error in sizing by a factor of 2 wont make a material difference to the design

It seems to me entirely possible to design a solution based on the above which is at least as robust for the installer but will, in many cases, give better results for not much more effort.

Finally cant see how MCS will ever protect the customer as it is an installer funded body.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaIm not entirely sure what this comment is intended to convey.

It means what it says, but if you want a rewording it might be 'not for the first time the data is messy (incomplete, haywire values at extreme ends of the weather curve etc etc), and as a result we get plots that look as if they have been done by a monkey'.

Of course I appreciate the target audience (not an ideal term, we are not from the nudge unit) is people considering a heat pump for the first time which means by definition they don't have one yet, and that means they don't have the detailed data a heat pump can provide. I've said as much previously. However, I do have a heat pump, and only a heat pump, my historical oil use data is of very limited, if any, use, beyond very crude sanity checking, if that. That means any experimental work I do will have to be on a heat pump.

Given that there appear to be flaws, sometimes very significant flaws, in the spreadsheet method of determining heat loss - for example, in my case I may have thought my heat loss was 12kW when in fact it was 8kW - I decided to look at alternative ways of determining heat loss. Because of my preference for empirical methods, I like the idea of taking a house in a steady state (ie constant IAT), measuring the energy delivered, and then saying that must also be the heat loss, because the house is in a steady state.

Initially it was only an idea, I had to plot the data to see whether it looks like it works in practice, and it seems like it does. Even a mild week in October, with the IAT kept constant, can give a pretty good idea of what the heat loss will be at lower OATs, simply by plotting hourly OAT against hourly energy delivered, and extrapolating to lower OATs. This isn't that surprising, given we believe that other factors notwithstanding, there is at a given IAT a linear relationship between OAT and heat loss. The other factors (solar gain, wind chill, air changes, and all the other known and unknown factors) are what produce the spread (variability) in the plot but it seems they are near enough evenly spread to cancel out, and the true linear relationship between OAT and heat loss pops out. I should add that I am very much a pragmatist, I don't have to understand all the minutiae (every detail of every factor), if the over-arching logic makes sense, and something works, then I am usually going to be happy with it. I am comfortable with the central premise of the empirical method, that in a steady state (constant IAT), the heat loss from and the energy delivered to a building must be the same, which in turn means if you can determine the energy delivered at various OATs, then you know the heat loss at various OATs, including the so called design OAT (which is a limit OAT, in the sense that it is the lowest OAT likely to be experienced, except on very rare occasions, and in that sense marks the upper limit of what the heat source needs to provide).

Having established the hourly plot method appears to work, the next step is to adapt it, if possible, to use the coarser data available from fossil fuel systems. The OAT is not difficult, a temperature data logger, around £20 on ebay, placed somewhere suitable outside, will record hourly temperature for as long as you want (the batteries last a year or more). You can convert the OAT to heating degree days if you want to, I myself am not yet sure that actually adds anything for hourly plots, but it may for daily plots. Energy delivered is more difficult, because standard fossil fuel systems do not record the necessary data directly. Instead, the lowest common denominator is manual daily readings of the energy in for gas. For oil systems, the situation is even worse, there is no way of knowing daily consumption on a standard oil heating setup, meaning this method can't work for oil based systems. The questions now are (a) whether daily readings are fine grained enough to give a satisfactory assessment of heat loss and (b) how to convert energy in to energy out. Note that during any assessment period used to determine the heat loss, the IAT must be kept reasonably constant. For gas boilers, this is usually done by on/off cycling controlled by a thermostat, but I am not sure that this matters, since in theory a gas boiler cycling 10kW equal on/off periods is the same as another gas boiler (or indeed a heat pump) running 5kW continuously, or more generally, and timed running will have a continuous running equivalent.

Taking the second question first, @jamespa suggests we can, if we know enough about a gas boiler, we can estimate its efficiency sufficiently accurately (see posts above), and then use that to estimate daily energy delivered to the house.

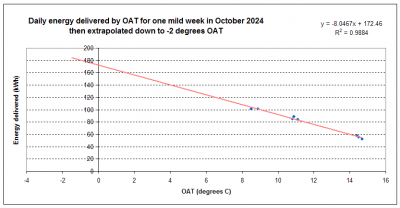

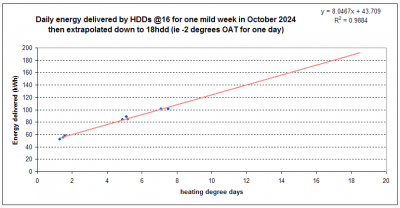

That just leaves the question of whether daily plots, with on/off periods during the day, will work. I can't do the on/off bit as I don't have thermostat controlled on/off data, but I can, with some data manipulation (my fault, because I didn't put all the right variables in all the right places) do daily plots. Before doing this with large data sets (= large amounts of work), I have done this for the recent mild week in October data set. This means only seven data points, but at least we should get some idea of where this is heading. I have done plots using both raw OAT means and heating degree days, to see if the latter adds anything. This is what I got. Bear in mind what we are looking for is a daily energy delivered of around 8kWh (energy needed/delivered at -2 degrees) x 24 = 192kWh, this being what I would expect if I had to endure 24 hours at -2 degrees OAT (sanity check: maximum ever daily energy delivered 183kWh to 1900 hours on 20th Jan 2024, rather oddly this was at a mean trailing OAT of 5 degrees, can't explain that):

Remarkably, just seven data points from a mild week in October get very close to predicting what energy will need to be delivered when the OAT drops to -2 degrees OAT. On the upper OAT chart it about 185kWh, on the lower HDD chart it is about 192kWh. If we divide the latter by 24 to get the kW rating, we get 8kW - exactly what we expect.

These two charts only use (a) daily total energy delivered and (b) daily mean OAT, and nothing else. Despite only having seven data points from a mild time of year, that very sparse data seems to be able to predict rather well what the energy needed will be at much cooler times of the year.

Put to a proof of concept test, I think it passes.

Midea 14kW (for now...) ASHP heating both building and DHW

I'm still running on my gas boiler and have been analysing my half-hourly gas use (and OAT, IAT, flow temp and return temp) for almost two years. I commissioned a desk-based Heat Engineer assessment last year which determined my heat loss to be 11kW. I also did my own room-based heat loss assessment which resulted in a figure of 11.7kW (I tended to err on the side of pessimism). An unsolicited Loop Homes analysis of my gas use Oct 22 - Oct 23 (daily gas use vs OATavg) suggested a heat loss of around 11kW @ -2C. My own gas use analysis for Jan 22 - Mar 23 (degree days vs gas use) showed a peak daily gas use of 260kWh (equivalent to 10.8kW avg) with regression analysis giving 10.4kW @ -2C. OAT temperature is from my personal weather station.

My gas use data is 'dirty' in that for much of the time the boiler had not been derated and was cycling with very high flow temperatures. Also the thermostat set temperature was not constant, with overnight setbacks, etc. The figures also included DHW. I have also now come to the conclusion that my present system heat output is restricted by the emitters.

I had considered commissioning a blower test after reading advice in this forum that it is worthwhile. A quick google suggests that I should be able to commission one for around £200. However, I am swayed by @heacol's comments and that I should just use an ACH value of 1. I am concerned about what I may otherwise discover regarding a service shaft for my plumbing from the bathroom, shower room and en-suite. On windy days I can feel a draught around my ankles there but sealing the shaft would be very impractical.

Subject to advice from a 'trusted professional', I suspect I will need a 10kW (at -2C) ASHP with all emitters replaced (so I would like to take the opportunity to be generous in sizing to help lower flow temperatures, subject to Mrs MK13's approval of course). Bathroom, etc, will need a conversation as (water) heated tower rails are fitted and the floors and walls are tiled. Extractor fans are fitted, which will pull-in warm air from the house when operating (i.e. when occupied) and doors could be left ajar when not occupied.

@cathoderay Incidentally, I tried an hourly analysis of consumption but the resulting graph was a splodge.

Posted by: @ianmk13@cathoderay Incidentally, I tried an hourly analysis of consumption but the resulting graph was a splodge.

Interesting (and a splodge is another example of what I recently called monkey plots). I wonder if the hourly plots fail because your system is very volatile. Using aggregated 24 hour data might smooth things out, as might trying to run the system as stable as possible while doing the measurements. You do at least have some of the key data for calculating energy out, if you can get flow rate and the specific heat of the circulating fluid then you will have everything you need.

Midea 14kW (for now...) ASHP heating both building and DHW

OK, another question, if I may.

If you have a particular known material (brick, glass, concrete etc.) forming the outside face of a container, you know the ambient temperature outside that container, you know the temperature of the material in question on its external face and you know the surface area of that external face, is it possible just with that information to calculate how much heat that face is transferring to the outside?

105 m2 bungalow in South East England

Mitsubishi Ecodan 8.5 kW air source heat pump

18 x 360W solar panels

1 x 6 kW GroWatt battery and SPH5000 inverter

1 x Myenergi Zappi

1 x VW ID3

Raised beds for home-grown veg and chickens for eggs

"Semper in excretia; sumus solum profundum variat"

Posted by: @majordennisbloodnokOK, another question, if I may.

If you have a particular known material (brick, glass, concrete etc.) forming the outside face of a container, you know the ambient temperature outside that container, you know the temperature of the material in question on its external face and you know the surface area of that external face, is it possible just with that information to calculate how much heat that face is transferring to the outside?

...Or, as an alternative question, if you have a surface that is kept at a constant temperature, will that surface emit the same amount of heat energy irrespective of what the surface is made of? (e.g. a flat metal surface at 50degC compared with a flat stone surface at 50degC, assuming both surface areas are the same and they are both facing an ambient air temperature of 20degC).

105 m2 bungalow in South East England

Mitsubishi Ecodan 8.5 kW air source heat pump

18 x 360W solar panels

1 x 6 kW GroWatt battery and SPH5000 inverter

1 x Myenergi Zappi

1 x VW ID3

Raised beds for home-grown veg and chickens for eggs

"Semper in excretia; sumus solum profundum variat"

@majordennisbloodnok - interesting questions that I don't know the answer to, but the thinking behind them is the same line of thinking I had when I was wondering about basing heat loss on external measurements (because that is where the heat ends up). Perhaps one of the more thermodynamically knowledgeable members might care to comment?

Midea 14kW (for now...) ASHP heating both building and DHW

-

Gen 6 Samsung ASHP losing 20C of DHW in 60 min directly after generation

1 month ago

-

Should I make my radiators smaller?

11 months ago

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 228 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

@transparent Triggered by the various commen...

By JamesPa , 5 minutes ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 35 minutes ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 42 minutes ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 1 hour ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

I've found that generally the humidity in the house is ...

By IRMartini , 1 hour ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 5 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 6 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 17 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 19 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 19 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 22 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 22 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 22 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 24 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago