Advice needed on hybrid system - ASHP not reaching flow temperature

Hi, hope you’re all keeping well.

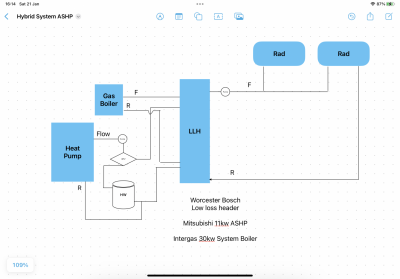

We had a Mitsubishi 11kw ASHP installed a month or so ago and we struggled to heat our house during the last cold snap we had. We made the decision to install a gas boiler alongside the ASHP to run on the colder days. Looking at the charts the specified flow temp of 50c for space heating has never been reached, it gets to around 45 degrees. The pipe runs are all insulated and i have even increased the compensation curve to the maximum. The flow temp for the hot water seems to reach 60 degrees but it doesn’t on the space heating side. I have attached a diagram of our setup at the moment. Please note that the gas boiler isn’t yet up and running as we are waiting on a sensor from Mitsubishi.

Thanks in advance.

Is it the radiator side of the LLH that's not reaching temperature? Or does the heat pump monitoring show it's not achieving 50degC supply temperature? It clearly can if you're getting 60degC on your hot water, so if the primary side isn't allowing 50degC in heating, I guess some setting or parameter is overriding your climatic curve setting.

But if you're getting 50degC on the primary side and not getting that on the secondary side, the finger of suspicion points at the LLH?

Have you got balanced even flow on primary and secondary sides? Higher flow on the secondary radiator side compared to the primary side will pull return water through the LLH, mix with the higher temperature flow from the ASHP, and cause a lower radiator supply temperature.

If you've not got flow valves on both sides to balance flow, you can do it thermally with some temperature sensors. These are cheap and cheerful, and when cable tied to the copper pipe under insulation will give a reasonable indication of what's what +/-0.5degC or so. https://www.amazon.co.uk/dp/B07TY6HRL4?psc=1&ref=ppx_yo2ov_dt_b_product_details

Thanks for getting back to me ally - I am not sure where the thermistors are which are giving me the readings on the melcloud app.

there doesn’t appear to be any balancing valves installed.

all I know is that the flow temps are showing around 45c on the app despite it been set to 50c on the comp curve. Does the piping layout look ok to you from my diagram?

do you think it could be a setting on the controller somewhere?

worthwhile mentioning that there is a pipe run of around 15m from the ASHP to the llh around 10m of this is outdoors

There is a setting on the Ecodan FTC to limit flow temp. I know because I lowered mine a few days ago. It's in the maintenance menu, Operation Settings, Heating Operation, Flow Temperature Range. In case you don't know, pass key is (probably) 0000 and it'll ask you to shut the system down (which is fine as it will start when you exit).

My flow thermistors are physically just above my (non-Mitsubishi) HW tank. The sensors are attached to the flow and return copper pipes like those on Ally's thermometers and the other end disappears into the FTC.

@parmstar Great, les us know how you get on. Piping on your circuit is simple enough, and with a hybrid bivalent system I can see the LLH being of benefit. I would suggest flow monitoring/setting valves on both primary circuits, one on the ASHP return, one on the boiler return, and one on the secondary flow return. They all need to be in balance. Fired boiler design flow might be lower than ASHP design flow, but I guess you've considered that and how to handle that.

- 27 Forums

- 2,520 Topics

- 58.6 K Posts

- 494 Online

- 6,800 Members

Join Us!

Worth Watching

Latest Posts

-

Hi all I'm having some trouble with a Grant ASHP and ...

By Renewables345 , 3 minutes ago

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

You are absolutely correct that the capacity table MUST...

By JamesPa , 10 minutes ago

-

RE: Heat Pump vs New Gas Boiler for Inherited House - Worth the Extra Cost?

@fretless6, where are you based? I might be able to con...

By Mars , 1 hour ago

-

RE: Underfloor Heating Installation Issues with Heat Pump

I'm going to install Thermacome ACOSI+ radiant ceiling....

By bobflux , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Now seems a good time to summarise the costs and effici...

By benson , 3 hours ago

-

RE: Tell us about your Solar (PV) setup

@mk4 Charge to 100%, discharge down to 10%.

By bobflux , 4 hours ago

-

RE: Daikin Altherma 3 LT compressor longevity question

This mess is intriguing: I wonder if this represent...

By bobflux , 5 hours ago

-

RE: Connecting Growatt SPH5000 over wired ethernet rather than wireless

The simplest wired option is usually the Growatt Ethern...

By Jonatan , 10 hours ago

-

RE: Electricity price predictions

@jamespa And it seems some of the nasty public cloud...

By Batpred , 17 hours ago

-

RE: Jokes and fun posts about heat pumps and renewables

Technology is rapidly advancing. BBC News reported th...

By Transparent , 20 hours ago

-

What matters for flow and pressure drop is internal dia...

By bobflux , 21 hours ago

-

RE: Do Fridges and Freezers have COP ratings?

@editor Thank you all for your replies and submitted in...

By Toodles , 23 hours ago

-

I know and yes. The secondary deltaT wont necessaril...

By JamesPa , 1 day ago

-

RE: Designing heating system with air to water heat pump in France, near Lyon

Just love the way you put it! 🤣

By Batpred , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thank you for sharing. So it seems that your Schneid...

By Batpred , 2 days ago

-

RE: Forum updates, announcements & issues

@upnorthandpersonal thanks for the thoughtful, consider...

By Mars , 2 days ago

-

RE: Solar Power Output – Let’s Compare Generation Figures

@mk4 All 21 panels have their own Enphase IQ7a microinv...

By Toodles , 2 days ago

-

RE: Setback savings - fact or fiction?

Great, so you have proven that MELCloud is consistently...

By RobS , 3 days ago

-

RE: Mitsu PUHZ120Y 'Outdoor Temp 'error?

Thanks David & James It almos...

By DavidAlgarve , 3 days ago

-

RE: Surge protection devices SPDs

@trebor12345 - your original Topic about the right type...

By Transparent , 3 days ago

-

RE: Help needed with Samsung AE120RXYDEG

@tomf I’ve been sent this from a service engineer at Sa...

By Mars , 3 days ago

-

RE: Buying large amp bidirectional RCD and RCBO

Yes... I went through this particular headache and ende...

By bobflux , 4 days ago

-

O-oh! Let's take this as an opportunity to 'pass the ...

By Transparent , 4 days ago