Posted by: @iancalderbank@cathoderay I believe you need to look at it differently : for a flow rate of 1.5m/H, the system (i.e. the pump plus the head loss due to the HP itself) can cope with an external pressure drop requirement of up to 80kpa. to achieve higher flow rates than that, the external pressure drop (head loss due to the pipework) has to be made lower. that's normal behaviour for a pump.

as was mentioned before - whilst the lid is off with your service engineer - as much detail of the pump as you can . a key give away for a speed pump with variable speed that is controlled externally (to the pump)( is TWO cables (one power, one control). Fixed speed pump (or one that does variable control internally to the pump) will be only 1 cable (power).

Also check the setting of DIP Switch S2-3 and S2-4 which should match the type of pump installed. Also see if there is a cable connected at socket CN17, which would indicate a signal cable to the pump.

Posted by: @cathoderay@iancalderbank and @derek-m - I will certainly get as much info as I can while the covers are off, including photos where possible.

Looking at the manual for the heat pump, it mentions a flow switch, but not a flow sensor, so it will be interesting to see what is actually installed and if the system does actually measure the flow rate.

Posted by: @derek-mAlso check the setting of DIP Switch S2-3 and S2-4 which should match the type of pump installed. Also see if there is a cable connected at socket CN17, which would indicate a signal cable to the pump.

I didn't get to read that until after the service, but luckily I took some photos, one of which shows Dip Switch S2, and S2-3 and S2-4 are both off, which appears from the manual to be the setting "00=variable speed pump (Max head:8.5m,Grundfos)" and this is sort of confirmed by photos of the pump itself which looks like it has Grundfos on it, and two black cables attached to it (none are brilliant photos, sorry). My installer says it is variable flow, controlled by the heat pump. The photos:

It also turns out I have a flow meter in the primary circuit, an analogue one with no electronics in the airing cupboard, but spot readings may be useful, though it is very tricky getting readings because of its position. In my excitement, I forgot to investigate the type and location of any flow meter in the heat pump itself.

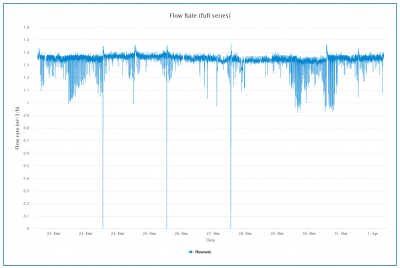

During the installation and service, my installer has recorded four readings from the analogue flow meter, and they range from 21 to 26 litres/min, which is 1.26 to 1.56m^3/h. These analogue readings are in the same ball park as the Midea modbus readings:

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay that pump looks like a grundfos UPMM, which is indeed PWM control capable and has two cables just as you show.

https://product-selection.grundfos.com/al/products/up-oem/upmm-oem?tab=documentation

I know what it looks like 'cos I've got one too 😉

My octopus signup link https://share.octopus.energy/ebony-deer-230

210m2 house, Samsung 16kw Gen6 ASHP Self installed: Single circulation loop , PWM modulating pump.

My public ASHP stats: https://heatpumpmonitor.org/system/view?id=45

11.9kWp of PV

41kWh of Battery storage (3x Powerwall 2)

2x BEVs

I received a technical documentation for a Midea clone with the description of the Modbus with the number, meaning and description in German. 147 registers and a few more for cascading. Would that still be of interest?

@gorm - thanks, maybe, post it or a link to it here anyway, if you can, more grist to the mill.

Midea 14kW (for now...) ASHP heating both building and DHW

You can find the description here (open in new tab), the modbus part starts on page 174, also alarms, password protected device parameters and service info. It is basically in German, but some information descriptions and commands of the wire controller are in different languages, for whatever reason. I think it's another Midea clone that is also missing certain electrotechnical information compared to other descriptions. If German descriptions need explanations I would try to help.

@gorm - thanks for the link. I am sure you are right, it is a Midea clone, the images all look familiar, and the modbus register values for the ones I checked are the same as the ones in the manuals I have. Vorsprung durch Technik.

Midea 14kW (for now...) ASHP heating both building and DHW

Ok, found this interesting notice in the text:

"Der Zugriff auf die Parameter oder Änderungen sind nur qualifiziertem Servicepersonal gestattet, das die

gesamte Verantwortung übernimmt. Wenden Sie sich im Zweifelsfall an Clivet."("Access to the parameters or changes are only permitted to qualified service personnel who have the assumes all responsibility. If in doubt, contact Clivet.")

The last word is the key, because Clivet is an Italian company. A search finds about the establishment of a new work by Clivet:

"In 2016, thanks to the industrial partnership with the Midea Group, Clivet has ..."

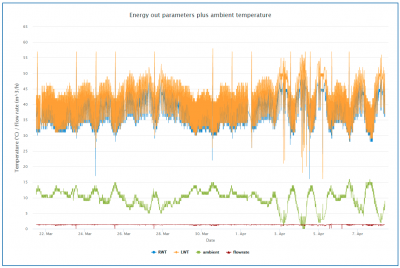

More high jinks with Highcharts JS. I have now got zooming working. Here is the minute data for energy out parameters (LWT, RWT and flow rate, plus ambient for reference) from the last couple of weeks. All present and correct, gives an overview, but too cluttered:

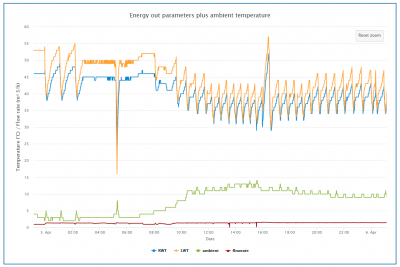

By dragging with the mouse, I can zoom into areas of interest. Here's data from the 5th April, a useful period to look at as it was cold overnight and warm during the day:

Plenty to be getting on with, to be sure!

Midea 14kW (for now...) ASHP heating both building and DHW

I'm back on the case, in particular, deciding what to measure and how. The idea is to get some measurements that aren't derived from the Midea wired controller data, as a way to confirm Midea aren't discretely marking their own home work in their favour. To recap, I have a Midea heat pump heating a primary water/glycol circuit that runs to a heat exchanger, and a secondary rad circuit on the other side of the heat exchanger. In general, I want to avoid wifi frippery and most definitely I want to avoid Home Assassin. The general idea is to measure over a wired modbus connection using minimalmodbus in Python, and write the data to csv files for further analysis and charting in Highcharts JS. I already have a modbus connection to the wired controller in the airing cupboard, which is also where the heat exchange sits. What might I measure?

(1) energy in: I have two sources for this data at the moment, the dedicated external Eastron non-modbus kWh meter that supplies the heat pump, and the Midea wired controller cumulative totals. Over short intervals (hours/days) the two can differ somewhat, but over longer periods (months) they are faily close, within about 2.5% of each other, with the Midea numbers almost always being smaller than the external meter numbers (meaning Midea based COPs are marginally better than those based on the external meter, but only by about 2.5% over the longer term).

At the moment I read the external meter manually. It does have a pulse LED and pulse counters do exist but it seems they might be prone to flakiness and they are not simple, it means adding layers of cost and complexity. Eastron do make a modbus enabled version of the kWh meter I have (SDM120) but that means changing the meter and at present I am not convinced it is necessary, since I already know that the Midea wired controller cumulative kWh numbers are close to the actual numbers (see above). Given that, I plan to use the Midea kWh in numbers, maybe with a small correction applied, and consider that they have been verified against the external meter. Should an opportunity arise, I might fit a modbus enabled SDM120, but it is not a priority right now.

(2) energy out (raw data needed is flow rate, LWT/RWT delta t and specific heat of circulating fluid): the first question is where to measure it. Midea will be measuring it inside the heat pump itself, where the values will be at their highest, and best. Arguably, the most meaningful place to measure it is at the outlet (rad circuit) side of the heat exchanger, since that is the net energy delivered to the house, in the same way that horsepower at the road wheels is a more meaningful measure than horsepower at the flywheel in a car. But the rad circuit has no flow meter and no viable proxy, for example from the circulating pump, to use to estimate flow. This means that to measure energy out at the rad side of the heat exchanger would mean adding a third party energy meter at that point, not cheap, and not easy (space is very tight, and there isn't a convenient straight run of pipe in the vicinity where it could be fitted.

As it happens, there is a very basic analogue flow meter in the primary circuit, and it confirms that the surprisingly static Midea reported flow rate on the primary circuit is probably correct, meaning I have an albeit rather crude Mark 1 eyeball based external verification that the Midea reported flow rate is correct, or at least good enough. That means that all I need to measure energy out at the input side of the heat exchanger is a couple of temperature sensors, one on the flow pipe, and one on the return pipe. Taken together, the analog flow meter and these two temperature sensors will give me a Midea independent figure for energy out.

Now, I imagined that modbus enabled temperature sensors would be widely available, but it seems they are not, or if they are, I am not looking in the right places. After a lot of digging around, I have come up with the following proposal:

(a) temperature sensors: the well known and affordable DS18B20 sensor. This comes in various form factors, the stainless steel enclosed one perhaps being the best suited to pipework attachment using cable tied, and can be got from UK sellers on ebay for about £3 a pop.

(b) the DS18B20 output is analog (a resistance that varies with temperature?) and I need to convert that to a modbus value, and there seem to be remarkably few adaptors that can do this. The only thing I have found that appears capable of doing so - it has the right voltage in requirements (I have USB power available on my modbus cable, ie 5V) and the right modbus setting (9600 baud etc) - has to come from China. It is listed (on ebay) as a "DC5V 12V TTL232 RS485 MODBUS RTU Module PLC DS18B20 Temperature Sensor Module" and I plan to use the bare (no sensor version) 5V RS485 version, and will attach the DS18B20 sensors myself (although the listing doesn't show this, I am pretty sure they can be daisy chained, and each given a unique address). On the other side of the module are VIN (voltage in), GRD (ground) and modbus A and B connections. It looks like this:

I wonder if anyone has any thoughts or comments before I set about ordering the hardware? Have I missed another simpler (note that I personally do not consider HA simple...) way of doing this? Is my proposal flawed? If it is, I will surely find out in due course, but if someone knows that it is flawed in advance, then I can start to look for another way. And please, can I ask, don't forget the title of this thread: it is a beginner's guide. That doesn't mean an idiot's guide, instead it means someone who knows how to use a screwdriver and a soldering iron, but has never done so before (and so is a beginner) when it comes to heat pump monitoring.

Midea 14kW (for now...) ASHP heating both building and DHW

Thanks for the post cathodeRay. Medium term follower first time poster 😛. I’ve been hoping you’d do an update. I’ve got a very similar setup to you by the sounds of it. I’d be very interested to see some photos or a description of how you’ve done your wired modbus connection. Unfortunately, I’m not much help when it comes to answering your technical temperature sensor questions, but I’m early following your progress! Keep up the good work.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 403 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 22 minutes ago

-

I cannot see the complete rcbo, since the photo is cut....

By Batpred , 35 minutes ago

-

RE: What determines the SOC of a battery?

The answer from Fogstar was crisp. My hypothesis, su...

By Batpred , 45 minutes ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 55 minutes ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 1 hour ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 1 hour ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 4 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 7 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 23 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago