@grahamh PWM Not Working

With a blushing SAMSUNG ENGINEER avoiding eye contact ,weakly trying to defend the PWM System on SAMSUNG HEAT PUMPS and your own excellent experience I have lost confidence in SAMSUNG .

I now accept that the PWM system, as implemented by SAMSUNG is mismatched to the Grundfoss PWM Motors.

However, I still have violent Short Cycling on both sides of an unwanted Heat Exchanger.

A 50 litre Volumising tank was fitted on the Heat Pump side of the Heat Exchanger removing one frequency of short-cycling.

I now have short Cycling on the Radiator side of the Heat Exchanger.

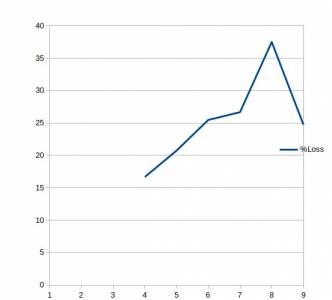

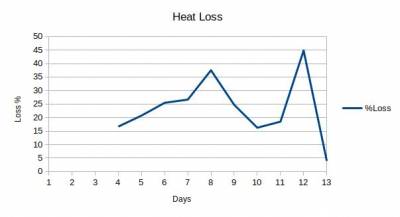

The tangle of pipes , heat exchanger and volumising tank are losing about 25% of the Energy generated by the Heat pump.

Heat losses

Should I worry about the "violent" short-cycling or wait until the motors ( plural) and the PCB relay arcs itself to oblivion?

ian

Ok so first never run the unit below 30 or even better 35c flow temp. You will get tons of cycling

Heat pumps don't work well below these temperatures. I haven't got time to explain here why but might blog on linked in about it this week. Next measure the return to the hp and return from heating. These temperatures should be the same if it's balanced . The plate is fine, will work brilliantly if it's all set up ok. It's there for a very good reason. It's not just keeping glycol out of the rads.

Don't worry too much about the cycling, it won't wear the unit out. It's designed to cope with this. The dream is to have less than 6 times a day you will never achieve this. Mine at home cycles 15 to 20 times a day. That's fine.

Concentrate on balancing primary hp flow and secondary heating flow. Get these the same and it's done.

If your installer had been listening when in training they would have been told how to do this. It's easy. As described above.

Heat pump builder

Posted by: @grahamhdont believe all the lies you are told.

I am sure you are correct. I will collect the evidence [of it not working] and send it to Samsung [not that I expect much out of that]

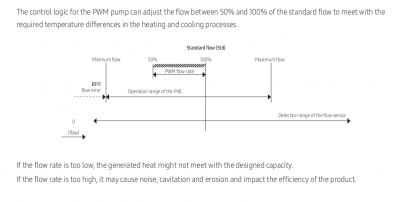

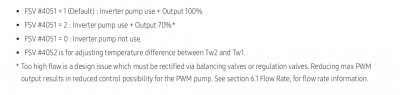

Their latest manual states the following (first image)

The second image shows the typical ambiguous language in the manual[s] from Samsung and could mean what you say ... fixed to either 70% or 100%.

@william1066 Latest Manual....first page?

Sorry William , what manual are you referring to here .

The NEW EHS Installation manual has nothing about this.

ian

Sorry William, I found the PWM Flow rate on page 58 of my new manual.

Many thanks also to Graham , the new version of the manual at 208 pages is infinitely better than the old version.

From page 58

" The installer is responsible to meet the exact designed flow rate ( Water Flow Rate(Std)(H/C) as stated in the applicable TDB."

What is my Designed Flow rate ...............my system was never designed!

What is a balancing valve? Would any old valve act as a balancing valve?

Posted by: @grahamhOk so first never run the unit below 30 or even better 35c flow temp. You will get tons of cycling

Heat pumps don't work well below these temperatures. I haven't got time to explain here why but might blog on linked in about it this week. Next measure the return to the hp and return from heating. These temperatures should be the same if it's balanced . The plate is fine, will work brilliantly if it's all set up ok. It's there for a very good reason. It's not just keeping glycol out of the rads.

Don't worry too much about the cycling, it won't wear the unit out. It's designed to cope with this. The dream is to have less than 6 times a day you will never achieve this. Mine at home cycles 15 to 20 times a day. That's fine.

Concentrate on balancing primary hp flow and secondary heating flow. Get these the same and it's done.

If your installer had been listening when in training they would have been told how to do this. It's easy. As described above.

@grahamh Do you mean ' less than 6 times a day' and '15 to 20 times a day' or per hour? 15 to 20 times a day does indeed seem to be nothing to worry about, but @iantelescope's cycling seems much more frequent. My 12kW Samsung occasionally starts cycling very frequently - 5 mins 30 secs on and 3 mins 30 secs off and so on. It generally happens when the ambient temperature is over 10 deg C and I presumed that the radiators were unable to get rid of the heat energy due to the lower flow temperatures and that the HP was unable to modulate low enough. However, today it was cycling with an ambient temperature of 6 deg C and flow temperature around 44 deg C. Delta T was actually quite high at 8.71 deg C shortly before it cycled off, which is the opposite of what I imagine is usually associated with short cycling at high ambient temperatures. Anybody have any ideas?

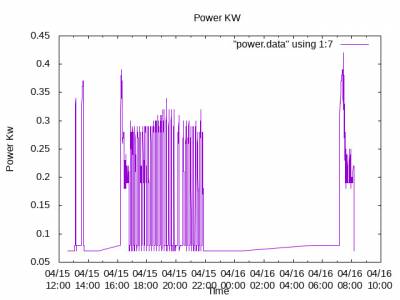

@mike-h World record for Hyper-Cycling!

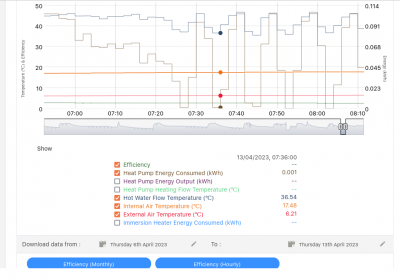

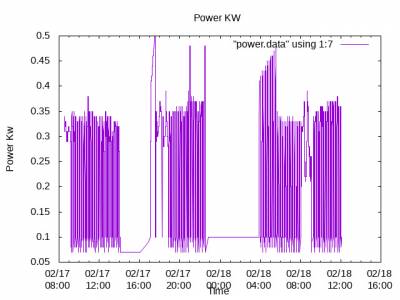

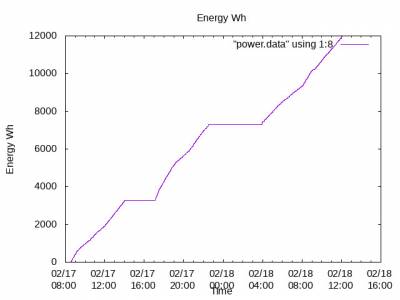

Have a look at my Hyper-Cycling SAMSUNG HEAT PUMP.

I make it 94 cycles in one day!

Can anyone beat this record?

The Hyper Cycling is consuming lots and lots of Juice!

Perhaps you can appreciate why I want the PWM motor driver to work!

The SAMSUNG HEAT PUMP was delivered with an unwanted Heat Exchanger dividing the Heat Pump to Radiator loop into TWO separate loops each with separate cycling problems at different frequencies!

A 50 litre Volumising tank was fitted into the Heat Pump to Heat Exchanger loop to eliminate cycling but at an even greater consumption of juice!

The Hyper cycling is consuming around 9 KWh of energy for the 17 th February 23.

.

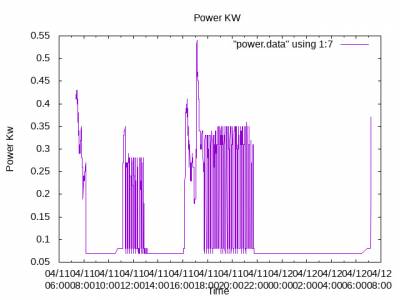

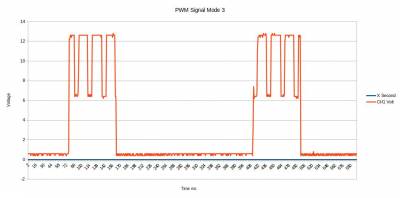

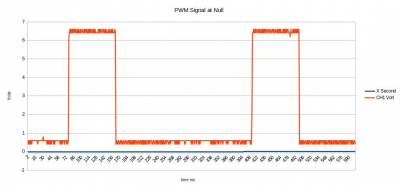

@mike-h PWM Signals producing E912 errors when Not in use!

I have been recording the PWM Signals presented to my GRUNDFOSS MOTORS.

When supplying Energy I get the following signal

When Not supplying energy I get the following signal....

Notice the Amplitude changes along with the curious PWM signal when supplying energy.

As ever with SAMSUNG things do not , however go entirely without Errors, E912 this time appears when Not supplying energy.

I am experimenting but may have to return to switching the Motor mains AND Modulating the PWM Signal!

Oh, SAMSUNG ,.......everything works but , there is always a BUT

ian

look i know its not what you want to hear but stop obsessing over the PWM output. Im afraid that most heat pumps dont really have a pwm function at all, they say they do in the book but the unit is not clever enough to control pump speed and inverter compressor speed. its just life. we have to move on. before we had PWM the units worked fine, they will do so now. if you have rapid cycling its not going to be fixed by altering the speed of the waiter through your unit. You have to look at the amount of heat you are rejecting from the water. this is a function of the speed of the water through the rads and the temperature they run at. there is very likely nothing wrong with your heat pump, the problem is always in the heating system itself. sort out the flow to the rads and the heat pump is suddenly fixed.

one of the reasons ive become disillusioned with the whole heat pump game is everyone blames the heat pump because an idiot put it onto a terrible heating system. If you connect a shit caravan to a nice car it becomes a terrible vehicle. its important to concentrate on the worst bit first.

Heat pump builder

Posted by: @grahamhOk so first never run the unit below 30 or even better 35c flow temp. You will get tons of cycling

Heat pumps don't work well below these temperatures.

Posted by: @grahamhthere is very likely nothing wrong with your heat pump, the problem is always in the heating system itself. sort out the flow to the rads and the heat pump is suddenly fixed.

So it's all about "supply and demand"

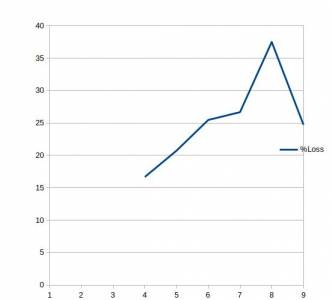

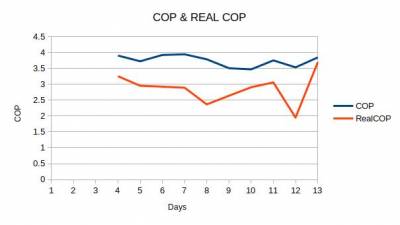

THE PWM

I have finally got a "hopefully working PWM Motor controlling the Motor Speed to control the Water Heat Power.

The Critical part in getting the PWM was setting the Water Flow rate until the PWM Signal was operating at the Center of it’s range.

If the rate of water flow is too great , or too small, the PWM Signal cannot control the water power.

I chose an operating power of half the 5 KW nominal power of the Heat Pump, 2.5 KW.

Since Power ( KW) = Water_Flow_rate ( M^3/sec) X Specific-heat_of water( KJ/(KgXC) X Delta _T

2.5 = Flow_rate X 4.3 X 3

Or

Flow_rate= 2.5 X 60 /(4.3 X 3) = 11.5 litres/per minute.

When the Water Flow rate was reduced to 12 lpm the following results were obtained.

And the REAL COP has improved

My Heat is however still Hyper-Cycling on the Radiator water loop

The Second PWM Motor will have to be supplied with a home made "Arduino" source.

ian

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 299 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

@skd I think your guess might well be right - unfortuna...

By Toodles , 4 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 15 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 4 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 7 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 24 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago