You probably remember we spoke about this one fixed flow rate in my forum post.

But my midea is stuck at 0.55m³/h well below the 1.0m³/h the unit starts to error out at according to Midea/freedom technical support.

Mine follows the weather comp settings I have put in pretty well but the speed of flow never changes

Although I do have a warm house that stays warm in all temps I believe the only thing keeping it functioning is the buffer and the circulation pump set to full chat.

My pipework is pretty large all copper to a buffer tank albeit it has around 9000 (over estimated obviously) 90⁰ bends before it gets there 😅

I have not read through this whole post yet so will do just thought I'd add my 2 pence

Posted by: @burtisBut my midea is stuck at 0.55m³/h well below the 1.0m³/h the unit starts to error out at according to Midea/freedom technical support.

Mine follows the weather comp settings I have put in pretty well but the speed of flow never changes

I am still waiting for a definitive answer on this from Freedom, though they have said the flow rate should vary, which does seem at odds with what we Midea owners observe. That said, if I look very closely at my flow rate it does sometimes vary, but not by very much. What we need to know is what the flow rate should do, then we can compare that to what it actually does.

Midea 14kW (for now...) ASHP heating both building and DHW

Hello there, I'm new to the forum. I see that cathodeRay has made many posts about his Midea ASHP does not seem to behaving properly, there are several posts about cycling and not getting enough heat out of the unit. I'm just starting to design a system which has the potential to cycle a lot.

@cathodeRay (not sure I can use that function on the forum just yet), please can you post a diagram of your system, it would likely be very helpful for my own system design.

Thanks

Bob

Posted by: @bobtskutterplease can you post a diagram of your system, it would likely be very helpful for my own system design.

I don't have a diagram of my system itself, but it is basically the system as set out in the Freedom Quick Installation Guide for Midea heat pumps, with the plate heat exchanger option for the hydraulic separation. It's basically a bog standard layout, plus the hydraulic separation.

'Normal' cycling over a wide range of moderate and warmer OATs: I increasingly suspect this is 'by design'. It is low frequency, not 'short cycling' and may just be something Midea owners who experience it have to live with.

I may be getting a bit closer to working out why my system has under-performed in cold weather, the current cold weather being a very useful 'natural experiment', and more importantly, what if anything can be done about it. Once I have something more definite, I will of course post it.

Midea 14kW (for now...) ASHP heating both building and DHW

Thank you for the quick reply. I thought I saw you mention you had a plate exchanger in your system, which is why i asked if you had a drawing. Do you know what duty and delta temperature it's designed for? (Delta temperature is the difference between the hot side [ASHP flow] and the cold side [heating circuit flow]).

Regards

Bob

Posted by: @bobtskutterDo you know what duty and delta temperature it's designed for?

No, and I don't even know it's spec apart from its size on the outside. Any badge with info has been obliterated by foam insulation that seems to have been stuck on with a contact adhesive, and I don't have any plans to rip it off! Freedom supply kits but not much more, I believe it may be a 'one size fits all' PHE to keep things 'simple'. In practice, there is certainly a drop of a few degrees across it ie the water exiting on the secondary side is cooler by a few degrees than the water entering on the primary side, based on IT thermometer measurements on black masking tape on the pipes. As the temp varies all the time as well, it is not an exact way of getting measurements, just a rough guide.

The general view seems to be that from a performance point of view, a PHE is a bad thing, because the primary LWT need to be a bit higher temperature (by the 'a few degrees' difference noted above) to get the desired flow temp in the secondary circuit, and getting that higher primary LWt incurs costs, But there are also pros to PHA, notably the physical separation of the two circuits, stops rad crud going through the heat pump, and and only the primary circuit needs glycol.

Midea 14kW (for now...) ASHP heating both building and DHW

oh that's a shame. I was hoping I could learn something about the minimum duty your system can handle so I can optimise my design for low duty operation. I'm looking at a 4kW Riello unit (Midea clone?) connected to a fan coil unit that can put out about 1.5kW so I'm worried about the system cycling too much. I'll look at some buffer tank design calculations and see where that takes me.

Regards

Bob

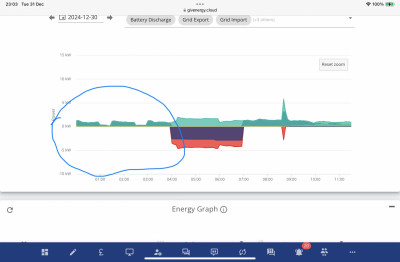

Contributing to the comments about compensation by overshoot in normal operation

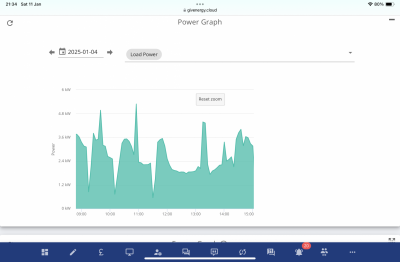

The first is de-frosting at virtually full capacity on our Vaillant It’s our full electricity load so you have to ignore the kettle and microwave usage. The ashp dominates obviously and the extra current draw at the beginning of the cycle must mean extra heat being delivered to compensate for the de-frost action.

We don’t have sophisticated heat monitoring only the Vaillant software, so no dynamic data of heat to look at.

The peak at the beginning of the cycle is much lower on normal cycles. In circled region (overnight setback means little power was needed).

2kW + Growatt & 4kW +Sunnyboy PV on south-facing roof Solar thermal. 9.5kWh Givenergy battery with AC3. MVHR. Vaillant 7kW ASHP (very pleased with SCOP 4.7) open system operating on WC

Posted by: @judithThe first is de-frosting at virtually full capacity on our Vaillant It’s our full electricity load so you have to ignore the kettle and microwave usage

My vaillant does the same, which sounds like a good idea, but the noise it makes is way above any normal noise that this otherwise whisper quiet unit makes, and quite tonal.

Can I ask if yours also does this. TBH it's somewhat annoying and has undermined my view of the unit. Of course I expect an increase in noise when it's cold, but the tonality is frustrating.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @bobtskutterI was hoping I could learn something about the minimum duty your system can handle

There is a lot of mumbo jumbo around on this subject. Manufacturers' data are often difficult to interpret (Midea for example have three 'capacity levels', Max norm and min, in their output tables, but so far as I know no one knows how or when to apply the different levels. At the same time most people have no idea what their actual heat pump output is, let alone what it actually does. They may or may not have an manufacturer's 'app' with with visually stimulating charts in bright colours but do you really trust what they are telling you? How did they get the data, and does it come from? Are the numbers massaged in any way? We don't know.

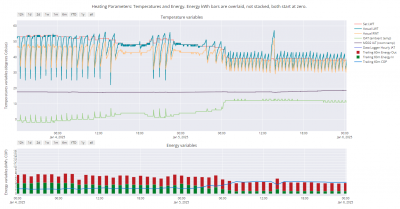

I do have data on what my heat pump actually does, and so far as I can tell (some basic cross checking with other data sources) it is reasonably accurate. It seems that in the real world my heat pump can operate at anything between 0kW and about 8.5kW. There are three operational modes over this range (1) from very cold to about 4 degrees OAT if regularly defrosts and performance (COP) is dire, (2) from about 4 to perhaps 6 degrees OAT as I recall, the point is it is a very narrow band, it operates in steady state (no cycling) and (3) at OATs above this narrow band it always cycles. It does reduce the LWT/RWT delta t a bit as the OAT increases, but much if not most of the output modulation is done by cycling. Rather oddly, despite having a variable flow rate water pump, it doesn't much if any use of that variability.

Posted by: @bobtskutterI'm worried about the system cycling too much.

With Midea and probably Midea clone heat pumps 'normal' (as opposed to defrost) cycling for much of time appears to be unavoidable. Does it matter? Possibly, perhaps even probably, not, because it is low frequency maybe around once an hour on average. It may just be that it is annoying seeing it on a chart because we are programmed to think cycling is a bad thing.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @judithWe don’t have sophisticated heat monitoring only the Vaillant software, so no dynamic data of heat to look at.

I do think you have to be careful here. you really need minute by minute data for the key parameters to be sure of what is going on, and typically, for whatever reason, manufacturers' apps don't make this available. Your chart shows power on the Y axis, presumably power out, but how is it determined (calculated)? Which variable has changed to change the power out? If you have Homely and its dashboard you do have access to this data, some HA users have it, or at least some of it, and I do through my modbus monitoring.

Posted by: @judithcompensation by overshoot in normal operation

I am not sure I understand this, it is almost an oxymoron! In 'normal' moderate and above OAT conditions, it is not really using 'compensation by overshoot', it is more that because it always cycles, the actual LWT spends some time above the set LWT, and some time below, with the effective mean LWT being close to the set LWT. When it is running in defrost mode, the actual LWT mostly (there are exceptions) only reaches the set LWT, ie no overshoot, and as a result the effective mean LWT is below the set LWT. This observation by the way is key to how I may have got the heat pump to just about cope with low OATs - I can allow the set LWT to go higher, to get a higher mean LWT without going outside the heat pumps operating range (more on this later...).

This chart, which I posted previously, shows my heat pump operating in its three modes: regular defrosts on the left with mostly no LWT over-shoot, two periods of steady state running at 4-5 degrees OAT with the actual LWT at the set LWT, and, on the right, 'normal' cycling with the with the effective mean LWT being close to the set LWT. It is not so much over-shooting as using regular cycling ie under and over-shooting to achieve a mean LWT close to where it should be. The big spike at 1300 on the 5th by the way is DHW heating.

Midea 14kW (for now...) ASHP heating both building and DHW

Hello,

TL;DR I think you have the weather compensation set too high at low OAT, try dropping the upper setting to 50C.

I've been going over the data on your trends with the knowledge you have a plate heat exchanger to separate the primary circuit from your heating system. Plate heat exchangers require a differential temperature to drive energy from the hot side to the cold side, so in your system it means the water temperature to your radiators is lower than the LWT (leaving water temperature) coming from the heat pump. I estimate that temperature difference is about 5C based on other plate heat exchangers I've seen.

When your outside air temperature is about 12C you appear to have a set LWT of 38C, so the water to your radiators is going to be about 33C (because the plate exchanger requires a differential temperature to transfer energy). If your room temperature is 20C that means you have 13C temperature difference between the water in the radiators and the room, which means the radiators won't transfer much energy. If the energy OUT (through the radiators) is lower then the energy IN (from the ASHP) then the flow temperature will go up, you can see that in the data. Eventually the RWT (return water temperature) reaches the set LWT of 38C and the ASHP shuts down. When the RWT drops below the set LWT by about 5C the ASHP starts again, notice how the water flow is low when the compressor starts. As the differential temperature between the LWT and RWT goes up, the water flow goes up - but it appears to step from a low value to a high value, i.e. it appears as though the pump isn't modulating.

The pump modulates by variable speed, which changes the output pressure of the pump. You can only CONTROL the flow through a system by changing pump speed if the system pipework & valves have a relatively large pressure drop, i.e. long lengths of pipe. You don't appear to have long lengths of pipe so the pressure loss caused by the water being pumped round your primary circuit isn't very much, so making a small change to pump speed makes a huge difference to flow rate, i.e. not much control. Have a look at "pump curves vs system curves" with an internet search.

When your OAT is low, your set flow temperature is too low and combined with the differential temperature over the plate heat exchanger your rads don't work properly - so the RWT goes up. Eventually the RWT gets too hot and the heat pump shuts down. Varying the water flow doesn't do anything because the energy can't get out of the system - the LWT is too low.

When your OAT is about 5C, your LWT is about 48C, so I estimate your radiators are at about 43C. i.e. hot enough to work properly. Notice how the water flow rate and compressor speed to change - because the system is hot enough to get the energy out of the radiators.

When the OAT is below 0C the LWT is about 55C and the compressor is working hard. From about 20:00 on 2/1/25 it looks like you're getting a lot of defrost cycles - notice how the compressor doesn't stop but the LWT and RWT keep dropping from about 50C to 30C. If you were to average the LWT and RWT after 20:00 on 2/1/25 I think it would be roughly 40C, which is probably boarder line to have your radiators working (there will be a 5C temperature reduction across the plate exchanger so the radiator temperature is probably about 35C).

There appears to be a sweet spot between 00:00 and 20:00 on 2/1/25, where the LWT is about 50C max.

I think you have the weather compensation set too high at low OAT, try dropping the upper setting to 50C.

Regards

Bob

(PS thank you for sharing so much detailed data).

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 412 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Without knowing it, @andrewj, you've laid down the gaun...

By Majordennisbloodnok , 4 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 9 minutes ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 42 minutes ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 1 hour ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 2 hours ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 4 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 4 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 4 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 5 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 20 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 22 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago