Posted by: @transparentfuse

I was about to use the f-word in a reply! Could not see where it is fitted when I looked at the Alibaba.com video…

Personally I'm not concerned if BasenGreen don't have an internal fuse in their enclosure.

I think the best place for this is where each battery gets connected to your own busbar.

That avoids trying to reach a blown fuse inside the lowest box in a tower!

What that fuse can't do (in either location) is to protect against an internal fault cased by a piece of metal shorting across the cell-terminals.

So the case-top itself must be able to withstand a weight on top of it without flexing.

And ideally there will be a layer of insulating material lining that lid to avoid it being the cause of such a short circuit.

If not, then steel still offers remarkably good resistance to an internal fire.

It won't melt until the temperature reaches 1300°C 😮

Save energy... recycle electrons!

I have completed the build of two Seplos Mason 280Ah cases (fogstar for the cases). Build time of a few hours each (not including balancing) after taking into account one mistake I made.

Comments

1) Assembly instructions could be more accurate and comprehensive; the PDF on fogstar’s website is out of date as the design appears to have changed a bit (fewer screws holding the front plate) and does not give useful info like which packet to find the components in.

2) There is an excess of many components (more screws than required) which may be a consequence of Fogstar shipping two boxes rather than everything in the case. I get nervous when there are spare components.

3) The use of Phillips screws (rather than pozi) resulted in a few mashed heads. Some of the ones on the BMS terminals did not like being torqued to 7Nm. Access to the larger screws to the front plate was not ideal, so tightening at a slight angle resulted in a bit of mashing. The T10 torx used to secure the lid and front were also liable to being mashed.

4) Design-wise, the metal forms the case is made out of offer the perfect place for screws and nuts to roll into and hide. One nut (on the B+ terminal) rolled away and into the cavity between the rows of cells, so I had to strip out much of what I’d done.

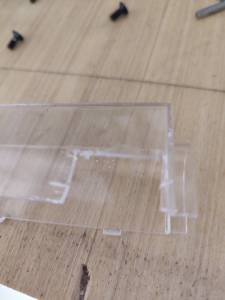

5) The fuse cover does not fit into place once the bus bars are connected to the fuse holder. It feels wrong that I had to hacksaw away some Perspex to make it fit.

6) The Futronics B+/B- connectors are hard to get hold of, expensive and can not handle much current. I wonder why they did not opt for Amphenol SurLok Plus like Pylontech.

Posted by: @chickenbigI have completed the build of two Seplos Mason 280Ah cases (fogstar for the cases). Build time of a few hours each (not including balancing) after taking into account one mistake I made.

Comments

1) Assembly instructions could be more accurate and comprehensive; the PDF on fogstar’s website is out of date as the design appears to have changed a bit (fewer screws holding the front plate) and does not give useful info like which packet to find the components in.

2) There is an excess of many components (more screws than required) which may be a consequence of Fogstar shipping two boxes rather than everything in the case. I get nervous when there are spare components.

Agree - the instructions are poor. I found going off the Youtube video that was kicking around was better - but this video now seems to be overdubbed with a AI voice and has lost a lot of the info. I don't think the component quantities are a Fogstar thing as I received boxes direct from Seplos with the same issue. They've nicely labelled the packets, but no instructions to match! I had an excess too - some of it looks down to the fact that the BMS/LCD is pre-installed, but it's not the whole reason. It does make you nervous that there is an excess.

Posted by: @chickenbig3) The use of Phillips screws (rather than pozi) resulted in a few mashed heads. Some of the ones on the BMS terminals did not like being torqued to 7Nm. Access to the larger screws to the front plate was not ideal, so tightening at a slight angle resulted in a bit of mashing. The T10 torx used to secure the lid and front were also liable to being mashed.

4) Design-wise, the metal forms the case is made out of offer the perfect place for screws and nuts to roll into and hide. One nut (on the B+ terminal) rolled away and into the cavity between the rows of cells, so I had to strip out much of what I’d done.

Yes, also agree. I lost two nuts like that on the 2nd box, got away with it on the first. My lid and front where hex black screws, not Torx - but also liable to stripping, but I hand tightened most of those.

Posted by: @chickenbig5) The fuse cover does not fit into place once the bus bars are connected to the fuse holder. It feels wrong that I had to hacksaw away some Perspex to make it fit.

Agree as well, mine had to bend to go over with a little force, but they don't sit well at all.

I would add another - I found the top two cell bars (PSA-A/PSA-B?) are hard to tighten down at back and front as the cells must have been a mm or two too high. Either longer screws needed, or adjustment of the height of the bar in the first place.

Thanks for those practical insights @chickenbig and @vaugi

1: It would appear that you two are in the position to (re-)write a manual.

Why not offer to do so for Fogstar with 'payment in kind'?

2: If the bolts and fittings supplied from China are poor quality or require screwdrivers of less-common varieties, then raise that with Fogstar.

For the (more discerning) UK market, Fogstar could put together their own packs of fittings, and negotiate a lower-price from Seplos for importing Mason boxes without those included.

Everyone wins.

3: Do either of you have photos to illustrate what you've just reported?

It would help readers of this topic who are still deciding whether to buy such a kit.

Save energy... recycle electrons!

(Comments in reverse order because the editor is placing them there and I am replying on a phone.)

Posted by: @vaugi(PSA-A/PSA-B?) are hard to tighten down

Indeed rather challenging. The most fun was with the back screws where getting it wrong would mean the screw could fall into the case! I found that trimming the EVA tape at the ends of the bracket helped, in addition to cutting a slice of the yellow insulation board. (I found correctly positioning the boards at the front nigh on impossible as the compression bracket sits a few millimeters above the base of the case, so I just stuck it flush with the bottom of the bracket.)

Posted by: @vaugihex black screws, not Torx

Perhaps that was my problem!

Posted by: @vaugiI lost two nuts like that on the 2nd box

Ouch, that would have been frustrating.

Posted by: @transparentin the position to (re-)write a manual.

My motivation level for that is a bit low at the moment. Am just savoring completing the batteries and hooking one up to an inverter; my mother no longer thinks I am a carbon copy of Frank Spencer.

Posted by: @transparentput together their own packs of fittings

I think doing that just for the BMS bus bar fixings (making them hex head bolt) would be a big upgrade. At the risk of being a cynic I am not sure the Futronics/ to Amphenol swap would benefit fogstar, since at the moment they can sell the un-crimped connectors for £20 a pair.

Posted by: @transparentDo either of you have photos to illustrate what you've just reported?

Sorry, I was working in poor light. Not sure I feel up for opening up a box because of the problem with screws and nuts falling into inaccessible areas (that one small error cost me about 1 hour in work this morning).

I've already done one with photos and sent it to Fogstar AND Seplos. I posted a link earlier in the thread

Seplos Mason Mobile Home Storage Battery Case

Please note, although i had a couple of issues that i needed to resolve, i am more than happy with the case. It has s sleek and modern appearance with a small footprint, the fact that it is mobile and ‘easy’ to manoeuvre whilst still being stable made it perfect for the location i had chosen to install it into.

I would highly recommend this casing and intend to buy another in the near future.

The case is supplied in two packages, one being the case itself, the other contains all the connecting accessories, screws and fixings.

1 Remove the case from its packaging. There are two options in building the battery, you can either lay the case on its back or build it in the upright position. I chose to build it in the upright position due to the weight of having to then lift it if i built it on its back. After adding the cells, i found it was difficult to actually knock it over, which i was concerned about whilst building it.

The case itself is virtually pre assembled, although i needed to remove parts of the assembly as I will describe later.

2 remove the front of the case, The casing is held together by machine screws with a 3mm hex key head, Not all the screws have been used for the pre assembly stage, i assume to make it a little easier.

Inside view after front cover removal. The linings for the case are supplied loose along with foam backings for the cells and reverse of the busbars

3 Remove the two BMS busbars, They are each secured by four small bolts that can be released using a phillips screwdriver, place the busbars in a safe place. They are wrapped in cellophane to protect them. The busbars have slots in them, rather than just holes. That is important as it allows for some leeway when the cells are fitted.

4 Before fitting the case linings, it is important to check the cells actually fit! I used 280Ah EVE Grade A cells from Fogstar. I installed the linings prior to checking the cells fitted snugly enough to provide some compression.

After placing the first column of cells it was clear that there would be no compression of the cells or that they would be held in place by the case.

You can see clearly that there is a gap between the top of the cells and the ‘top plate’. I measured that gap to be 14mm. I felt uncomfortable as i didnt feel the cells would be secure and that the gap would potentially allow cells to expand and possibly degrade.

I also realised that due to the construction of the case, the bottom cells were only in contact with the frame of the case along their outer edges. This also concerned me as they may have expanded in the unsupported area, a term i refer to as ‘bellying out’ - not a technical term but my explanation!!

This photo shows the bottom frame onto which the cells would rest

5 Supplied with the case were these packings/shims

Perhaps they are to allow for different cell heights and are used to pack up from the bottom? They cant be to be fitted in between the cells as the cells would then not fit. I decided not to use them as packings from the bottom, as it wouldnt have stopped the potential ‘bellying out’.

I need to add though, that perhaps i was overthinking things, Im sure the cases have been ‘designed to death’ and tested by technicians etc

Notwithstanding the above comment, i decided to adopt a different method to ensure compression of the cells.

I added a 16mm piece of melamine and placed it over the bottom rails and added the case lining material onto the melamine surface

6 Before replacing the cells, I needed to remove the top of the casing, and the BMS (which comes ready installed onto a bracket) and also the top plate of the casing which would allow for it to be used for compression of the cells and hold them in place.

I needed to use a long reach phillips head screwdriver to release the fixings at the rear of the BMS bracket. The BMS bracket and top of the case were removed together as there were a few electrical connections holding them together. I decided to leave those connections in situ. I just laid the BMS plate and top of the casing on top of the case itself, making sure of course that i was secure and couldnt fall or become damaged.

This next photo shows the cells in place and top plate adding some compression (remember there are foam pads between each cell, so its not a massive amount of compression). If you wanted a greater amount of compression, you could use something larger than 16mm melamine, but then there is a chance you would need to alter the BMS busbars.

Which, from the next photograph, you can see that they fit perfectly, however the busbars between the cells didnt! There were about 6 busbars that i needed to alter so that they fitted. The busbars have four holes, three of which are elongated, for some reason the last hole isnt? I found by elongating that hole in the direction of the other holes, i could make them fit. If all the holes were elongated it would have been simple and would compensate for compression of the cells.

It is important to follow the sequence of attaching the BMS busbar connections to the cells, a couple of the connecting wires are coded red, but actually fit onto a cell negative connection. The connecting wires are clearly marked on the BMS busbar with a + or a - , so all you need to make sure is that each cell has a + connection and you make sure that those with a - marking on the BMS busbar go to a negative connection on a cell. Once youve got it in place and start to add the busbars between the cells it becomes self explanatory as the wires themselves are not long enough to cause any real confusion.

Before connecting the cells together i added the BMS busbars, having removed the cellophane coverings. But before doing so i had a ‘dry fit’ just to make sure it was all going together properly.

7 I actually reinstalled the top of the case and the BMS at this point, to make sure it all fitted back together again, but on reflection it made sense to add the connections to the BMS when they were easily accessible, so i removed the top of the case and BMS on its bracket again. I would suggest that before replacing the BMS bracket and top of the case that you add all the connections at this stage.

8 The main connections from the battery and to the power outlets to/from the BMS are not as shown on the Seplos instructions. They are also numbered differently. The next photo shows the connecting strips/ribbons connected in the correct places. You need to install the battery terminals and fuse holder

The fuse holder cover just pulls off, its tight but just pull it off. You will need to cut the plastic cover for the fuse holder to allow for the connections to the fuse. You need to cut one side and one end as shown

And close up photos showing the ribbon/main connections

More to follow as i have exceeded the max number of attachments.

please see below

A useful tip is to tape kitchen roll or similar over any gaps during construction to prevent screws or nuts falling into undesirable areas.

following on from above

9 The final part of the internal assembly was to ensure all connections were tight and to connect the BMS to the BMS busbars. The prewired looms are different in that one of them has a black connector to go the BMS and the other has a white connector (both have the same connectors at the other end)

The Black connector loom fits onto BMS at the connection nearest the front and the white one to the rear.

10 Before replacing the front you will need to connect the cables, already connected to the bms and back control panel when it arrived, to the front display,

10 switch on the battery at the rear of the case to test and the front display should light up

Thanks for that photographic detail @misterb

It's good to see assembly of the newer vertically-oriented Seplos battery enclosure.

I like the fact that the battery terminals face outwards horizontally. That makes it more difficult to drop a screwdriver across them and cause a short-circuit.

But I don't like knowing that you were fiddling around with the metalwork above the cells after they were in situ ! 😮

I would've completed all of the cell connections first (busbars and balance wires).

Then I'd have placed an insulation layer (50mm-wide PVC tape) down across all of those live terminals before I started working above them.

I'd do all the upper connections to the BMS, fuse, front-panel etc with those cell terminals still covered.

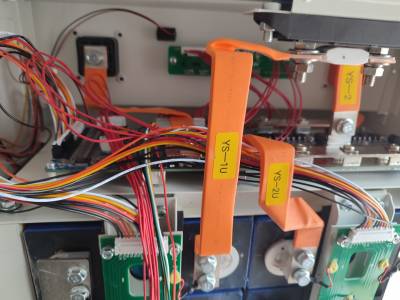

The last operation I'd do is to peel back my insulation tape between the orange-covered bus bars YS-1U and YS-2U and the live terminals to which they must each be bolted.

I'm unsure if I'd then leave my PVC tape in place.

I'd need to satisfy myself that it doesn't hinder air-flow across the 'tops' of the cells when the battery is in operation.

The initial assembly of the battery really is the most hazardous moment in its entire life.

Unfortunately it is also the first operation which a DIY installer needs to undertake... whilst they have the least experience!

Save energy... recycle electrons!

Thanks for the sound/sensible advice, it's something I will follow when I get my next one.

Perhaps if the case front was in two pieces, then the cell connections could be completed and the lower part of the front casing could be fitted, preventing any contact with the lower assembly? Alternatively a piece of ply cut to the correct dimensions and temporarily fixed to the front to cover the cell connections?

- 26 Forums

- 2,364 Topics

- 53.6 K Posts

- 293 Online

- 6,029 Members

Join Us!

Worth Watching

Latest Posts

-

RE: ASHP sizing - value of Heat Transfer Coefficient

Sorry, but I cant see what the point of this is unless ...

By JamesPa , 4 hours ago

-

RE: Octopus Cosy Heat Pump Owners & Discussion Thread

TC Thermostatic Radiator Valve TRV Plastic Decorators S...

By Toodles , 8 hours ago

-

RE: Ecodan unable to hit legionella target temp - what's the consensus?

UPDATE: Thanks everyone who commened with suggestions h...

By 9jwr9 , 12 hours ago

-

-

How long will your energy contract last?

Some heat pump tariffs don’t run as long as a heat pu...

By Toodles , 2 days ago

-

@morgan They are unsupervised these days, can’t get the...

By Toodles , 2 days ago

-

-

RE: Setback savings - fact or fiction?

Exactly. We only need to compare conditions, to decide ...

By cathodeRay , 4 days ago

-

RE: Balancing financial efficiency and comfort using the Octopus Cosy tariff

I found because I have very low heat loss I can set bac...

By RadWhisperer , 4 days ago

-

RE: Need Help Optimising My Rushed ECO4 Install: 12kW Bosch Heat Pump

Welcome @mickamills We too have an oversized 12kW Sa...

By Old_Scientist , 4 days ago

-

RE: My Powerwall 3 Consumes 3-4 kWh/Day in Self-Consumption: Is This Normal?

@caron I can confirm that the power usage of the PW3 is...

By Old_Scientist , 4 days ago

-

RE: Speedcomfort radiator fans

Thats true, but having tried (and succeeded) in constru...

By JamesPa , 4 days ago

-

RE: Solis S6-EH1P8K-L-PLUS – Why I Chose It and What I’ve Learned So Far

@bash brilliant, thanks for the feedback

By energy9165 , 4 days ago

-

RE: Heat Pump Heats the House… But It’s Not Cosy. Emitter Changes or System Tweak?

@alastair There I was, feeling grumpy, he said “Cheer u...

By Toodles , 4 days ago

-

RE: Grant Aerona: Is there a setting to keep the 2-port valve open during pump blockade

Depends on OAT. Mine cycles at OAT>10 and of course...

By JamesPa , 4 days ago

-

RE: New Fogstar 15.5kWh upright solution

@transparent My conclusion is as you have noted, tha...

By Bash , 4 days ago

-

RE: Mitsubishi Ecodan R290 10kW performance

And to you too. Wishing you a very enjoyable festive s...

By Sheriff Fatman , 4 days ago

-

RE: External pipework insulation

They do? But that isn't apparent from the photos we'r...

By Transparent , 4 days ago

-

RE: Say hello and introduce yourself

@velcro welcome to the forums. Please feel free start a...

By Mars , 5 days ago

-

Daikin EDLA11D3V3 DHW Settings

I have a newly installed EDLA11D3V3 which I'm still get...

By Velcro , 5 days ago