Are Chinese-manufactured heat pumps falling short of their promised efficiency and performance, leaving consumers and homeowners out in the cold? Our investigation exposes worrying discrepancies in the testing data of some widely-used and available units. Documents provided to us by Pawel, reveal significant inconsistencies in the performance claims of several Chinese heat pump models.

Let’s be clear: this is not an indictment of heat pumps. On the contrary, we firmly believe they have a significant role to play in the future of sustainable heating. However, it’s crucial for homeowners and consumers to exercise due diligence in their purchasing decisions.

When faced with the option of a less expensive model manufactured in China that has been recommended by an installer to keep initial costs down, it’s essential to be fully informed about the potential consequences. Our goal at Renewable Heating Hub is to empower homeowners with the knowledge needed to make informed choices, ensuring they benefit from the true potential of heat pump technology without falling prey to misleading claims.

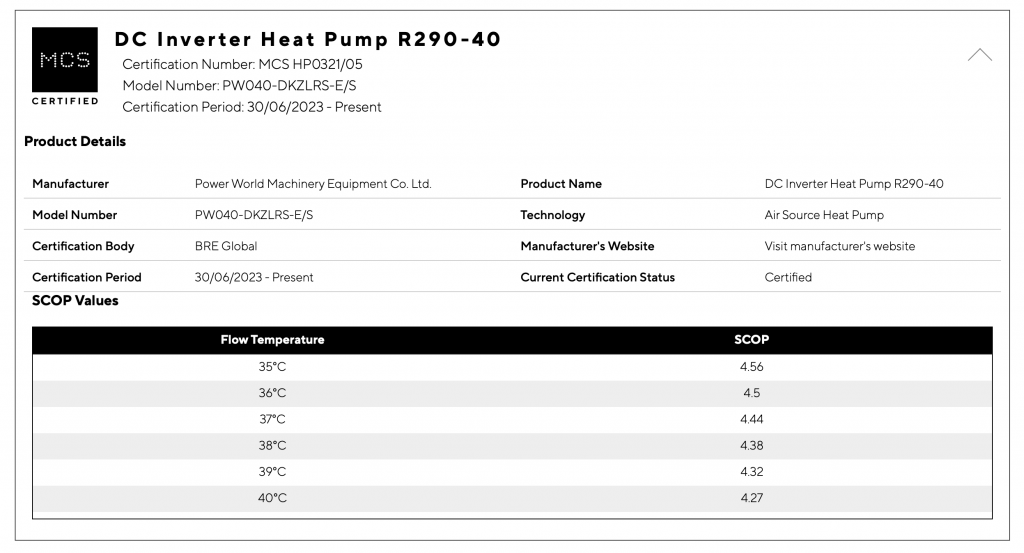

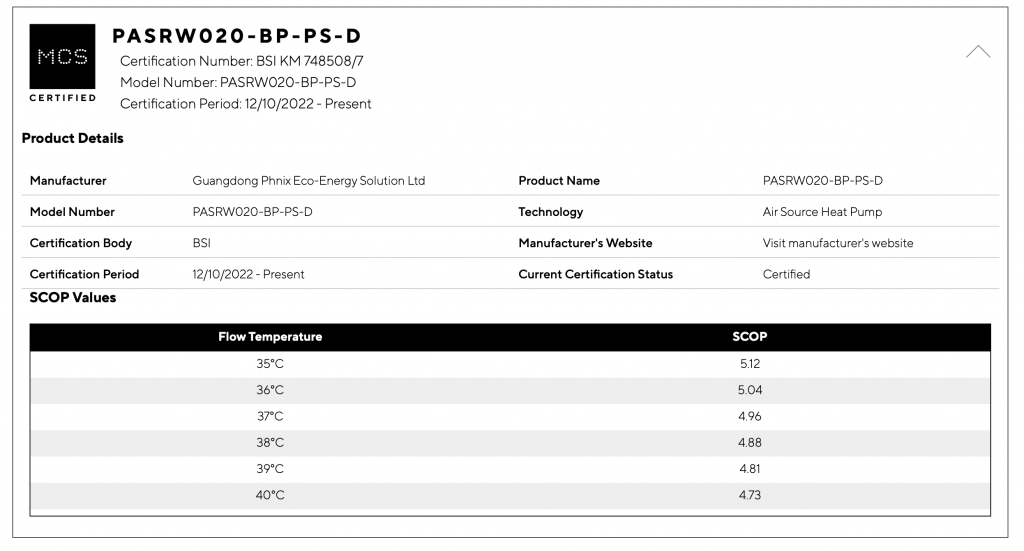

We look at these models – the PW040-DKZLRS-E/S from Power World, the PASRW020-BP-PS-D from PHNIX and the BLN-012TC1/BLN-018TC1 from SolarEast – to uncover the truth about their efficiency.

While we primarily examined the models above, this is just the tip of the iceberg. Our research extends to a wider range of models, each marred by troubling irregularities in their testing data.

We possess test reports revealing similar issues in other heat pumps, including the Fantastic Energy FEIHCD040S, Gondzik’s Zulu 13 R290 and Zulu 23 R290, Guangdong ZenzAir’s ZAF-17II/HPSP1, GZ Axen’s KS-90W/EN7BP and Jiangsu’s MMHP22D1 & MMHP22D2. The list continues with Exinda’s XDASH20D3A, XDASH20D3B, XDASH20D3C and their respective S variants.

These findings suggest a systemic issue in the efficiency claims of these Chinese-made heat pumps, casting doubt on their advertised performance and long-term cost-effectiveness, which sheds light on a widespread problem, potentially affecting countless consumers who trusted in these products’ efficiency promises.

What does this mean to homeowners?

The heat pumps in question, despite their testing discrepancies, are currently certified by the MCS, making them eligible for government grants. This MCS certification suggests a reliability and efficiency that may not align with what happens in reality, as the test results appear to have been artificially enhanced. Homeowners are thus potentially misled into installing these units, expecting a performance that may not be delivered.

Why should this matter to you? Imagine purchasing a heat pump, banking on its promised performance and Seasonal Coefficient of Performance (SCOP), only to discover it falls short. This shortfall means higher running costs – costs you’re likely to attribute to poor design, installation or commissioning. But the real culprit is the product’s inability to deliver on its promised efficiency.

Our findings and research

Power World PW040-DKZLRS-E/S

An examination of Technical Report No.: 64.181.23.00422.01, issued by TÜV SÜD Certification and Testing (China), uncovers critical findings that challenge the integrity and efficiency of this heat pump.

Low Temperature Application. Part Load Ratios and Conditions:

- Part Load A (88%): Outdoor temp -7°C, Inlet/Outlet Water temp -7°C/34°C.

- Part Load B (54%): Outdoor temp 2°C, Inlet/Outlet Water temp 2°C/30°C.

- Part Load C (35%): Outdoor temp 7°C, Inlet/Outlet Water temp 7°C/27°C.

- Part Load D (15%): Outdoor temp 12°C, Inlet/Outlet Water temp 12°C/24°C.

Medium Temperature Application. Part Load Ratios and Conditions:

- Part Load A (88%): Outdoor temp -7°C, Inlet/Outlet Water temp -7°C/52°C.

- Part Load B (54%): Outdoor temp 2°C, Inlet/Outlet Water temp 2°C/42°C.

- Part Load C (35%): Outdoor temp 7°C, Inlet/Outlet Water temp 7°C/36°C.

- Part Load D (15%): Outdoor temp 12°C, Inlet/Outlet Water temp 12°C/30°C.

When you delve into the specifics of this data the following discrepancies emerge:

- Compressor Frequency Constraint: The compressor frequency for both test points C and D is noted as 30 Hz. If the heat pump cannot operate below 30 Hz, then at lower part loads (which usually require a lower operational frequency for the compressor), the heat pump may not decrease its capacity as much as it should theoretically. This results in disproportionately high heating capacities for the given outlet temperatures.

- Potential Implications: If the heat pump cannot modulate its operation below a certain frequency, this limitation could lead to a scenario where the heat pump operates more efficiently at lower part loads than it actually does. This would make the heat pump appear to perform better in terms of heating capacity than might be expected given the temperature conditions. It could therefore be misinterpreted as deliberate manipulation of performance data if the heat pump’s inability to operate below a certain frequency threshold is not transparently disclosed. Such an omission significantly impacts the portrayal of the Coefficient of Performance (COP) and the overall efficiency of the heat pump, potentially misleading consumers about its true capabilities.

- Mismatch in Heating Capacity for Test Points C and D: The heating capacities for test points C and D do not decrease proportionately with the decrease in outlet temperatures when compared to other test points. This mismatch can occur if the heat pump is maintaining a minimum operational level due to the 30 Hz compressor frequency constraint, which prevents the unit from reducing its output as the demand (part load) decreases.

The mismatch in heating capacities at test points C and D, given the constant compressor frequency and the lower outlet temperatures, suggests that the heat pump’s performance at these part loads is not as variable as one would expect. This could be indicative of a performance curve that is not linear across all operational ranges, which should be communicated transparently to users and reflected accurately in performance data sheets.

The consistency of the compressor frequency at 30 Hz suggests a lower limit to the modulation capabilities of the heat pump. Such a limitation should be accounted for in the COP calculation and clearly stated in the performance data to ensure that users are not misled about the efficiency and operational flexibility of the heat pump across its entire working range.

PHNIX PASRW020-BP-PS-D

In the case of the PASRW020-BP-PS-D model, Pawel also provided a technical assessment from the Danish Technological Institute (DTI) in addition to the testing data in Technical Report No.: 64.181.22.00329.01 Rev.00, which was also compiled by TÜV SÜD Certification and Testing (China). The assessment from DTI spotlighted several issues in the PHNIX heat pumps’ testing, not dissimilar to the previous case.

- Mismatch in Heating Capacities: In test points C and D, the measured heating capacities were significantly higher than expected. This was likely because the heat pumps could not operate below a certain compressor frequency, leading to inflated heating capacities at these part loads.

- Non-Compliance: The tests did not follow the EN 14825:2018 standard correctly. According to this standard, if a heat pump cannot reach the required part load ratio, the indoor heat exchanger temperatures must be adjusted. These adjustments were not made, resulting in inaccurately high COPs and overstated seasonal energy efficiency.

- Implications for Energy Label Ratings: The failure to adjust temperatures according to EN 14825:2018 led to increased COPs in test points C and D, inflating the seasonal energy efficiency and affecting the heat pumps’ ratings on energy labels.

According to DTI this assessment highlights critical testing protocol deviations, raising questions about the reliability of the reported energy efficiency of this PHNIX heat pump model.

Tests were also conducted by Fraunhofer Institute and, in summary, the heat pump frequently entered defrost mode during tests, which hindered the ability to measure it in a stationary state. Adjustments were made to extend the time between defrost cycles, yet this didn’t allow for stationary operation of the heat pump.

Their tests faced further issues at -7°C, where the heat pump continuously malfunctioned and reported an error. The team decided to measure the points at positive temperatures (12C), but even under these conditions, the heat pump did not perform as expected, showing irregular output increases.

SolarEast BLN-012TC1 & BLN-018TC1

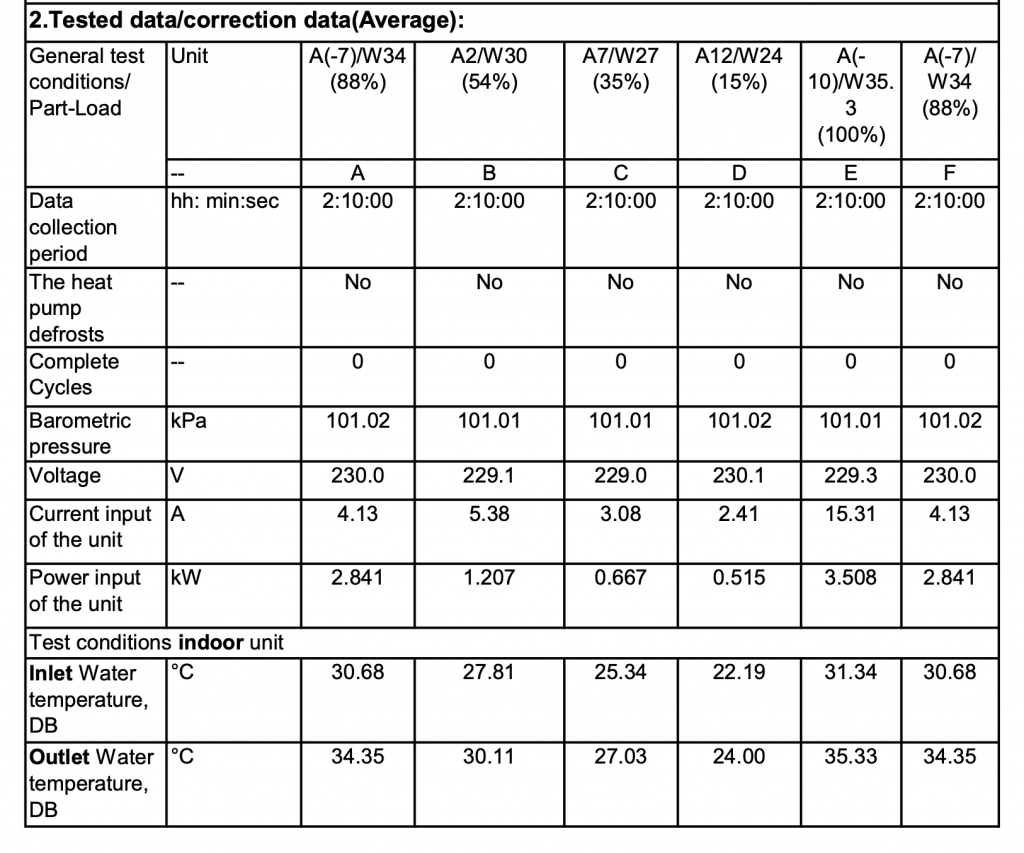

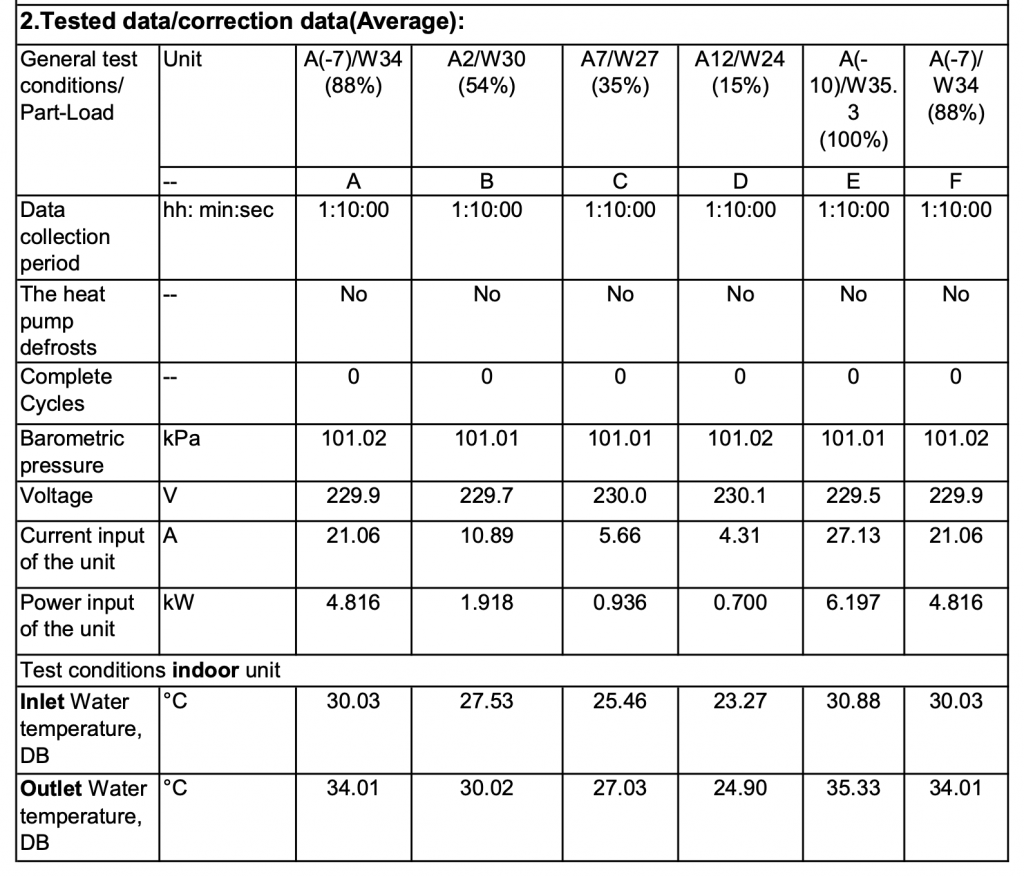

In Technical Report No.: 64.181.22.02858.01 Rev.00 dated 24/10/2022, once again compiled by TÜV SÜD Certification and Testing (China), when you look at the data collection period for the test across samples A-F, the time allocated for the test is 2 hours, 10 minutes.

In tests for BLN-018TC1, dated 24/04/2023 (Technical Report No.: 64.181.22.04448.02 Rev.00), the data collection period has been reduced to 1 hour, 10 minutes. Corresponding with this reduced collection period, we have seen test reports from other brands and models that have also reduced data collection times.

Correspondence from testing labs that was shared with us contends that, given the frequent initiation of defrost cycles that adversely affect a heat pump’s performance, shortening the data collection period can prevent the evaporator from icing up during tests, thereby helping to improve the test results, and giving the products a better efficiency rating.

Heat Pump Misrepresentations: A Call for Greater Consumer Awareness

It is concerning that despite the emerging issues, these heat pumps are still listed on the MCS and remain eligible for government grants. This situation is further complicated by the existence of OEM units, essentially the same models marketed under different brand names, which are also included on the MCS list. Adding to the complexity, you won’t find their certificates on the Keymark database in Europe because they have been removed.

The lack of action from MCS to revoke these potentially misleading certifications raises significant concerns. This situation is particularly troubling for homeowners who installed these heat pumps under government grants, relying on what appears to be flawed data. The real impact on these households, who placed their trust in the system’s integrity and the MCS’s accreditation, is a critical and potentially distressing issue that needs addressing.

It also raises serious questions about the capabilities of these heat pumps and the consequences of inflated test results. Consider this: a product marketed as a 22kW unit, such as the NORDIC R290 Propane 22KW, might actually be a 10kW heat pump with an overstated nominal heating capacity. This is not just misleading; it represents a significant deviation from the expected performance, resulting in a unit that is potentially incapable of delivering the performance advertised on its badge.

For a cautious consumer, it’s advisable to consider choosing products from established European, Japanese and Korean brands. These brands are often supported by testing from credible, professional labs, offering an additional layer of assurance regarding their quality and reliability. It’s always beneficial to research and select products that have a strong track record of safety and efficacy.

No great surprise there. You get what you pay for…

There were suspicions last summer: https://renewableheatinghub.co.uk/forums/renewable-heating-air-source-heap-pumps-ashps/en14825-chinese-ashp-manufacturers-cooking-the-books

A well-known UK stockist of Japanese made ASHPs by Chofu, across their UK range state COPs to EN14511 @ A7W35 in their web site, marketing and installation literature that are significantly higher than the OEM’s product data sheet and web site figures. My real world experience is that the OEM SCOPs are more realistic and achievable. Japanese technical data and quality control is usually very robust & reliable. Branding the product up for the UK market is the performance equivalent of a ‘go faster’ badge on a boy racer’s car it seems…

UK branded product literature:

Chofu OEM literature:

6 kW unit +17%, 10kW unit +20%, 13kW unit +22%, 17kW unit +11%. But they are physically identical units….

@AllyFish I completely missed your post from last summer – this coincides with the timelines when our contact that “leaked" the test reports to various authorities around Europe and the UK. How did you hear about this at the time?

Buy an Ecodan….made in Scotland, frae girders! 🙂 (/tongue in cheek)

Via contacts on LinkedIn. Yes, the same exposé 😉

When I see ‘Made in China’ on the label, I invariably look for an alternative.

Answer: yes, probably lied to. Reality: probably doesn’t matter much unless you were borderline on capacity.

my made in china unit seems spot on. Not a whole lot of Chinese in it mind you, all the important stuff is from Carel, Italian …. Don’t know what’s worse 🤣

I think whats more important than this, is to have the devices that do have perfectly reasonable databook performance figures , installed in such a way that they achieve those figures, monitored after the fact to make sure. rather than the constant flow that we see of badly designed/implemented setups that don’t.

Whats the real world impact of the COP data being slightly elevated due to the compressor frequency unable to modulate below 30Hz though?

I’m in Australia and the price of these european made units are at least twice and up to 3 times the cost of a China sourced unit.

China produce 35% of the worlds heat pumps. Just like with PV cells, the rest of the world need to sharpen up their tech stack and IP to combat the superior tooling China have that allow for cheaper manufacturing processes.

Cheaper manufacturing doesn’t equal a poorer product or worse outcome for consumers.

A poor installation, or even just an average installation, of a european manufactured unit will have a greater impact on performance and outcome for a customer than some high level statistical data of a Chinese manufacturered unit.

The actual impact on device functionality = zero. The author of this article is just trying to discredit Chinese products.

If he had studied the compressor manufacturer’s specifications (in this case, HIGHLY=HITACHI), he would know that 30Hz is the minimum frequency for stable operation.

The attempt to achieve a linear heating output curve is completely misguided. The customer should, instead, be pleased that the COP is higher.

@pavel, this isn’t about discrediting Chinese products… it’s about transparency, integrity in testing and protecting homeowners who make decisions based on claimed performance and government-backed certifications and funding.

While 30Hz may be a compressor’s minimum operational frequency, if the heat pump cannot modulate below this threshold, then its part-load performance will inevitably be affected. What’s problematic is not the 30Hz constraint itself, but the fact that this limitation is often not disclosed transparently, and yet these units still achieve high SCOP ratings based on part-load performance that isn’t realistically achievable in the real world. That misleads consumers.

These test irregularities (shorter test periods, data collection timed to avoid defrost cycles and non-compliance with EN standards) are not hypothetical. They are real, documented, and in some cases, verified by third-party European labs. They call into question the accuracy of performance claims and whether MCS-listed products genuinely meet the expectations set for them.

Suggesting that homeowners should be “pleased” with an inflated COP based on favourable test setups entirely misses the point. COP is only valuable if it reflects real-world performance, not a carefully staged lab scenario that doesn’t represent actual operation in UK homes.

Our article makes no sweeping generalisations about all Chinese products. It highlights verifiable concerns with specific models and the systemic issues that allow questionable data to pass into certification schemes like MCS. If any manufacturer (Chinese or otherwise) presents inflated or non-compliant data, it’s in everyone’s interest that it’s scrutinised.

Would be nice to see some data for Midea units, as these are widely rebadged and used by a number of major ‘manufacturers’ I believe.