@sicky I can’t separate out the garage EWI easily since it was part of a bigger job. The insulation was 70mm which is about what you need for building regs sign off (extension under br control).

our wall was double skin solid brick. Anything less on insulation would not be cost effective on all the other stuff needed, to be honest.

We have a full house vent system so never have to worry about condensation even in cold corners (the sensors and lack of problems prove it). This vent system was extended to warm garage and extension. If you’re worried about condensation, cold spots and potential mould then you could investigate a single room heat extraction & vent system, designed for a bathroom or kitchen.

2kW + Growatt & 4kW +Sunnyboy PV on south-facing roof Solar thermal. 9.5kWh Givenergy battery with AC3. MVHR. Vaillant 7kW ASHP (very pleased with SCOP 4.7) open system operating on WC

Posted by: @sickyi found a company that cut grooves for the UFH pipes into the concrete floors to keep the profile down and their price was ok (to do annex, utility and conservatory), they claim they space the pipes so that they’re compatible with ASHPs, but the whole quote is provided just off floor plans so there must be so many assumptions that it makes me a bit wary

That's good.

I was about to ask how you intended adding UFH pipes to an existing (100mm) concrete pad.

You need to be asking them about the grout/mortar which they intend using to surround the pipes, and fill the slots to the top.

If it's a fast setting cement-based formulation, then it runs the risk of forming micro-cracks around the pipes when heat passes through.

They limit heat transfer from pipe to concrete.

I placed pipe below my concrete pad before pouring it, but followed the advice and left it 6-weeks before attempting to run warm water through it.

It's possible that they will prefer a compound similar to that used for tiled flooring, with latex to allow flexing.

The lower the water temperature, the closer together the pipes need to be.

But that makes the pipe-run longer, which reduces flow.

The maximum length should be 100m, but ideally far less.

The trick is to use two (or more) pipe-runs within the same concrete pad.

Save energy... recycle electrons!

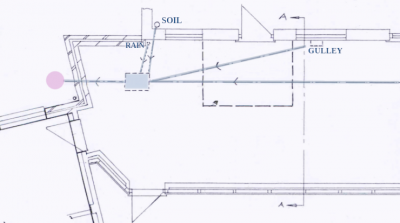

@sicky may I ask about the foul water drainage shown on the plan?

What happened to the rectangular access cover when the conservatory was built?

Does the sewer running horizontally provide foul-water services for the house(s) to the right of the drawing?

Is it still live?

Was a new inspection chamber placed where I've shown a purple circle above?

Were the underground pipes labelled SOIL and GULLEY re-routed to the new inspection chamber?

Was the rainwater downpipe routed to a new soakaway at a distance of 5m from the dwelling?

Save energy... recycle electrons!

@transparent I just rechecked the quote (jk floor heating), it is 125mm spacing but in discussion they suggested the conservatory may benefit from 100mm pipe centres, but the rest would remain 125mm.

they do offer, as an extra, a ‘flexseal’, I couldn’t find the blurb on it just now but I have read about it and I think like you recommend, it’s a flexible layer in preparation for a levelling layer and then flooring.

i’m hoping to hear from them next time they have someone in the area so I can physically show them my concerns around door thresholds etc and chat about solutions

@transparent yeah…that…see pic

’gulley’ would be the kitchen waste

soil stack is in the right place

the rain pipe isn’t there, you can just see one on the outside of the cavity wall, that’s in the right place

As you can see there’s an inspection hatch of sorts, but I tried to lift it to investigate and I couldn’t get it to open. It’s marked in the room and I have these photos for reference.

the planning application mentions a soak away, but a few years ago I rang planning and building control who couldn’t confirm a soak away was installed, there’s been no real sign of one while we’ve been doing work.

theres an inspection chamber on the driveway, that’s probably 5m or so from the original not the location you suggest, I can only assume it’s all the same drainage system, but I’d guess it wasn’t installed as part of this work, I’ve no idea really if it’s a rainwater or sewage hatch, should there be one of each?

Two points before we go further...

1. A house which doesn't have an operational foul water system is uninhabitable, can't be sold on the open market, and may be uninsurable.

It's the most basic of the checks which should be done by a surveyor acting on behalf of a prospective purchaser.

Building over a live sewer is a no-no, and should've been picked up by Building Control Officers, and the Planning Dept when those drawings were submitted.

It would usually be dealt with as a Planning Condition, whereby its relocation is a requirement of consent being granted.

2: I can immediately see that the standard of building work to construct the conservatory matches that which we've come to expect from companies installing heat-pumps.

Ie the 'standards' haven't been implemented, and the work is of poor quality.

At this rate, @editor will need to start a whole new section of this forum to address Building Works! 😥

The To-Do list:

A: You absolutely need to establish where your home's foul water pipes run, and whether you have responsibility for ensuring sewerage pipework for your neighbours.

Start with the 'new' inspection chamber 5m away, lift the cover and see where it's flowing from/to.

Get someone else to flush a toilet and check if your own house is connected to it.

Start adding this information to a copy of your plans.

B: establish what those pipes do which are already disappearing into the concrete pad.

C: Those electrical sockets are too low. They should be 400mm above Finished Floor Level (FFL).

Open them up and let's see where the connecting wires are running.

We don't want to see them going downwards into the floor!

D: Is the kitchen gulley still operational and visible within the conservatory?

E: I doubt that the company who can cut slots in the floor would be prepared to work around the existing inspection cover.

You really do need to see what's below it.

I bet I could lift it with a pneumatic drill!

Save energy... recycle electrons!

Just a couple of observations

1. Sadly I would say the standard of work is exactly what one expects, this is either the building trade and/or quite possibly in part DiY, and the use of the extension is/was somewhat subsidiary to the 'main' house; just from casual observation poor construction seems to occur frequently in these circumstances.

2. Sockets at the level depicted are very common, I would say (from casual observation) more common that sockets higher up (just because of the age of our housing stock). I don't know when it became a requirement to locate them higher and to what extent that requirement applied to extensions.

3. Combined drainage, where foul and surface water route to same drain, were the norm until (I think) the 1970s. I dont doubt that, where combined drainage exists, new surface water drainage eg from an extension gets connected in whether or not it should be.

4. As @transparent says the integrity of the foul drainage is paramount and should definitely be checked!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@sicky -- please don't be daunted by any of the above.

There are a number of options to resolve the issues of foul-water drains, depending on what you find.

Nor are they particularly expensive.

Underground drainage components are pretty cheap when you look at the overall renovation work.

A 3m length of 110mm diameter pipe is about £14, and an inspection chamber, risers and cover can be bought for less than £100.

There's nothing to prevent you doing (the majority of) the work yourself...

... and you certainly don't want to be paying a qualified tradesman just to dig a hole!

I have a 'live' sewer running beneath my extension, for which I took advice from the local Building Control officers (who aren't actually meant to do so!).

I placed new inspection chambers at each end of the run, and ensured that there were no joins/elbows actually beneath the floor.

Here's the downhill side, where you can see the cover of the inspection chamber, and a couple of spare 'riser' rings.

These allow me to set the height of the concrete cover once I've worked out where the finished ground level will be.

The building trade may take short-cuts and fail to properly install stuff,

but self-builders don't.

We're hardly likely to compromise the standards on our own house!

Building Control surveyors know this.

Once they've assessed our work on the first of the 14 main check-points, it's unlikely they'll bother to attend on-site again!

This Forum will continue to advise you as you wish.

Just keep us informed of what you find.... preferably with an accompanying photo.

@editor and I can split this out into a separate topic, so please ignore the Topic Title and keep posting.

Save energy... recycle electrons!

Save energy... recycle electrons!

Could a method to calculate heat loss in a room be to set the thermostat on max and measure the max temperature the room can achieve at a measured OAT? I know my flow temp is approximately 55 degrees C with two 1500w radiators at dt50, the room gets to approx 19.5 degrees when I've been trying this the past week. OAT ~0-5 degrees C.

@lakey - welcome to the forum.

An interesting question. I suspect (interested to hear others thoughts) in theory possibly, in practice rather difficult if not impossible.

The essence of empirical heat loss methods is having things in steady state, ie steady indoor air temperature (IAT), and ideally steady outside air temperature (OAT). If that is the case, then the heat loss must be the same as the heat (energy) put in. It certainly works for whole homes where you can relatively easily determine the energy delivered to the whole home, but the practical problem I see using the same method for a particular room is how to measure the heat (energy) delivered to that room. In theory the heat transfer equation will give you the amount: for each of the two rads, delta t across the rad x flow rate x specific heat capacity of the circulating fluid. The first and last are either known or can be measured, but the problem is how to know the flow rate in that particular rad. Knowing the flow rate for the whole system tells you nothing about the flow rate in a particular rad, and without that you are scuppered - unless anyone can come up with a way of determining the actual heat transfer by a particular radiator in the real world.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay thank you, I only have one thermostat for the house hence looking at the room data. I doubt my house is the same temperature throughout, it certainly doesn't feel it though not deliberately zoned. I also only really care about this one room as the rest I can oversize rads in, this one I was hoping to limit the conservatism due to wall space constraints!

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 432 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Without knowing it, @andrewj, you've laid down the gaun...

By Majordennisbloodnok , 19 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 23 minutes ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 56 minutes ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 1 hour ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 2 hours ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 4 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 4 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 4 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 6 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 20 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 22 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago