Thank s for the questions @derek-m

we have had accumulated heat when we are away for several days. It gets up to 70c in one sunny mid-summer day and we have had neighbours letting out hot water in the past, so not ideal.

However we now have a bigger tank with 250ltr volume and a pressure release valve as required. So we don’t know how hot it will get but anticipate it will, as before.

If I can it would be good to know what the system is capable of before we go away.... and come back to a bigger problem.

addition

the panels are evacuated glass tubes with sealed copper pipe core filled with fluid, pushed into a top manifold collector immersed in a circulating wet system with glycol.

Im not sure if it matters if the copper and glass tubes over heat- just assumed it wasn’t worth testing it out. As for the glycol I don’t know how it would behave at very high temperature. My fear is that water boils at 100c and I think that the tank got pretty close to that at one time.

Posted by: @sunandairjust wondered if the Ecodan could work in reverse to cool it while we were away.

Unlikely... because you've got a unit designed for the UK market.

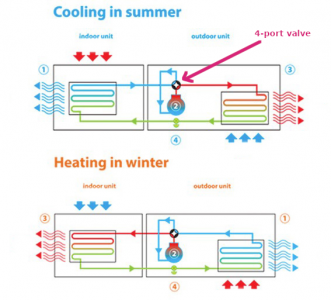

Heat pumps for the USA market usually incorporate a 4-port (2-way) valve which allows them to double-up as an air-conditioner in hot weather.

Here's a typical diagram in which I've highlighted that valve.

If your starting point is that you already have the Ecodan ASHP installed, then you need to look for an alternative strategy to get rid of the excess heat in the DHW cylinder.

In my case I have a Thermal Store, which means it also supplies Under-Floor Heating (UFH).

So I've designated one UFH loop which can be opened in the event of an over-temperature sensor triggering on the thermal-store.

That enables the thick concrete pad of that UFH zone to act as a dump-load.

You need to think of somewhere else (other than the Ecodan) which could act as a dump-load for you.

Save energy... recycle electrons!

Posted by: @sunandairThank s for the questions @derek-m

we have had accumulated heat when we are away for several days. It gets up to 70c in one sunny mid-summer day and we have had neighbours letting out hot water in the past, so not ideal.

However we now have a bigger tank with 250ltr volume and a pressure release valve as required. So we don’t know how hot it will get but anticipate it will, as before.

If I can it would be good to know what the system is capable of before we go away.... and come back to a bigger problem.

addition

the panels are evacuated glass tubes with sealed copper pipe core filled with fluid, pushed into a top manifold collector immersed in a circulating wet system with glycol.

Im not sure if it matters if the copper and glass tubes over heat- just assumed it wasn’t worth testing it out. As for the glycol I don’t know how it would behave at very high temperature. My fear is that water boils at 100c and I think that the tank got pretty close to that at one time.

Please correct me if I am wrong, but I would assume that your system is designed to pump water through the solar thermal panels, until the water temperature in the hot water cylinder reaches a maximum setting, at which point it would stop pumping water through the panels until the temperature in the hot water cylinder falls to a lower setting. Such a safety system would be required to prevent the water in the cylinder from boiling, and hence pressurising the cylinder.

This would lead me to believe that the solar thermal panels are capable of coping with the high temperatures to which they may be heated, when there is no cooling water flowing through them.

Please provide details of the make and model of your system and size of panels etc.

As far as I am aware, all ASHP's contain a 4-port reversing valve, since this is required to perform the defrost cycle.

According to the operators manual, the Ecodan can be operated in cooling mode, though this would not be the norm when used with radiators, since there could be a high likelihood of puddles of water due to condensation.

It may therefore be possible to pass cooling water through the heating coil within the hot water cylinder, though how successful this may prove could be dependent upon the relative position of the heating coil associated within the heat pump, in relation to that associated with the solar thermal system.

It would also be necessary to force, or manually set, the diverter valve in DHW mode, to prevent the possibility of puddles underneath the radiators.

Posted by: @derek-mI would assume that your system is designed to pump water through the solar thermal panels, until the water temperature in the hot water cylinder reaches a maximum setting,

You are correct @derek-m

A solar thermal system (which is pressurized of course) might contain water above 100degC. The 'proper' pipework has to be operable up to 160degC

The circuit will also include a temperature/pressure relief valve.

When it's triggered, it dumps the water/glycol mix into a Collection/Recovery tank.

That then prevents the solar-thermal system from operating of course.

Save energy... recycle electrons!

If my understanding is correct, a solar thermal system should operate in the following manner.

When the temperature of the panels is below that of the hot water cylinder, the circulation pump is stopped, and the liquid, be it water or a water glycol mixture will drain into the reservoir tank. The system, although sealed, contains both liquid and air.

As the temperature of the panels increases above that of the hot water cylinder, by a defined amount, the circulation pump will start, and pump the liquid, at a controlled rate, from the reservoir up through the panels. The liquid flowing through the panels will absorb heat energy, which will be carried via the return pipework to the heating coil inside the hot water cylinder. Thermal energy will therefore be transferred from the panels to the hot water cylinder.

Whilst there is sufficient solar energy available, the temperature in the hot water cylinder will increase. This process is fine, until the temperature of the water within the cylinder starts to approach undesirable levels. I have just had a quick look at the manual for the Resol Controller, which shows a maximum temperature limit, which when reached, stops the circulation pump from operating. The liquid therefore drains back to the reservoir, and no further heat transfer takes place. The system therefore contains over-temperature protection, which in the Resol case can be set as high as 90C.

I believe that once the cylinder temperature falls to the point where the over-temperature limits resets, the system reverts back to normal operation.

Since a solar thermal system is required to operate without constant human monitoring and intervention, I must assume that the panels are designed to cope with the maximum possible temperature that may occur when liquid is not flowing around the system.

I therefore question the need to actually cool the hot water cylinder, with a heat pump or otherwise. If the temperature in the cylinder is getting higher than desired, then check the setting of the maximum temperature limit, and lower this if necessary.

Posted by: @derek-mI have just had a quick look at the manual for the Resol Controller, which shows a maximum temperature limit, which when reached, stops the circulation pump from operating. The liquid therefore drains back to the reservoir, and no further heat transfer takes place [.....]

I believe that once the cylinder temperature falls to the point where the over-temperature limits resets, the system reverts back to normal operation.

Possibly. But I'm not aware of a 'reservoir' which allows that to occur.

The one I have simply holds the liquid which has been allowed to drain out via the escape valve.

You have to retrieve it manually and pour it back into the solar-thermal pipework.

Until then, the system won't work because you've got no fluid to pump! 🤨

Save energy... recycle electrons!

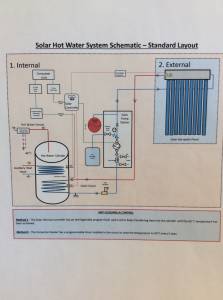

@transparent @derek-m I have settings for Maximum Store (hot water tank) temperature and Emergency Collector temperature,

exceeding either of which results in the Solar Thermal pump shutting down. The expansion tanks attached to my installation are shown below.

It got pretty hot last summer and the system seemed to cope. The data points I am now logging should show if any of these limits get reached.

16kW Midea Monobloc R32 Heat Pump (Heating & DHW)

4kW Solar PV (No battery storage yet)

CPC 12 INOX Solar Thermal (DHW)

That's a great photo @alan-m - for all sorts of reasons 🙂

We can see the flow & return stainless-steel flexible pipe run to the roof-top collector, the pump on the return side, and the connections to the pressure-vessel and reservoir.

Better still, it's installed neatly onto a plywood sheet, which is positioned in front of a timber-frame with internal insulation boarding.

It's the sort of "this is how it should be done" pic which we need more of on this forum.

Save energy... recycle electrons!

Posted by: @derek-mPosted by: @sunandairThank s for the questions @derek-m

we have had accumulated heat when we are away for several days. It gets up to 70c in one sunny mid-summer day and we have had neighbours letting out hot water in the past, so not ideal.

However we now have a bigger tank with 250ltr volume and a pressure release valve as required. So we don’t know how hot it will get but anticipate it will, as before.

If I can it would be good to know what the system is capable of before we go away.... and come back to a bigger problem.

addition

the panels are evacuated glass tubes with sealed copper pipe core filled with fluid, pushed into a top manifold collector immersed in a circulating wet system with glycol.

Im not sure if it matters if the copper and glass tubes over heat- just assumed it wasn’t worth testing it out. As for the glycol I don’t know how it would behave at very high temperature. My fear is that water boils at 100c and I think that the tank got pretty close to that at one time.

Please correct me if I am wrong, but I would assume that your system is designed to pump water through the solar thermal panels, until the water temperature in the hot water cylinder reaches a maximum setting, at which point it would stop pumping water through the panels until the temperature in the hot water cylinder falls to a lower setting. Such a safety system would be required to prevent the water in the cylinder from boiling, and hence pressurising the cylinder.

This would lead me to believe that the solar thermal panels are capable of coping with the high temperatures to which they may be heated, when there is no cooling water flowing through them.

Please provide details of the make and model of your system and size of panels etc.

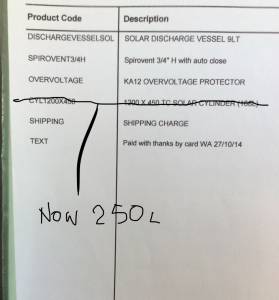

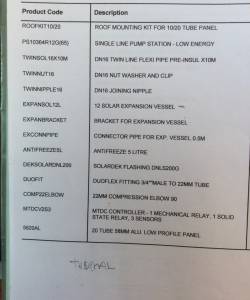

Hi Derek sorry for delay-travelling- ive grabbed a file on the system and I’m photographing info while on a train.

The main controller is a MTDCV2S3 or MTDC Temperature Difference Controller. The system has a program built in to set up a system recooling. What happens is at a given time at night the pump is activated to circulate the water through the solar panel and cooling the water in the cylinder overnight.

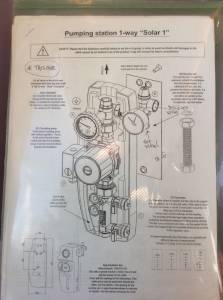

The attached parts list might be helpful. Also attached is schematic Andy a drawing of the pumping station.

as stated previously the solar panel is a 20 glass tube arrangement with sealed copper cores containing a heat transfer liquid inside. These copper cores plug into a top manifold and transfers the heat to the circulating glycol.

we have the st.st. pipework as pictured by @transparent as well as the pressure release valve and discharge tank.

The system operates very effectively and we’ve never had an overheat but I’m wanting to exploit any possible recooling mechanism which might work from the Ecodan or as @transparent says - to dump the heat in some way during holiday periods.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 487 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 1 second ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 26 minutes ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 28 minutes ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 1 hour ago

-

RE: What determines the SOC of a battery?

The answer from Fogstar was crisp. My hypothesis, su...

By Batpred , 1 hour ago

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 2 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 4 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 5 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 7 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 8 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 24 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago