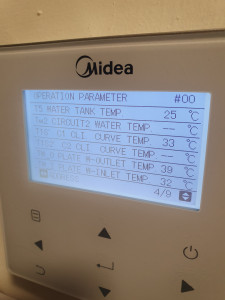

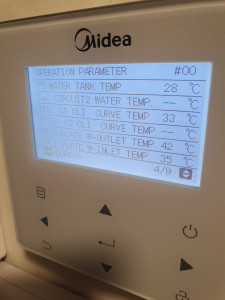

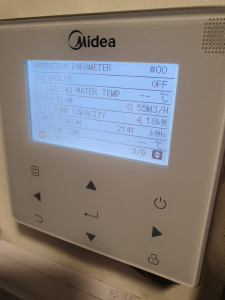

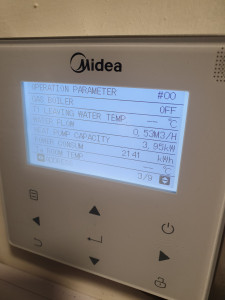

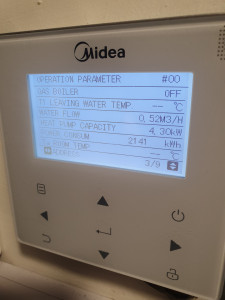

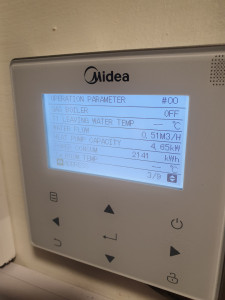

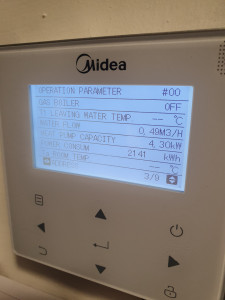

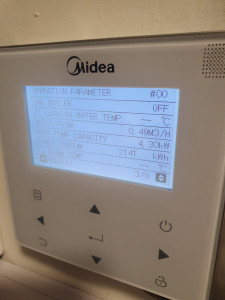

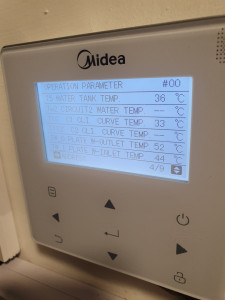

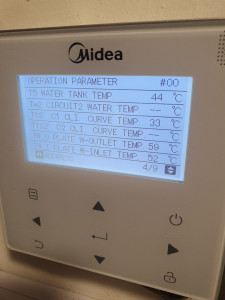

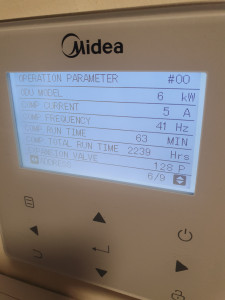

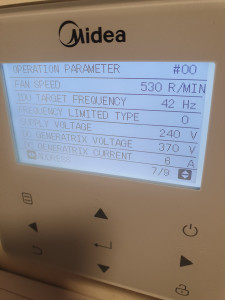

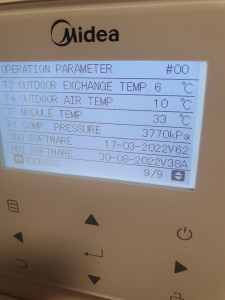

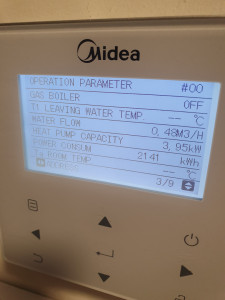

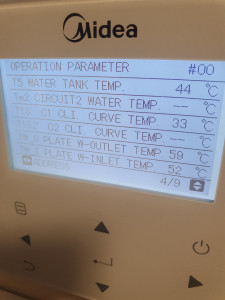

There is also enough info there to calculate calculate power output, which is LWT/RWT delta t x flow rate/3.6 x circulating fluid specific heat (the divide by 3.6 is to get from m^3/h to litres per second.

Thus we get 6 x (0.54/3.6) x 4.2 = 3.78 which is close enough to the 3.83 shown. This suggests the flow rate is sufficient for that level of power output (another way of getting to that conclusion is to rearrange the equation to get the flow rate needed to get 3.8kW power at a delta t of 6:

flow rate = kW x 3.6 / (delta t x specific heat) = 3.8 x 3.6 / (6 x 4.2) = 0.54m^3/h...).

The next question is how long does your heat pump take to heat the water from X to Y (assuming a 200L or thereabouts tank, it should take about 30-40 minutes to raise the temp by around 15 degrees, today, mine did 34 degrees to 50 degrees in 30 mins at a flow rate of around 1.48m^3/h at an average delta t of 5 and with some glycol in the system). Very roughly pro rata, at a third of the flow rate yours should take three times as long.

What I am getting at here is the credibility of the data.

Midea 14kW (for now...) ASHP heating both building and DHW

Will try and grab these next time or I may force it to go to 50⁰ just to check. I keep it at 45⁰ and just let it top up we have a 150L tank.

Yeah it doesn't take long to heat up

Cheers for you insight buddy

Posted by: @burtisWill try and grab these next time

If you know when it will go into DHW heating mode (because it is on a timer?) then it won't take much to get useful readings, say flow rate, LWT/RWT (so you can calculate delta t) and DHW tank temp every 5 minutes will be enough to show the outline of how you tank heats up. Or if it is 'always on', you can force a reheat by running a tap (which incidentally is what the Freedom annual service requires, to confirm the system is working correctly).

DHW heating is when the heat pump normally works hardest, and is therefore a good time to see what it is actually putting out, and the fact that there is a directly measurable outcome makes things easier.

I have become increasing suspicious of Midea flow rates and their control. For a start, they are not directly measured, they are instead inferred from the pump's 'running parameters' (electrical?) and is known to be somewhat inaccurate (though tolerable): "The flow rates parameters are calculated according to the pump running parameters,the deviation is different at different flow rates,the maximum of deviation is 15%" (source: Midea M-thermal Mono Installation and Owners Manual Apr 2020 p64). The same manual on page 5 gives the range of flow rates for each model:

Assuming you model is one of the 12/14/16kW models, then you flow rates are below their expected range. In my case, they are in range, but fixed (~1.45m^3/h) and this appears to cause my 14kW model to be only a 6-8kW model. In both our cases something is not right.

It would be very helpful if other Midea (or Midea clone) heat pump owners could report their heat pump running data (especially flow rates).

All this said, I happen to have an analogue flow meter installed in my primary circuit which is totally independent of the Midea monitoring, and it shows that in general terms the Midea reported flow rate on my system is broadly in line with the analogue readings.

Midea 14kW (for now...) ASHP heating both building and DHW

Interesting 🤔

Mines being the 6KW looking at that data you provided there it's running right on the bottom end for flow.As long as It doesn't drop below 0.4 it should be fine.

MideaUK said it could be a poorly wired up secondary circulation pump that stays running after the heat pump is done it job causing a flow issue or E0 fault code would be down to the installer to check this is suppose.

Ideally i guess if the buffer was re piped as a volumiser on the return and that circulation pump removed it would be more efficient and less pump noise issues and less energy used to run the pump.

Another point to note I was chatting to the phone bloke from MideaUK he mentioned that they don't like using glycol and to use anti freeze valves instead for efficiency sake.

We shall see it's all a waiting game now anyway to see what MCS and the installer say

@burtis - what seems to be happening in both our heat pumps is the flow rate is somehow capped at the lower end of their respective ranges, with the result that in more demanding conditions they can't cope.

I'm not sure who MideaUK are - last time I looked it was some sort of shell office, the real 'MideaUK' was Freedom, but maybe Midea now have their own presence here. Be that as it may, there advice ("most likely a plumbing problem" and "could be a poorly wired up secondary circulation pump") is of the "there seems to be a lot of it about" variety, insofar as it doesn't add much. Nor am I sure why they think the secondary (emitter circuit pump) could be causing primary circuit flow rate problems.

From the research @jamespa and I have done, it seems the primary circulating pump is supposed to be PWM (pulse width modulation) controlled, and that is supposed to be how it achieves its full range. On inspection, my heat pump does at least appear to have the relevant cable to do this in place, but for what ever reason it isn't doing anything.

You have a buffer, as you know these are contentious. At times Freedom have insisted on them (or a plate heat exchanger, which is what I have), otherwise you can kiss your warranty goodbye, at other times they have not insisted on them. Others have got freedom to agree to their removal. I have decided to live with my plate heat exchanger, and accept it compromises my heating a bit, because on the other hand I do like the idea of hydraulic separation (I won't for example get radiator crud, not that I have any, blocking the primary circuit filter, as you have had). If I had a buffer I am pretty sure I would remove it, or as you suggest turn it into a volumiser.

The use of either glycol or antifreeze is a trade off. I prefer glycol on the grounds that it manages a potential freeze up better, as in it just does its thing. If you have antifreeze valves, then you have to manually refill the system to get it going again after a freeze up. That said, another school of thought says the real risk of a heat pump freeze up is extremely small - you need prolonged cold weather plus a power cut or heat pump malfunction to get to the risk - and so why bother. I think the answer to that question may be to ask it again after an owner has had their heat pump freeze up.

Yes, you need to wait to hear what MCS and your installer have to say, but in the meantime do try to get that DHW reheat data. I'm hoping it will reveal what your system is actually doing.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayFrom the research @jamespa and I have done, it seems the primary circulating pump is supposed to be PWM (pulse width modulation) controlled,

I wonder if the Installers have appreciated the difference between a pump which has PWM inbuilt within the pump itself, and one where the Heat-Pump controls the speed by sending PWM signals down a wire?

Them simply stating that a pump is 'PWM controlled' isn't sufficient.

Save energy... recycle electrons!

Posted by: @burtisIt's all a bit over my head all this maybe one day I will dig into it deeper but really I shouldn't have to.

Ofgem and DESNZ are both aware that there is a dearth of knowledge holding up the implementation of future energy strategy.

There's no point having a Minister making a policy decision if those who are required to implement it don't adequately understand the issue.

Here's a snapshot from part of Ofgem's recent Consultation on Energy Innovation:

That Consultation closed last week. But I submitted responses, both to their fixed Question Set and also to other comments in the accompanying Guidance Notes.

What gets discussed in forum topics like this one are providing me with evidence to inform my responses.

Instead of merely answering questions in Government Consultations, I tend to present one or two examples which support my observations.

Those in turn, contain links back to forum discussions.

Here's another snapshot from a different part of the same Ofgem Consultation:

Ofgem is the Energy Industry Regulator.

They create and monitor the regulations which are implemented by the likes of MCS and NAPIT.

Although that section is specifically about enabling Innovation, it does seem to suggest that they want to hear from the ordinary members of the public, rather than just those working in the Energy Sector. Is this perhaps an opportunity for @editor to write something based on what @burtis is reporting here?

Save energy... recycle electrons!

@transparent - I summarised the results here. What we actually found were wiring diagrams showing the PWM control cable (in addition to the power cable) and on my actual heat pump you can see two cables (multicore) physically attached to and presumably (?) connected to the circulating pump. I'm pretty sure we also found something on how the external PWM controls the pump, including no signal = max RPM, but I can't seem to track that down. I don't think my installer touched any of this, the heat pump came out of its box and went into place, with minimal work done on it bar making the actual piping mains supply and wired controller connections. Neither is there anything in the Freedom installation manual (which my installer used) that says anything about doing anything to the circulating pump.

Edit: changed 'two wires physically' to 'two cables (multicore) physically'

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayon my actual heat pump you can see two cables (multicore) physically attached to and presumably (?) connected to the circulating pump

Good. Two cables.

So that suggests a power-supply cable, and a separate control cable.

What does @burtis have?

Save energy... recycle electrons!

@transparent - here's the page with more details and images on what my heat pump has.

Midea 14kW (for now...) ASHP heating both building and DHW

Currently viewing this topic 3 guests.

Recently viewed by users: Toodles 1 hour ago, JamesPa 59 minutes ago, Transparent 32 seconds ago.

- 26 Forums

- 2,426 Topics

- 55.1 K Posts

- 330 Online

- 6,104 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Is my Samsung gen6 outside air temp sensor missing a sheath/sleeve?

@toodles Don’t get me started on car headlight bulbs!

By Papahuhu , 43 minutes ago

-

RE: The good, the bad and the not that great – my heat pump installation

@burtis I only use the app to see what is going on and ...

By Toodles , 1 hour ago

-

RE: Installer Fitted 9kW Instead of 11kW Heat Pump and Changed MCS Paperwork - What do I do?

I've now had an interesting email from a Complaints Res...

By MairiA , 1 hour ago

-

RE: R290 and Foundation Air Bricks

I discussed this topic with my installer late last year...

By EffTee , 1 hour ago

-

RE: Reliable, easy to use home battery options

Correct. LiFePO₄ cells mustn't be charged if their te...

By Transparent , 1 hour ago

-

RE: Water outage in the the south-east

Indeed!Any contamination in the well water would be tra...

By Transparent , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

I hear some cases of apparent misconfiguration of inver...

By Batpred , 4 hours ago

-

Are split ASHPs with R290 refrigerant coming soon?

Question. Are there any (or likely to be in the near t...

By iotum , 6 hours ago

-

RE: Setback savings - fact or fiction?

Indeed. In many ways, a defrost is a setback, with the ...

By cathodeRay , 6 hours ago

-

RE: Heat pump not reaching flow temperature

The good news is that it leaves no excuse if it doesn't...

By JamesPa , 6 hours ago

-

RE: How to use my Hanchu battery storage for home without it feeding back into the grid?

@countryman-helmsley In that case is there a button ...

By IRMartini , 6 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

Thanks. Thats pretty much my intended route i...

By JamesPa , 7 hours ago

-

RE: Is it normal to use power from the grid when running off the battery?

The Solis S6 has various modes of use. I currently have...

By Batpred , 8 hours ago

-

RE: Ideal HP290 14kW ASHP - how to optimise

Great. It’s not bad is it, though I agree it may repres...

By Davesoa , 8 hours ago

-

RE: Ecodan Pump Issues… Circulation pump turns off when heat pump compressor turns off

@f1p apologies, you are absolutely correct

By Patch321 , 8 hours ago

-

RE: Samsung E101 Error Message and my ASHP Efficiency

@johnnyb amazing that the our forum is serving its purp...

By Mars , 23 hours ago

-

Best option for controller upgrade? - Grant Aerona

Fairly new heat pump owner - Grant Aerona 3 10kw - and ...

By Topher , 23 hours ago

-

RE: Daikin Wireless Thermostat

@toodles Yes. British Gas seems to have done an exce...

By Bash , 1 day ago

-

Just a brief update to keep things transparent. Secti...

By DREI , 1 day ago

-

I continue to receive emails from homeowners sharing he...

By Mars , 1 day ago