X/Y Co-ordinates ??

First , could I change the Weather Compensation Graph Names.

The X axis should be called the Outside Air Temperature, OAT

The Y axis should be called the Water Temperature, WT :

The Weather Compensation curves are defined by two Coordinate pairs:

1) . When the Outside air Temperature , OAT = -5 C , the Water Temperature, WT should be +45 C.

2) When the outside Temperature , OAT = +15 , the Water Temperature should be +25 C.

I have , incorrectly, set the outside air temperature to firstly +20 C and then +17 C when the Water Temperature is +25 C,

after Being instructed to increase the coordinates on the wrong axis.

Many thanks , @cathoderay , Red face time again.

I will not , however , be repeating this "experiment" , with the cycling time being reducing to Zero, providing plenty of food for thought.

Posted by: @iantelescopeRed face time again

I did say earlier I wondered weather Samsung's obfuscated implementation of weather compensation meant it was easy to mix up OAT and Set LWT, and that maybe you had been adjusting the OAT (X axis) when it was the Set LWT (Y axis) that needs adjusting.

In you previous post you say:

"Conclusions:

1) My Heat Pump will work , for long periods during the daytime , providing a stable Room and Water Temperature , without a Physical Room Thermostat.

2) My Heat Pump , when run without a Thermostat will , however, reduce the Cycle Time to zero as the difference between the Water Temperature and the Weather compensation curve reduces to Zero.

3) Reducing the Cycle time to zero when the Water Temperature approaches the Weather Compensation curve is potentially very damaging the Heat Pump"

to which I would reply:

1) yes, this is what we aim for, day and night, assuming always on (no setbacks)

2) this seems to me to describe something moving to a steady state, which is again what we aim for (Steady Eddie...). When the cycle time reaches zero, there is no cycling and the heat pump is in a steady state

3) I have no idea why running at a steady state, cycle time zero (ie no cycling) is potentially very damaging to the heat pump, since this Steady Eddie no cycling running state is the Holy Grail of heat pump running. At a given OAT, the Set LWT should be steady at the Set LWT indicated by the weather compensation curve, with no (zero cycle length) cycling. It should be like an airliner at high altitude, cruising along nice and steady, not jumping up and down all over the place as the engines ramp up and down.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathhoderay

Short Cycling , No Cycling ?

Again , many thanks for your input.

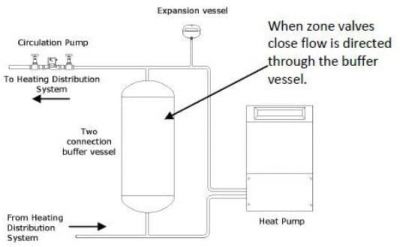

My Short Cycling was originally , some Two years ago now, to have been repaired by inserting a 50 l buffer tank.

Surely, if short cycling reduces the life span of my Heat Pump , then , a slow reduction to Zero over 5 hours , followed by another 5 hour period of Zero Cycling with the motors hard on would be deleterious to put it mildly?

Refrigeration is , surely a cycling process , firstly pumping up the gas pressure during the Run Period then forcing the gas through a controlled nozzle before allowing the expanded gas to evaporate cooling the surroundings in the process.:

Refrigeration is a Cycling process, All Refrigerators must cycle ..........the only question is the cycle and Run periods.

According to the DECC and the MCS "short cycling " is defined when the Average Period reduces below 6 minutes and the Average Run Period reduces below 5 minutes.

Zero is allot less than 6 minutes.

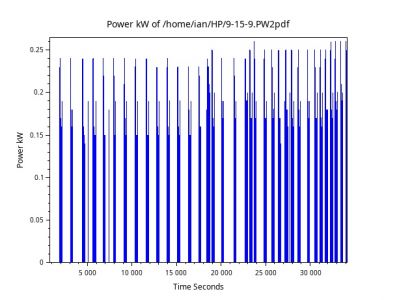

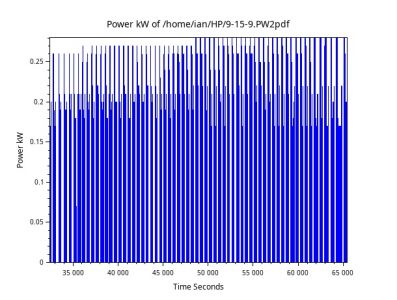

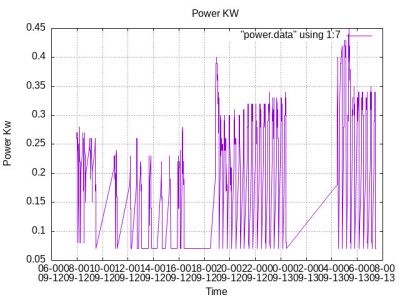

Shortening Cycles on 16th Sept in Power consumption :

Further Reduction in cycle time on 16th Sept in Power consumption, hyper-cycling . The Room Temperature increasing to 25 C.

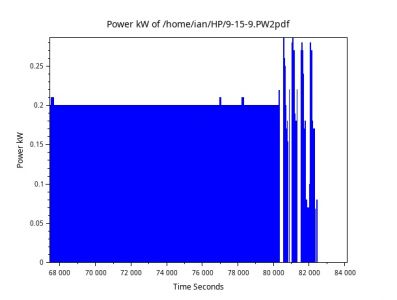

Zero Cycling ...............total power hard ON.in Power consumption . Zero is allot less than 6 minutes. No refrigeration for 3 hours and twenty minutes!

with the Room Temperature falling until , eventually, restarting cycling and refrigeration.

@iantelescope - I think we need to clear up what we mean by cycling, and then short cycling. To me something that cycles is something that regularly moves between two (or more) states. For example, something might cycle (implies goes round) between a high and low, or even off, state. This is generally what we mean when we talk about heat pump cycling, specifically the heat output goes up and down, usually because the compressor is cycling on and off. This cycling can be visualised by looking at various parameters moment by moment, for example actual LWT, the current draw (in amps) of the power used (in watts). I prefer using actual LWT, I rather suspect other things like power, such as you use, may be very volatile, and thus perhaps appear to cycle when in fact they are not. There are also other variable, things like compressor (on/off or frequency as a proxy for that) but it all gets very muddy very quickly. Who knows what is actually being measured, and how? After all, and AC current is itself a cycling current - it alternates. That's why I prefer using the actual LWT. If a heat pump is cycling, it will always be clearly apparent there, and the frequency will be easily determined.

Cycling once an hour or so is not a problem, and many heat humps have to cycle to reduce output when demand is low, because they cannot reduce their continuous output to a low enough level. If the house only needs 4W (of power), and the heat pump can only go as low as 6W continuous, then it can average 4W by cutting out - cycling - some of the time.

At the same time, heat pumps like my earlier airliner example, like to cruise smooth and level. Cycling the afterburner frequently on an airliner to average out at a certain altitude may look impressive, but it is a bumpy ride, a lot of wear and tear, and prone to inefficiencies. It is the same with heat pumps, if you have them cycling on and off, the ride gets bumpy, wear and tear increases, and inefficiency creeps in. The point at which heat pump cycling gets too frequent - short cycling sets in - is not set in stone, you give a typically less than lucid (why make things simple if you can make them complicated) MCS one which might mean short cycling is cycling that happens ten times an hour, or less (every six minutes or less). Since we are talking about cycling, I suggest that actual run time is a red herring. Lets say cycling every six minutes or less is a good enough working definition of short cycling, the point at which we think (has anyone actually done the research, as opposed to pontificating?) the heat pump may be adversely affected.

Your charts in your most recent post cover very short time frames (all less than a minute) and the variable measured (power) is extremely volatile. As other have suggested, this cycling just isn't credible, as a proxy for actual output cycling - there is no way the actual output of a heat pump does that, there is just too much inertia (latency) in the system. I think it is a case of of the wrong probe in the wrong place. You may be diagnosing short cycling, when in fact it isn't there, because you are looking at the wrong measurement.

Which brings us back to monitoring the actual LWT, the IAT and the OAT. To crack this one, you need to monitor your actual LWT, at a sufficient sampling frequency (I use once a minute) to detect cycling. The sampling doesn't even need to be that (absolutely) accurate to detect cycling - to detect cycling when only need relative values (does the LWT go up and down, or stay the same?). Instead of giving yourself a heart attack over hyper-cycling, find a way to monitor actual LWT and see what is actually happening.

There is a saying in medicine, never treat a lab result, always treat the (whole) patient. It exists for a reason.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathooderay

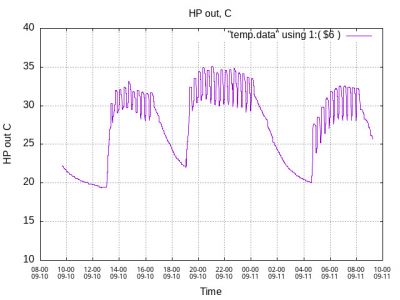

Short Cycling in C

I have a multitude of different sensors all of which show short cycling.

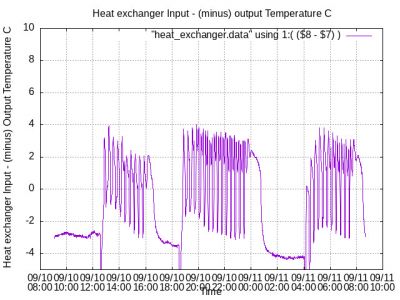

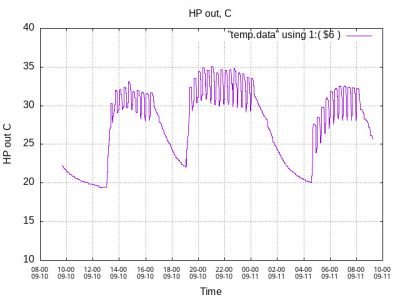

1) Thermo couple sensors at the Heat Pump output:

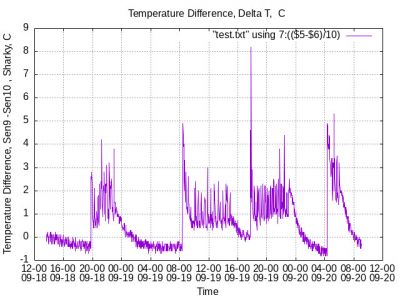

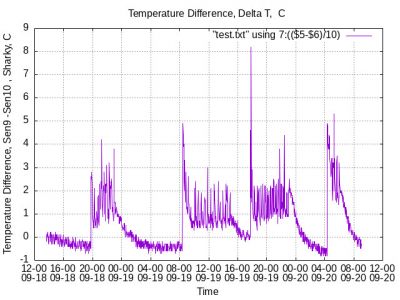

2) DS18B20 Sensors at the primary input ports of my Heat Exchanger, Sowing Delta_T in C:

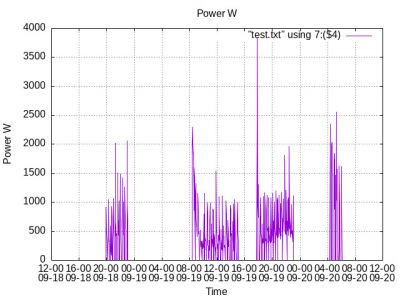

3) Sharky Temperature Sensors at the entry point of the Radiator , Secondary ,

4) Water Power at the Radiator circuit Secondary , Sharky :

5) Mains Power on the input to the entire Heat Pump :

I have many hundreds of megabytes of data/Graphs covering Two years over a multitude of sensors.

6) Heat Pump stops Cycling for thee hours and twenty minutes.......

DECC Recommendations

DECC Report

Recommendations used to install Buffer tank to reduce Short Cycling in Oct 2022 .

1) DECC Recommendations:

8

Recommendations

Both ASHPs and GSHPs should be designed for a minimum run time of circa six

minutes, which will avoid the worst excesses of detrimental performance caused by

short cycling;

Ideally, systems should be designed for slightly higher run times than this – for the

particular GSHP system used here there appears to be an optimum performance at

around 10 to 15 minutes, whilst run times of ~ 8 minutes for the ASHP gave COP

values close to catalogue steady state values;

Explore all options to achieve these minimum run times including:

o Zoning to ensure sufficient radiator surface is available at all times (as was

achieved here by using the lounge / dining room as the reference zone,

although a room thermostat override or wide switching band thermostat would

also be required to avoid room thermostat induced short cycling);

o Buffer tanks;

The 4-pipe buffer tanks arrangement tested here shows a promising method of

achieving the required minimum run times without the need for excessive volumes

(roughly 8 litres / kW heat output was used here);

o Ideally the 4-pipe buffer tank would be designed to achieved a high degree of

stratification so as to maintain flow temperatures to the CH system throughout

the heat pump off periods;

o Care needs to be taken in setting-up a 4-pipe buffer tank system to ensure

that the flows through the heat pump and through the fully open CH system

are well matched.

2) Recommendations from MCS :

3) Recommendations from Kensa

Posted by: @iantelescopeI have a multitude of different sensors all of which show short cycling.

I'm not sure they do. Take the first chart in your second to last post, this one:

I take it this is what we conventionally call LWT, the temperature of the water leaving the heat pump. As I remarked earlier, this is the most useful variable for assessing cycling. Assuming I am reading the chart correctly, the X axis is time (upper row of legend is time, lower date in mm-dd format), with the grid squares being 2 hours, the Y axis is degrees C. Now let us zoom in on the first period of cycling, between 1300 and 1700 on 10th Sept:

Assuming the grid to be 2 hours, I count six spikes (cycles) between 1400 and 1600, which works out as three per hour, which is well below the short cycling threshold, ditto for the other cycling periods shown on the whole plot. I suspect the other variables and their plots are all being affected by various malign influences that create what I have called in another circumstance cavernous numbers meaningless to man. Or to use a medical analogy, you stuck the wrong probe in the wrong orifice.

To repeat, the plot that tells you whether your heat pump is short cycling or not is the LWT plot. The one shown here shows your heat pump is not short cycling.

Midea 14kW (for now...) ASHP heating both building and DHW

Following an incident with my heat pump I have lost both personal self confidence , and, with the substance and tone of some of the "advice ".

I have returned to a safe , and stable, Heat Pump with a thermostat defined Cycle time of ~20 minutes and a Run Time of 6 minutes.

I have reduced the Flow rate on the primary, Heat Pump water loop to ~17 lpm, and, reduced the secondary Flow rate to ~7 lpm.

Both flow rate reductions were set using the Pulse width Modulated , PWM inputs to my motors.

My Delta_T on the output has increased to 4 ..6/7 C

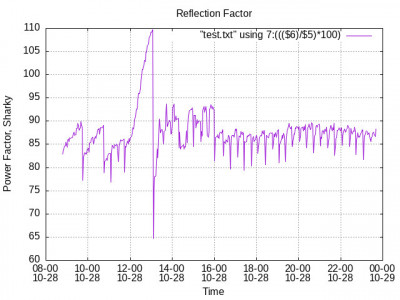

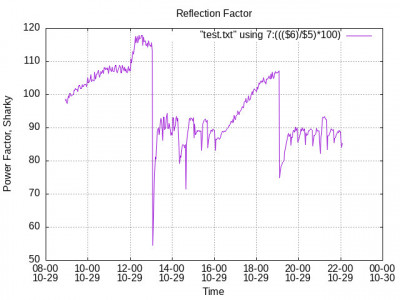

Reflection Energy and Delta_T:

With an increased Delta_T the amount of energy reflected back into the Heat -exchanger from the Radiators has reduced.

However, with a background in electrical engineering , I am , as ever, concerned about the amount of energy reflected back into the Heat Exchanger and the Heat Pump itself.

An Electrical transmission line can be "tuned" to return , or reflect ,0.01 % of the incoming energy as "Imaginary " energy , or power .

My Water Pipes, can , just, for comparison, reflect some 70..80% of the incoming energy !!

Why are we generating Heat Pump Energy with an 400% efficiency only to later transmit that energy with 20/30 % efficiency?

Why Transmit energy using water pipes ?

As an aside, please do not dismiss my "thoughts" about reflection factors .....................Refrigeration engineers sometimes CO2 as the transmission gas with a lower reflection factor.

@iantelescope - I'm sorry, but this is gobbledygook to me. You need to use plainer English, and explain your methods in enough details to allow others to understand what you are doing. I'm guessing, but is your 'reflection factor' the energy 'returned' to the heat pump ie not transferred to the house while the circulating fluid passes through the radiators? If so, why have you now fixed on this as being important?

I am more that happy to discuss your thoughts, as I am sure are others, as long as they are intelligible. At present they are not, to the extent you post might be said to resemble what might in other settings be called a word salad. Science at whatever level progress through both experiment, theory and discussion, and all three need clear language, otherwise the venture will fail.

Midea 14kW (for now...) ASHP heating both building and DHW

I too understand reflection factors from a mW communications background and their use is completely inappropriate for water flow along pipes. Keeping it simple is most appropriate to prioritise the necessary corrective action of your ashp.

2kW + Growatt & 4kW +Sunnyboy PV on south-facing roof Solar thermal. 9.5kWh Givenergy battery with AC3. MVHR. Vaillant 7kW ASHP (very pleased with it) open system operating on WC

CORRELATIONS??

With a Buffer Tank Switch I can CORRELATE the Buffer tank with COP , REAL-COP , Percent Losses and external outside Air Temperatures.

The Following coefficients of Correlation have been calculated since new year 2025.

1: The Correlation coefficient between BUFFER use AND Percentage LOSS is +0.44 . Meaning that if I use correlates with my Percentage LOSS .

2: The Correlation coefficient between BUFFER use AND Energy Consumption is - 0.36 . Meaning that buffer use correlates with my Consumption.

3: The Correlation coefficient between BUFFER use AND The COP is +0.375 . Meaning that Buffer use correlates with my COP .

4: The Correlation coefficient between BUFFER use AND The REAL COP is +0.65 . Meaning that Buffer use correlates with my REAL COP .

I am fully aware of the dangers of the USE and abuse of Cross Correlations.

However, the use of a buffer is POSITIVELY correlated with COP & REAL COP

My Buffer tank stays but will remain , and will remain switchable.

ian

CORRELATIONS CORRECTIONS ??

Sorry , SOME logical and spelling mistakes !!

With a Buffer Tank Switch I can CORRELATE the use of my Buffer tank with COP , REAL-COP , Percent Losses and external outside Air Temperatures.

The Following coefficients of Correlation have been calculated since new year 2025.

1: The Correlation coefficient between BUFFER use AND Percentage LOSS is +0.44 . Meaning that if I use MY BUFFER the Percentage LOSS INCREASES.

2: The Correlation coefficient between BUFFER use AND Energy Consumption is - 0.36 . Meaning that buffer use MY BUFFER the ENERGY Consumption DECREASES.

3: The Correlation coefficient between BUFFER use AND The COP is +0.375 . Meaning that if I use my Buffer my COP INCREASES .

4: The Correlation coefficient between BUFFER use AND The REAL COP is +0.65 . Meaning that if I use my Buffer the REAL-COP GREATLY INCREASES.

I am fully aware of the dangers of the USE and abuse of Cross Correlations.

However, the use of a buffer is POSITIVELY correlated with COP & REAL COP

ian

- 26 Forums

- 2,367 Topics

- 53.7 K Posts

- 210 Online

- 6,042 Members

Join Us!

Worth Watching

Latest Posts

-

-

RE: Who's your electricity provider and what's your tariff?

@majordennisbloodnok This may be a better thread to ...

By Batpred , 12 hours ago

-

RE: Help needed with Grant Aerona 3 issues

Noted. Its a pity you didnt capture the flow rate and ...

By JamesPa , 18 hours ago

-

RE: Best Heat Pump Brand in the UK

Last Call to Vote & Win! Haven't voted for your Hea...

By Mars , 18 hours ago

-

RE: Solis S6-EH1P8K-L-PLUS – Why I Chose It and What I’ve Learned So Far

Interesting question. To be frank, since I have no inte...

By Majordennisbloodnok , 1 day ago

-

RE: Changing from 4-port buffer to volumizer

@andy1618 see the very sage advice from @editor above. ...

By JamesPa , 1 day ago

-

RE: New Fogstar 15.5kWh upright solution

The video shows the JK balancer, but the connection of ...

By Batpred , 2 days ago

-

RE: Ecodan unable to hit legionella target temp - what's the consensus?

@9jwr9 Hi, yes this is the issue with every (stand alon...

By ASHP-BOBBA , 2 days ago

-

RE: Help me keep the faith with my air source heat pump installation

@adamk FWIW I managed unintentionally to 'coax' mine in...

By JamesPa , 2 days ago

-

RE: Octopus Cosy Heat Pump Owners & Discussion Thread

You are in essence right. Adia only works with selecte...

By JamesPa , 2 days ago

-

No, you haven’t missed out, @batpred. This thread’ll st...

By Majordennisbloodnok , 2 days ago

-

RE: Tesla Powerwall – More of a ‘Luxury’ Than an ROI Winner!

Also, though they weren’t prepared to match the price t...

By Toodles , 2 days ago

-

RE: How long will your energy contract last?

My INTELLI-FIX-12M-25-08-29 has less than 12 months to ...

By Batpred , 2 days ago

-

RE: GivEnergy 2025 forthcoming batteries and inverters

Then, perhaps @toodles , you should've made a submissio...

By Transparent , 2 days ago

-

RE: Balancing financial efficiency and comfort using the Octopus Cosy tariff

I am wondering if anyone with an EV could find the 7p/k...

By Batpred , 2 days ago

-

Possibly, but it would also reduce DeltaT across the em...

By JamesPa , 2 days ago

-

RE: ASHP sizing - value of Heat Transfer Coefficient

@cathoderay It was reminiscent of the BBC Open Universi...

By Toodles , 2 days ago

-

-

@morgan They are unsupervised these days, can’t get the...

By Toodles , 5 days ago