@derek-m & @jamepa

Red face Time..... again!

You are correct derek I have made an error in reading the Power from the wrong register within the sharky..

I have been mistakenly reading the Flow rate instead of the Power........my mistake.

The Registers within the Sharky start at 0 going to 11 while I have been reading address 1 to 12 .....elementary my dear Watson.

Reading manually would be impossible , given the file size and the time between readings.

Only the Power reading is affected.

Sorry, I stand corrected ....again.

I will , hopefully, fix the Power reading this afternoon......

I wasn't suggesting that you read the values from the Sharky display on a regular basis, I just wanted a one-off instantaneous set of readings so that it could be clarified what data was actually being obtained.

I will look forward to getting the correct data.

Did you receive my request for a graph for sensor 1? Is there any problem in providing this data?

Power Reading fault may be caused by interference!

Probably from the Capacitive Motors, with the Grundfoss Motors being Capacitive NOT inductive.

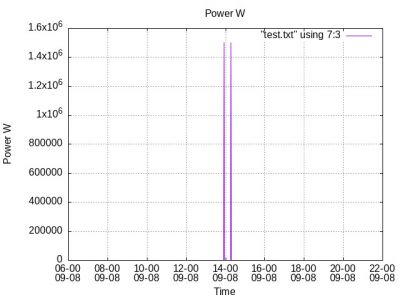

In tying to correct the Power as recorded by the Sharky I have now recorded large negative power Spikes.

As I was saying earlier it is possible to produce apparent Power spikes when calculating Power.

Power = dE/dt can produce violent apparent power spikes by the differentiation of Energy .

The Sharky is producing powerful Apparent negative Power Spikes producing massive negative Power pulses.

Readings from Sharky.......

Energy Volume Flow Power Low Temperature High Temperature Year month Day hour Min Sec

5126 2191970 417 150000040 255 254 2024 09 14 12 49 12

5126 2191984 417 13 256 256 2024 09 14 12 51 17

5126 2191999 418 150000064 255 252 2024 09 14 12 53 22

5126 2192013 417 150000059 250 250 2024 09 14 12 55 28

5126 2192129 416 150000069 260 257 2024 09 14 13 12 09

5126 2192303 415 5126 2192318 414 5126 2192332 418 33 257 257 2024 09 14 13 41 22

I think that the motors are beginning to object !

ian

.

Thank you for the Sharky readings, but could you please include the units and any decimal points.

Please don't go off at a tangent on apparent power spikes, since this could just be due to the timing of the scanning by the logger. Let's concentrate upon assessing how your system is performing.

Hi Derek,

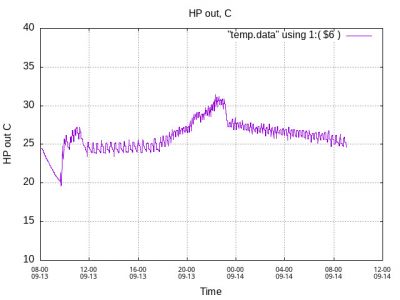

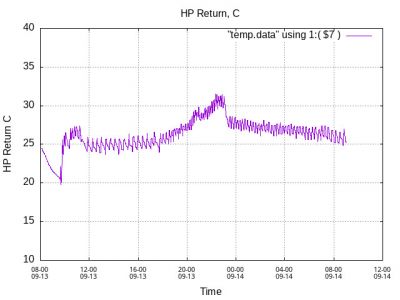

Here is the Sensor 1 recording of Heat Pump output sensors last night taken with a Thermocouple Clamped to the pipe , i.e. not internal:

SEn1 ans Sen2.

The Sharky continues to produce Noise ..........................no sensible readings from 1512 until now, 1556.

Character data correct but Electrical readings corrupted!

!Now producing something sensible , but ,but I am concerned about the electrical , but not aural , noise

Sensible again!!

5127 2192782 419 2020 289 249 2024 09 14 14 46 03

5127 2192797 417 1442 289 261 2024 09 14 14 48 09

5127 2192812 418 220 271 267 2024 09 14 14 50 14

5127 2192826 417 151 266 262 2024 09 14 14 52 19

5127 2192841 416 2105 306 264 2024 09 14 14 54 24

5127 2192855 419 1570 306 273 2024 09 14 14 56 29

5127 2192870 418 266 286 279 2024 09 14 14 58 35

Will stop experiment if this continues ....................concerned for motors.

Errors galore!

,

Please ignore, mispost

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Please explain what you mean by 'errors galore'.

Please explain how you are monitoring and recording the various signals from the sensors and Sharky. Are you using any form of screened cabling? Do any of the cables run near electrical supply cables?

Posted by: @derek-mPlease explain what you mean by 'errors galore'.

Please explain how you are monitoring and recording the various signals from the sensors and Sharky. Are you using any form of screened cabling? Do any of the cables run near electrical supply cables?

Agree with the above questions, look forward to the getting answers.

Please also advise what you mean when you say 'concerned for motors' and why.

Please confirm you have (or will) adjust the WC parameters as suggested and are otherwise operating it stably.

Many thanks.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Nail on Head!

You have , again , hit the nail on the head with your question about decimal points et al.

The Sharky produces , internally , a full 16 bit representation of Water Power ,Water Temp Out,Water Temp Return, Energy,volume and Flow rate

However, the Water flow can reverse in direction causing the Power to go negative.

A negative Power here produces havoc.

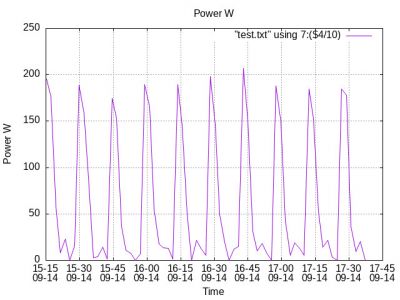

I have , therefore, reduced all negative Powers to zero for Water Power:

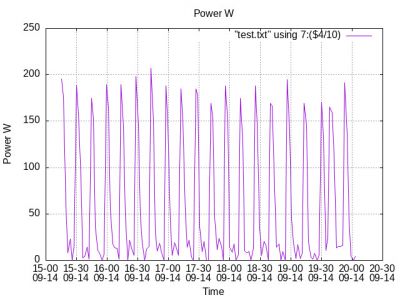

Power in Water taken by my Sharky inside the Radiator Water circuit.

With a Run time of 3 minutes , a cycle time of 19 minutes and an amplitude of 200 Watts , the average Cycle power is:

Average_Cycle_ Power = 200 X 3 X 60/(19 X60) = 31.5 Watts .

The Run Time is far too short at 3 minutes, and constitutes "short Cycling".

The interference is probably related to the Pulse Rise Time, which is very short but, hopefully , well below the sharky response time.

More problems should be expected from the pulse rise times.

The Sharky uses scientific notation, e-1,e-2 for Power , Flow rate, Volume, Temp out and Temp in.

As an Instrumentation and Control System Engineer, the starting point is always to ensure that all sensors are correctly installed, the equipment has been correctly configured and the readings obtained are as close to true as possible. I suggest that must be our starting point.

Please ensure that all temperature sensors are making good thermal contact with any pipework and have been adequately covered with insulation.

You state that some of the temperature sensors are thermocouples. How are you converting the mV signal to a temperature representation? Has the conversion device been configured for that type of thermocouple?

What is the model of your Sharky? Who installed and configured it? Did it come with a calibration certificate? How are you obtaining and interpreting the data from the Sharky, please provide details?

What other sensors are you using and how are you reading the data?

I would suggest that you purchase a set of these temperature indicators so that it should be possible to use them to check the accuracy of your present equipment.

The copy and paste does not appear to have worked, so Google 'Thlevel-Thermometer'.

Measurement problems.

The Measurements from My Sharky have now settled down following an hour long incident where the Sharky readings were corrupted.

As I have said one problem was the apparent Water reversal within the Radiator pipes causing the production of negative Power.

Because a negative power is not expected the sharky mistakenly converts the Negative number into a huge positive number, 15000046 for example.

This is a standard error with binary systems.

I have reduced all such to zero values in the Power :

The power was also mistakenly read , by me, from the wrong register, and , finally the maker of Sharky forgot to include a e-1 scientific notation multiplier.

altogether , a seemingly impossible set of simultaneous problems.!

The Cycle Power = Power Amplitude X Run_Time X 60 / ( Cycle Time X 60) = 31.6 Watts.

The Rise time of this Power signal is very Short , certainly less than my sample period of 2 minutes, and, may yet pose a interference problem similar to that experienced earlier today.

Given that I have not experienced any interference problems over the past year I am concerned as to why the interference has occurred today.

Motors would be my prime suspect........and I know from experience the lengths that Samsung and Grundfoss take to avoid the known inrush current problem with Electrostatic motors.

The large and fast inrush current are known to present a problem, and , I am concerned with driving the motors with too large a rise time producing large interference signals.

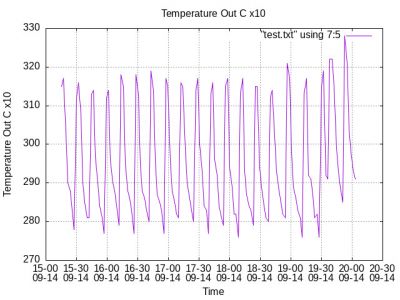

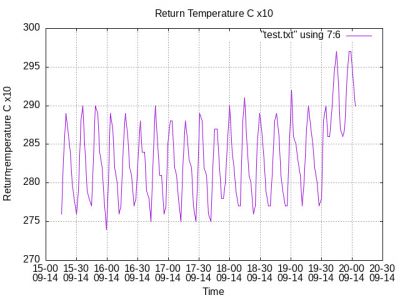

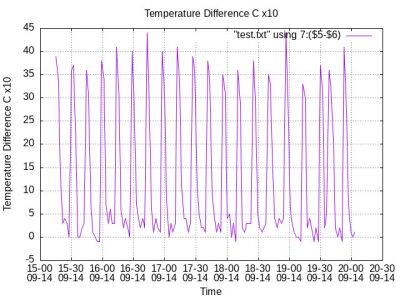

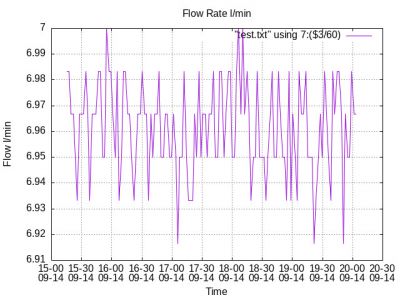

The other Sharky measurements are currently OK :

Here Temperature out , Temperature Return, Temperature Difference and Flow rate.

I will change the axes later , and build room and outside recording sensors.

- 27 Forums

- 2,505 Topics

- 58.1 K Posts

- 211 Online

- 6,237 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Rate the quality of your heat pump design and installation

@n1ckw Just a thought, if you are taking in from the gr...

By Toodles , 11 minutes ago

-

Daikin 8kw Monobloc not switching off when room thermostat exceeds set point

We get huge amounts of solar gain. I had the Maduka r...

By Bash , 41 minutes ago

-

RE: Any thoughts on control strategies for heat pumps?

Given your background, you will have come across contro...

By JamesPa , 1 hour ago

-

It has been said that both manufacturers and installers...

By JamesPa , 1 hour ago

-

RE: New Solar, Batteries, Air Source and Under Floor Heating advice please

Good idea IMHO. You just need some appropriate time co...

By JamesPa , 3 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Hi all. I have made some progress regarding cause of cy...

By Tasos , 3 hours ago

-

RE: Need some help with choosing the right Rads

Wow, thats a big (or very poorly insulated) bathroom. ...

By JamesPa , 4 hours ago

-

RE: Setback savings - fact or fiction?

Monty Python may have asked 'what have the Romans ever ...

By cathodeRay , 5 hours ago

-

RE: Knock on effective of balancing radiators

Decorators caps, not screwed down (they can actually be...

By JamesPa , 6 hours ago

-

RE: Homely setup on daikin heat pump

@craigh Hello, I had best explain how my Homely control...

By Toodles , 6 hours ago

-

The road to upgrading to the latest CU standard is ofte...

By Batpred , 18 hours ago

-

RE: Electricity price predictions

I'm not so sure that the rest of society values a maths...

By JamesPa , 20 hours ago

-

RE: Say hello and introduce yourself

Thanks a lot GC61 - I'll open a separate thread in due ...

By Kev1964-IRL , 22 hours ago

-

RE: The Hidden Secret to a Successful Heat Pump: Pipe Size Matters

@falesh having a house of similar age the two issues I ...

By Terry1812 , 23 hours ago

-

RE: Our Experience installing a heat pump into a Grade 2 Listed stone house

Remember that the house continues to lose energy when t...

By JamesPa , 23 hours ago

-

RE: Renewables & Heat Pumps in the News

@editor I'd missed that, and it's a very good response ...

By Sheriff Fatman , 1 day ago

-

There has been quite a bit of discussion (mostly on OEM...

By MartinRobinson , 1 day ago

-

RE: RDSAP10 effect on existing heat pump EPC rating?

@af1 My EPC rating jumped from E to C after installatio...

By dr_dongle , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@odd_lion the minimum MCS requirement is 2.8. I don't...

By benson , 1 day ago

-

RE: Advice on potential HW Cylinder size

I think the comment about heating from cold is quicker ...

By sjcsystems , 2 days ago

-

RE: Ideal HP290 14kW ASHP - how to optimise

Hi You can get a stethoscope for less than 10€ on Ama...

By bobflux , 2 days ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Your DT is to low, you do not have enough heat exchange...

By ASHP-BOBBA , 2 days ago

-

RE: What determines the SOC of a battery?

I am aware. But is your chart direct from a Pace BMS ap...

By Batpred , 2 days ago

-

RE: Call for heat on open loop weather comp system

I don't know Grant system but most ASHP are very simila...

By ASHP-BOBBA , 2 days ago